LAND ROVER FREELANDER 2001 Workshop Manual

FREELANDER 2001

LAND ROVER

LAND ROVER

https://www.carmanualsonline.info/img/64/57250/w960_57250-0.png

LAND ROVER FREELANDER 2001 Workshop Manual

Trending: tow, boot, roof, fuel cap release, relay, engine coolant, service schedule

Page 851 of 1007

CORROSION PREVENTION AND SEALING

77-4-20 SEALING

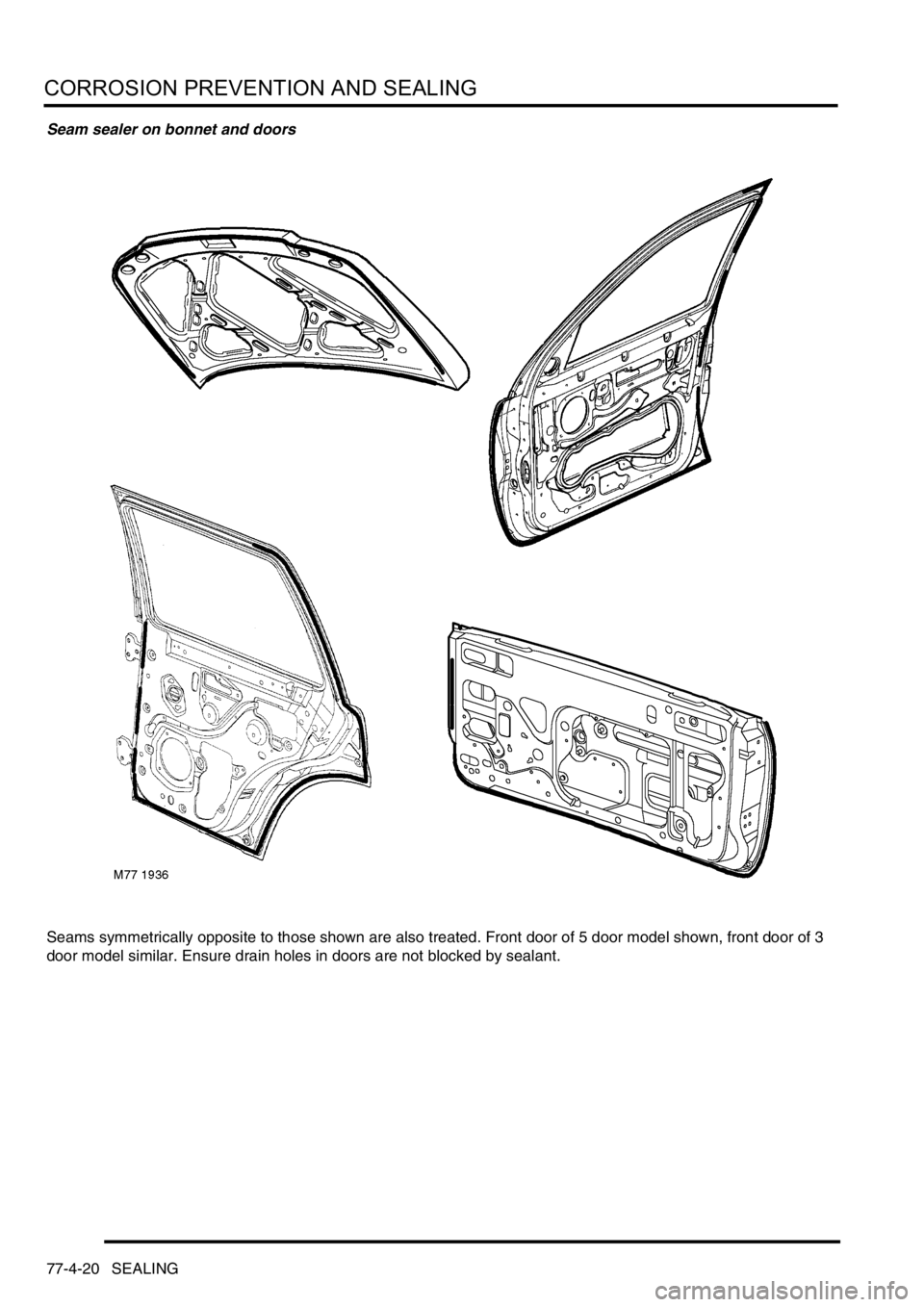

Seam sealer on bonnet and doors

Seams symmetrically opposite to those shown are also treated. Front door of 5 door model shown, front door of 3

door model similar. Ensure drain holes in doors are not blocked by sealant.

Page 852 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-21

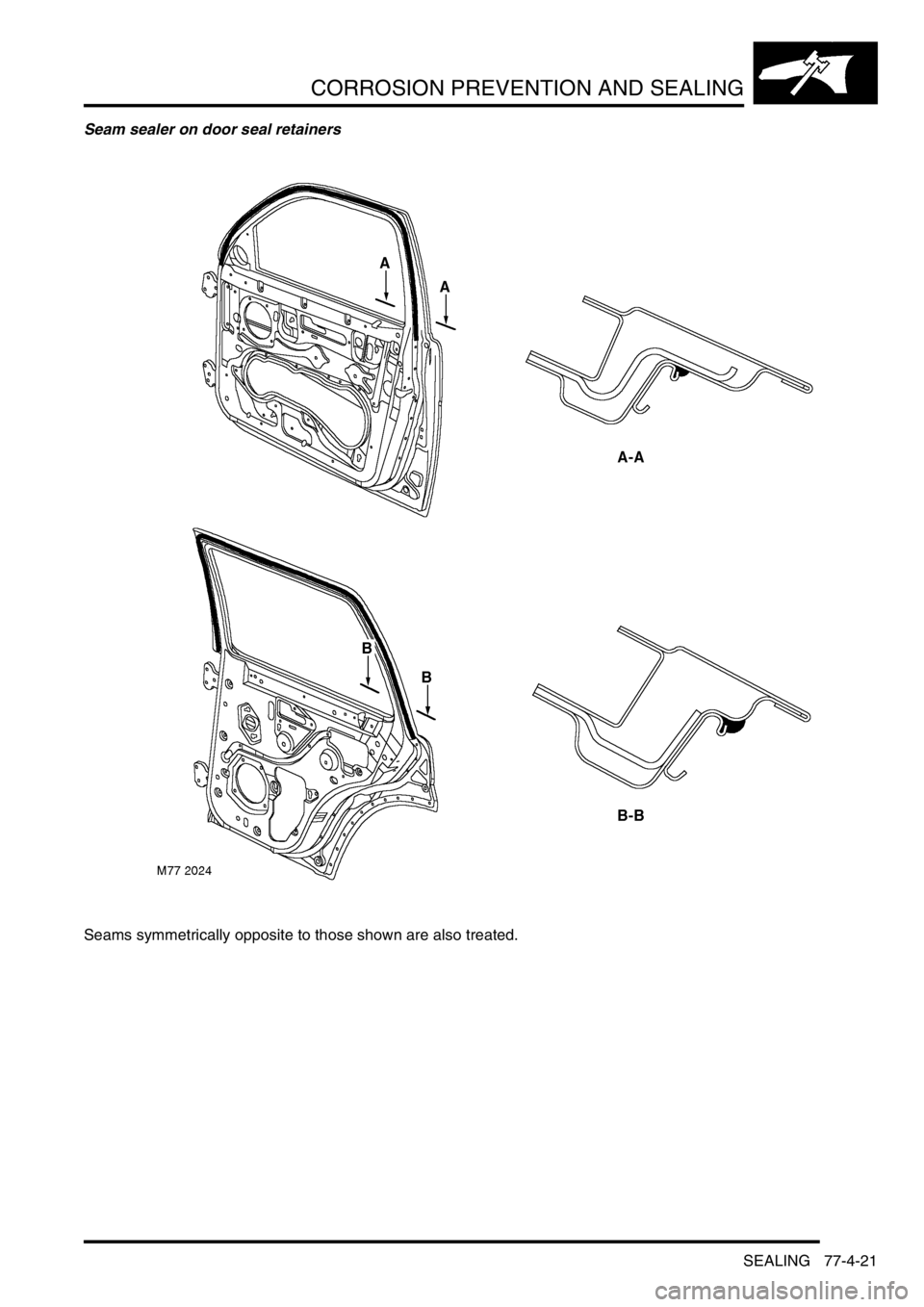

Seam sealer on door seal retainers

Seams symmetrically opposite to those shown are also treated.

Page 853 of 1007

CORROSION PREVENTION AND SEALING

77-4-22 SEALING

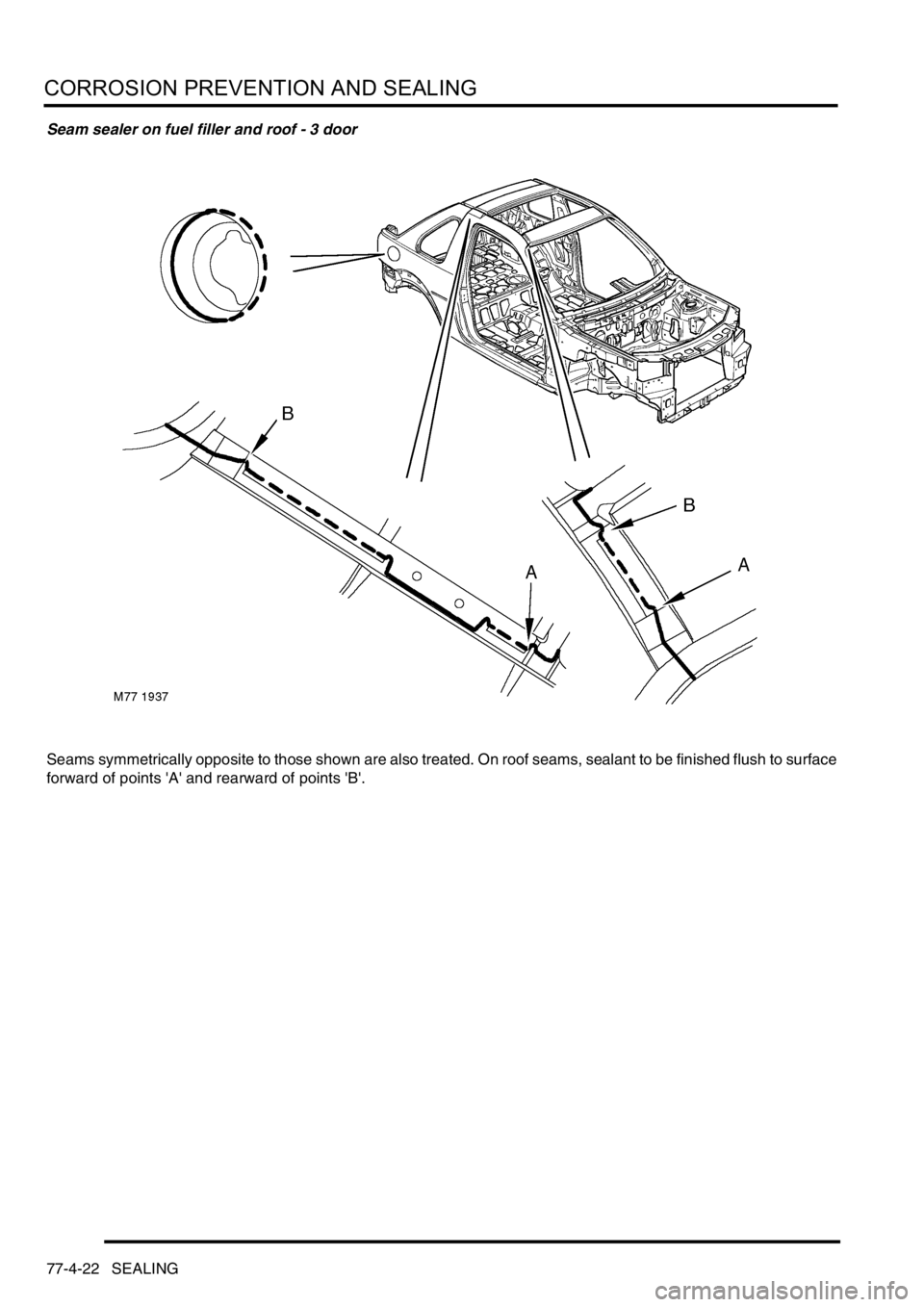

Seam sealer on fuel filler and roof - 3 door

Seams symmetrically opposite to those shown are also treated. On roof seams, sealant to be finished flush to surface

forward of points 'A' and rearward of points 'B'.

Page 854 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-23

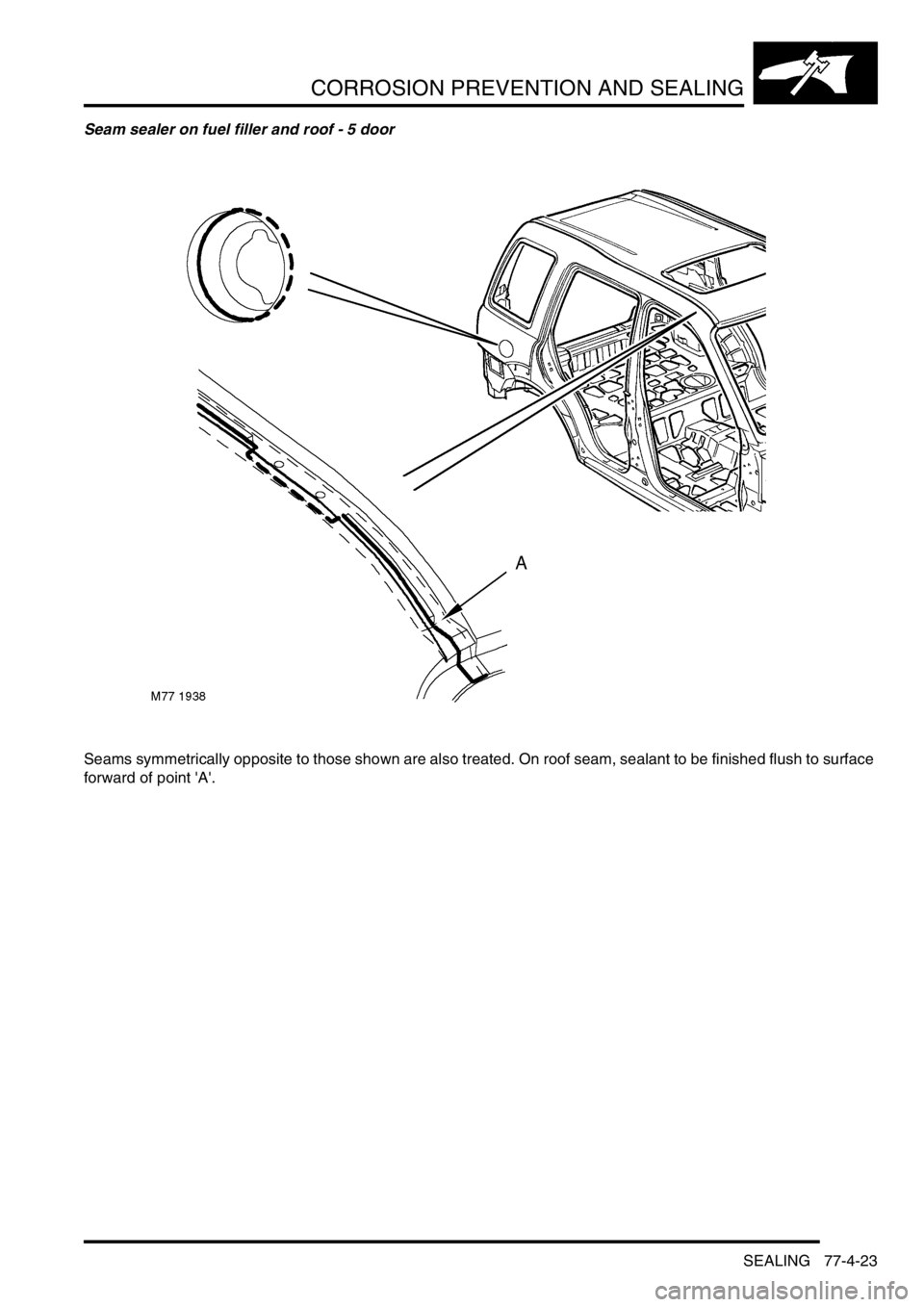

Seam sealer on fuel filler and roof - 5 door

Seams symmetrically opposite to those shown are also treated. On roof seam, sealant to be finished flush to surface

forward of point 'A'.

Page 855 of 1007

CORROSION PREVENTION AND SEALING

77-4-24 SEALING

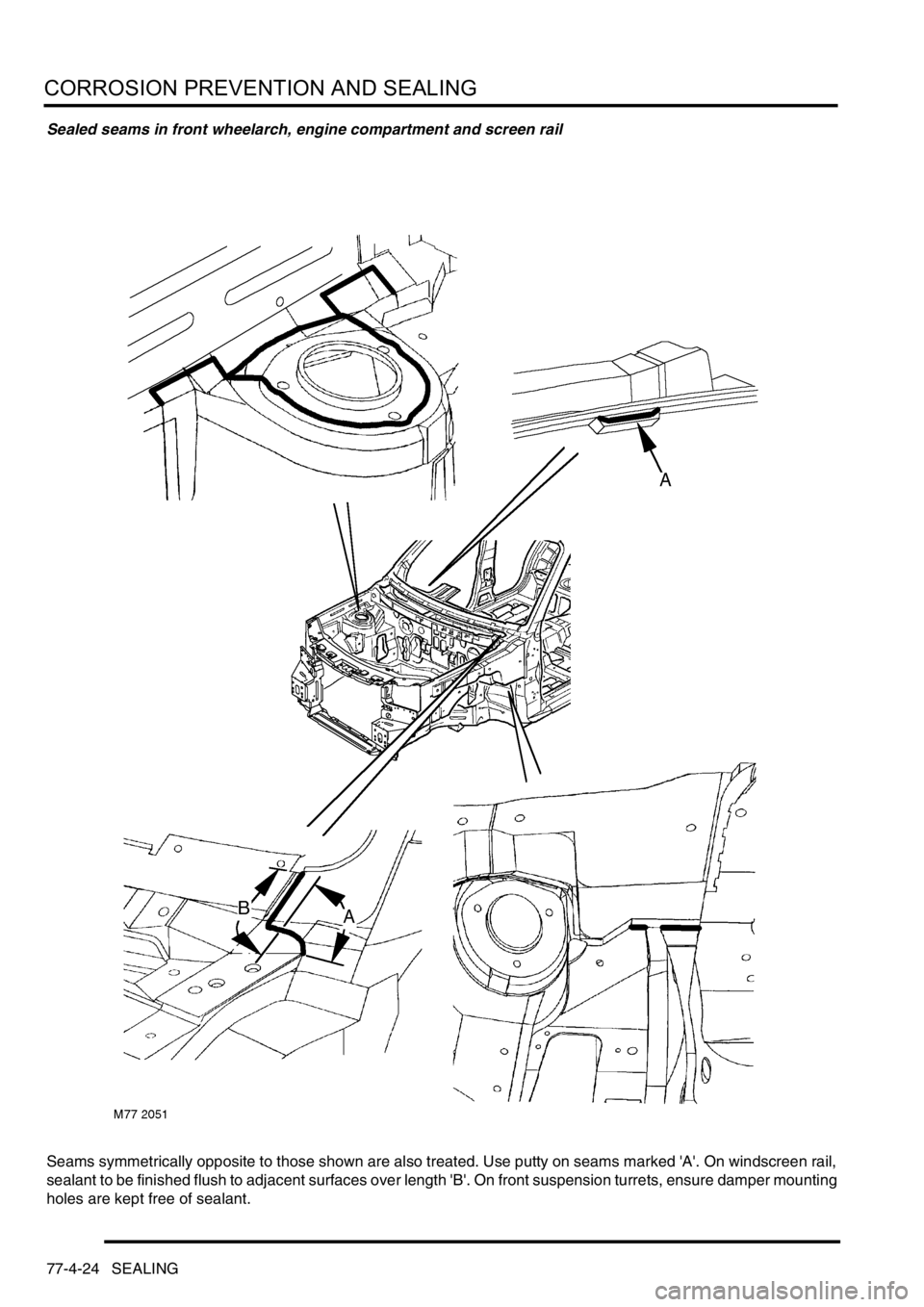

Sealed seams in front wheelarch, engine compartment and screen rail

Seams symmetrically opposite to those shown are also treated. Use putty on seams marked 'A'. On windscreen rail,

sealant to be finished flush to adjacent surfaces over length 'B'. On front suspension turrets, ensure damper mounting

holes are kept free of sealant.

Page 856 of 1007

CORROSION PREVENTION AND SEALING

SEALING 77-4-25

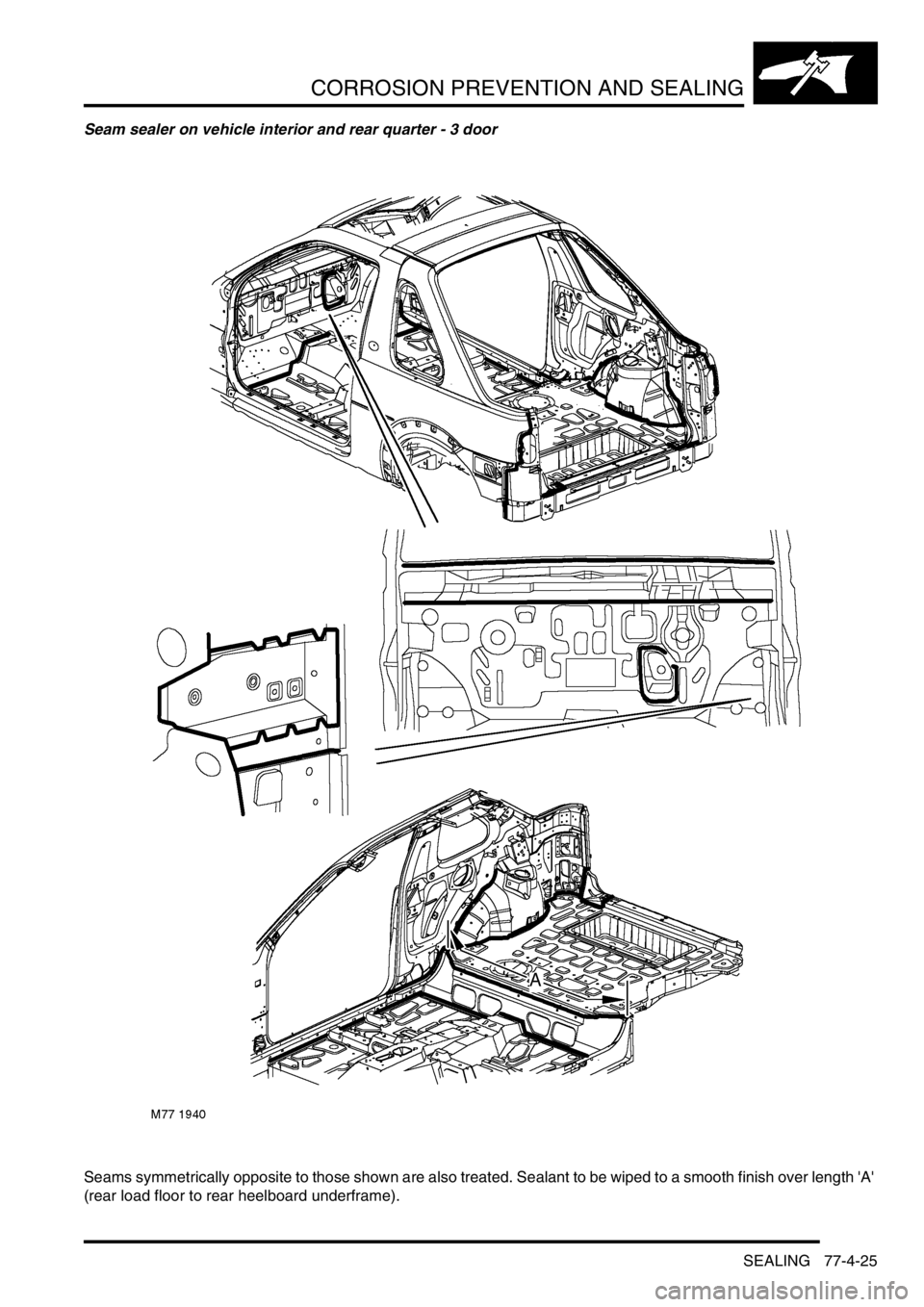

Seam sealer on vehicle interior and rear quarter - 3 door

Seams symmetrically opposite to those shown are also treated. Sealant to be wiped to a smooth finish over length 'A'

(rear load floor to rear heelboard underframe).

Page 857 of 1007

CORROSION PREVENTION AND SEALING

77-4-26 SEALING

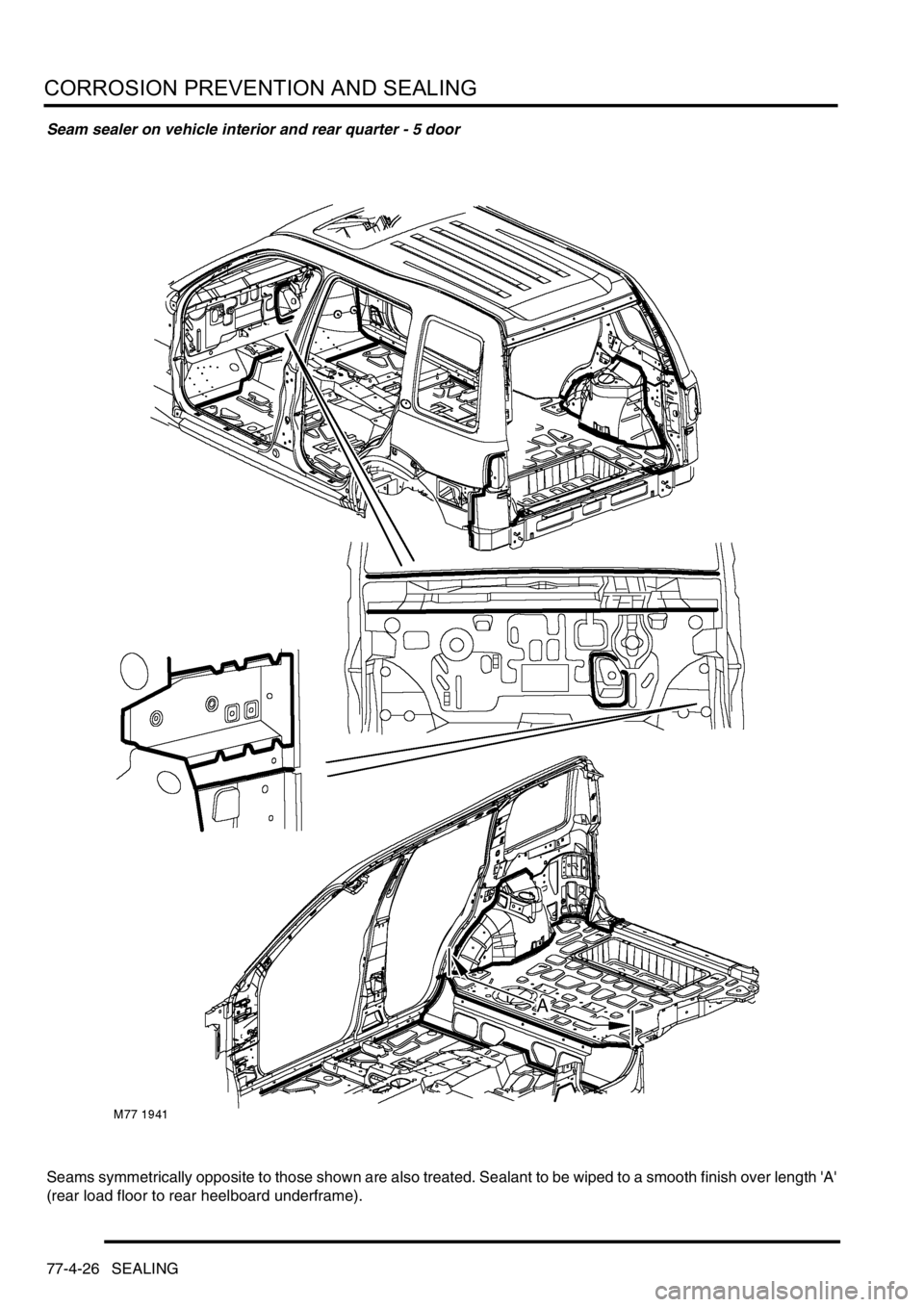

Seam sealer on vehicle interior and rear quarter - 5 door

Seams symmetrically opposite to those shown are also treated. Sealant to be wiped to a smooth finish over length 'A'

(rear load floor to rear heelboard underframe).

Page 858 of 1007

CORROSION PREVENTION AND SEALING

INTERNAL SEALING 77-4-27

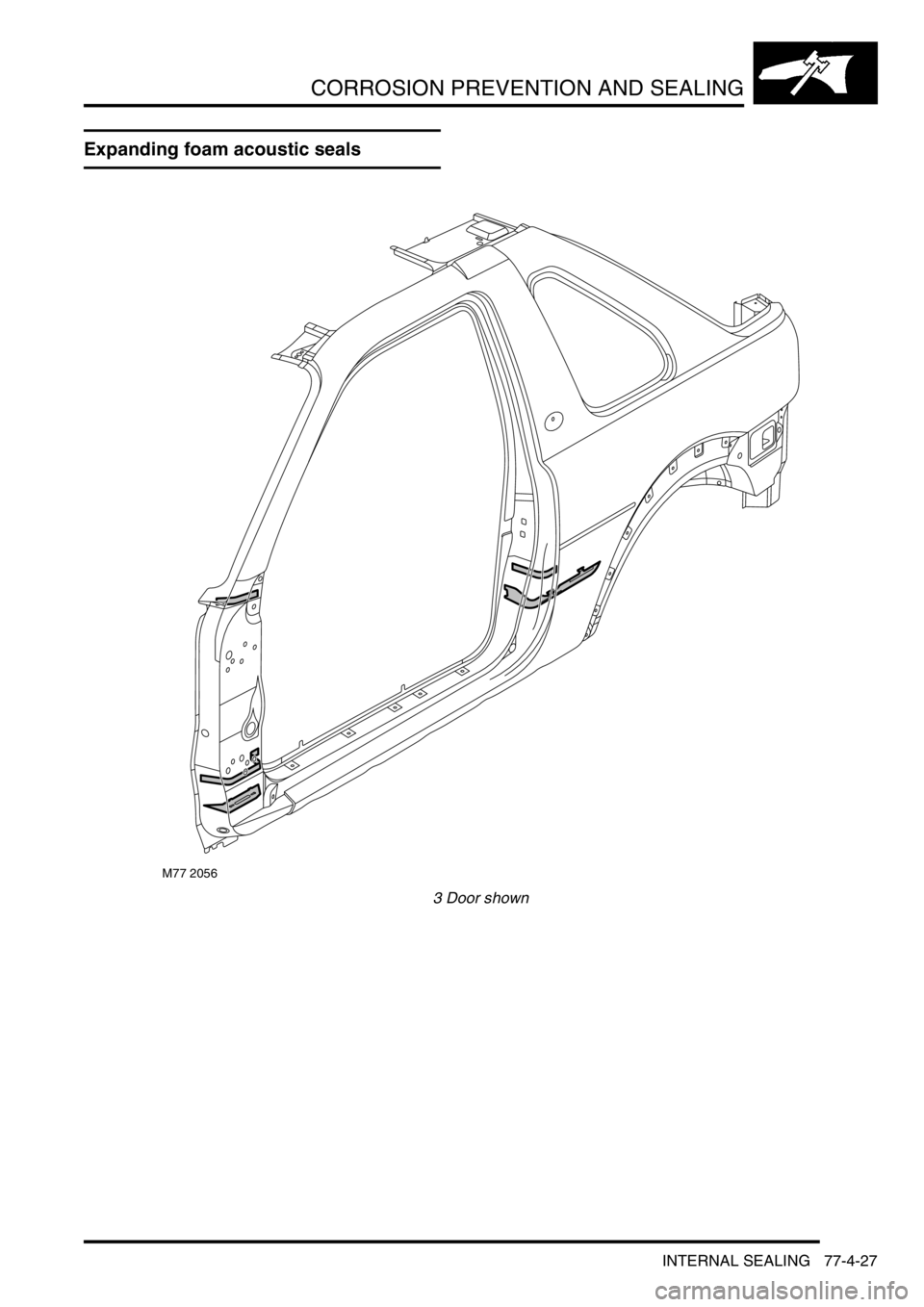

INT ERNAL SEALING

Expanding foam acoustic seals

3 Door shown

M77 2056

Page 859 of 1007

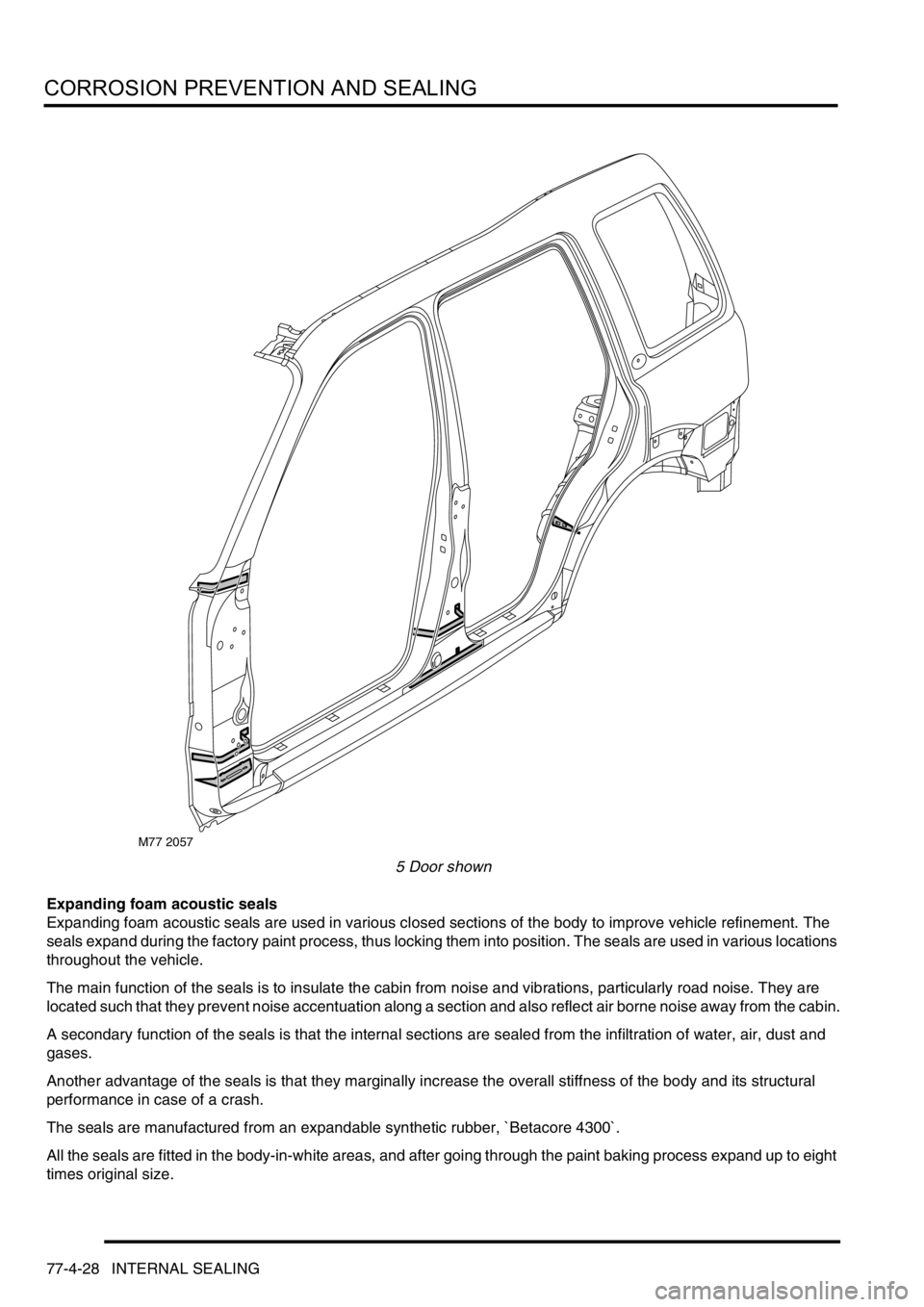

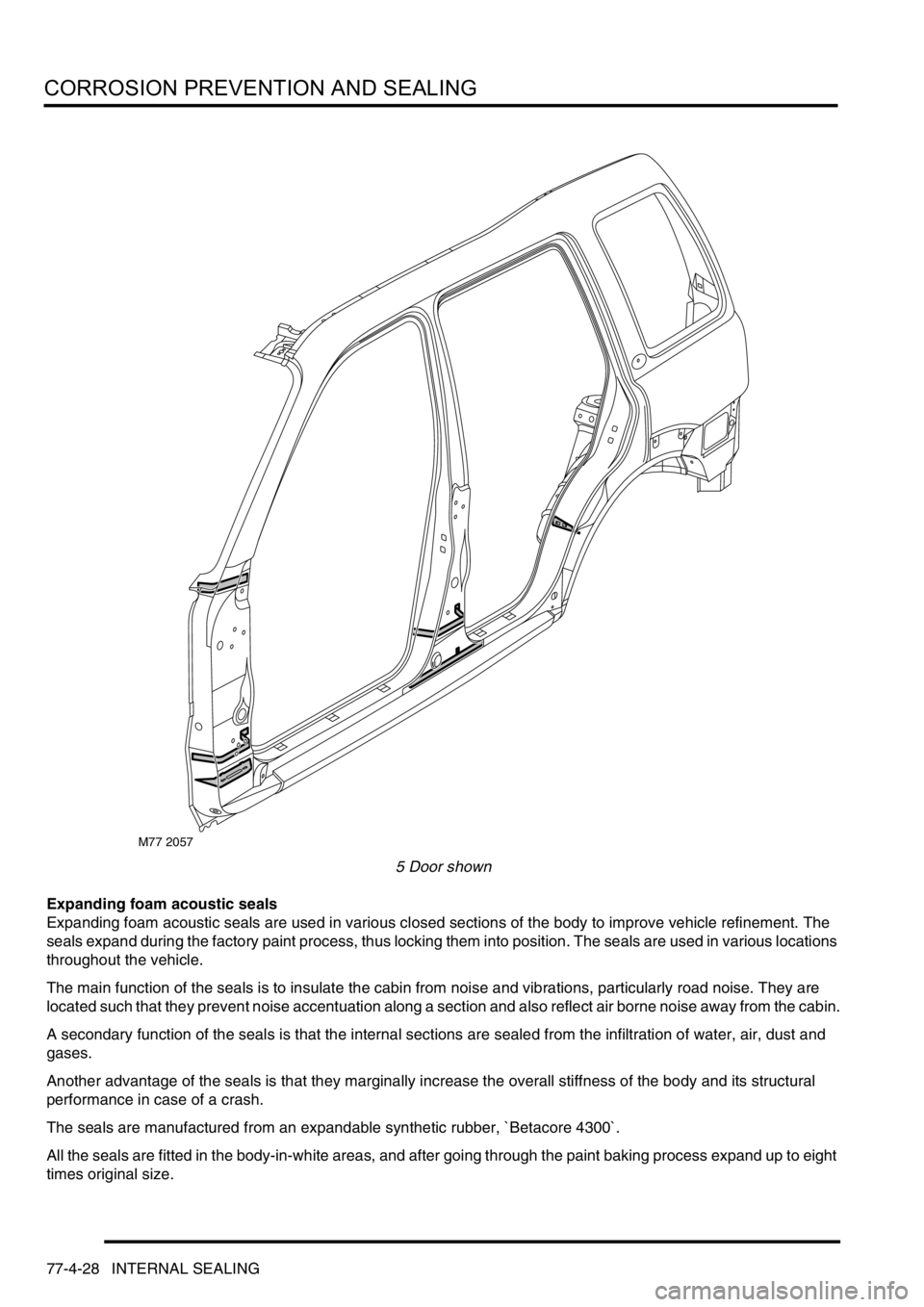

CORROSION PREVENTION AND SEALING

77-4-28 INTERNAL SEALING

5 Door shown

Expanding foam acoustic seals

Expanding foam acoustic seals are used in various closed sections of the body to improve vehicle refinement. The

seals expand during the factory paint process, thus locking them into position. The seals are used in various locations

throughout the vehicle.

The main function of the seals is to insulate the cabin from noise and vibrations, particularly road noise. They are

located such that they prevent noise accentuation along a section and also reflect air borne noise away from the cabin.

A secondary function of the seals is that the internal sections are sealed from the infiltration of water, air, dust and

gases.

Another advantage of the seals is that they marginally increase the overall stiffness of the body and its structural

performance in case of a crash.

The seals are manufactured from an expandable synthetic rubber, `Betacore 4300`.

All the seals are fitted in the body-in-white areas, and after going through the paint baking process expand up to eight

times original size.

M77 2057

Page 860 of 1007

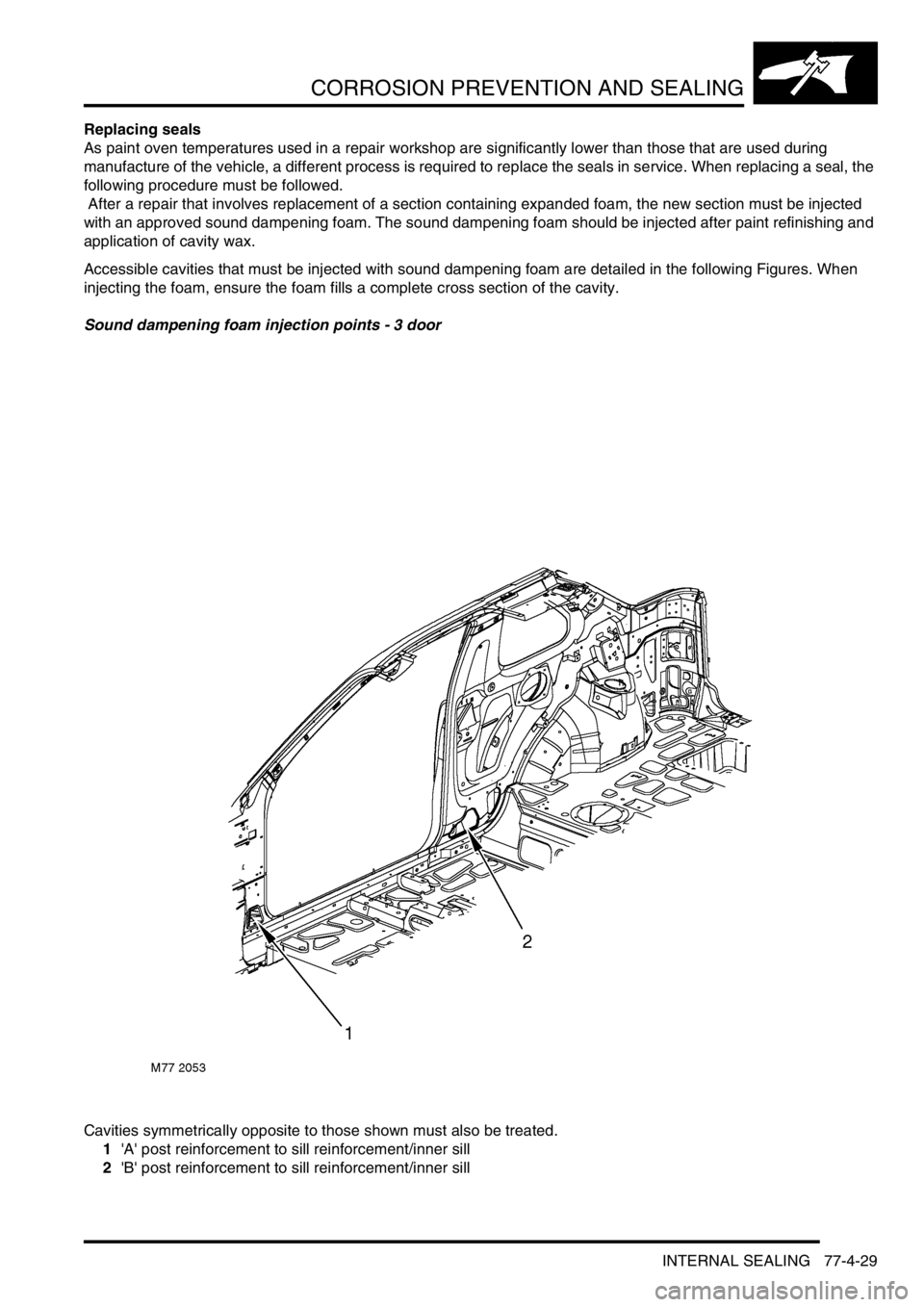

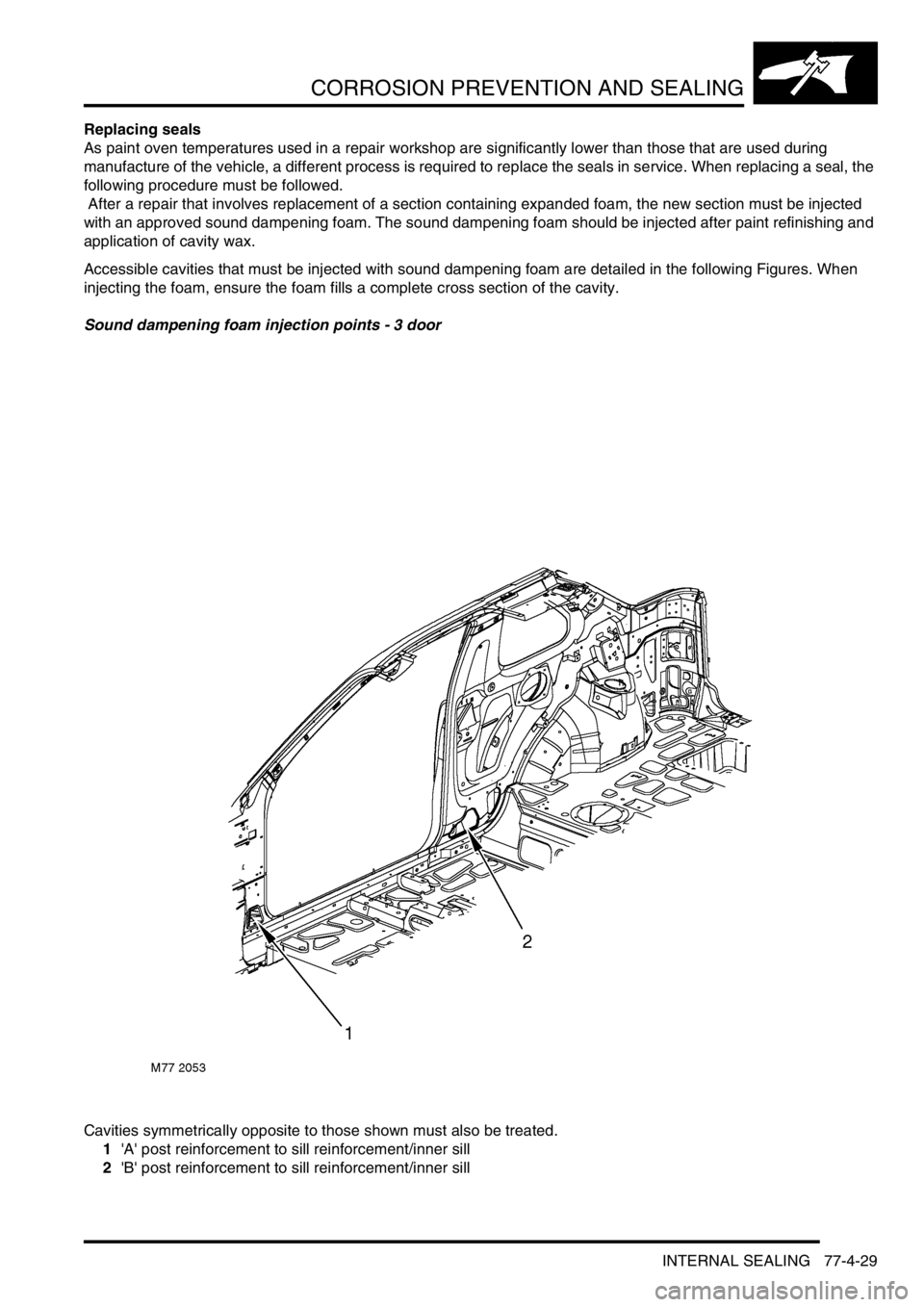

CORROSION PREVENTION AND SEALING

INTERNAL SEALING 77-4-29

Replacing seals

As paint oven temperatures used in a repair workshop are significantly lower than those that are used during

manufacture of the vehicle, a different process is required to replace the seals in service. When replacing a seal, the

following procedure must be followed.

After a repair that involves replacement of a section containing expanded foam, the new section must be injected

with an approved sound dampening foam. The sound dampening foam should be injected after paint refinishing and

application of cavity wax.

Accessible cavities that must be injected with sound dampening foam are detailed in the following Figures. When

injecting the foam, ensure the foam fills a complete cross section of the cavity.

Sound dampening foam injection points - 3 door

Cavities symmetrically opposite to those shown must also be treated.

1'A' post reinforcement to sill reinforcement/inner sill

2'B' post reinforcement to sill reinforcement/inner sill

Trending: oil level, air condition, run flat, jump start, engine oil, refrigerant type, handbrake