lock LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 519 of 1007

STEERING

57-26 REPAIRS

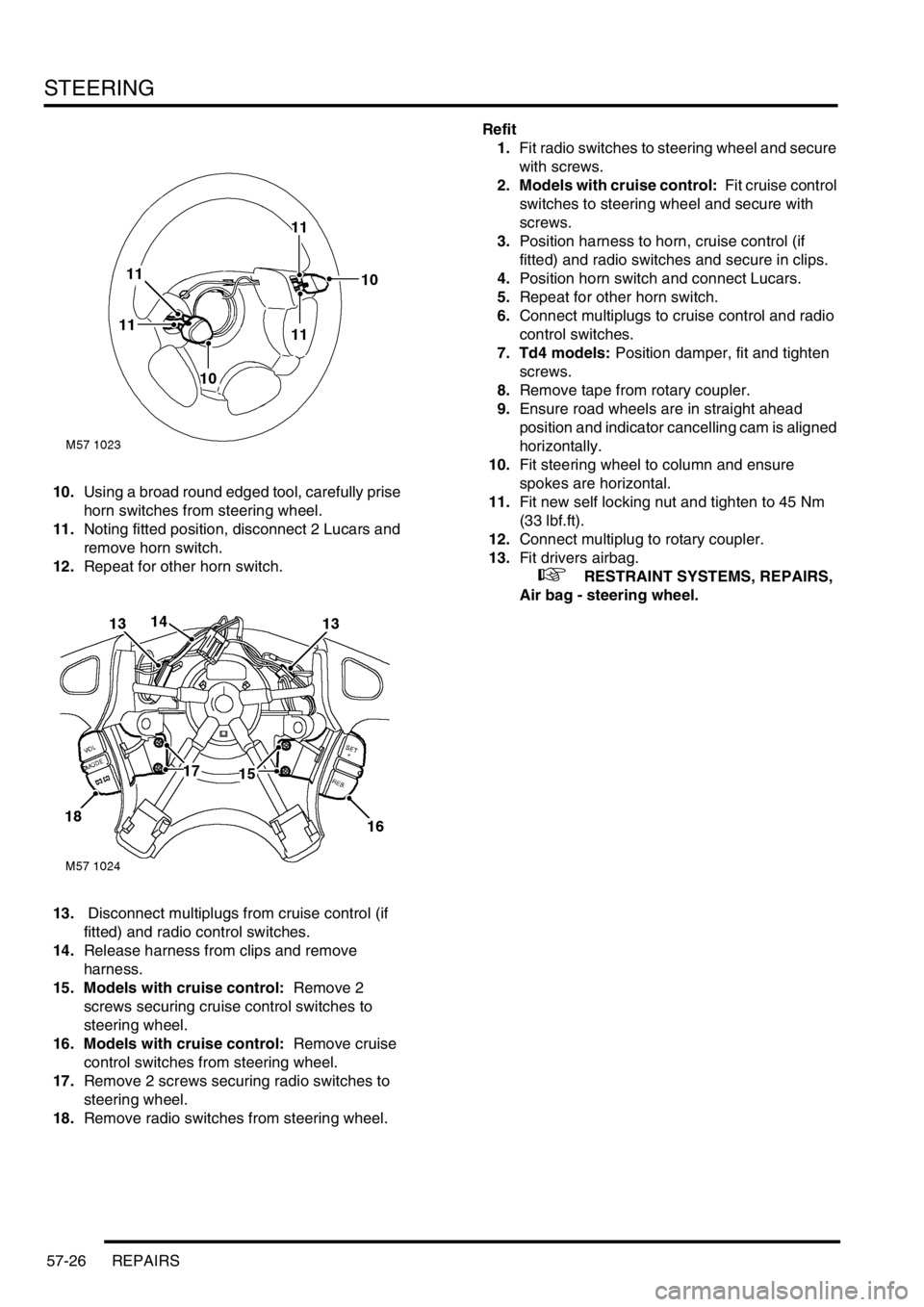

10.Using a broad round edged tool, carefully prise

horn switches from steering wheel.

11.Noting fitted position, disconnect 2 Lucars and

remove horn switch.

12.Repeat for other horn switch.

13. Disconnect multiplugs from cruise control (if

fitted) and radio control switches.

14.Release harness from clips and remove

harness.

15. Models with cruise control: Remove 2

screws securing cruise control switches to

steering wheel.

16. Models with cruise control: Remove cruise

control switches from steering wheel.

17.Remove 2 screws securing radio switches to

steering wheel.

18.Remove radio switches from steering wheel.Refit

1.Fit radio switches to steering wheel and secure

with screws.

2. Models with cruise control: Fit cruise control

switches to steering wheel and secure with

screws.

3.Position harness to horn, cruise control (if

fitted) and radio switches and secure in clips.

4.Position horn switch and connect Lucars.

5.Repeat for other horn switch.

6.Connect multiplugs to cruise control and radio

control switches.

7. Td4 models: Position damper, fit and tighten

screws.

8.Remove tape from rotary coupler.

9.Ensure road wheels are in straight ahead

position and indicator cancelling cam is aligned

horizontally.

10.Fit steering wheel to column and ensure

spokes are horizontal.

11.Fit new self locking nut and tighten to 45 Nm

(33 lbf.ft).

12.Connect multiplug to rotary coupler.

13.Fit drivers airbag.

+ RESTRAINT SYSTEMS, REPAIRS,

Air bag - steering wheel.

Page 548 of 1007

REAR SUSPENSION

REPAIRS 64-13

Sub frame

$% 64.35.78

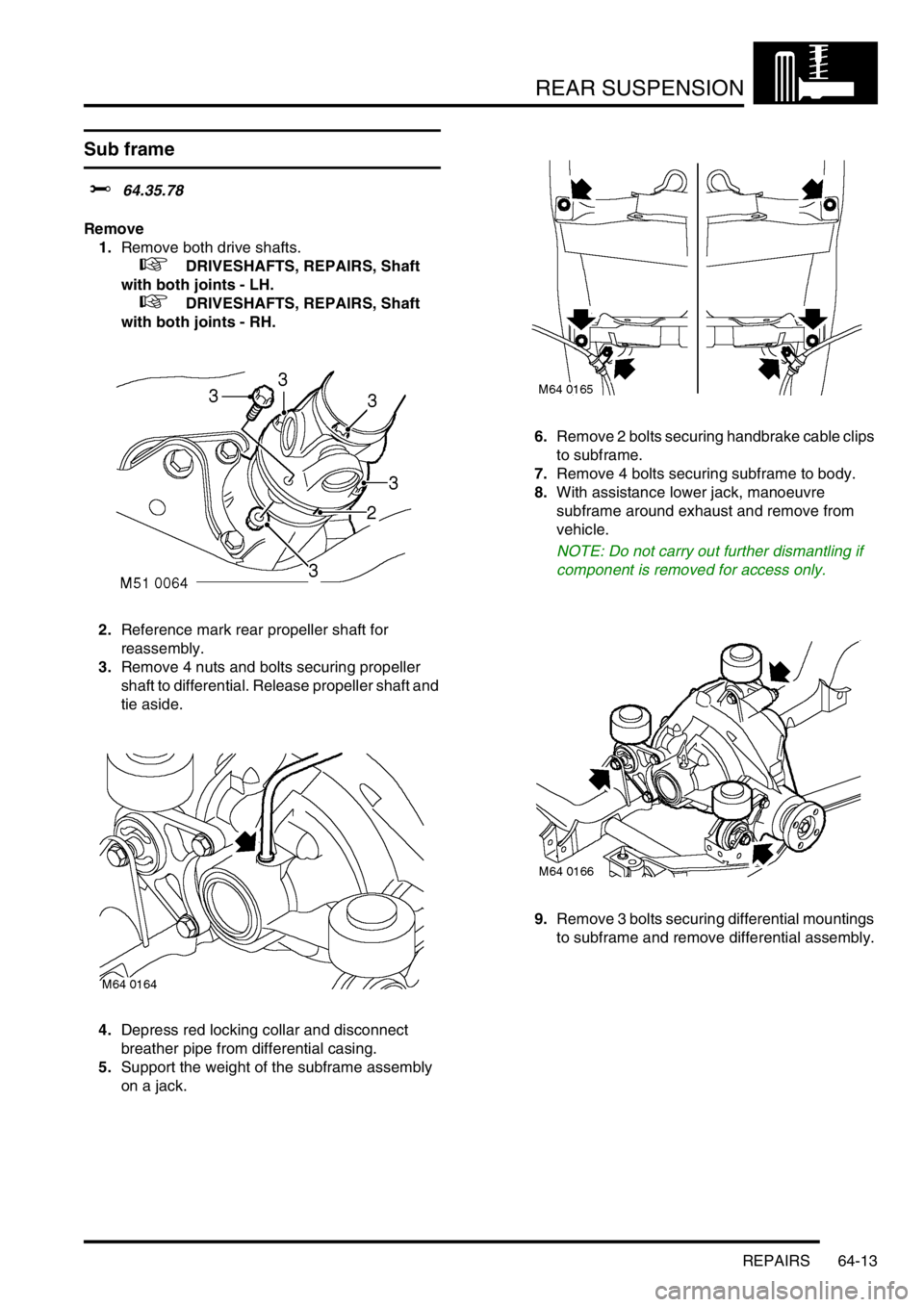

Remove

1.Remove both drive shafts.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - LH.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

2.Reference mark rear propeller shaft for

reassembly.

3.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

4.Depress red locking collar and disconnect

breather pipe from differential casing.

5.Support the weight of the subframe assembly

on a jack.6.Remove 2 bolts securing handbrake cable clips

to subframe.

7.Remove 4 bolts securing subframe to body.

8.With assistance lower jack, manoeuvre

subframe around exhaust and remove from

vehicle.

NOTE: Do not carry out further dismantling if

component is removed for access only.

9.Remove 3 bolts securing differential mountings

to subframe and remove differential assembly.

Page 551 of 1007

BRAKES

70-2 ADJUSTMENTS

Cable - handbrake - check and adjust

$% 70.35.10

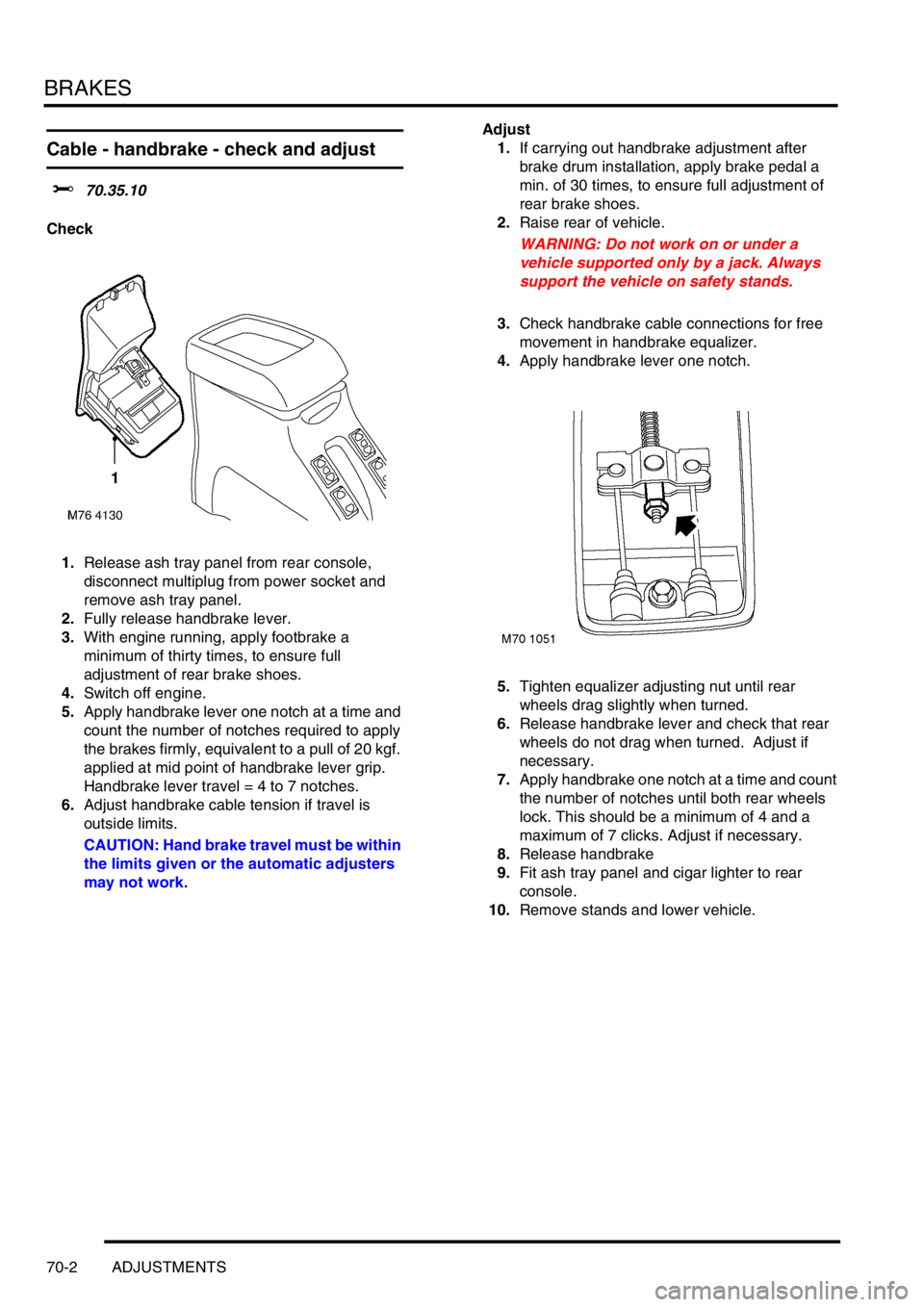

Check

1.Release ash tray panel from rear console,

disconnect multiplug from power socket and

remove ash tray panel.

2.Fully release handbrake lever.

3.With engine running, apply footbrake a

minimum of thirty times, to ensure full

adjustment of rear brake shoes.

4.Switch off engine.

5.Apply handbrake lever one notch at a time and

count the number of notches required to apply

the brakes firmly, equivalent to a pull of 20 kgf.

applied at mid point of handbrake lever grip.

Handbrake lever travel = 4 to 7 notches.

6.Adjust handbrake cable tension if travel is

outside limits.

CAUTION: Hand brake travel must be within

the limits given or the automatic adjusters

may not work.Adjust

1.If carrying out handbrake adjustment after

brake drum installation, apply brake pedal a

min. of 30 times, to ensure full adjustment of

rear brake shoes.

2.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Check handbrake cable connections for free

movement in handbrake equalizer.

4.Apply handbrake lever one notch.

5.Tighten equalizer adjusting nut until rear

wheels drag slightly when turned.

6.Release handbrake lever and check that rear

wheels do not drag when turned. Adjust if

necessary.

7.Apply handbrake one notch at a time and count

the number of notches until both rear wheels

lock. This should be a minimum of 4 and a

maximum of 7 clicks. Adjust if necessary.

8.Release handbrake

9.Fit ash tray panel and cigar lighter to rear

console.

10.Remove stands and lower vehicle.

Page 588 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-7

Stalk - rear seat belt - LH - 5 door

$% 76.73.32

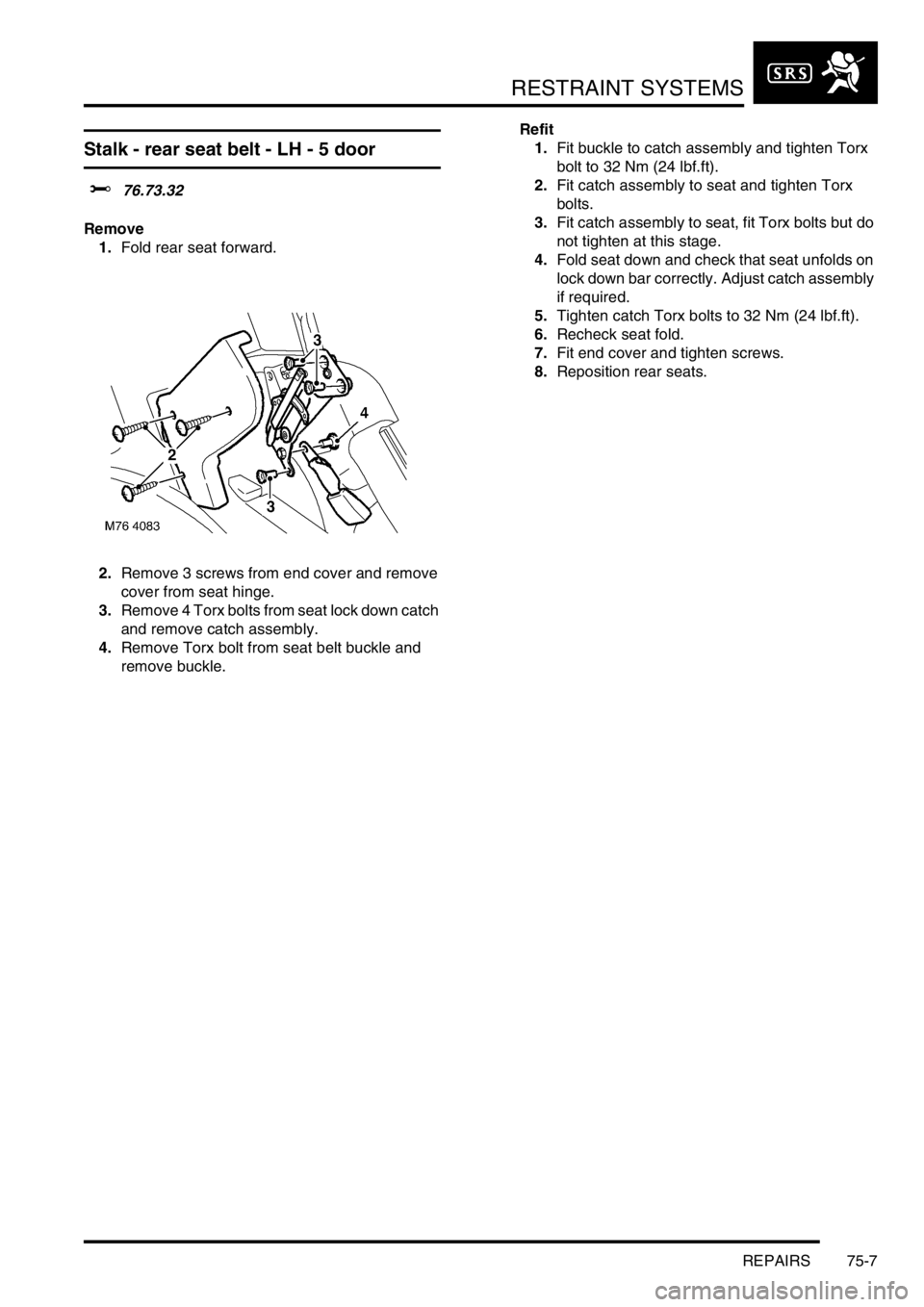

Remove

1.Fold rear seat forward.

2.Remove 3 screws from end cover and remove

cover from seat hinge.

3.Remove 4 Torx bolts from seat lock down catch

and remove catch assembly.

4.Remove Torx bolt from seat belt buckle and

remove buckle.Refit

1.Fit buckle to catch assembly and tighten Torx

bolt to 32 Nm (24 lbf.ft).

2.Fit catch assembly to seat and tighten Torx

bolts.

3.Fit catch assembly to seat, fit Torx bolts but do

not tighten at this stage.

4.Fold seat down and check that seat unfolds on

lock down bar correctly. Adjust catch assembly

if required.

5.Tighten catch Torx bolts to 32 Nm (24 lbf.ft).

6.Recheck seat fold.

7.Fit end cover and tighten screws.

8.Reposition rear seats.

Page 589 of 1007

RESTRAINT SYSTEMS

75-8 REPAIRS

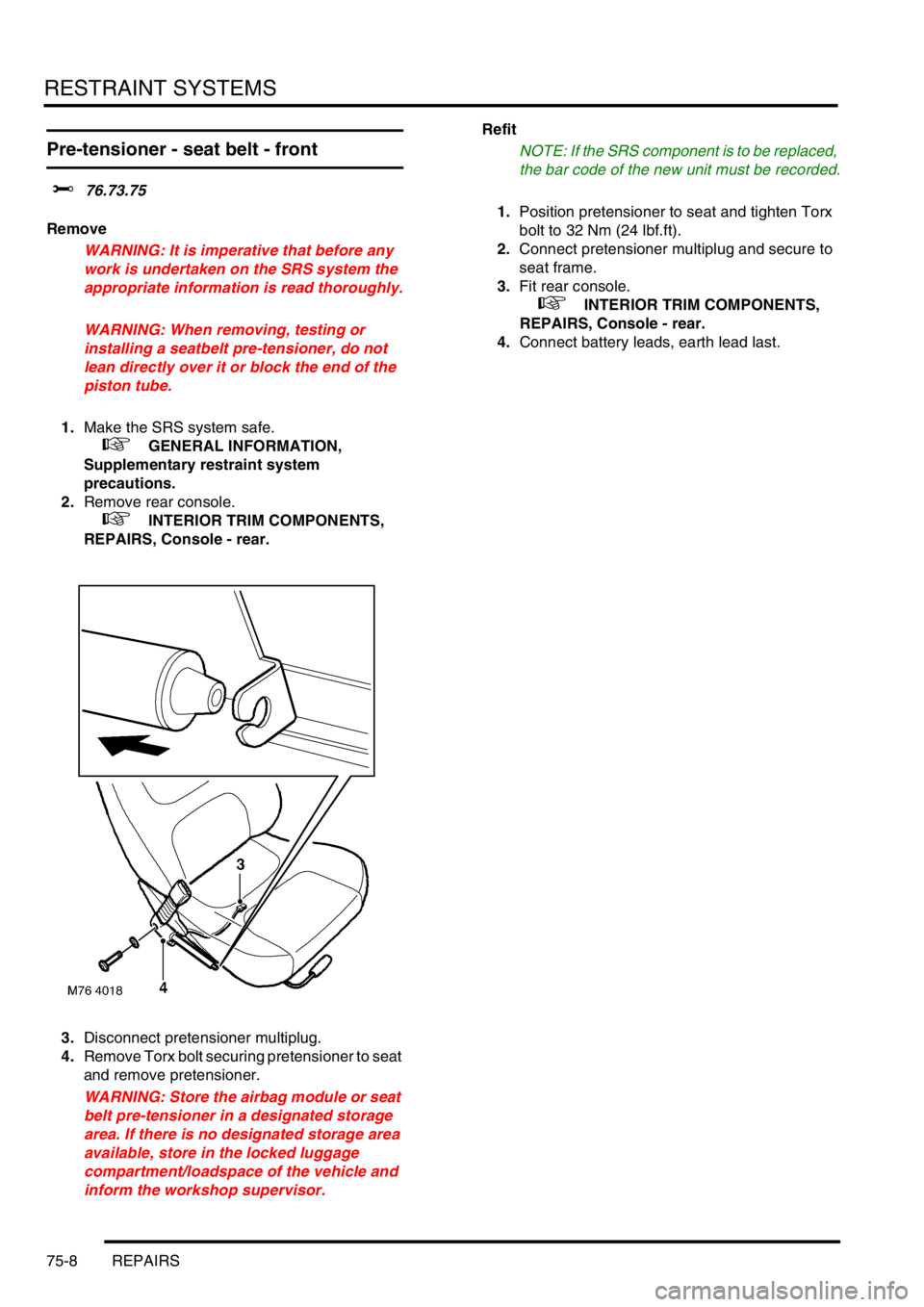

Pre-tensioner - seat belt - front

$% 76.73.75

Remove

WARNING: It is imperative that before any

work is undertaken on the SRS system the

appropriate information is read thoroughly.

WARNING: When removing, testing or

installing a seatbelt pre-tensioner, do not

lean directly over it or block the end of the

piston tube.

1.Make the SRS system safe.

+ GENERAL INFORMATION,

Supplementary restraint system

precautions.

2.Remove rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.

3.Disconnect pretensioner multiplug.

4.Remove Torx bolt securing pretensioner to seat

and remove pretensioner.

WARNING: Store the airbag module or seat

belt pre-tensioner in a designated storage

area. If there is no designated storage area

available, store in the locked luggage

compartment/loadspace of the vehicle and

inform the workshop supervisor.Refit

NOTE: If the SRS component is to be replaced,

the bar code of the new unit must be recorded.

1.Position pretensioner to seat and tighten Torx

bolt to 32 Nm (24 lbf.ft).

2.Connect pretensioner multiplug and secure to

seat frame.

3.Fit rear console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - rear.

4.Connect battery leads, earth lead last.

Page 592 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-11

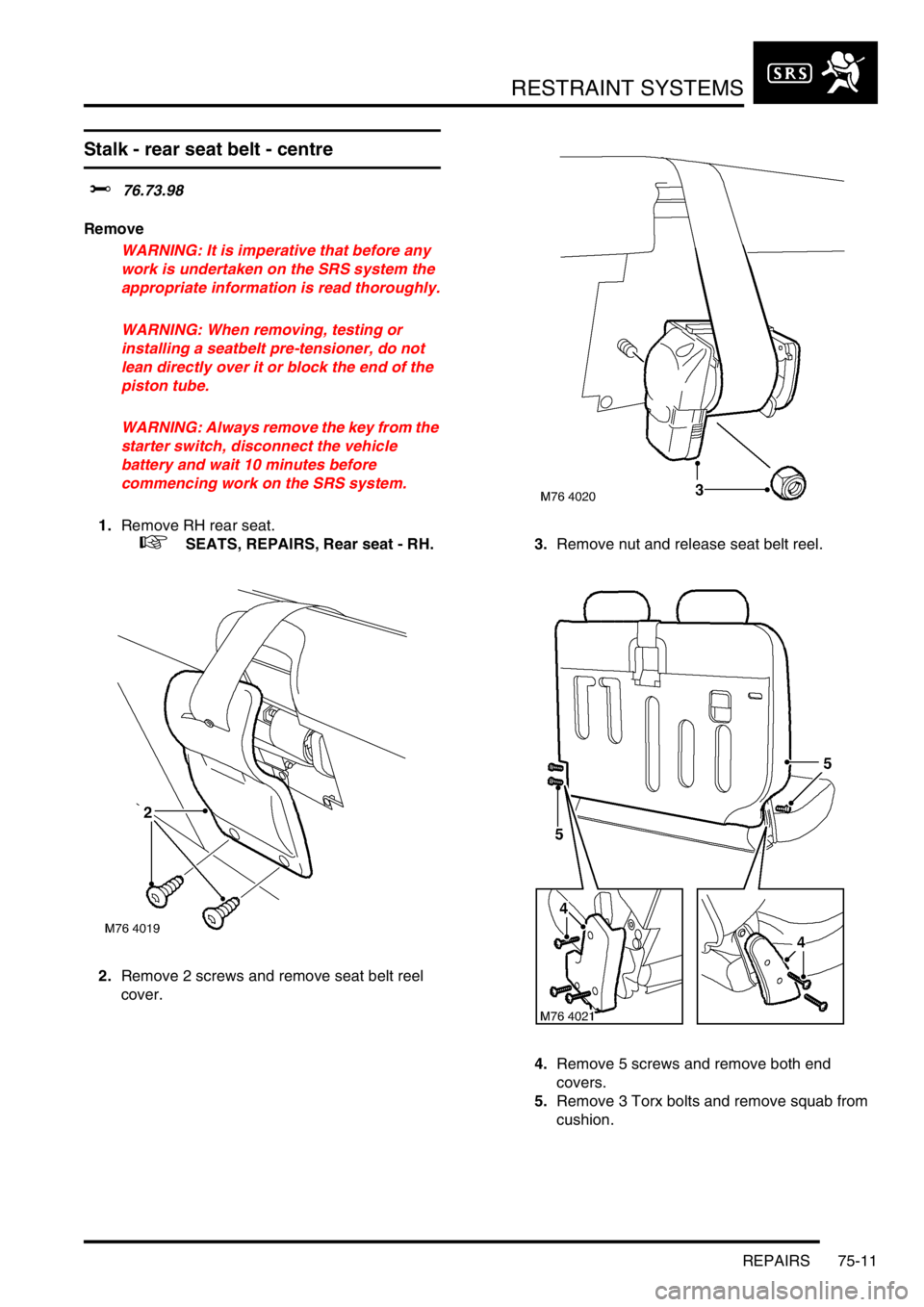

Stalk - rear seat belt - centre

$% 76.73.98

Remove

WARNING: It is imperative that before any

work is undertaken on the SRS system the

appropriate information is read thoroughly.

WARNING: When removing, testing or

installing a seatbelt pre-tensioner, do not

lean directly over it or block the end of the

piston tube.

WARNING: Always remove the key from the

starter switch, disconnect the vehicle

battery and wait 10 minutes before

commencing work on the SRS system.

1.Remove RH rear seat.

+ SEATS, REPAIRS, Rear seat - RH.

2.Remove 2 screws and remove seat belt reel

cover.3.Remove nut and release seat belt reel.

4.Remove 5 screws and remove both end

covers.

5.Remove 3 Torx bolts and remove squab from

cushion.

Page 600 of 1007

RESTRAINT SYSTEMS

REPAIRS 75-19

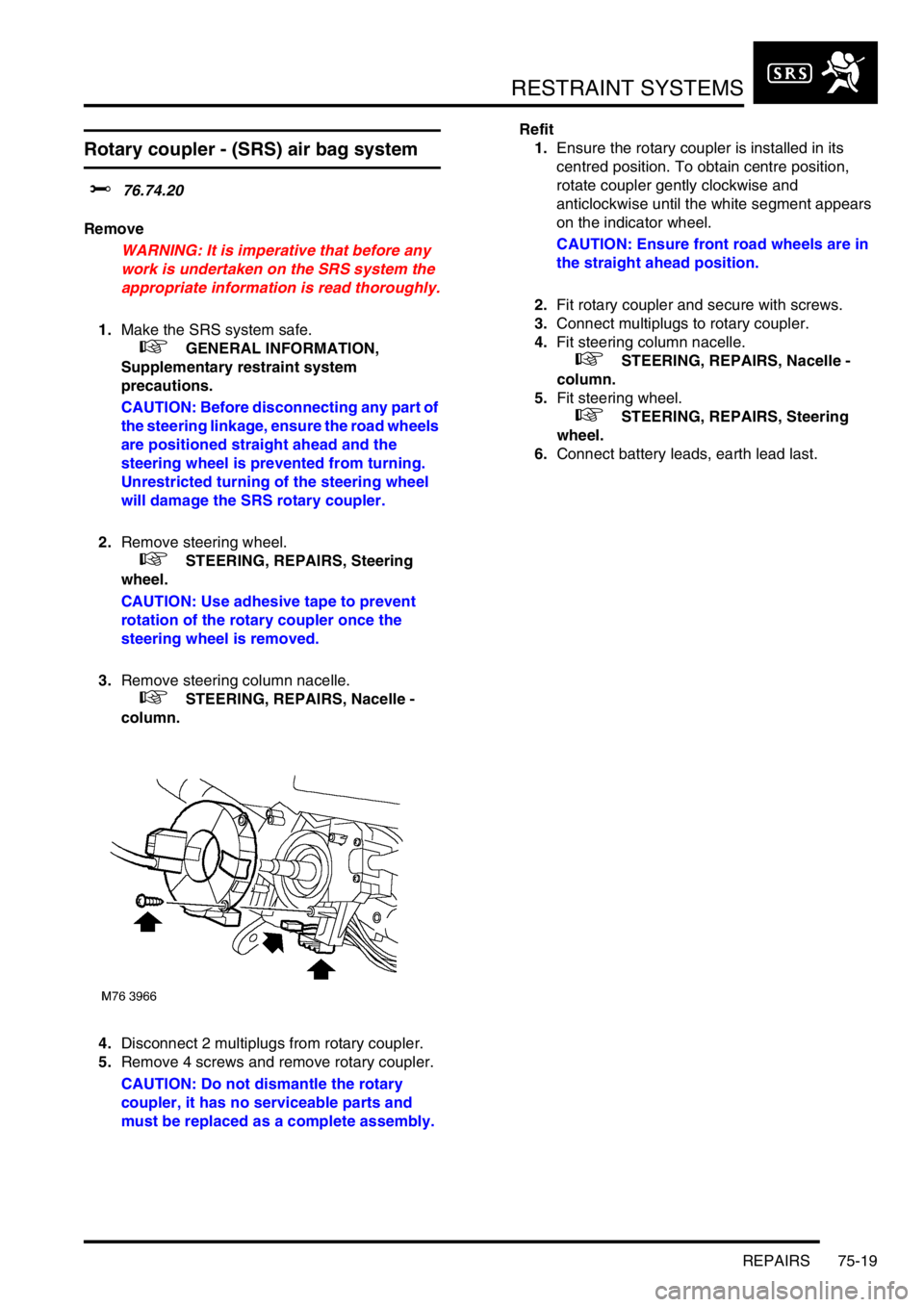

Rotary coupler - (SRS) air bag system

$% 76.74.20

Remove

WARNING: It is imperative that before any

work is undertaken on the SRS system the

appropriate information is read thoroughly.

1.Make the SRS system safe.

+ GENERAL INFORMATION,

Supplementary restraint system

precautions.

CAUTION: Before disconnecting any part of

the steering linkage, ensure the road wheels

are positioned straight ahead and the

steering wheel is prevented from turning.

Unrestricted turning of the steering wheel

will damage the SRS rotary coupler.

2.Remove steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

CAUTION: Use adhesive tape to prevent

rotation of the rotary coupler once the

steering wheel is removed.

3.Remove steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

4.Disconnect 2 multiplugs from rotary coupler.

5.Remove 4 screws and remove rotary coupler.

CAUTION: Do not dismantle the rotary

coupler, it has no serviceable parts and

must be replaced as a complete assembly.Refit

1.Ensure the rotary coupler is installed in its

centred position. To obtain centre position,

rotate coupler gently clockwise and

anticlockwise until the white segment appears

on the indicator wheel.

CAUTION: Ensure front road wheels are in

the straight ahead position.

2.Fit rotary coupler and secure with screws.

3.Connect multiplugs to rotary coupler.

4.Fit steering column nacelle.

+ STEERING, REPAIRS, Nacelle -

column.

5.Fit steering wheel.

+ STEERING, REPAIRS, Steering

wheel.

6.Connect battery leads, earth lead last.

Page 607 of 1007

DOORS

76-1-2 ADJUSTMENTS

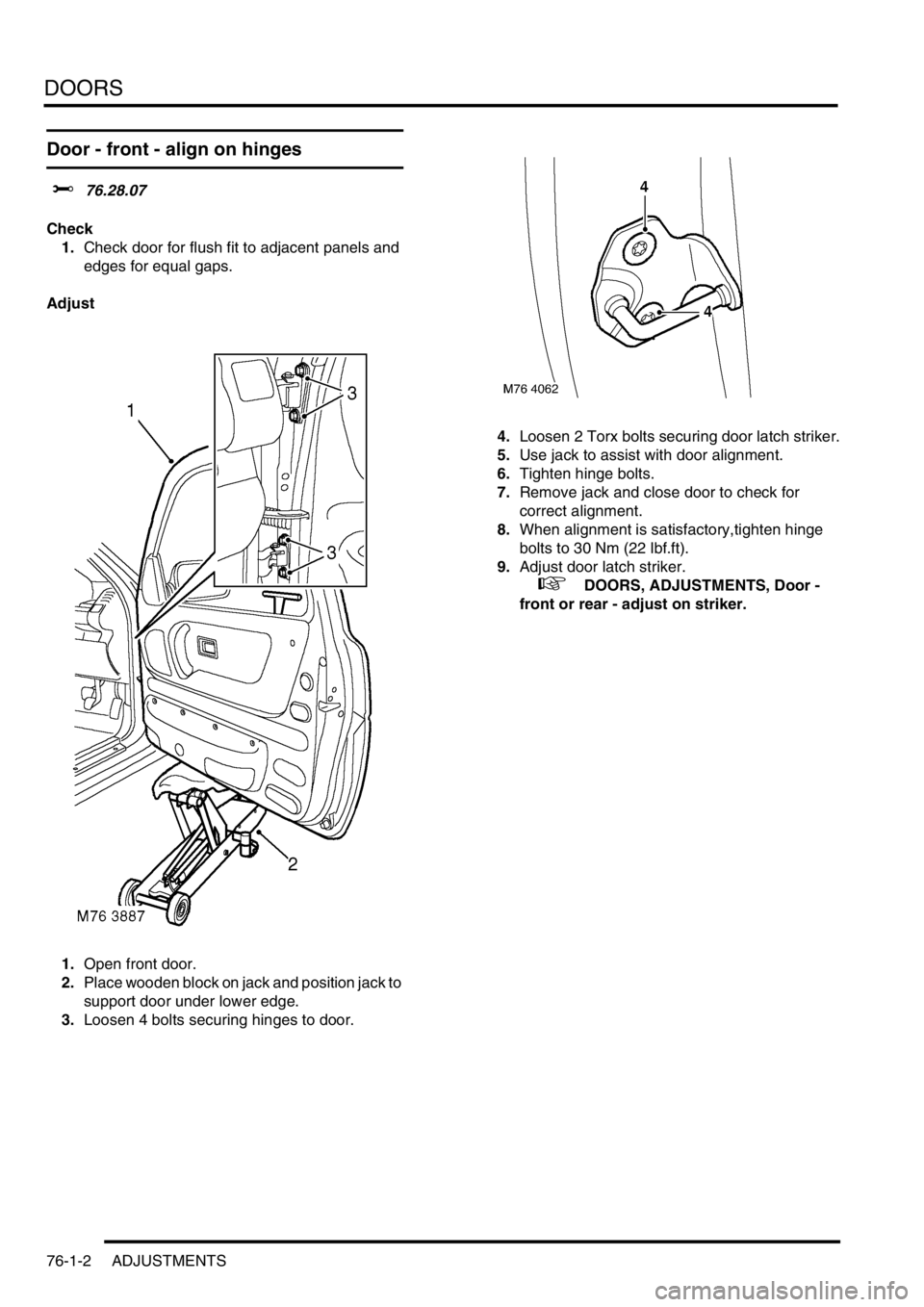

Door - front - align on hinges

$% 76.28.07

Check

1.Check door for flush fit to adjacent panels and

edges for equal gaps.

Adjust

1.Open front door.

2.Place wooden block on jack and position jack to

support door under lower edge.

3.Loosen 4 bolts securing hinges to door.4.Loosen 2 Torx bolts securing door latch striker.

5.Use jack to assist with door alignment.

6.Tighten hinge bolts.

7.Remove jack and close door to check for

correct alignment.

8.When alignment is satisfactory,tighten hinge

bolts to 30 Nm (22 lbf.ft).

9.Adjust door latch striker.

+ DOORS, ADJUSTMENTS, Door -

front or rear - adjust on striker.

Page 615 of 1007

DOORS

76-1-10 REPAIRS

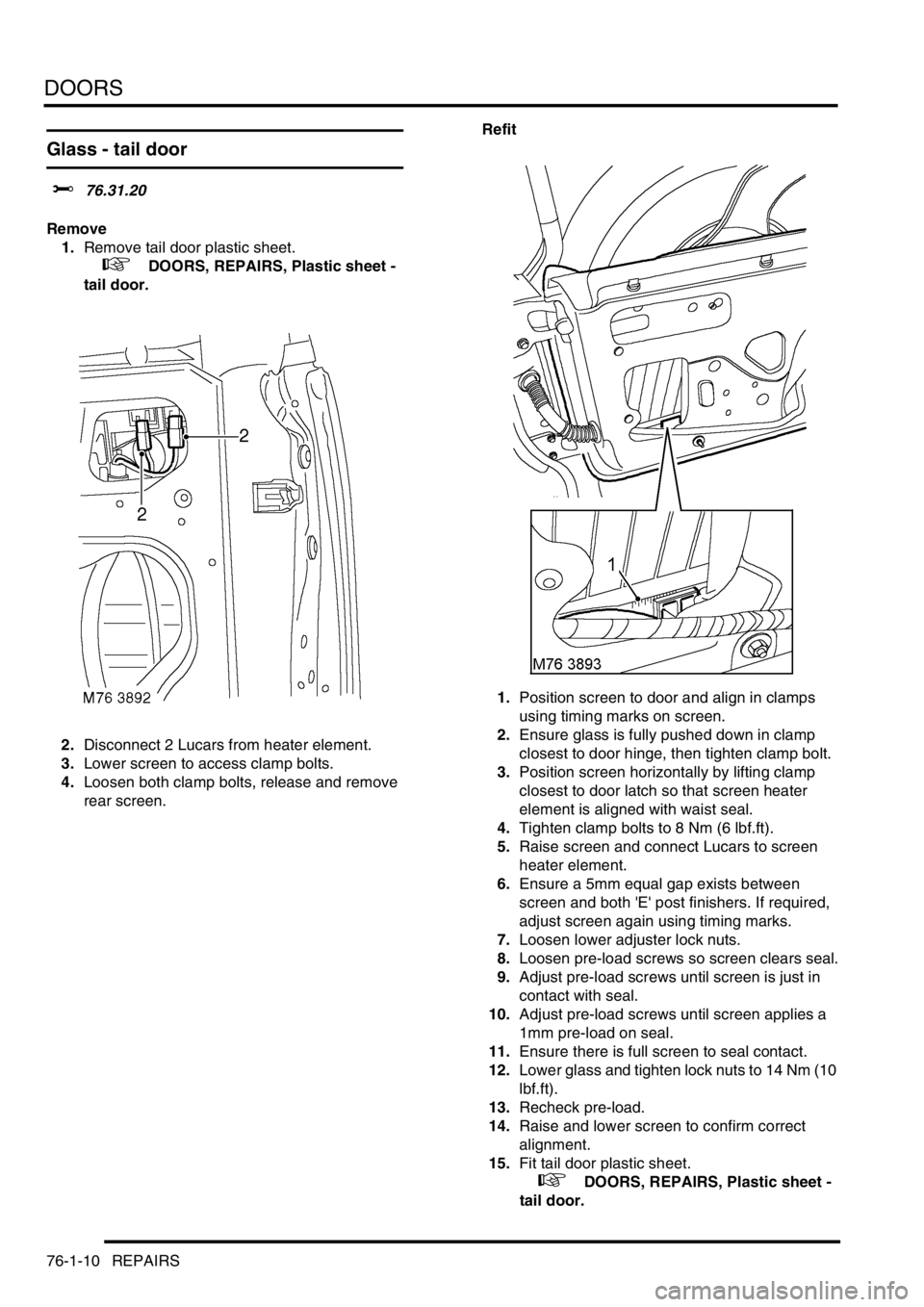

Glass - tail door

$% 76.31.20

Remove

1.Remove tail door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

tail door.

2.Disconnect 2 Lucars from heater element.

3.Lower screen to access clamp bolts.

4.Loosen both clamp bolts, release and remove

rear screen.Refit

1.Position screen to door and align in clamps

using timing marks on screen.

2.Ensure glass is fully pushed down in clamp

closest to door hinge, then tighten clamp bolt.

3.Position screen horizontally by lifting clamp

closest to door latch so that screen heater

element is aligned with waist seal.

4.Tighten clamp bolts to 8 Nm (6 lbf.ft).

5.Raise screen and connect Lucars to screen

heater element.

6.Ensure a 5mm equal gap exists between

screen and both 'E' post finishers. If required,

adjust screen again using timing marks.

7.Loosen lower adjuster lock nuts.

8.Loosen pre-load screws so screen clears seal.

9.Adjust pre-load screws until screen is just in

contact with seal.

10.Adjust pre-load screws until screen applies a

1mm pre-load on seal.

11.Ensure there is full screen to seal contact.

12.Lower glass and tighten lock nuts to 14 Nm (10

lbf.ft).

13.Recheck pre-load.

14.Raise and lower screen to confirm correct

alignment.

15.Fit tail door plastic sheet.

+ DOORS, REPAIRS, Plastic sheet -

tail door.

Page 617 of 1007

DOORS

76-1-12 REPAIRS

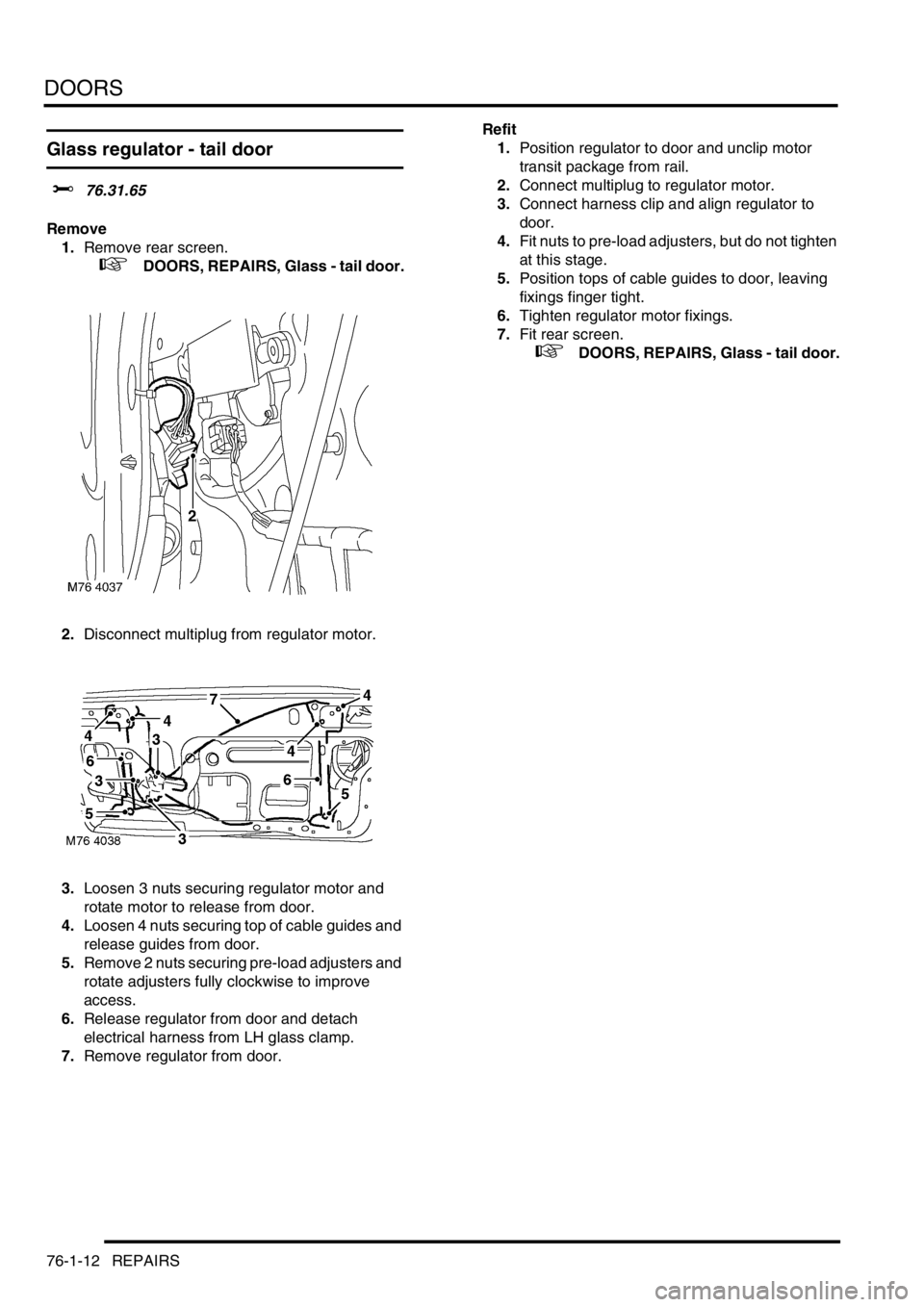

Glass regulator - tail door

$% 76.31.65

Remove

1.Remove rear screen.

+ DOORS, REPAIRS, Glass - tail door.

2.Disconnect multiplug from regulator motor.

3.Loosen 3 nuts securing regulator motor and

rotate motor to release from door.

4.Loosen 4 nuts securing top of cable guides and

release guides from door.

5.Remove 2 nuts securing pre-load adjusters and

rotate adjusters fully clockwise to improve

access.

6.Release regulator from door and detach

electrical harness from LH glass clamp.

7.Remove regulator from door.Refit

1.Position regulator to door and unclip motor

transit package from rail.

2.Connect multiplug to regulator motor.

3.Connect harness clip and align regulator to

door.

4.Fit nuts to pre-load adjusters, but do not tighten

at this stage.

5.Position tops of cable guides to door, leaving

fixings finger tight.

6.Tighten regulator motor fixings.

7.Fit rear screen.

+ DOORS, REPAIRS, Glass - tail door.