LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 161 of 1007

MAINTENANCE

10-14 MAINTENANCE

Ancillary Drive Belt – Td4

Check

1.Check ancillary drive belts for tension, signs of

fraying, damage and for any oil contamination.

Replace

1.Replace ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

Ancillary Drive Belt – K1.8

Check

1.Check ancillary drive belts for tension, signs of

fraying, damage and for any oil contamination.

Replace

1.Replace ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - K1.8 without

A/C.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - K1.8 with A/

C.

Page 162 of 1007

MAINTENANCE

MAINTENANCE 10-15

Ancillary Drive Belt – KV6

Check

1.Check ancillary drive belts for tension, signs of

fraying, damage and for any oil contamination.

Replace

1.Replace ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - KV6.

Camshaft Timing Belt – K1.8

Check

1.Check camshaft drive belt and renew if

necessary.

+ ENGINE - K SERIES 1.8, REPAIRS,

Camshaft timing belt.

Page 163 of 1007

MAINTENANCE

10-16 MAINTENANCE

Camshaft Timing Belt – KV6

Check

1.Check camshaft drive belt and renew if

necessary.

+ ENGINE - K SERIES KV6, REPAIRS,

Camshaft timing belt.

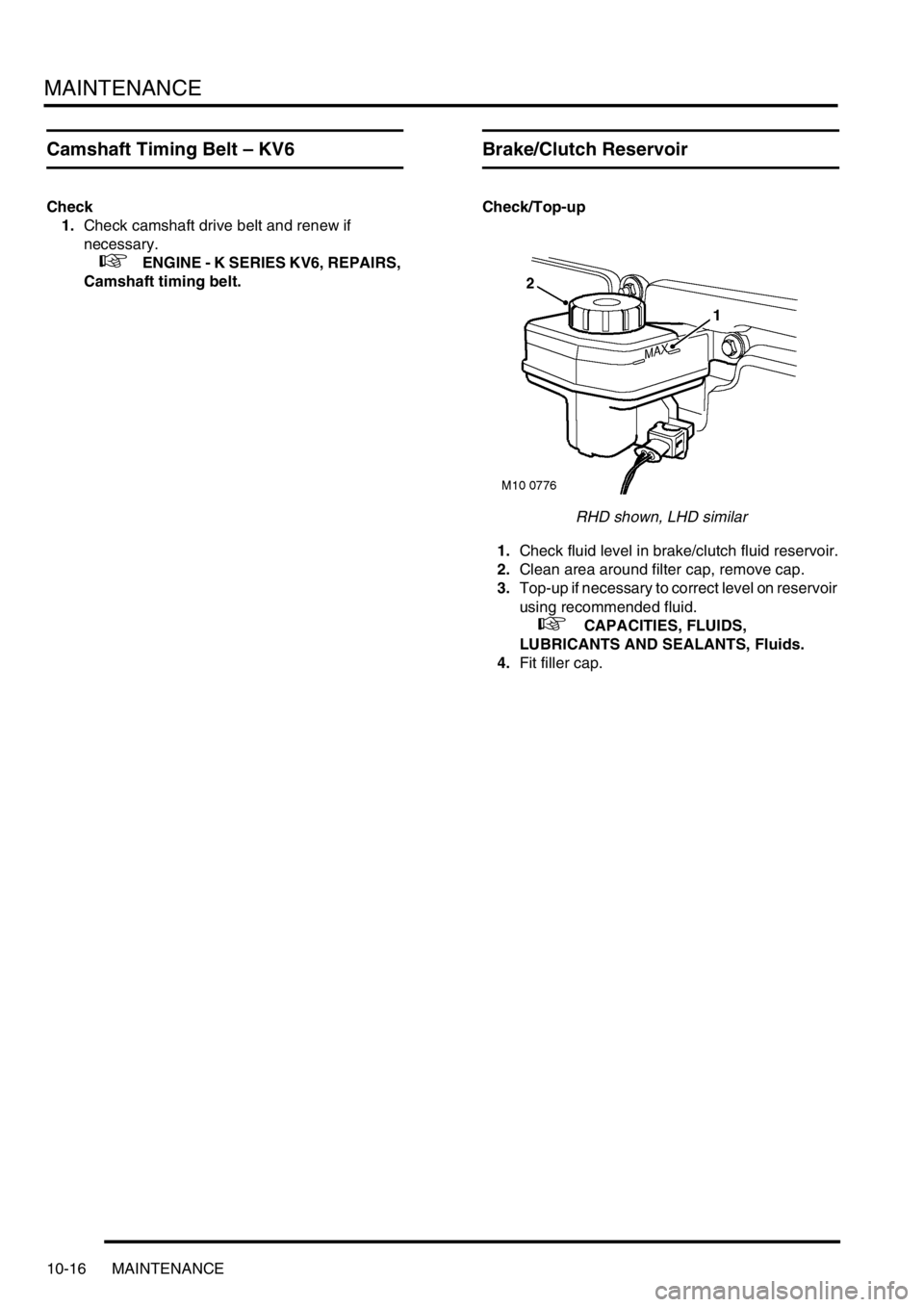

Brake/Clutch Reservoir

Check/Top-up

RHD shown, LHD similar

1.Check fluid level in brake/clutch fluid reservoir.

2.Clean area around filter cap, remove cap.

3.Top-up if necessary to correct level on reservoir

using recommended fluid.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

4.Fit filler cap.

Page 164 of 1007

MAINTENANCE

MAINTENANCE 10-17

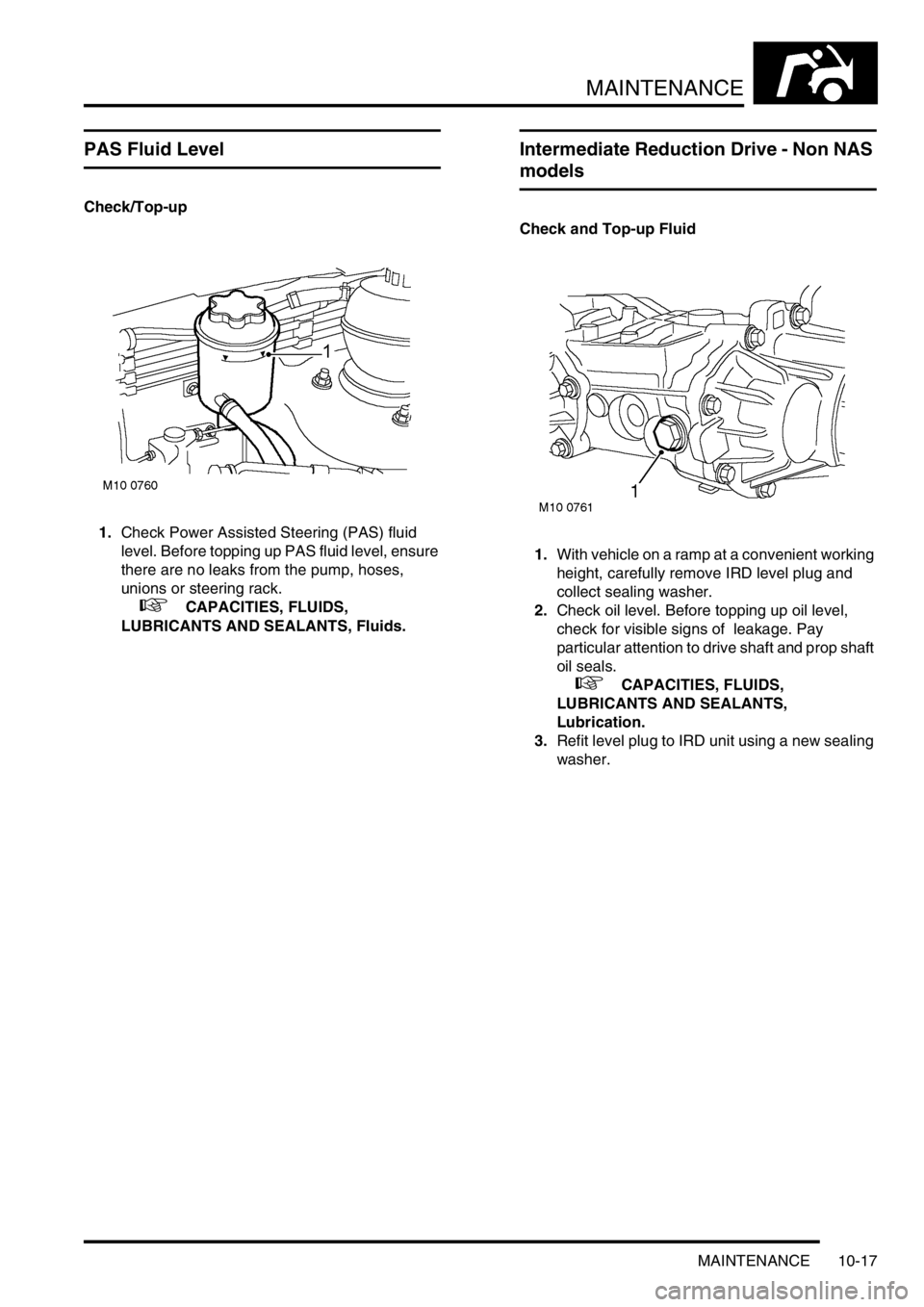

PAS Fluid Level

Check/Top-up

1.Check Power Assisted Steering (PAS) fluid

level. Before topping up PAS fluid level, ensure

there are no leaks from the pump, hoses,

unions or steering rack.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

Intermediate Reduction Drive - Non NAS

models

Check and Top-up Fluid

1.With vehicle on a ramp at a convenient working

height, carefully remove IRD level plug and

collect sealing washer.

2.Check oil level. Before topping up oil level,

check for visible signs of leakage. Pay

particular attention to drive shaft and prop shaft

oil seals.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Refit level plug to IRD unit using a new sealing

washer.

Page 165 of 1007

MAINTENANCE

10-18 MAINTENANCE

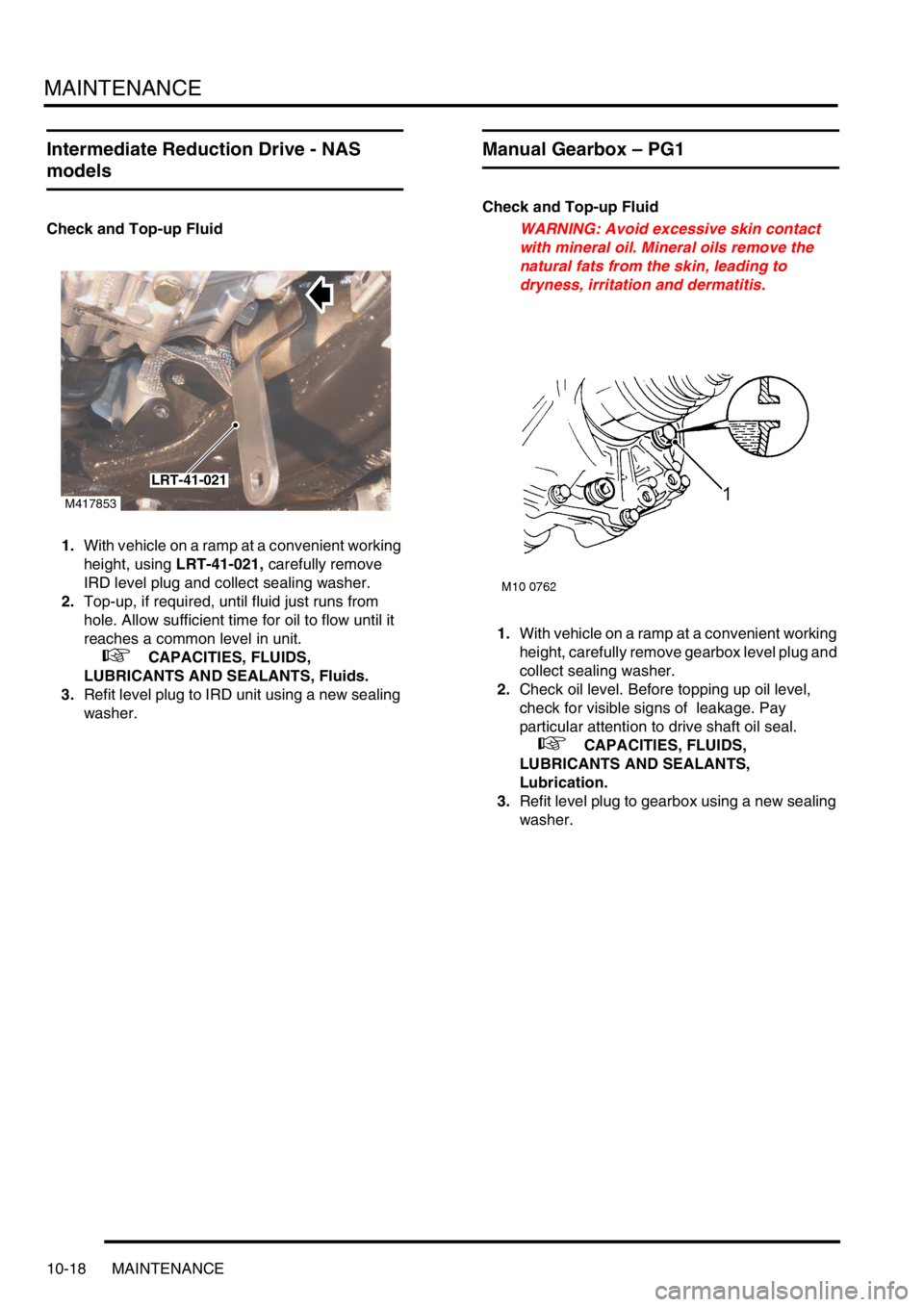

Intermediate Reduction Drive - NAS

models

Check and Top-up Fluid

1.With vehicle on a ramp at a convenient working

height, using LRT-41-021, carefully remove

IRD level plug and collect sealing washer.

2.Top-up, if required, until fluid just runs from

hole. Allow sufficient time for oil to flow until it

reaches a common level in unit.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS, Fluids.

3.Refit level plug to IRD unit using a new sealing

washer.

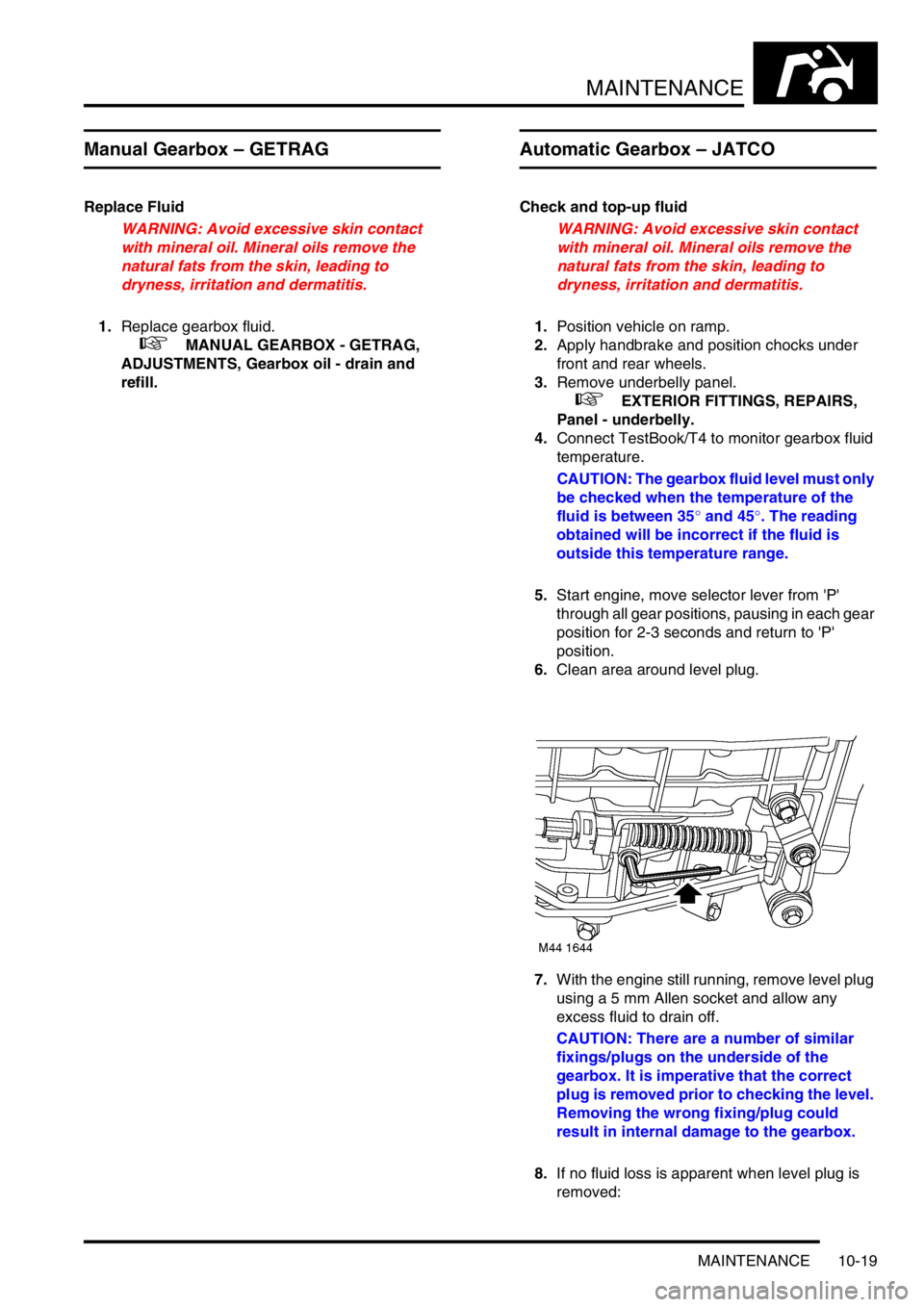

Manual Gearbox – PG1

Check and Top-up Fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.With vehicle on a ramp at a convenient working

height, carefully remove gearbox level plug and

collect sealing washer.

2.Check oil level. Before topping up oil level,

check for visible signs of leakage. Pay

particular attention to drive shaft oil seal.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

3.Refit level plug to gearbox using a new sealing

washer.

M417853

LRT-41-021

Page 166 of 1007

MAINTENANCE

MAINTENANCE 10-19

Manual Gearbox – GETRAG

Replace Fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.Replace gearbox fluid.

+ MANUAL GEARBOX - GETRAG,

ADJUSTMENTS, Gearbox oil - drain and

refill.

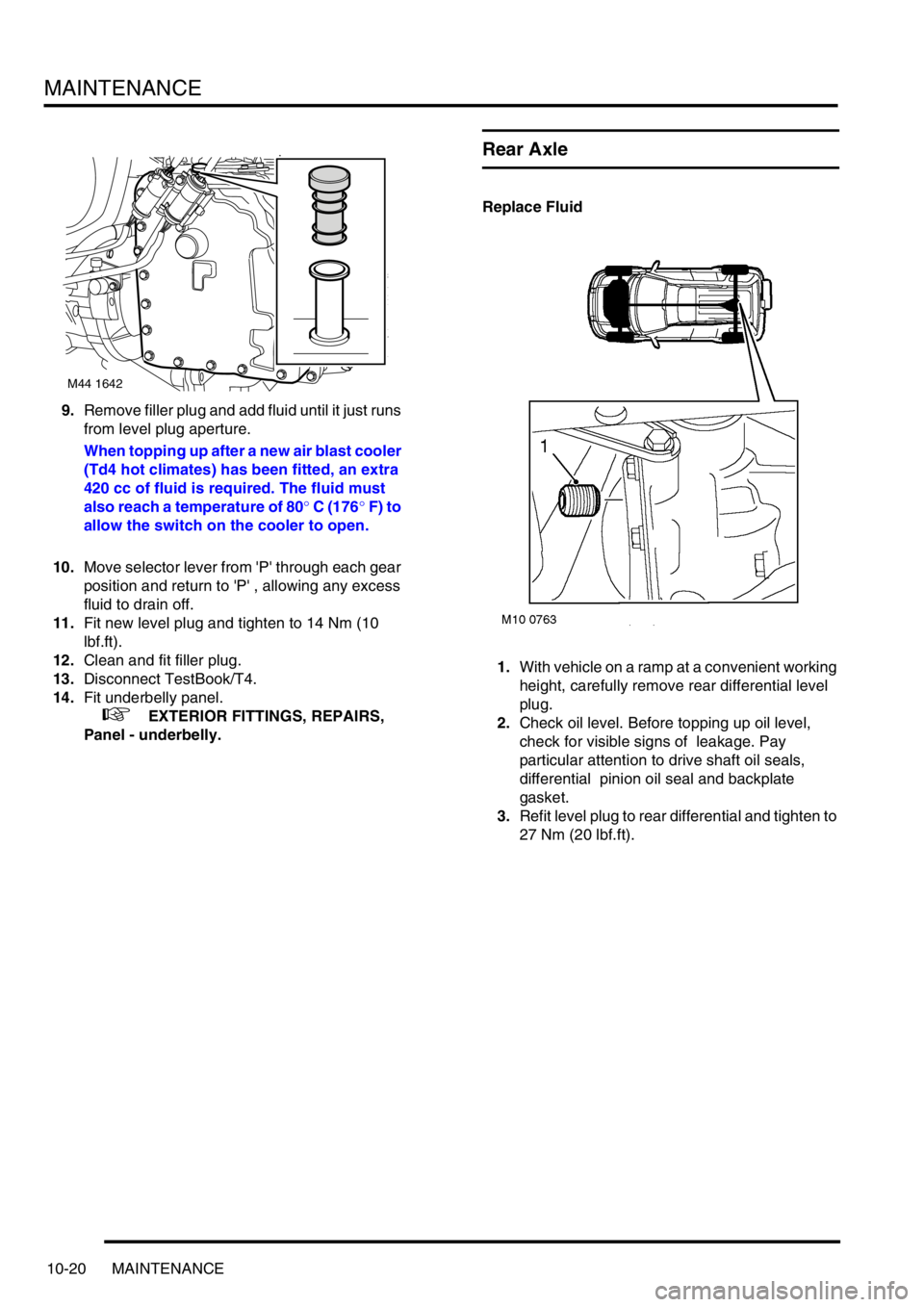

Automatic Gearbox – JATCO

Check and top-up fluid

WARNING: Avoid excessive skin contact

with mineral oil. Mineral oils remove the

natural fats from the skin, leading to

dryness, irritation and dermatitis.

1.Position vehicle on ramp.

2.Apply handbrake and position chocks under

front and rear wheels.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Connect TestBook/T4 to monitor gearbox fluid

temperature.

CAUTION: The gearbox fluid level must only

be checked when the temperature of the

fluid is between 35° and 45°. The reading

obtained will be incorrect if the fluid is

outside this temperature range.

5.Start engine, move selector lever from 'P'

through all gear positions, pausing in each gear

position for 2-3 seconds and return to 'P'

position.

6.Clean area around level plug.

7.With the engine still running, remove level plug

using a 5 mm Allen socket and allow any

excess fluid to drain off.

CAUTION: There are a number of similar

fixings/plugs on the underside of the

gearbox. It is imperative that the correct

plug is removed prior to checking the level.

Removing the wrong fixing/plug could

result in internal damage to the gearbox.

8.If no fluid loss is apparent when level plug is

removed:

Page 167 of 1007

MAINTENANCE

10-20 MAINTENANCE

9.Remove filler plug and add fluid until it just runs

from level plug aperture.

When topping up after a new air blast cooler

(Td4 hot climates) has been fitted, an extra

420 cc of fluid is required. The fluid must

also reach a temperature of 80° C (176° F) to

allow the switch on the cooler to open.

10.Move selector lever from 'P' through each gear

position and return to 'P' , allowing any excess

fluid to drain off.

11.Fit new level plug and tighten to 14 Nm (10

lbf.ft).

12.Clean and fit filler plug.

13.Disconnect TestBook/T4.

14.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

Rear Axle

Replace Fluid

1.With vehicle on a ramp at a convenient working

height, carefully remove rear differential level

plug.

2.Check oil level. Before topping up oil level,

check for visible signs of leakage. Pay

particular attention to drive shaft oil seals,

differential pinion oil seal and backplate

gasket.

3.Refit level plug to rear differential and tighten to

27 Nm (20 lbf.ft).

M44 1642

Page 168 of 1007

MAINTENANCE

MAINTENANCE 10-21

Clutch Pipes and Unions

Check

1.Check route of clutch pipe from master cylinder

to slave cylinder. Ensure that pipe is correctly

retained and shows no signs of fluid leakage or

chafing.

2. Check unions for signs of fluid leakage.

Windscreen and Rear Washer Reservoir

Check and Top-up

1.Release cap from washer reservoir and fill with

the correct concentration of screen washer

fluid.

2.Refit cap ensuring it is securely fastened.

Battery

Check

1.Check battery condition indicator. Green =

OK. Black = Battery requires charging. Clear/

white = New battery required.

2.Clean and check security of battery terminals.

Smear with petroleum jelly.

Page 169 of 1007

MAINTENANCE

10-22 MAINTENANCE

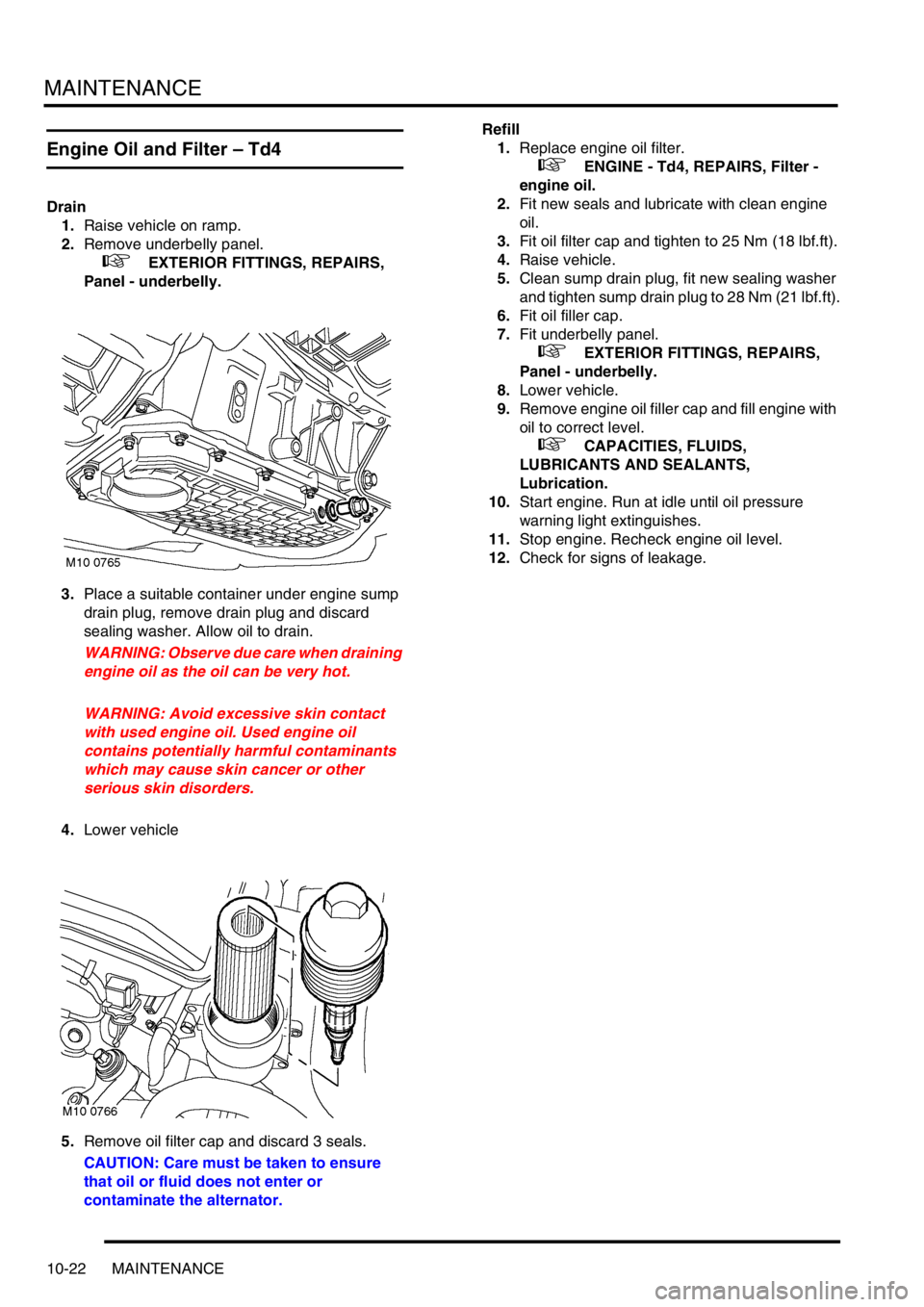

Engine Oil and Filter – Td4

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove drain plug and discard

sealing washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Lower vehicle

5.Remove oil filter cap and discard 3 seals.

CAUTION: Care must be taken to ensure

that oil or fluid does not enter or

contaminate the alternator.Refill

1.Replace engine oil filter.

+ ENGINE - Td4, REPAIRS, Filter -

engine oil.

2.Fit new seals and lubricate with clean engine

oil.

3.Fit oil filter cap and tighten to 25 Nm (18 lbf.ft).

4.Raise vehicle.

5.Clean sump drain plug, fit new sealing washer

and tighten sump drain plug to 28 Nm (21 lbf.ft).

6.Fit oil filler cap.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Lower vehicle.

9.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

10.Start engine. Run at idle until oil pressure

warning light extinguishes.

11.Stop engine. Recheck engine oil level.

12.Check for signs of leakage.

Page 170 of 1007

MAINTENANCE

MAINTENANCE 10-23

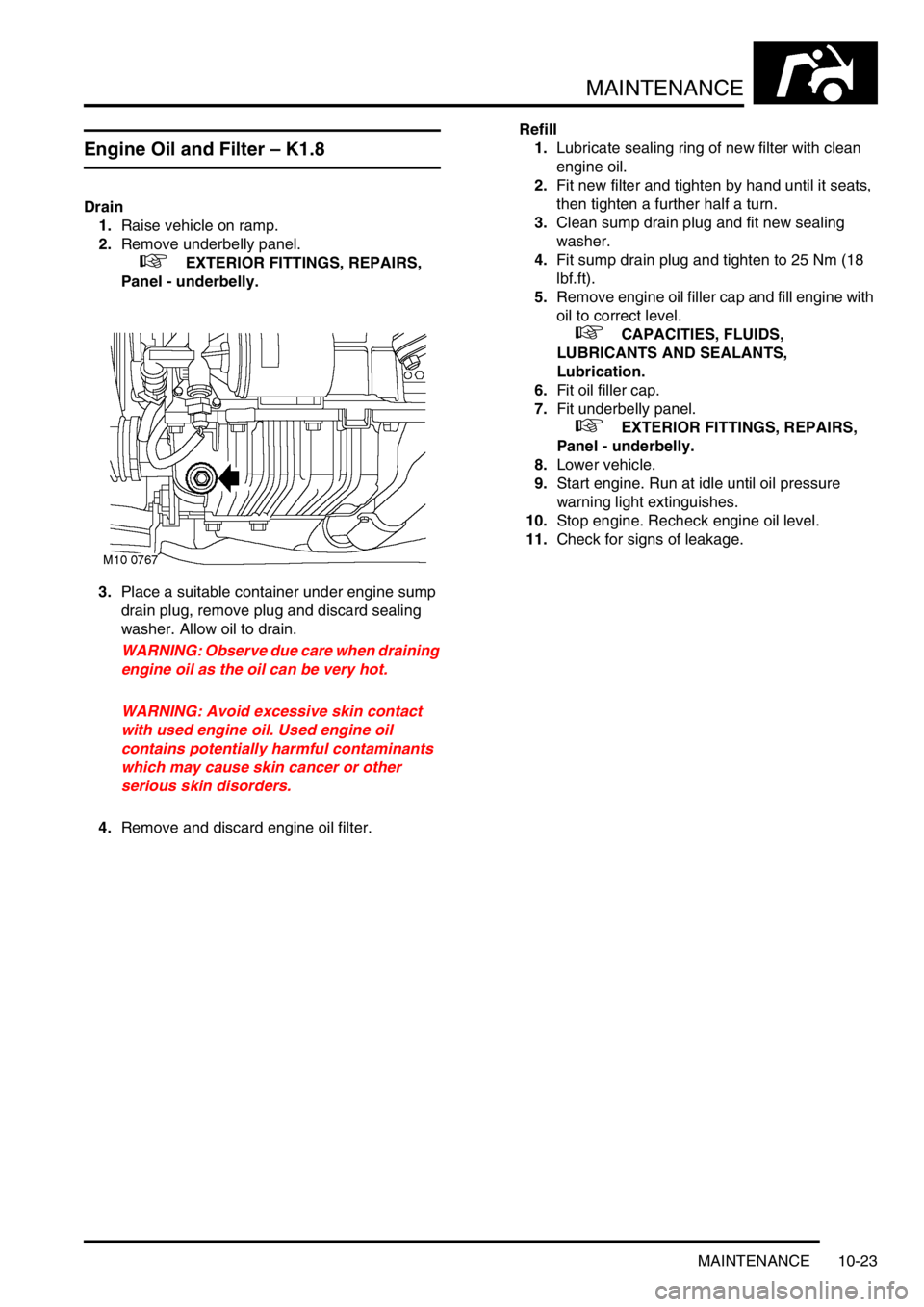

Engine Oil and Filter – K1.8

Drain

1.Raise vehicle on ramp.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Place a suitable container under engine sump

drain plug, remove plug and discard sealing

washer. Allow oil to drain.

WARNING: Observe due care when draining

engine oil as the oil can be very hot.

WARNING: Avoid excessive skin contact

with used engine oil. Used engine oil

contains potentially harmful contaminants

which may cause skin cancer or other

serious skin disorders.

4.Remove and discard engine oil filter.Refill

1.Lubricate sealing ring of new filter with clean

engine oil.

2.Fit new filter and tighten by hand until it seats,

then tighten a further half a turn.

3.Clean sump drain plug and fit new sealing

washer.

4.Fit sump drain plug and tighten to 25 Nm (18

lbf.ft).

5.Remove engine oil filler cap and fill engine with

oil to correct level.

+ CAPACITIES, FLUIDS,

LUBRICANTS AND SEALANTS,

Lubrication.

6.Fit oil filler cap.

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Lower vehicle.

9.Start engine. Run at idle until oil pressure

warning light extinguishes.

10.Stop engine. Recheck engine oil level.

11.Check for signs of leakage.