LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 201 of 1007

ENGINE - K SERIES KV6

12-3-24 REPAIRS

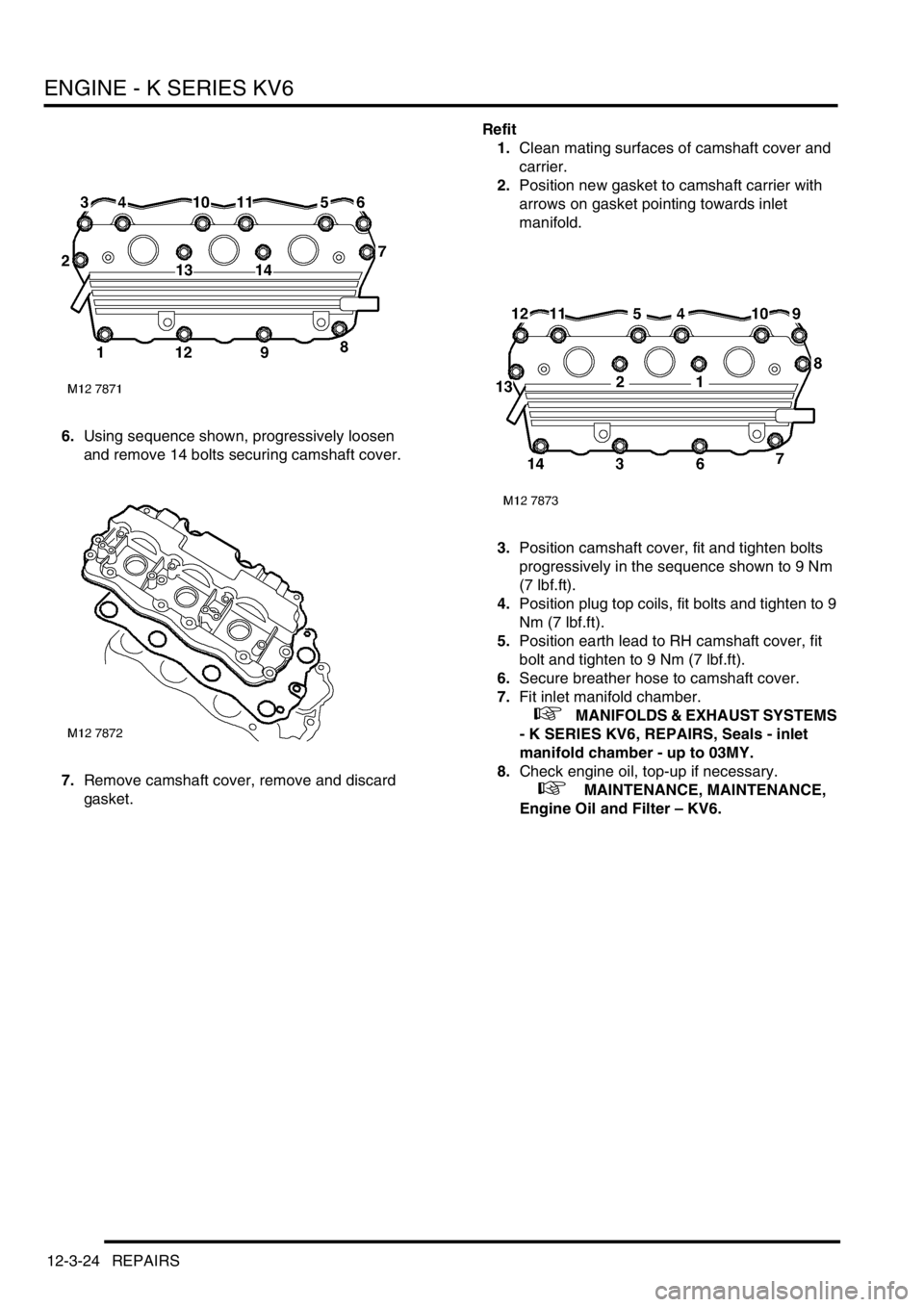

6.Using sequence shown, progressively loosen

and remove 14 bolts securing camshaft cover.

7.Remove camshaft cover, remove and discard

gasket.Refit

1.Clean mating surfaces of camshaft cover and

carrier.

2.Position new gasket to camshaft carrier with

arrows on gasket pointing towards inlet

manifold.

3.Position camshaft cover, fit and tighten bolts

progressively in the sequence shown to 9 Nm

(7 lbf.ft).

4.Position plug top coils, fit bolts and tighten to 9

Nm (7 lbf.ft).

5.Position earth lead to RH camshaft cover, fit

bolt and tighten to 9 Nm (7 lbf.ft).

6.Secure breather hose to camshaft cover.

7.Fit inlet manifold chamber.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Seals - inlet

manifold chamber - up to 03MY.

8.Check engine oil, top-up if necessary.

+ MAINTENANCE, MAINTENANCE,

Engine Oil and Filter – KV6.

Page 202 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-25

Cover - engine acoustic

$% 12.30.50

Remove

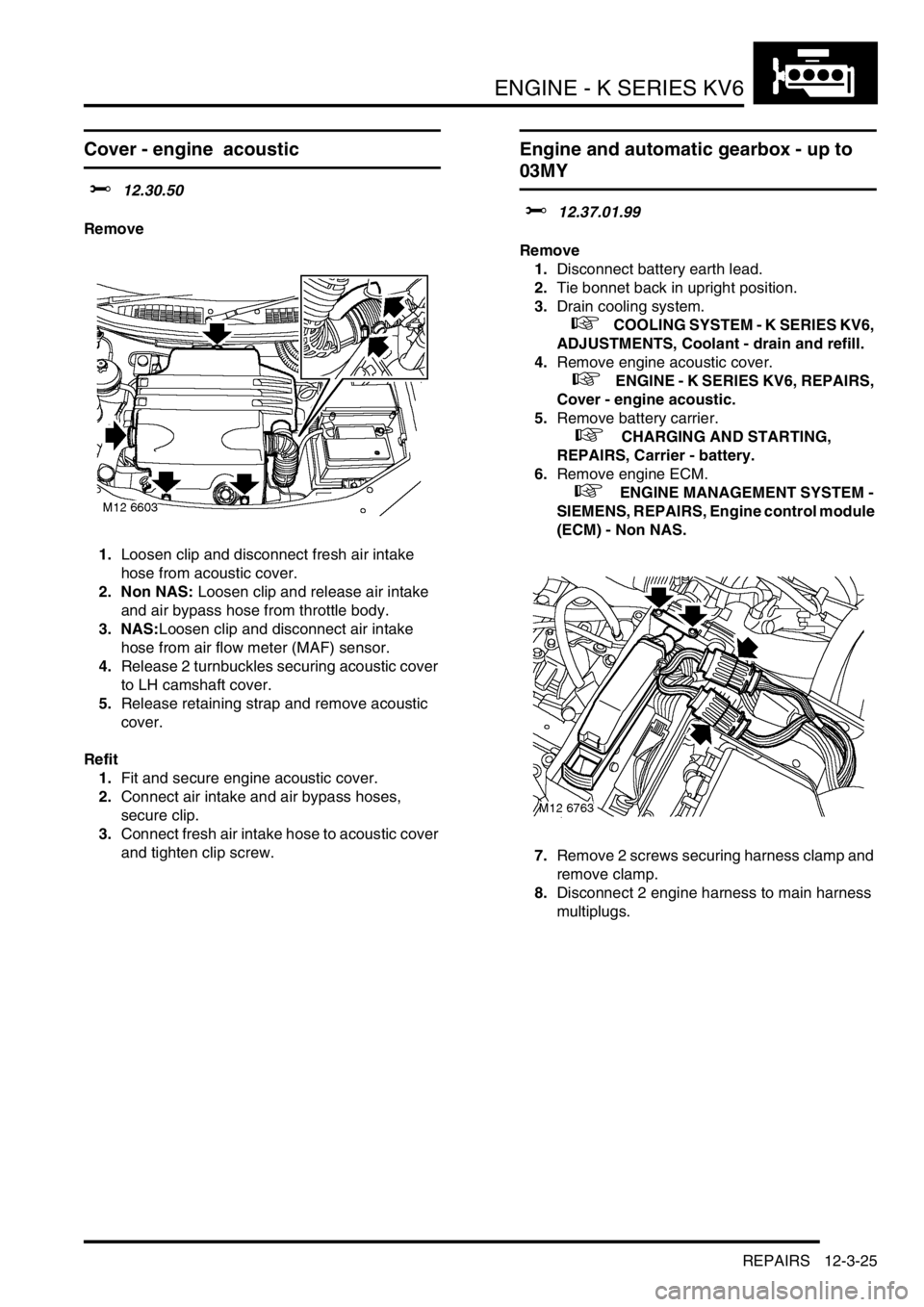

1.Loosen clip and disconnect fresh air intake

hose from acoustic cover.

2. Non NAS: Loosen clip and release air intake

and air bypass hose from throttle body.

3. NAS:Loosen clip and disconnect air intake

hose from air flow meter (MAF) sensor.

4.Release 2 turnbuckles securing acoustic cover

to LH camshaft cover.

5.Release retaining strap and remove acoustic

cover.

Refit

1.Fit and secure engine acoustic cover.

2.Connect air intake and air bypass hoses,

secure clip.

3.Connect fresh air intake hose to acoustic cover

and tighten clip screw.

Engine and automatic gearbox - up to

03MY

$% 12.37.01.99

Remove

1.Disconnect battery earth lead.

2.Tie bonnet back in upright position.

3.Drain cooling system.

+ COOLING SYSTEM - K SERIES KV6,

ADJUSTMENTS, Coolant - drain and refill.

4.Remove engine acoustic cover.

+ ENGINE - K SERIES KV6, REPAIRS,

Cover - engine acoustic.

5.Remove battery carrier.

+ CHARGING AND STARTING,

REPAIRS, Carrier - battery.

6.Remove engine ECM.

+ ENGINE MANAGEMENT SYSTEM -

SIEMENS, REPAIRS, Engine control module

(ECM) - Non NAS.

7.Remove 2 screws securing harness clamp and

remove clamp.

8.Disconnect 2 engine harness to main harness

multiplugs.

Page 203 of 1007

ENGINE - K SERIES KV6

12-3-26 REPAIRS

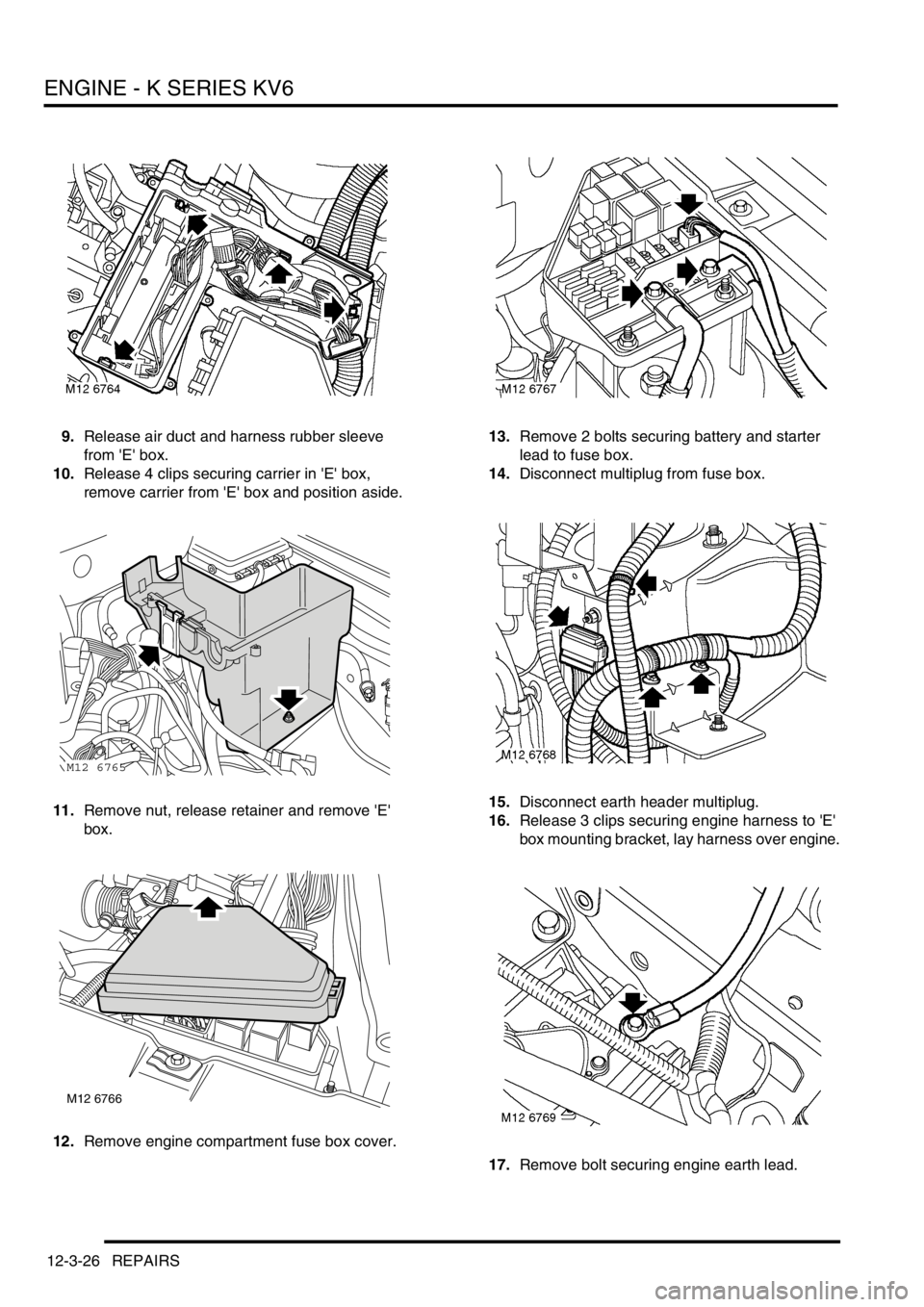

9.Release air duct and harness rubber sleeve

from 'E' box.

10.Release 4 clips securing carrier in 'E' box,

remove carrier from 'E' box and position aside.

11.Remove nut, release retainer and remove 'E'

box.

12.Remove engine compartment fuse box cover.13.Remove 2 bolts securing battery and starter

lead to fuse box.

14.Disconnect multiplug from fuse box.

15.Disconnect earth header multiplug.

16.Release 3 clips securing engine harness to 'E'

box mounting bracket, lay harness over engine.

17.Remove bolt securing engine earth lead.

M12 6765

M12 6766

Page 204 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-27

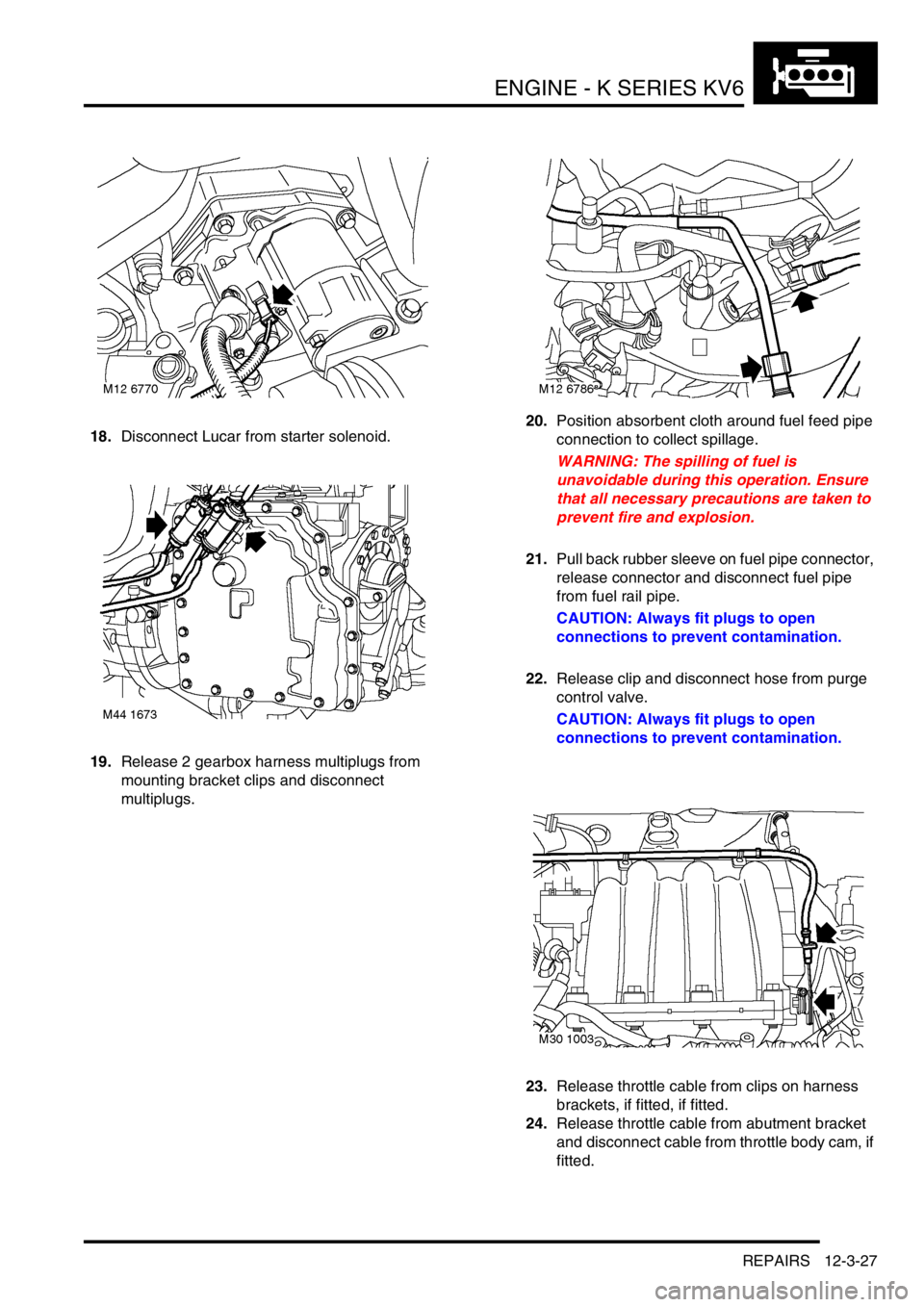

18.Disconnect Lucar from starter solenoid.

19.Release 2 gearbox harness multiplugs from

mounting bracket clips and disconnect

multiplugs.20.Position absorbent cloth around fuel feed pipe

connection to collect spillage.

WARNING: The spilling of fuel is

unavoidable during this operation. Ensure

that all necessary precautions are taken to

prevent fire and explosion.

21.Pull back rubber sleeve on fuel pipe connector,

release connector and disconnect fuel pipe

from fuel rail pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

22.Release clip and disconnect hose from purge

control valve.

CAUTION: Always fit plugs to open

connections to prevent contamination.

23.Release throttle cable from clips on harness

brackets, if fitted, if fitted.

24.Release throttle cable from abutment bracket

and disconnect cable from throttle body cam, if

fitted.

Page 205 of 1007

ENGINE - K SERIES KV6

12-3-28 REPAIRS

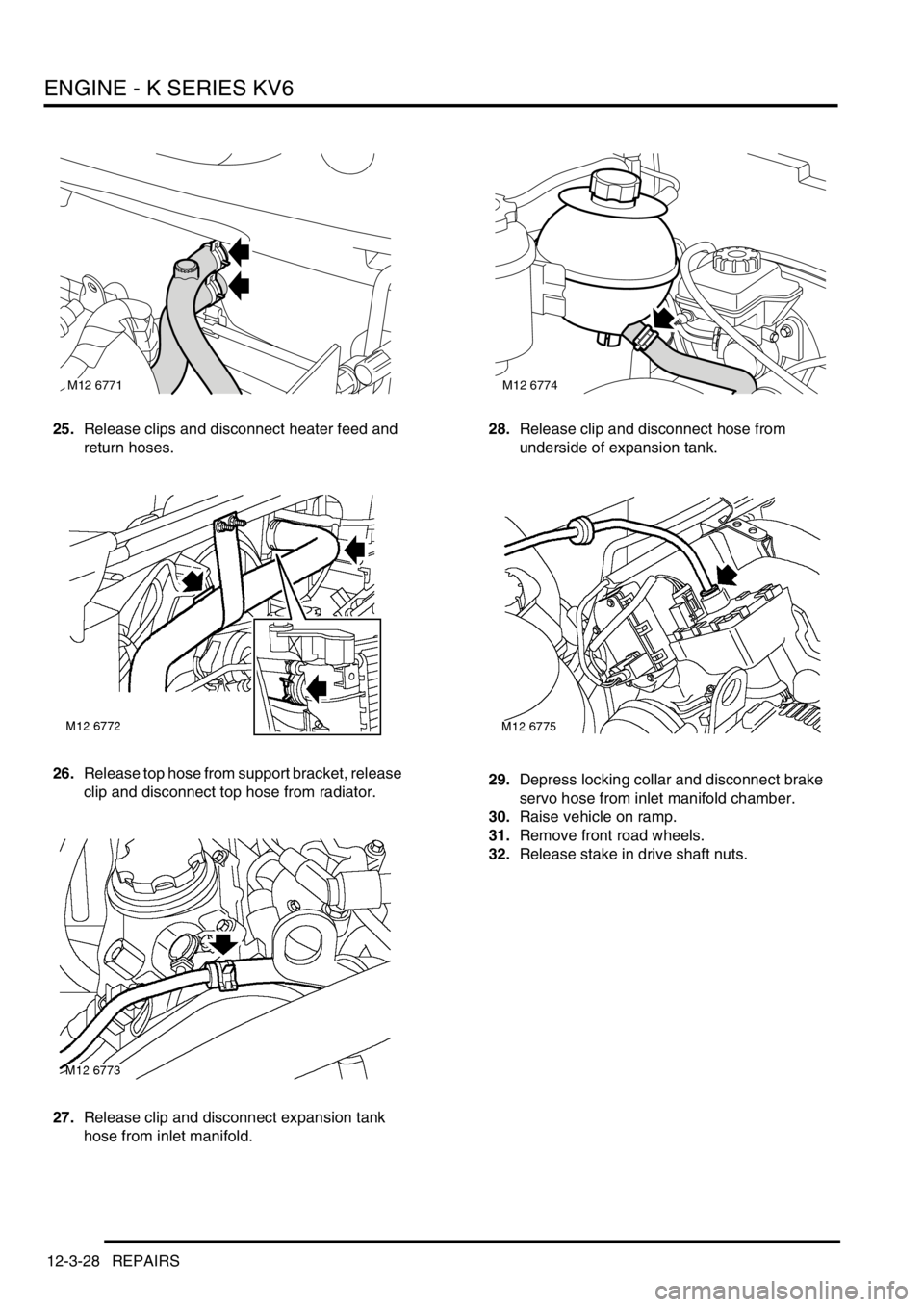

25.Release clips and disconnect heater feed and

return hoses.

26.Release top hose from support bracket, release

clip and disconnect top hose from radiator.

27.Release clip and disconnect expansion tank

hose from inlet manifold.28.Release clip and disconnect hose from

underside of expansion tank.

29.Depress locking collar and disconnect brake

servo hose from inlet manifold chamber.

30.Raise vehicle on ramp.

31.Remove front road wheels.

32.Release stake in drive shaft nuts.

M12 6771M12 6774

Page 206 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-29

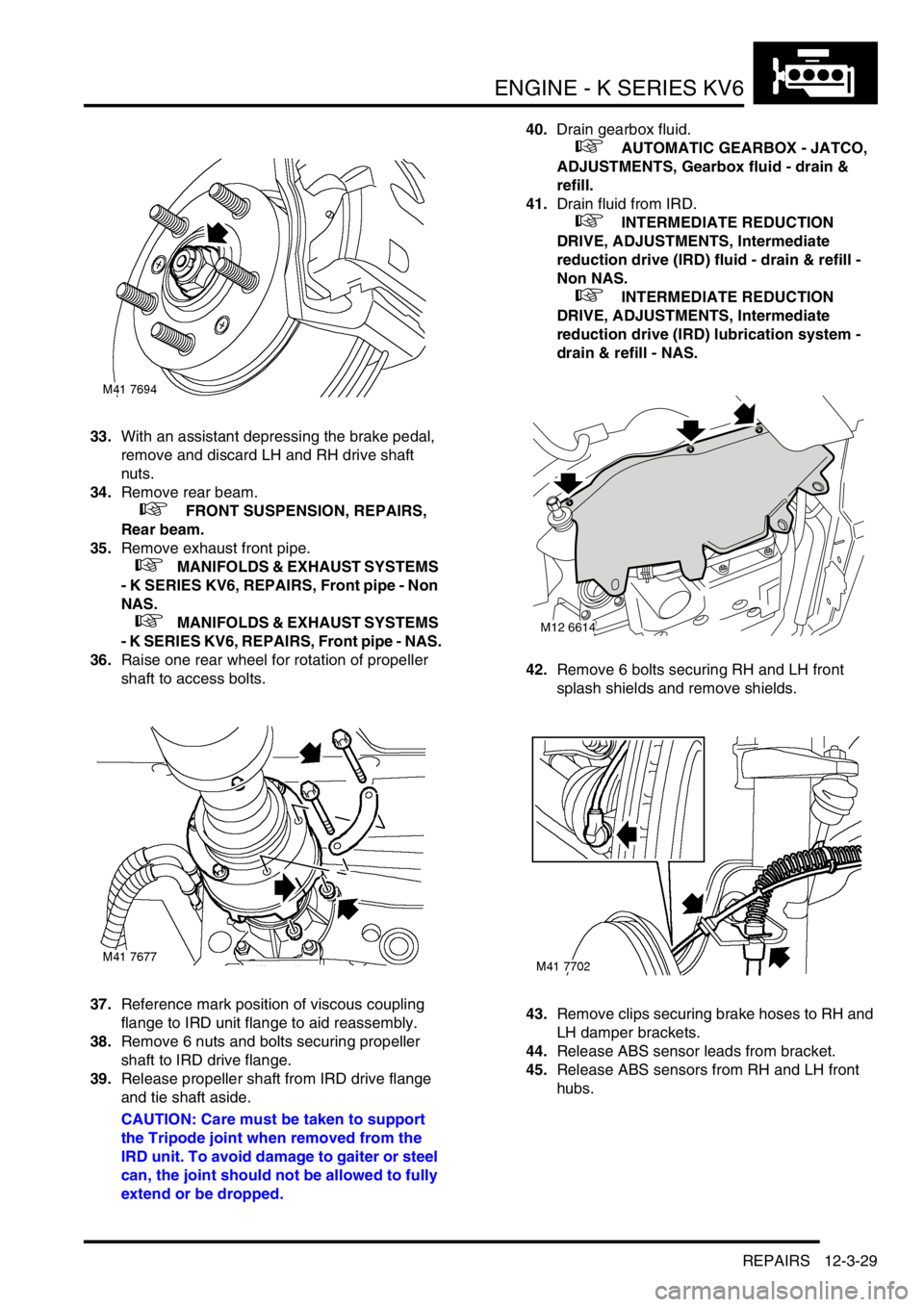

33.With an assistant depressing the brake pedal,

remove and discard LH and RH drive shaft

nuts.

34.Remove rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

35.Remove exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.

36.Raise one rear wheel for rotation of propeller

shaft to access bolts.

37.Reference mark position of viscous coupling

flange to IRD unit flange to aid reassembly.

38.Remove 6 nuts and bolts securing propeller

shaft to IRD drive flange.

39.Release propeller shaft from IRD drive flange

and tie shaft aside.

CAUTION: Care must be taken to support

the Tripode joint when removed from the

IRD unit. To avoid damage to gaiter or steel

can, the joint should not be allowed to fully

extend or be dropped.40.Drain gearbox fluid.

+ AUTOMATIC GEARBOX - JATCO,

ADJUSTMENTS, Gearbox fluid - drain &

refill.

41.Drain fluid from IRD.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

42.Remove 6 bolts securing RH and LH front

splash shields and remove shields.

43.Remove clips securing brake hoses to RH and

LH damper brackets.

44.Release ABS sensor leads from bracket.

45.Release ABS sensors from RH and LH front

hubs.

M12 6614

Page 207 of 1007

ENGINE - K SERIES KV6

12-3-30 REPAIRS

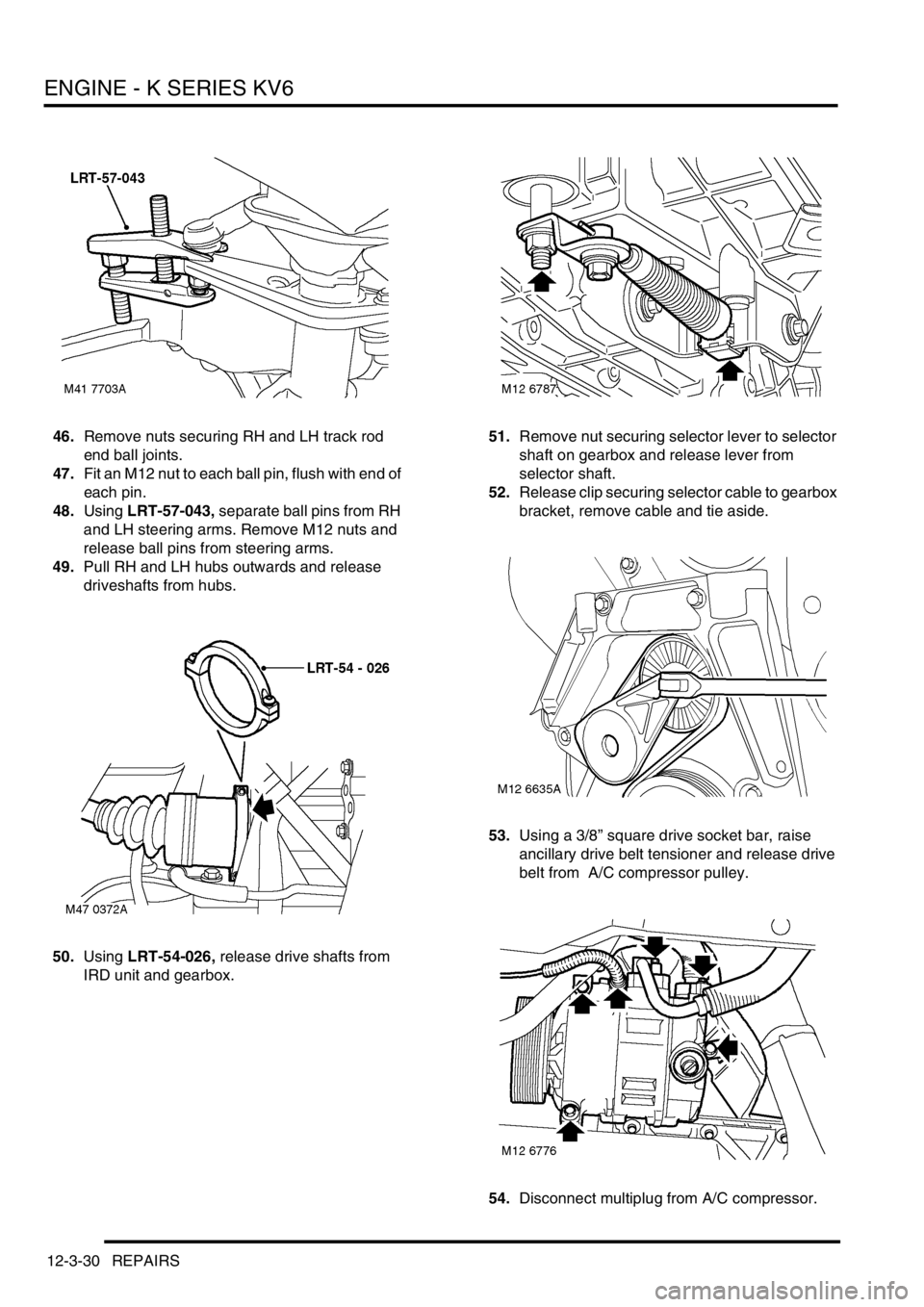

46.Remove nuts securing RH and LH track rod

end ball joints.

47.Fit an M12 nut to each ball pin, flush with end of

each pin.

48.Using LRT-57-043, separate ball pins from RH

and LH steering arms. Remove M12 nuts and

release ball pins from steering arms.

49.Pull RH and LH hubs outwards and release

driveshafts from hubs.

50.Using LRT-54-026, release drive shafts from

IRD unit and gearbox.51.Remove nut securing selector lever to selector

shaft on gearbox and release lever from

selector shaft.

52.Release clip securing selector cable to gearbox

bracket, remove cable and tie aside.

53.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and release drive

belt from A/C compressor pulley.

54.Disconnect multiplug from A/C compressor.

Page 208 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-31

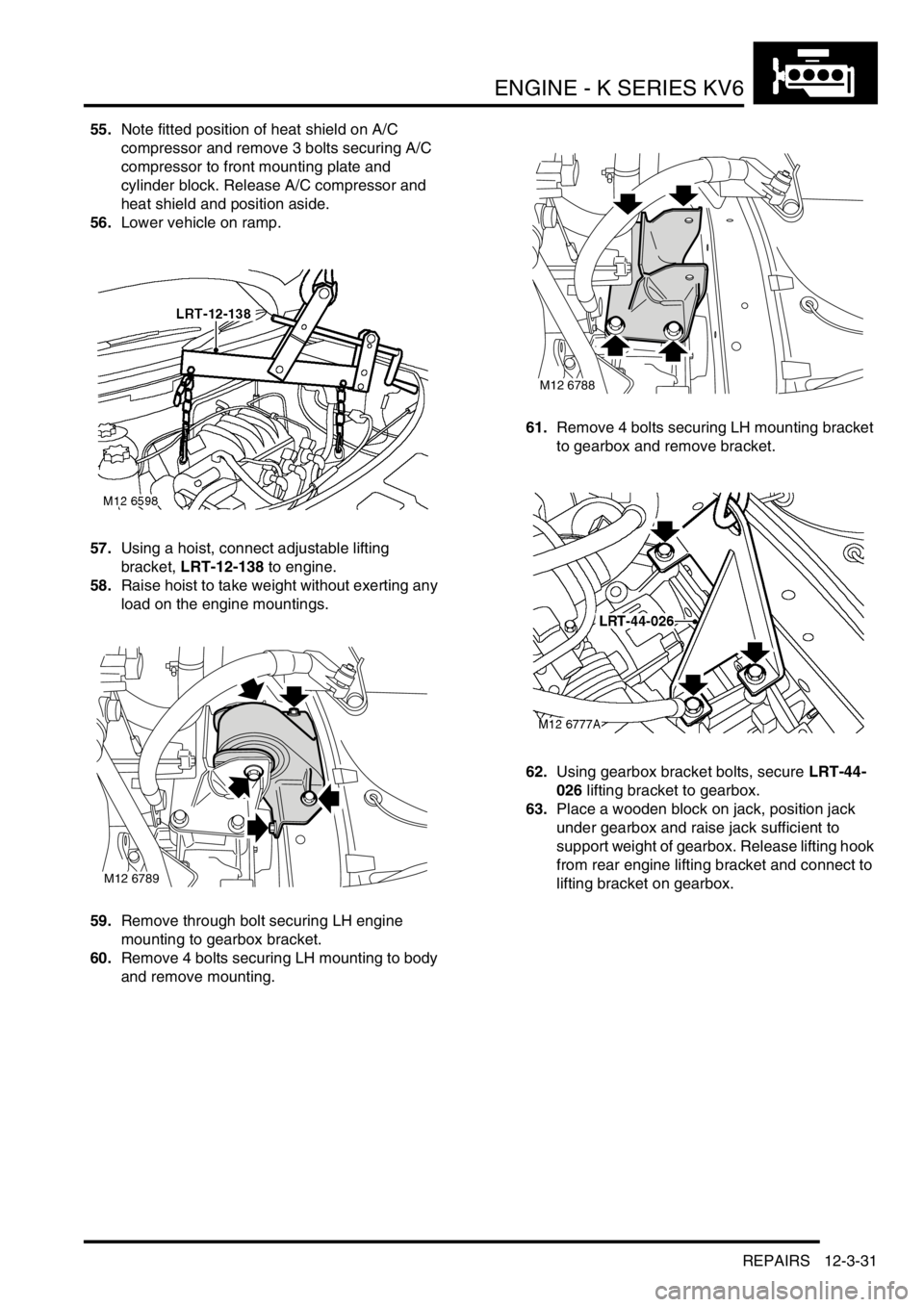

55.Note fitted position of heat shield on A/C

compressor and remove 3 bolts securing A/C

compressor to front mounting plate and

cylinder block. Release A/C compressor and

heat shield and position aside.

56.Lower vehicle on ramp.

57.Using a hoist, connect adjustable lifting

bracket, LRT-12-138 to engine.

58.Raise hoist to take weight without exerting any

load on the engine mountings.

59.Remove through bolt securing LH engine

mounting to gearbox bracket.

60.Remove 4 bolts securing LH mounting to body

and remove mounting.61.Remove 4 bolts securing LH mounting bracket

to gearbox and remove bracket.

62.Using gearbox bracket bolts, secure LRT-44-

026 lifting bracket to gearbox.

63.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from rear engine lifting bracket and connect to

lifting bracket on gearbox.

M12 6789

M12 6788

Page 209 of 1007

ENGINE - K SERIES KV6

12-3-32 REPAIRS

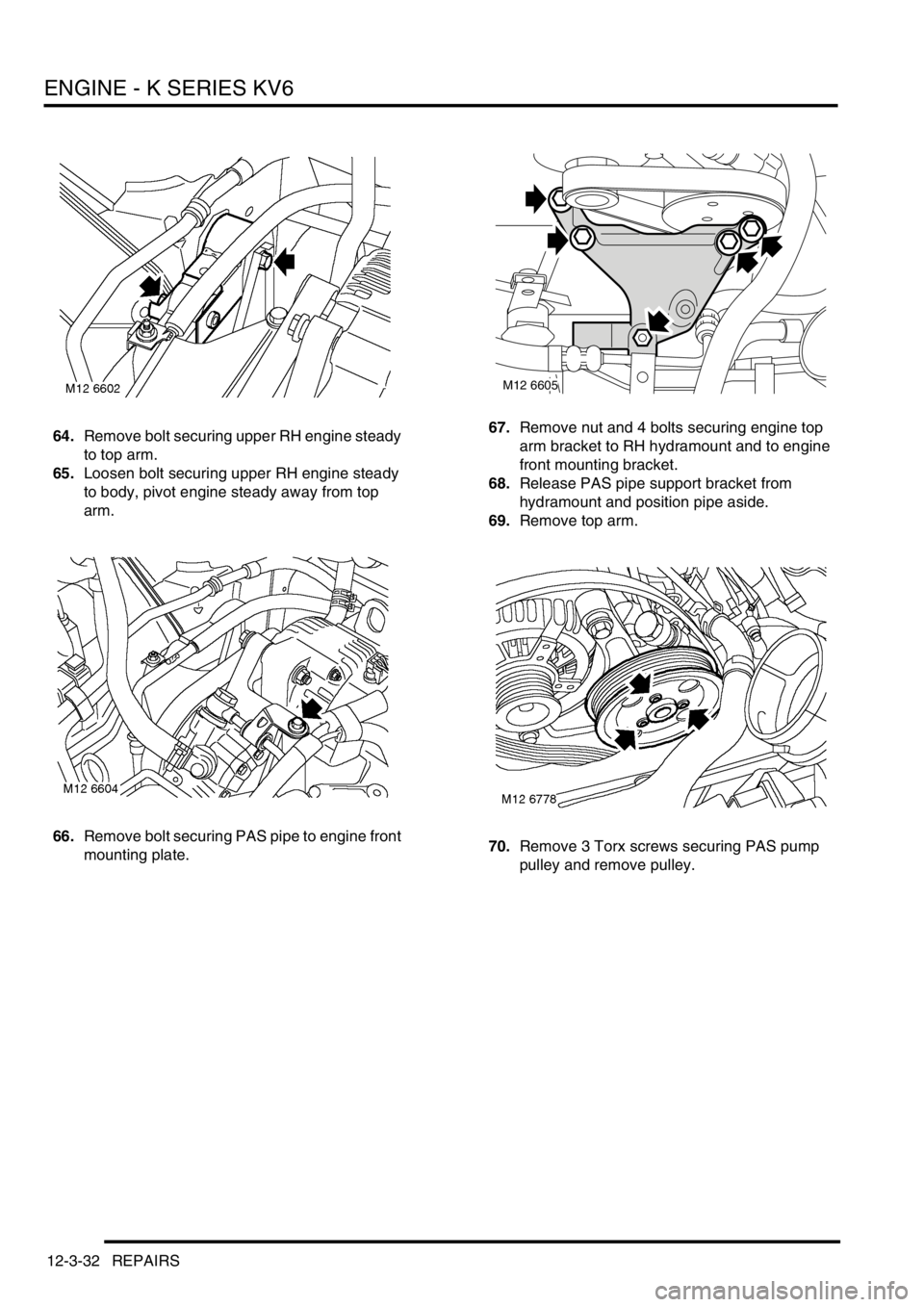

64.Remove bolt securing upper RH engine steady

to top arm.

65.Loosen bolt securing upper RH engine steady

to body, pivot engine steady away from top

arm.

66.Remove bolt securing PAS pipe to engine front

mounting plate.67.Remove nut and 4 bolts securing engine top

arm bracket to RH hydramount and to engine

front mounting bracket.

68.Release PAS pipe support bracket from

hydramount and position pipe aside.

69.Remove top arm.

70.Remove 3 Torx screws securing PAS pump

pulley and remove pulley.

M12 6605

Page 210 of 1007

ENGINE - K SERIES KV6

REPAIRS 12-3-33

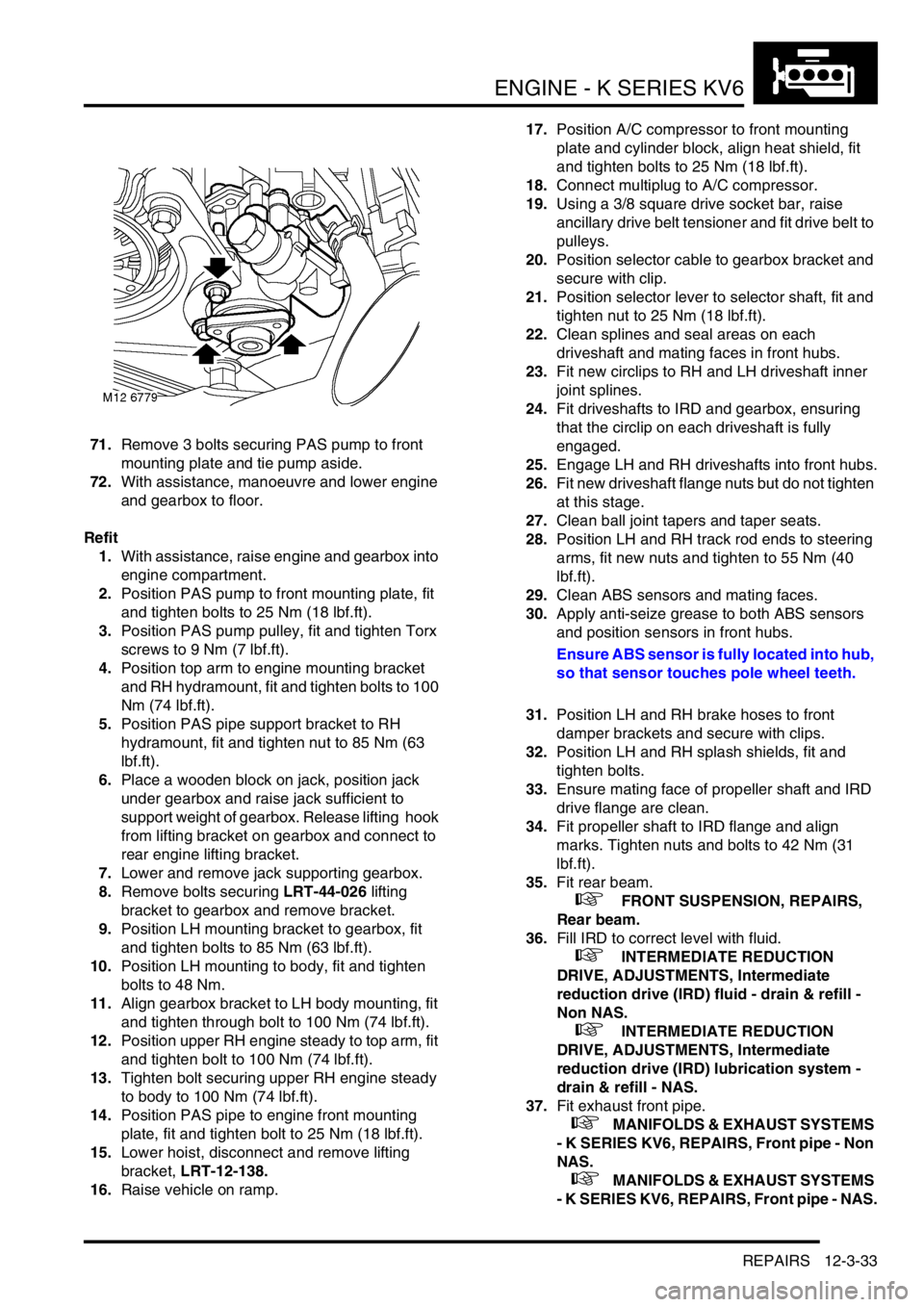

71.Remove 3 bolts securing PAS pump to front

mounting plate and tie pump aside.

72.With assistance, manoeuvre and lower engine

and gearbox to floor.

Refit

1.With assistance, raise engine and gearbox into

engine compartment.

2.Position PAS pump to front mounting plate, fit

and tighten bolts to 25 Nm (18 lbf.ft).

3.Position PAS pump pulley, fit and tighten Torx

screws to 9 Nm (7 lbf.ft).

4.Position top arm to engine mounting bracket

and RH hydramount, fit and tighten bolts to 100

Nm (74 lbf.ft).

5.Position PAS pipe support bracket to RH

hydramount, fit and tighten nut to 85 Nm (63

lbf.ft).

6.Place a wooden block on jack, position jack

under gearbox and raise jack sufficient to

support weight of gearbox. Release lifting hook

from lifting bracket on gearbox and connect to

rear engine lifting bracket.

7.Lower and remove jack supporting gearbox.

8.Remove bolts securing LRT-44-026 lifting

bracket to gearbox and remove bracket.

9.Position LH mounting bracket to gearbox, fit

and tighten bolts to 85 Nm (63 lbf.ft).

10.Position LH mounting to body, fit and tighten

bolts to 48 Nm.

11.Align gearbox bracket to LH body mounting, fit

and tighten through bolt to 100 Nm (74 lbf.ft).

12.Position upper RH engine steady to top arm, fit

and tighten bolt to 100 Nm (74 lbf.ft).

13.Tighten bolt securing upper RH engine steady

to body to 100 Nm (74 lbf.ft).

14.Position PAS pipe to engine front mounting

plate, fit and tighten bolt to 25 Nm (18 lbf.ft).

15.Lower hoist, disconnect and remove lifting

bracket, LRT-12-138.

16.Raise vehicle on ramp.17.Position A/C compressor to front mounting

plate and cylinder block, align heat shield, fit

and tighten bolts to 25 Nm (18 lbf.ft).

18.Connect multiplug to A/C compressor.

19.Using a 3/8 square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

20.Position selector cable to gearbox bracket and

secure with clip.

21.Position selector lever to selector shaft, fit and

tighten nut to 25 Nm (18 lbf.ft).

22.Clean splines and seal areas on each

driveshaft and mating faces in front hubs.

23.Fit new circlips to RH and LH driveshaft inner

joint splines.

24.Fit driveshafts to IRD and gearbox, ensuring

that the circlip on each driveshaft is fully

engaged.

25.Engage LH and RH driveshafts into front hubs.

26.Fit new driveshaft flange nuts but do not tighten

at this stage.

27.Clean ball joint tapers and taper seats.

28.Position LH and RH track rod ends to steering

arms, fit new nuts and tighten to 55 Nm (40

lbf.ft).

29.Clean ABS sensors and mating faces.

30.Apply anti-seize grease to both ABS sensors

and position sensors in front hubs.

Ensure ABS sensor is fully located into hub,

so that sensor touches pole wheel teeth.

31.Position LH and RH brake hoses to front

damper brackets and secure with clips.

32.Position LH and RH splash shields, fit and

tighten bolts.

33.Ensure mating face of propeller shaft and IRD

drive flange are clean.

34.Fit propeller shaft to IRD flange and align

marks. Tighten nuts and bolts to 42 Nm (31

lbf.ft).

35.Fit rear beam.

+ FRONT SUSPENSION, REPAIRS,

Rear beam.

36.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) lubrication system -

drain & refill - NAS.

37.Fit exhaust front pipe.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - Non

NAS.

+ MANIFOLDS & EXHAUST SYSTEMS

- K SERIES KV6, REPAIRS, Front pipe - NAS.