LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 171 of 1007

MAINTENANCE

10-24 MAINTENANCE

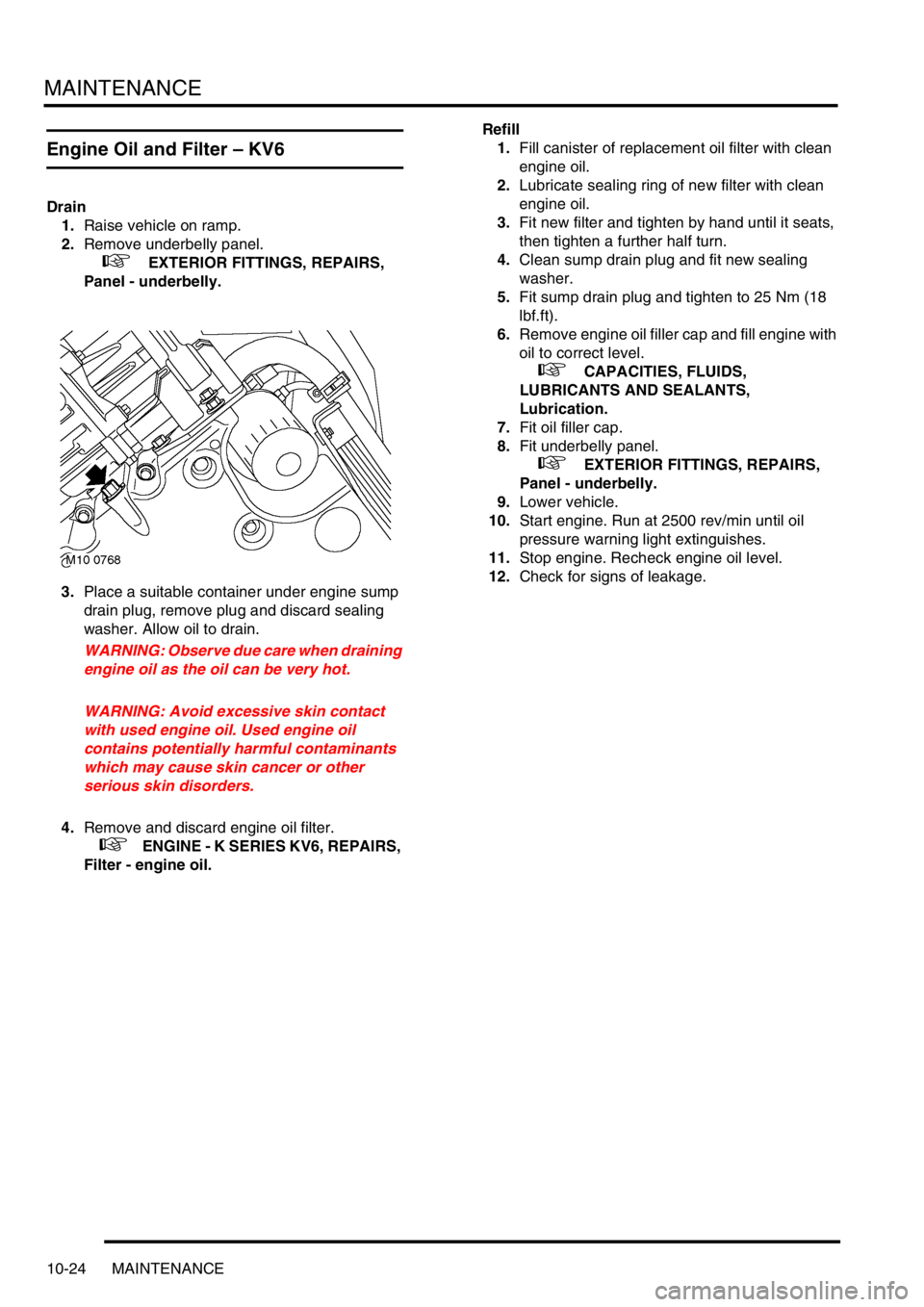

Engine Oil and Filter – KV6

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove plug and discard sealing

washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Remove and discard engine oil filter.

+ ENGINE - K SERIES KV6, REPAIRS,

Filter - engine oil.Refill

1.Fill canister of replacement oil filter with clean

engine oil.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit new filter and tighten by hand until it seats,

then tighten a further half turn.

4.Clean sump drain plug and fit new sealing

washer.

5.Fit sump drain plug and tighten to 25 Nm (18

lbf.ft).

6.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

7.Fit oil filler cap.

8.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

9.Lower vehicle.

10.Start engine. Run at 2500 rev/min until oil

pressure warning light extinguishes.

11.Stop engine. Recheck engine oil level.

12.Check for signs of leakage.

Page 172 of 1007

MAINTENANCE

MAINTENANCE 10-25

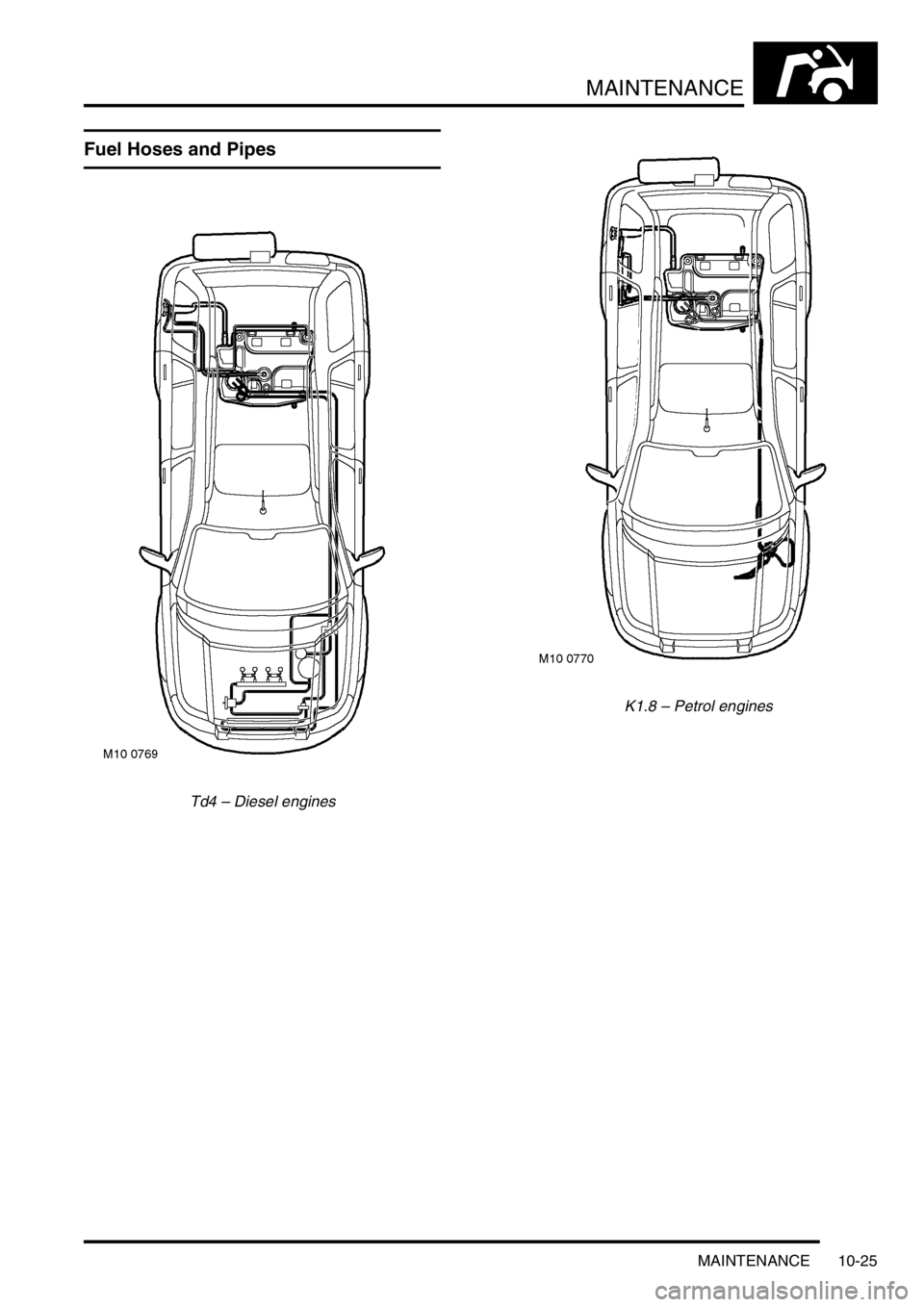

Fuel Hoses and Pipes

Td4 – Diesel enginesK1.8 – Petrol engines

Page 173 of 1007

MAINTENANCE

10-26 MAINTENANCE

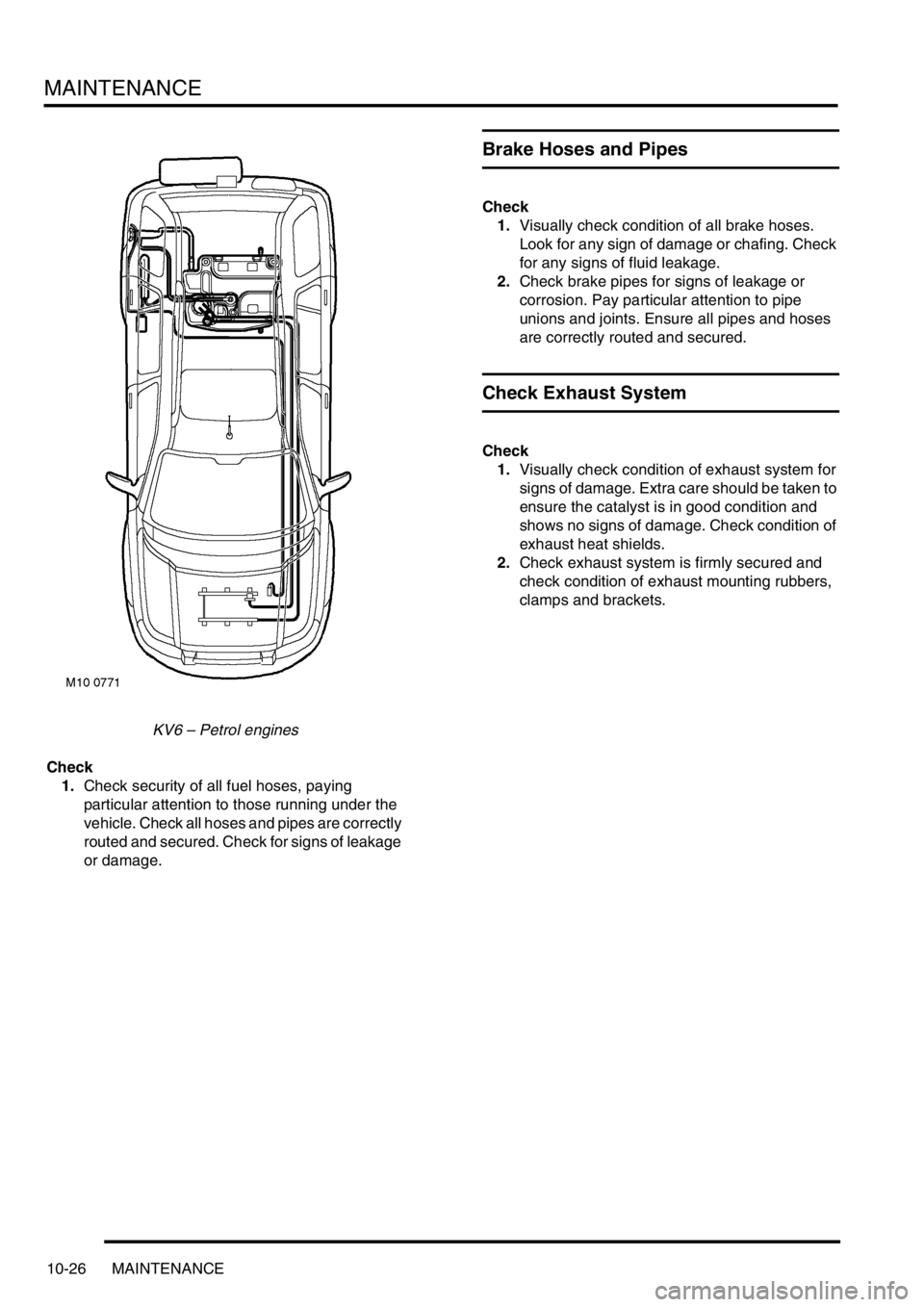

KV6 – Petrol engines

Check

1.Check security of all fuel hoses, paying

particular attention to those running under the

vehicle. Check all hoses and pipes are correctly

routed and secured. Check for signs of leakage

or damage.

Brake Hoses and Pipes

Check

1.Visually check condition of all brake hoses.

Look for any sign of damage or chafing. Check

for any signs of fluid leakage.

2.Check brake pipes for signs of leakage or

corrosion. Pay particular attention to pipe

unions and joints. Ensure all pipes and hoses

are correctly routed and secured.

Check Exhaust System

Check

1.Visually check condition of exhaust system for

signs of damage. Extra care should be taken to

ensure the catalyst is in good condition and

shows no signs of damage. Check condition of

exhaust heat shields.

2.Check exhaust system is firmly secured and

check condition of exhaust mounting rubbers,

clamps and brackets.

Page 174 of 1007

MAINTENANCE

MAINTENANCE 10-27

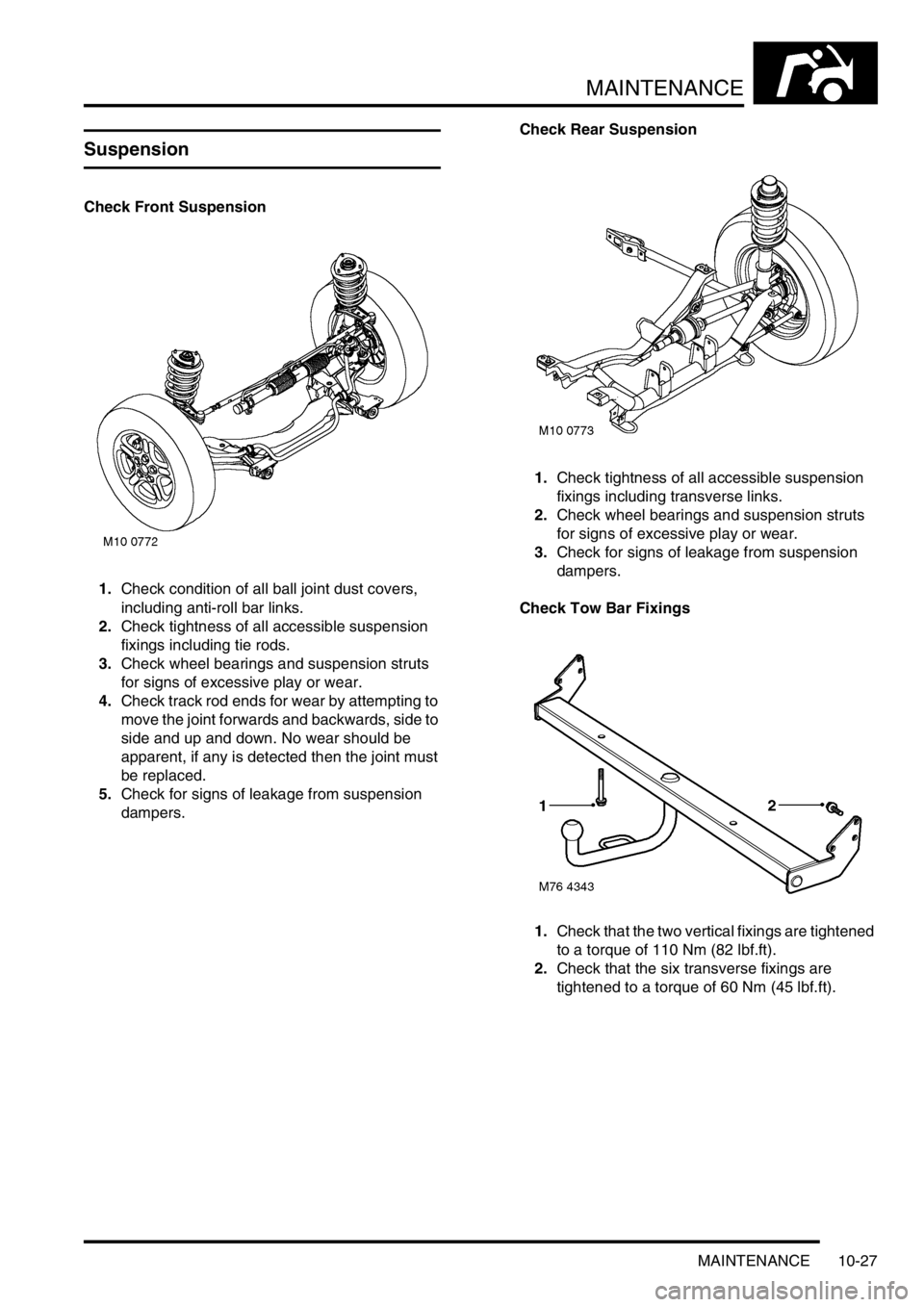

Suspension

Check Front Suspension

1.Check condition of all ball joint dust covers,

including anti-roll bar links.

2.Check tightness of all accessible suspension

fixings including tie rods.

3.Check wheel bearings and suspension struts

for signs of excessive play or wear.

4.Check track rod ends for wear by attempting to

move the joint forwards and backwards, side to

side and up and down. No wear should be

apparent, if any is detected then the joint must

be replaced.

5.Check for signs of leakage from suspension

dampers.Check Rear Suspension

1.Check tightness of all accessible suspension

fixings including transverse links.

2.Check wheel bearings and suspension struts

for signs of excessive play or wear.

3.Check for signs of leakage from suspension

dampers.

Check Tow Bar Fixings

1.Check that the two vertical fixings are tightened

to a torque of 110 Nm (82 lbf.ft).

2.Check that the six transverse fixings are

tightened to a torque of 60 Nm (45 lbf.ft).

Page 175 of 1007

MAINTENANCE

10-28 MAINTENANCE

Steering

Check

1.Check/tighten steering unit and steering rod

ball joint fixings.

2.Check condition of ball joints and dust covers.

3.Check steering rack bellows for any signs of

leakage.

Road Test

There are two purposes for conducting a road test.

Firstly, to ensure the work completed within the

dealership meets the standards required as laid

down by dealership processes. Secondly, for a

skilled technician to assess the general condition of

the vehicle and report any conditions that the

customer should be made aware of.

CAUTION: Two wheel dynamometer tests must

not be carried out. Four wheel dynamometer

tests must be restricted to 3 mph (5 kph).

Engine Start

1.Check for correct operation of starter switch.

Ensure the engine starts in a correct manner.

Leave the engine running.

Starter Inhibitor Switch – (Automatic only)

1.Select 'D' gear lever position.

2.Check that engine will not start.

3.Select 'R' gear lever position and repeat start

check.

4.Check that engine will start in 'P' and 'N'

positions.

Selector Cable – (Automatic only)

1.Check for correct setting of gear selector cable.

Engine Performance and Throttle Operation

1.Start engine and check that it starts easily.

2.Check that 'oil pressure' and 'no charge'

warning lamps extinguish.

3.Check that throttle pedal movement is free and

unrestricted.

4.Check that engine is responsive to throttle

movement.

Clutch and Gear Selection –

(Manual only, normal driving conditions)

1.Check that clutch engages smoothly without

judder, slipping or noise.

2.Check for abnormal transmission noise.

3.Check for smooth quiet gear changes and that

gear selected engages easily.

Page 176 of 1007

MAINTENANCE

MAINTENANCE 10-29

Gear Change and Parking Pawl Engagement –

(Automatic only, normal driving conditions)

1.Select 'R' and check for smooth take up.

2.Select 'D' and check for smooth up-changes of

ratio from rest.

3.Slow down vehicle and check for smooth down-

changes of ratio.

4.Stop vehicle on a slope.

5.Select 'P' and release handbrake.

6.Check that vehicle does not move and that

selector does not slip out of 'P'.

7.Carry out a similar check with vehicle facing in

the opposite direction.

Steering

1.With vehicle stationary, turn steering from lock

to lock. Check for smooth operation and ensure

there is no undue noise from the power steering

pump or drive belt.

Suspension

1.Check for noise, irregularity in ride (e.g.

dampers) and wheel imbalance.

Foot brake

1.Check for pedal effort, travel, braking

efficiency, pulling and binding.

Handbrake

1.Apply handbrake firmly, check travel and

ratchet hold and release.

Instruments

1.Check for correct operation of all instruments

and warning devices where practical.

Body

1.Check for abnormal body noise.

Seat Belts

1.Check for operation of inertia reels.Road Test

1.Drive vehicle on a short road test. Check all

vehicle systems for correct operation. Pay

particular attention to:

lEngine noise

lGearbox noise

lSuspension noise

lBody noise

lBraking system operation

lGear selection

lEngine performance

2.Where possible, check for correct operation of

Hill Descent Control (HDC) system. This should

not be carried out if excessive journey time is

required.

3.After road test, carry out a final inspection of the

vehicle on vehicle ramps.

4.Check all underbonnet fluid levels and top-up if

necessary.

Page 177 of 1007

MAINTENANCE

10-30 MAINTENANCE

Endorse Service Record

Check

1.Insert date and mileage of next service.

2.Insert current mileage.

3.Tick one of the boxes on the brake fluid

replacement indicator.

4.Tick one of the boxes on the camshaft drive belt

indicator.

5.Endorse service record with dealer stamp.

6.Sign and date the service record.

7.Sign and date the maintenance check sheet.

Report any Unusual Features

Check

1.Produce a written report detailing additional

work necessary, or items which may require

attention prior to the next service.

Page 178 of 1007

ENGINE - K SERIES KV6

ADJUSTMENTS 12-3-1

ENGIN E - K SERIES KV6 ADJUST ME NTS

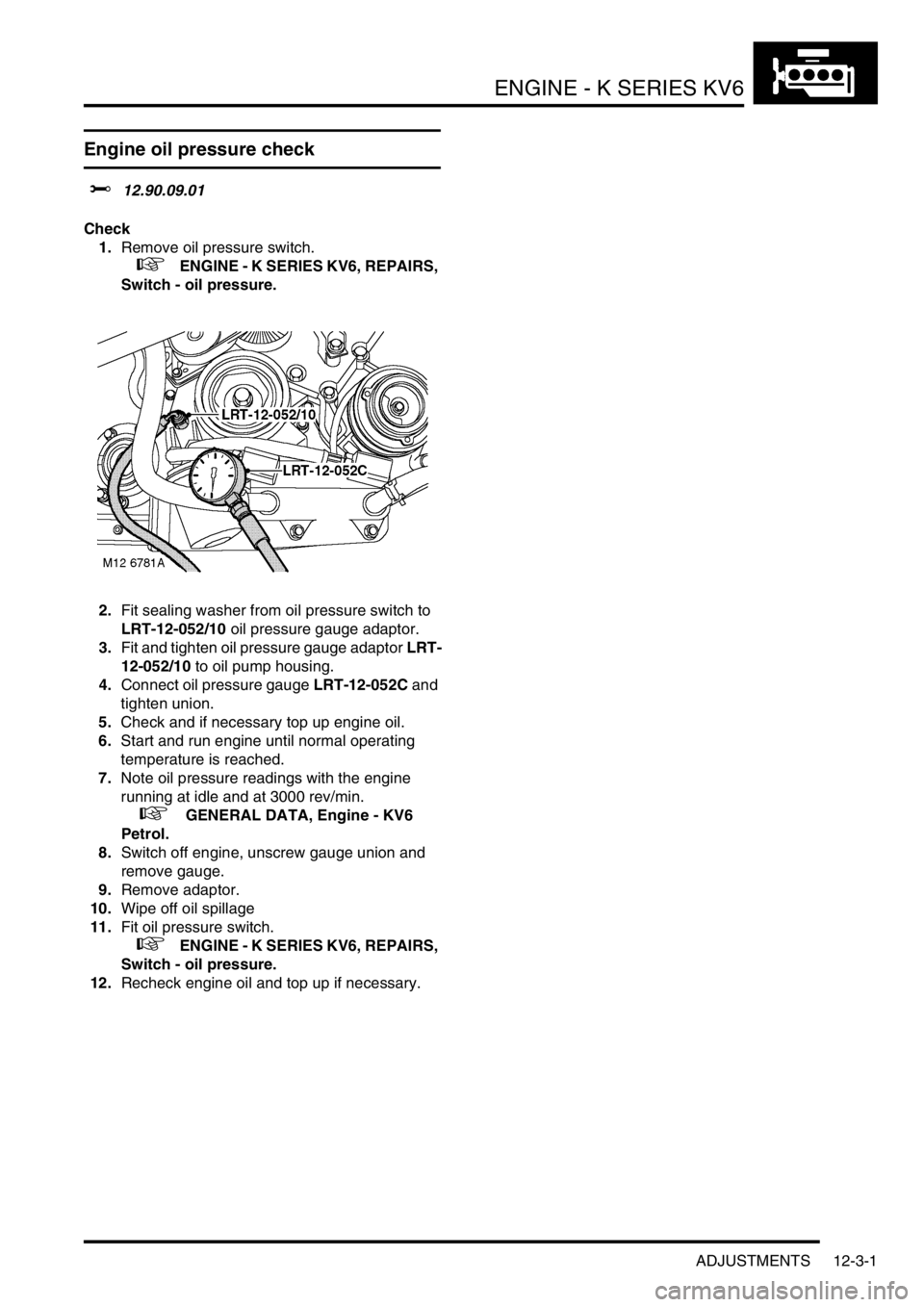

Engine oil pressure check

$% 12.90.09.01

Check

1.Remove oil pressure switch.

+ ENGINE - K SERIES KV6, REPAIRS,

Switch - oil pressure.

2.Fit sealing washer from oil pressure switch to

LRT-12-052/10 oil pressure gauge adaptor.

3.Fit and tighten oil pressure gauge adaptor LRT-

12-052/10 to oil pump housing.

4.Connect oil pressure gauge LRT-12-052C and

tighten union.

5.Check and if necessary top up engine oil.

6.Start and run engine until normal operating

temperature is reached.

7.Note oil pressure readings with the engine

running at idle and at 3000 rev/min.

+ GENERAL DATA, Engine - KV6

Petrol.

8.Switch off engine, unscrew gauge union and

remove gauge.

9.Remove adaptor.

10.Wipe off oil spillage

11.Fit oil pressure switch.

+ ENGINE - K SERIES KV6, REPAIRS,

Switch - oil pressure.

12.Recheck engine oil and top up if necessary.

Page 179 of 1007

Page 180 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-3

REPAIRS

Camshafts - LH cylinder head

$% 12.13.02

Remove

1.Disconnect battery earth lead.

2.Remove camshaft timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

3.Remove LH camshaft rear timing belt.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft rear timing belt - LH cylinder

head.

4.Remove LH camshaft cover gasket.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft cover gasket - LH - Up to 03MY.

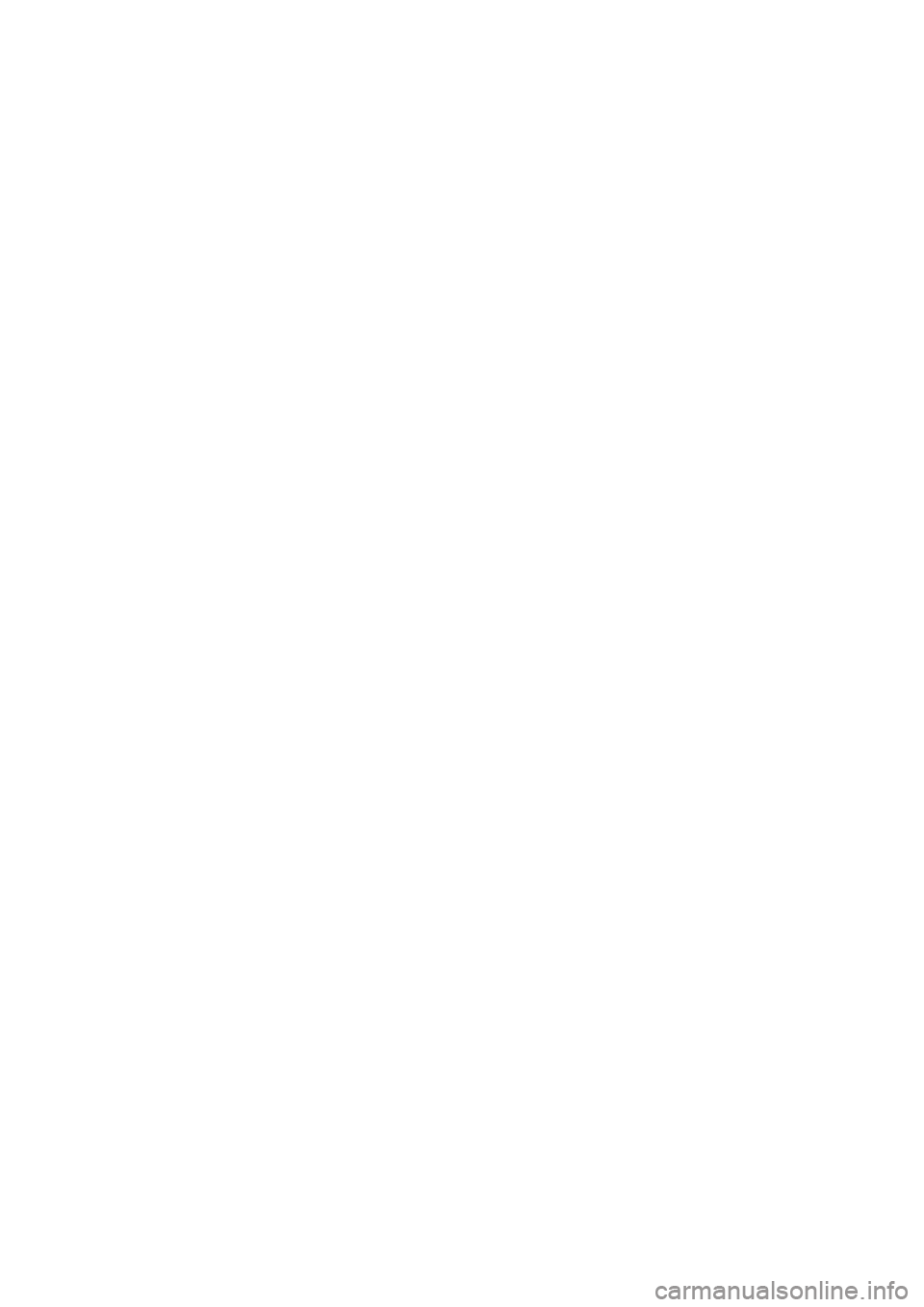

5.Remove 4 bolts and remove front camshaft

drive belt cover backplate from cylinder head.

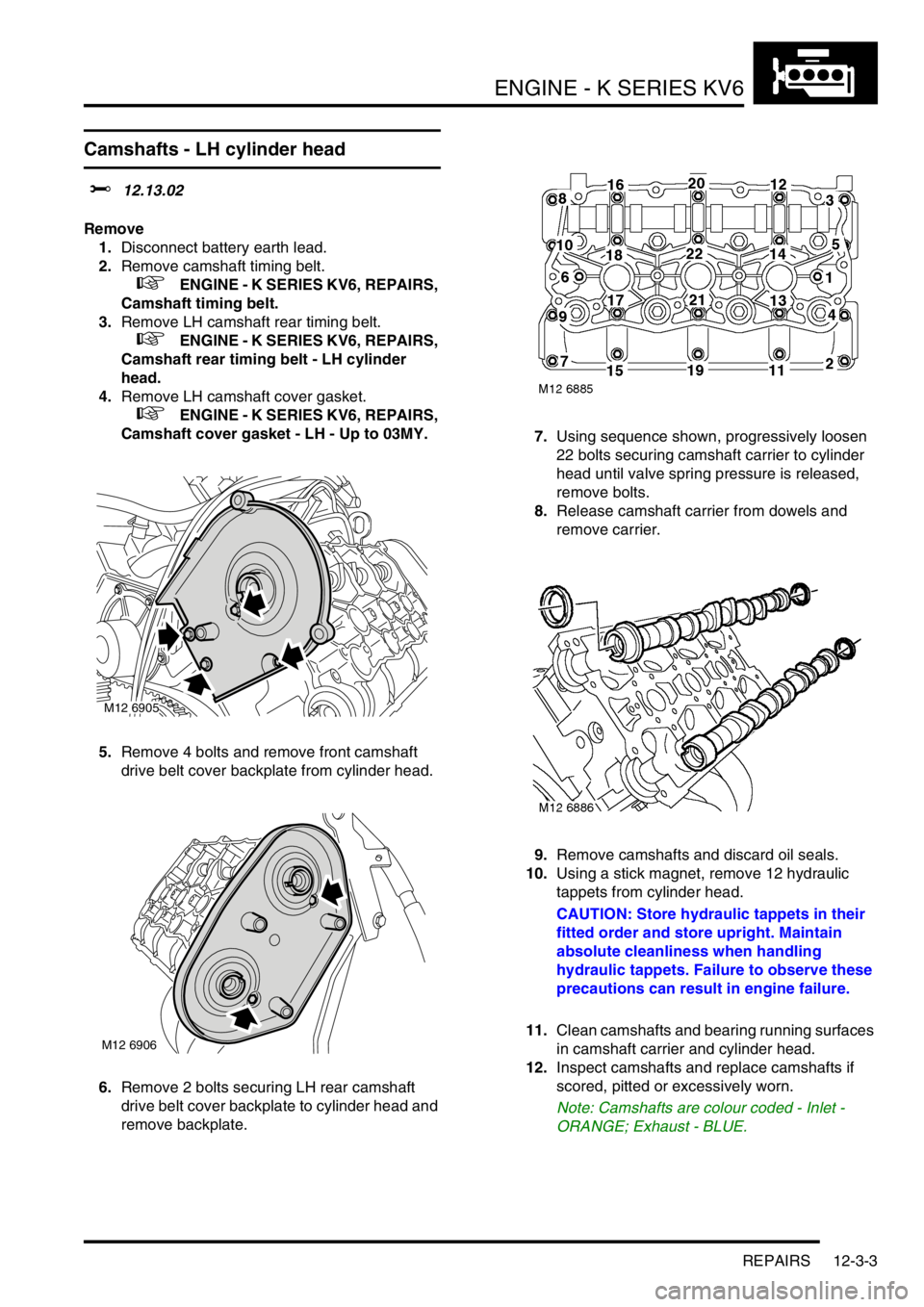

6.Remove 2 bolts securing LH rear camshaft

drive belt cover backplate to cylinder head and

remove backplate.7.Using sequence shown, progressively loosen

22 bolts securing camshaft carrier to cylinder

head until valve spring pressure is released,

remove bolts.

8.Release camshaft carrier from dowels and

remove carrier.

9.Remove camshafts and discard oil seals.

10.Using a stick magnet, remove 12 hydraulic

tappets from cylinder head.

CAUTION: Store hydraulic tappets in their

fitted order and store upright. Maintain

absolute cleanliness when handling

hydraulic tappets. Failure to observe these

precautions can result in engine failure.

11.Clean camshafts and bearing running surfaces

in camshaft carrier and cylinder head.

12.Inspect camshafts and replace camshafts if

scored, pitted or excessively worn.

Note: Camshafts are colour coded - Inlet -

ORANGE; Exhaust - BLUE.

M12 6905

M12 6906