LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 891 of 1007

Page 892 of 1007

AIR CONDITIONING

REPAIRS 82-5

REPAIRS

Drive belt - compressor - Td4

$% 82.10.02

Remove

1.Disconnect battery earth lead.

2.Remove ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

3.Loosen clamp and pivot bolts of compressor

drive belt tensioner.

4.Remove compressor drive belt.Refit

1.Ensure compressor drive belt and compressor,

crankshaft and tensioner pulleys are clean.

2.Fit compressor drive belt.

3.Adjust compressor drive belt.

+ AIR CONDITIONING,

ADJUSTMENTS, Drive belt - compressor -

Td4.

4.Fit ancillary drive belt.

+ CHARGING AND STARTING,

REPAIRS, Ancillary drive belt - Td4.

5.Connect battery earth lead.

M82 0721

Page 893 of 1007

AIR CONDITIONING

82-6REPAIRS

Compressor - Td4

$% 82.10.20

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Disconnect battery earth lead.

3.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

4.Remove compressor drive belt.

+ AIR CONDITIONING, REPAIRS,

Drive belt - compressor - Td4.

WARNING: Under no circumstances should

refrigerant hoses be disconnected without

first discharging the system.

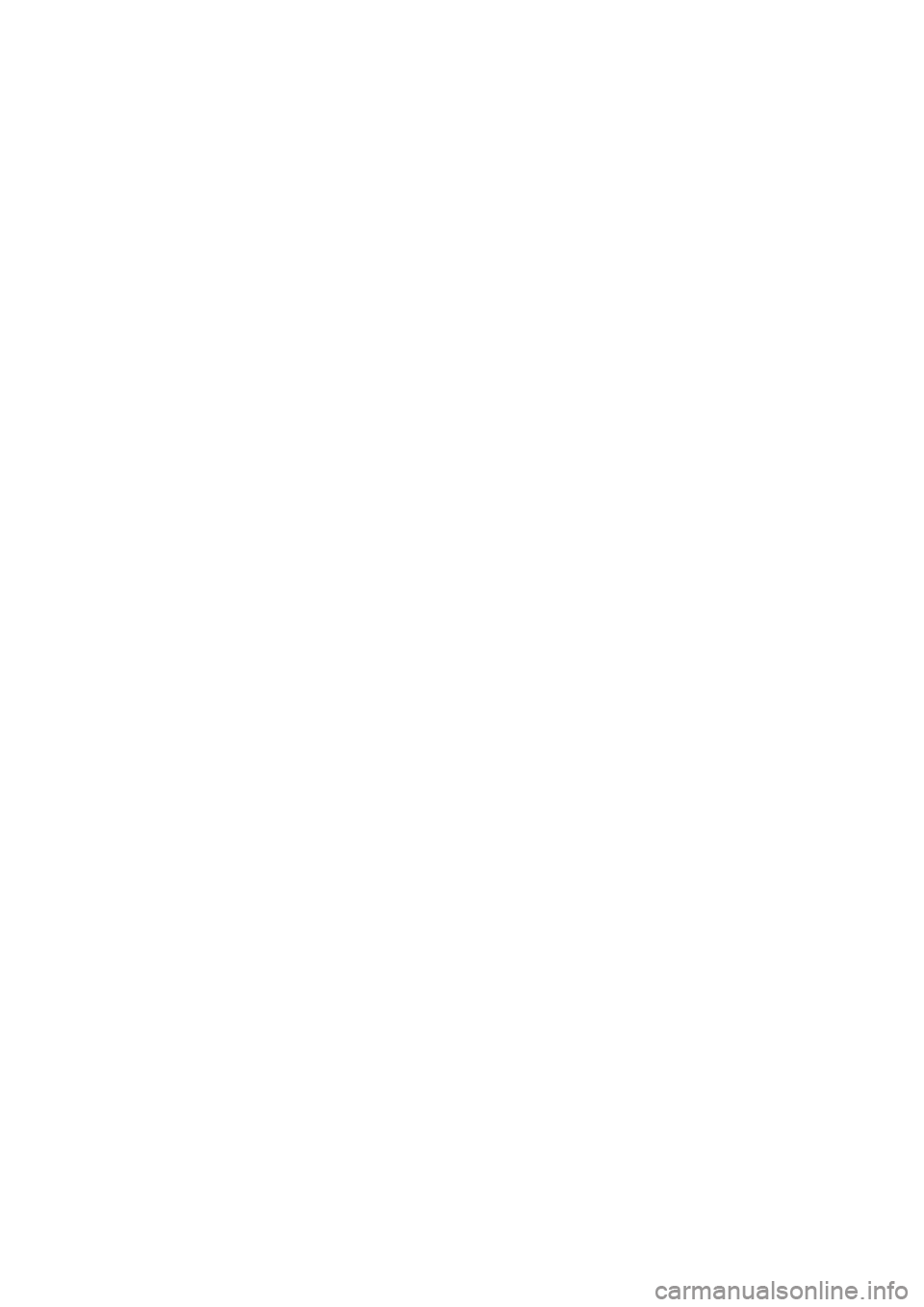

5.Remove 2 bolts securing A/C pipes to

compressor. Release pipes from compressor.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

6.Remove and discard 'O' rings from A/C pipes.7.Loosen bolt securing compressor support

bracket to sump, do not remove.

8.Remove 3 bolts and remove compressor from

mounting bracket. Move support strap aside,

disconnect compressor multiplug and remove

compressor.

Refit

1.If a new compressor is being installed, drain the

required amount of refrigerant oil from the new

compressor.

+ GENERAL INFORMATION, Air

conditioning compressor replacement.

2.A new compressor is sealed and pressurised

with Nitrogen gas, slowly release the sealing

cap, gas pressure should be heard to release

as the seal is broken.

3.Ensure mating faces of A/C pipes and

compressor are clean.

4.Fit A/C compressor to mounting bracket, align

support strap and tighten bolts to 25 Nm (18

lbf.ft).

5.Connect multiplug to compressor.

6.Lubricate new 'O' rings with clean refrigerant oil

and fit to evaporator pipes

7.Position A/C pipes to compressor, fit bolts and

tighten to 22 Nm (16 lbf.ft).

8.Replace receiver drier.

+ AIR CONDITIONING, REPAIRS,

Receiver drier.

9.Fit compressor drive belt.

+ AIR CONDITIONING, REPAIRS,

Drive belt - compressor - Td4.

10.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

11.Connect battery earth lead.

12.Remove stands and lower vehicle.

Page 894 of 1007

AIR CONDITIONING

REPAIRS 82-7

Compressor - KV6

$% 82.10.20

Remove

1.Disconnect battery earth lead.

2.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

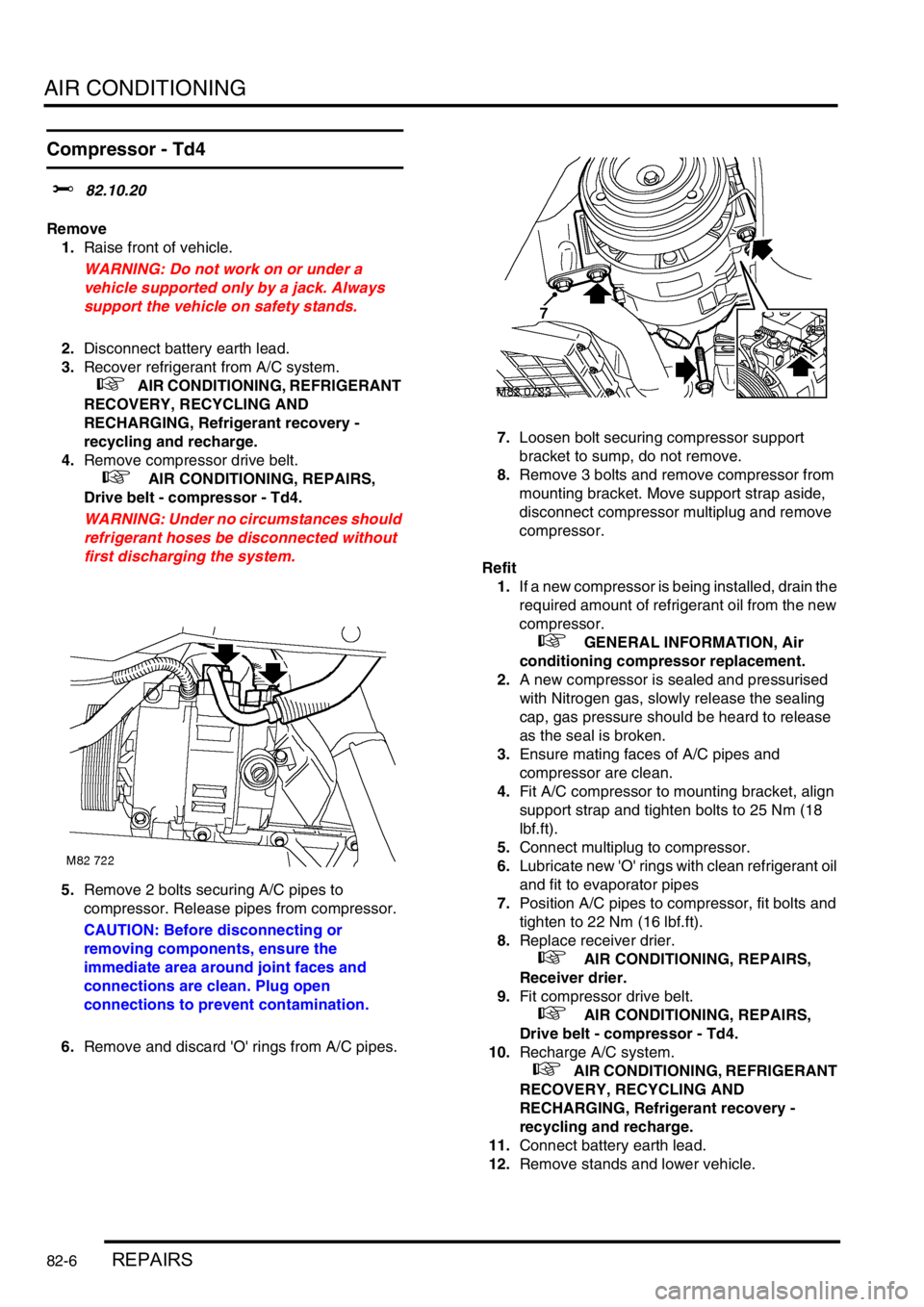

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Remove RH front road wheel.

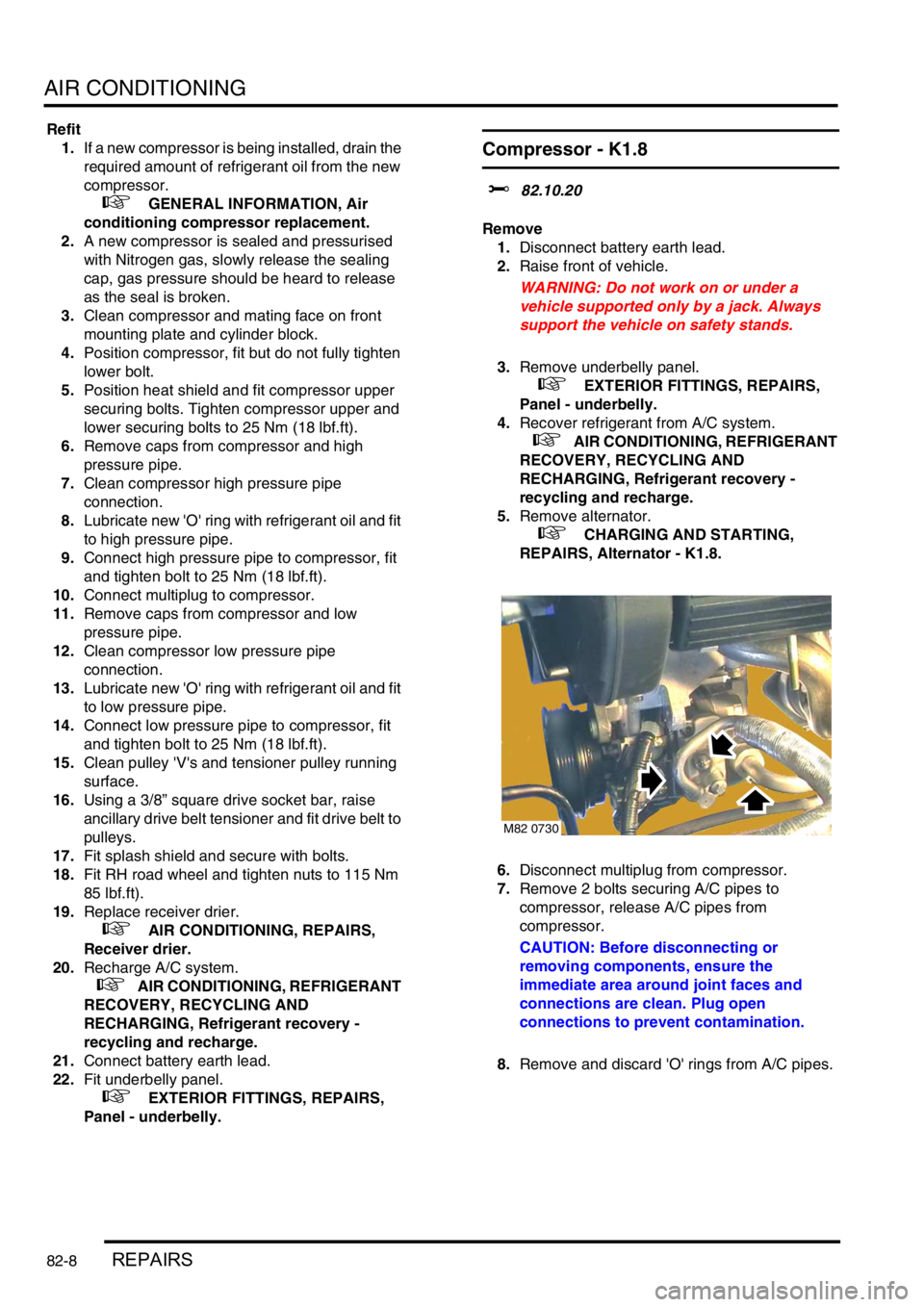

5.Remove 3 bolts securing RH splash shield to

body and remove shield.

6.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and release drive

belt from A/C compressor pulley.7.Remove 2 bolts securing high and low pressure

pipes to compressor. Release pipes from

compressor, remove and discard 'O' rings.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

8.Disconnect multiplug from compressor.

9.Note fitted position of heat shield on

compressor and remove 3 bolts securing

compressor to front mounting plate and

cylinder block. Remove compressor and heat

shield.

M12 6614

Page 895 of 1007

AIR CONDITIONING

82-8REPAIRS

Refit

1.If a new compressor is being installed, drain the

required amount of refrigerant oil from the new

compressor.

+ GENERAL INFORMATION, Air

conditioning compressor replacement.

2.A new compressor is sealed and pressurised

with Nitrogen gas, slowly release the sealing

cap, gas pressure should be heard to release

as the seal is broken.

3.Clean compressor and mating face on front

mounting plate and cylinder block.

4.Position compressor, fit but do not fully tighten

lower bolt.

5.Position heat shield and fit compressor upper

securing bolts. Tighten compressor upper and

lower securing bolts to 25 Nm (18 lbf.ft).

6.Remove caps from compressor and high

pressure pipe.

7.Clean compressor high pressure pipe

connection.

8.Lubricate new 'O' ring with refrigerant oil and fit

to high pressure pipe.

9.Connect high pressure pipe to compressor, fit

and tighten bolt to 25 Nm (18 lbf.ft).

10.Connect multiplug to compressor.

11.Remove caps from compressor and low

pressure pipe.

12.Clean compressor low pressure pipe

connection.

13.Lubricate new 'O' ring with refrigerant oil and fit

to low pressure pipe.

14.Connect low pressure pipe to compressor, fit

and tighten bolt to 25 Nm (18 lbf.ft).

15.Clean pulley 'V's and tensioner pulley running

surface.

16.Using a 3/8” square drive socket bar, raise

ancillary drive belt tensioner and fit drive belt to

pulleys.

17.Fit splash shield and secure with bolts.

18.Fit RH road wheel and tighten nuts to 115 Nm

85 lbf.ft).

19.Replace receiver drier.

+ AIR CONDITIONING, REPAIRS,

Receiver drier.

20.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

21.Connect battery earth lead.

22.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

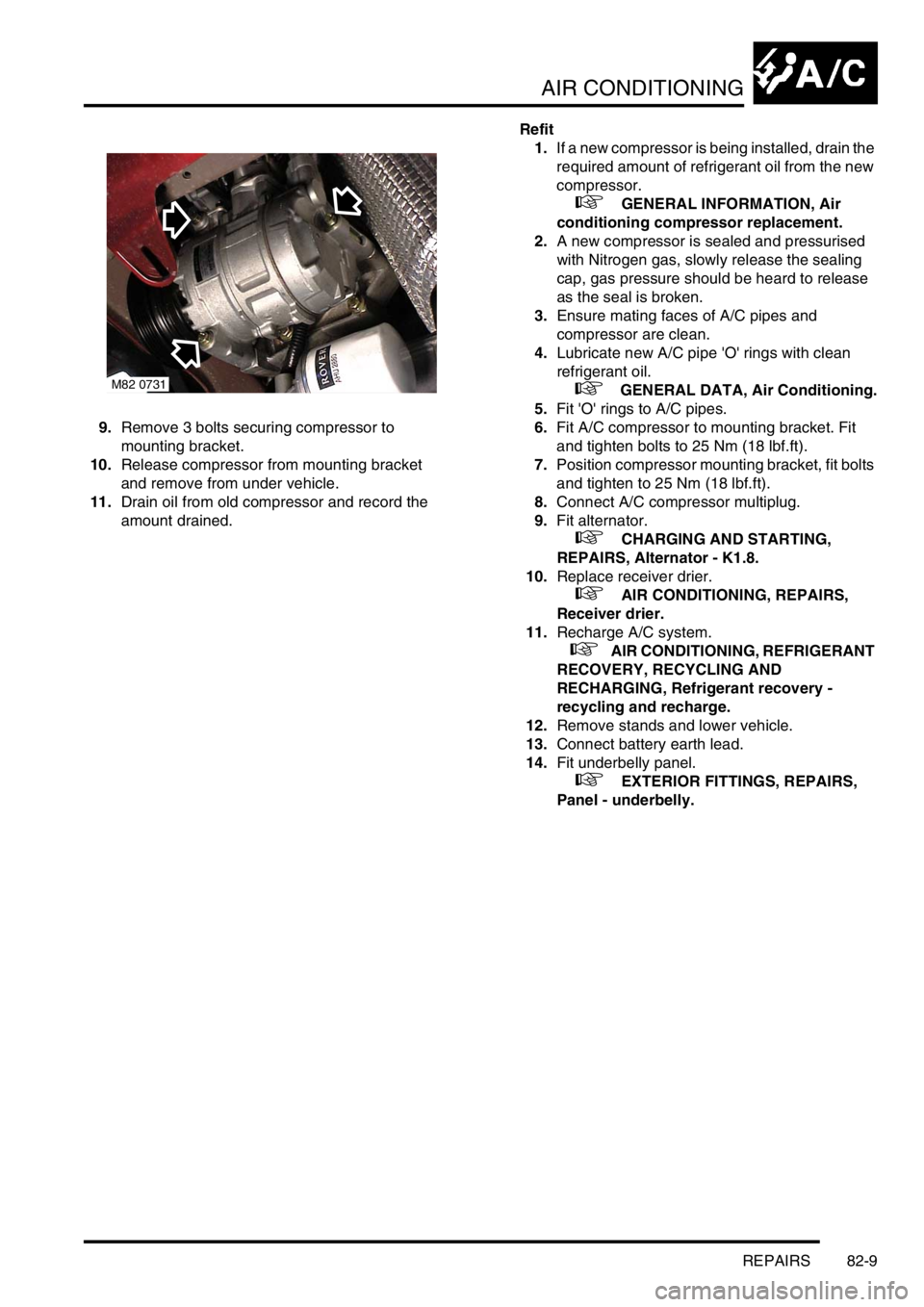

Compressor - K1.8

$% 82.10.20

Remove

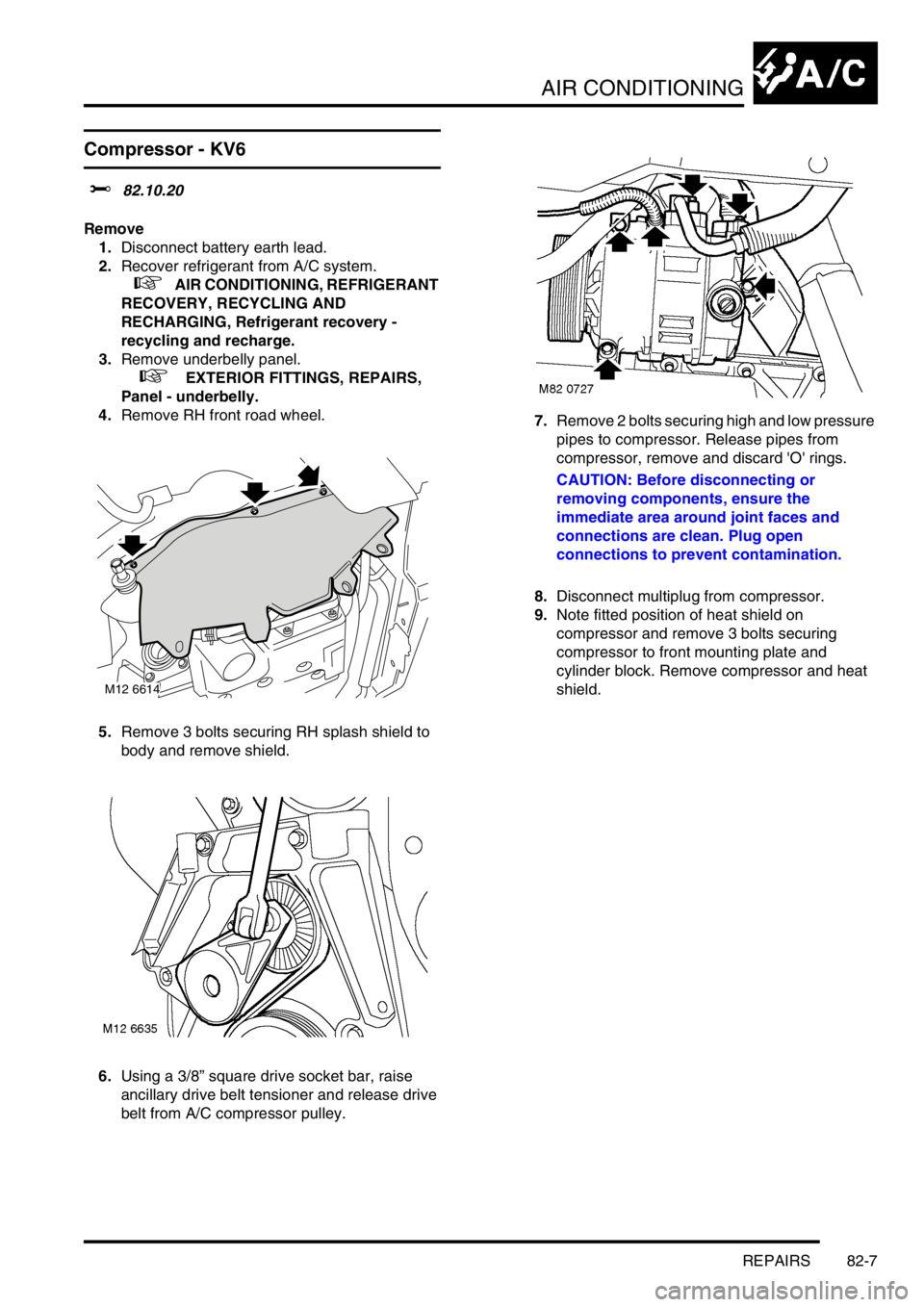

1.Disconnect battery earth lead.

2.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

3.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

4.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

5.Remove alternator.

+ CHARGING AND STARTING,

REPAIRS, Alternator - K1.8.

6.Disconnect multiplug from compressor.

7.Remove 2 bolts securing A/C pipes to

compressor, release A/C pipes from

compressor.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

8.Remove and discard 'O' rings from A/C pipes.

M82 0730

Page 896 of 1007

AIR CONDITIONING

REPAIRS 82-9

9.Remove 3 bolts securing compressor to

mounting bracket.

10.Release compressor from mounting bracket

and remove from under vehicle.

11.Drain oil from old compressor and record the

amount drained.Refit

1.If a new compressor is being installed, drain the

required amount of refrigerant oil from the new

compressor.

+ GENERAL INFORMATION, Air

conditioning compressor replacement.

2.A new compressor is sealed and pressurised

with Nitrogen gas, slowly release the sealing

cap, gas pressure should be heard to release

as the seal is broken.

3.Ensure mating faces of A/C pipes and

compressor are clean.

4.Lubricate new A/C pipe 'O' rings with clean

refrigerant oil.

+ GENERAL DATA, Air Conditioning.

5.Fit 'O' rings to A/C pipes.

6.Fit A/C compressor to mounting bracket. Fit

and tighten bolts to 25 Nm (18 lbf.ft).

7.Position compressor mounting bracket, fit bolts

and tighten to 25 Nm (18 lbf.ft).

8.Connect A/C compressor multiplug.

9.Fit alternator.

+ CHARGING AND STARTING,

REPAIRS, Alternator - K1.8.

10.Replace receiver drier.

+ AIR CONDITIONING, REPAIRS,

Receiver drier.

11.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

12.Remove stands and lower vehicle.

13.Connect battery earth lead.

14.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

M82 0731

Page 897 of 1007

AIR CONDITIONING

82-10REPAIRS

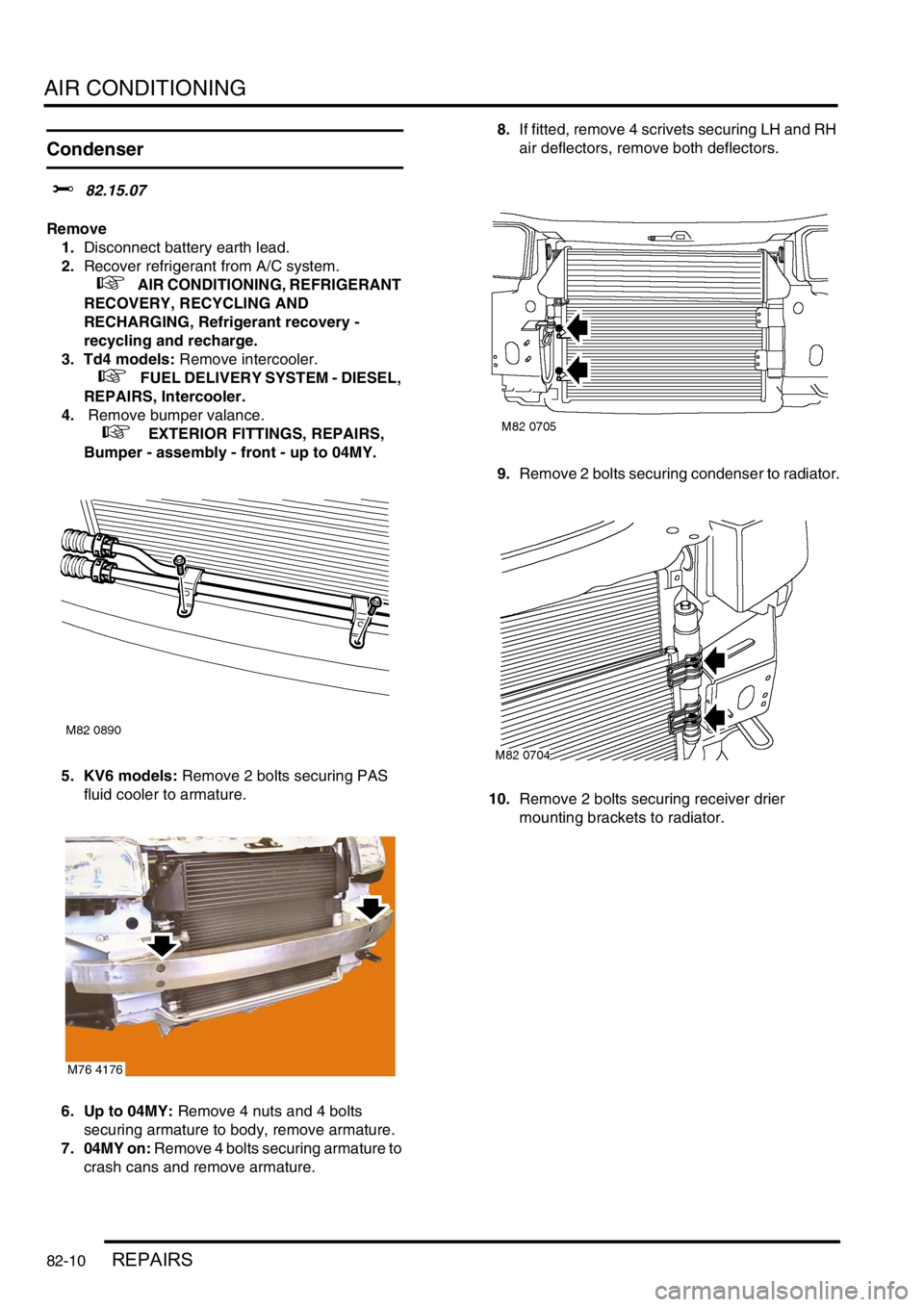

Condenser

$% 82.15.07

Remove

1.Disconnect battery earth lead.

2.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

3. Td4 models: Remove intercooler.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Intercooler.

4. Remove bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

5. KV6 models: Remove 2 bolts securing PAS

fluid cooler to armature.

6. Up to 04MY: Remove 4 nuts and 4 bolts

securing armature to body, remove armature.

7. 04MY on: Remove 4 bolts securing armature to

crash cans and remove armature.8.If fitted, remove 4 scrivets securing LH and RH

air deflectors, remove both deflectors.

9.Remove 2 bolts securing condenser to radiator.

10.Remove 2 bolts securing receiver drier

mounting brackets to radiator.

M76 4176

Page 898 of 1007

AIR CONDITIONING

REPAIRS 82-11

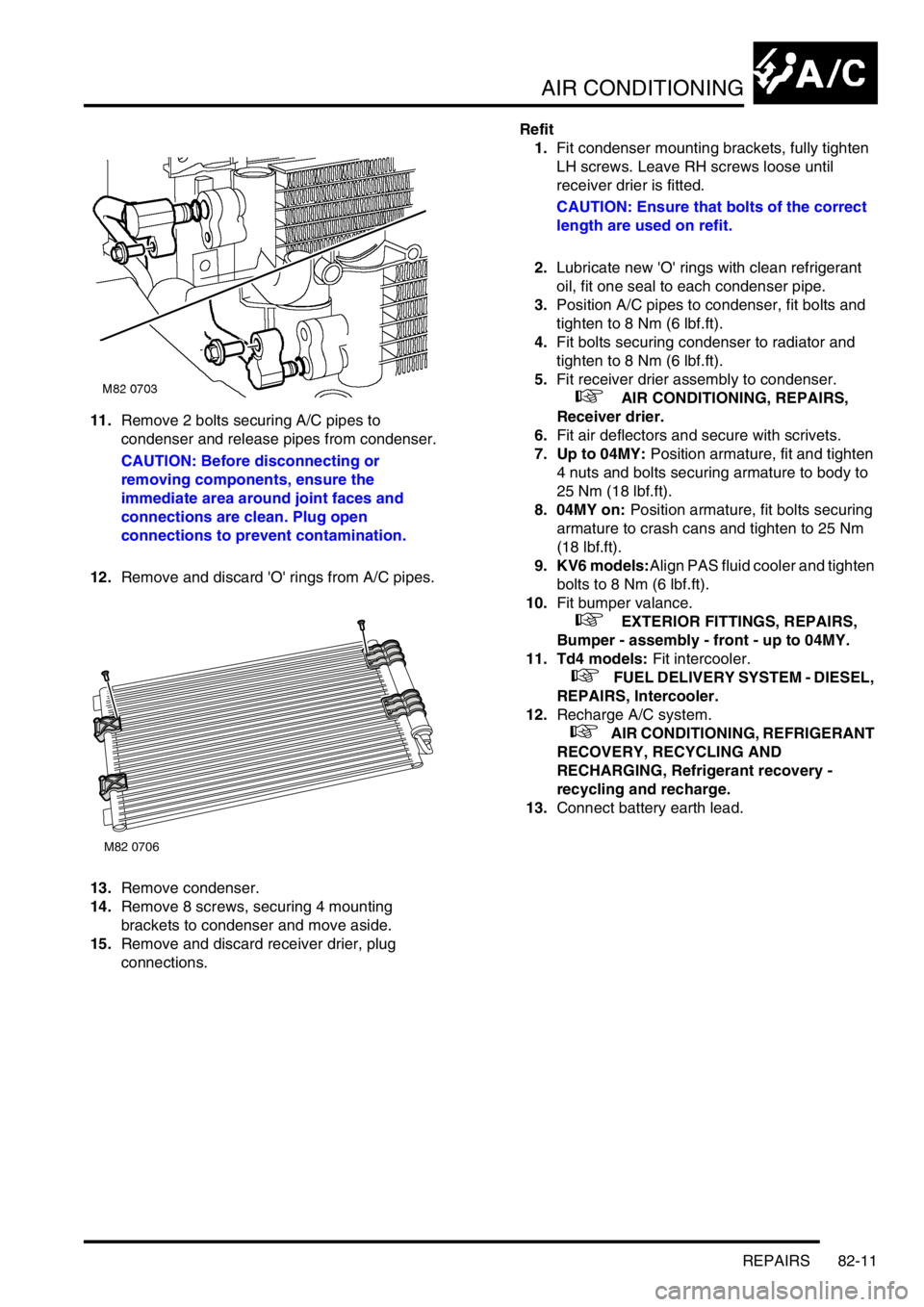

11.Remove 2 bolts securing A/C pipes to

condenser and release pipes from condenser.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

12.Remove and discard 'O' rings from A/C pipes.

13.Remove condenser.

14.Remove 8 screws, securing 4 mounting

brackets to condenser and move aside.

15.Remove and discard receiver drier, plug

connections.Refit

1.Fit condenser mounting brackets, fully tighten

LH screws. Leave RH screws loose until

receiver drier is fitted.

CAUTION: Ensure that bolts of the correct

length are used on refit.

2.Lubricate new 'O' rings with clean refrigerant

oil, fit one seal to each condenser pipe.

3.Position A/C pipes to condenser, fit bolts and

tighten to 8 Nm (6 lbf.ft).

4.Fit bolts securing condenser to radiator and

tighten to 8 Nm (6 lbf.ft).

5.Fit receiver drier assembly to condenser.

+ AIR CONDITIONING, REPAIRS,

Receiver drier.

6.Fit air deflectors and secure with scrivets.

7. Up to 04MY: Position armature, fit and tighten

4 nuts and bolts securing armature to body to

25 Nm (18 lbf.ft).

8. 04MY on: Position armature, fit bolts securing

armature to crash cans and tighten to 25 Nm

(18 lbf.ft).

9. KV6 models:Align PAS fluid cooler and tighten

bolts to 8 Nm (6 lbf.ft).

10.Fit bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

11. Td4 models: Fit intercooler.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Intercooler.

12.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

13.Connect battery earth lead.

M82 0706

Page 899 of 1007

AIR CONDITIONING

82-12REPAIRS

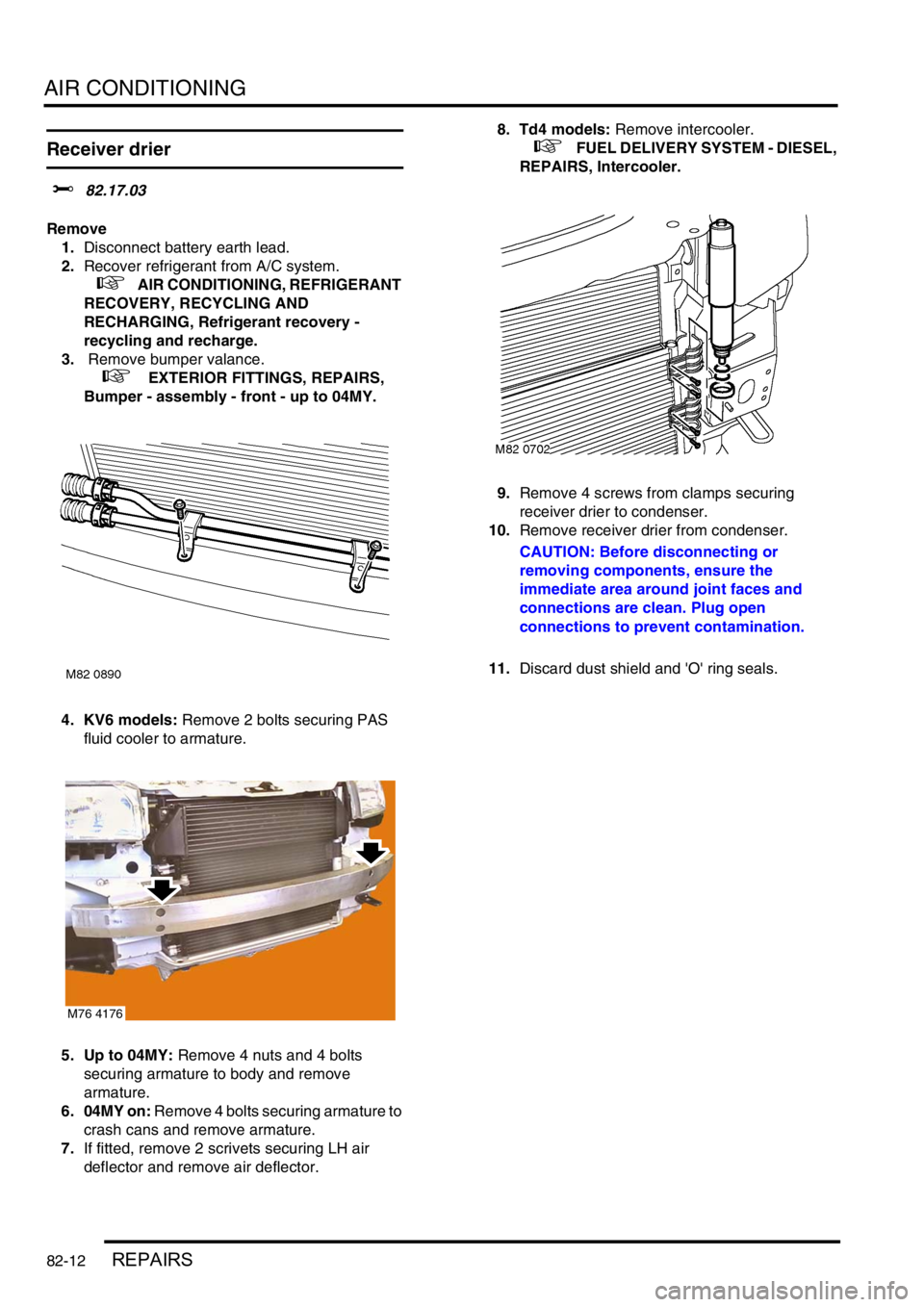

Receiver drier

$% 82.17.03

Remove

1.Disconnect battery earth lead.

2.Recover refrigerant from A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

3. Remove bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

4. KV6 models: Remove 2 bolts securing PAS

fluid cooler to armature.

5. Up to 04MY: Remove 4 nuts and 4 bolts

securing armature to body and remove

armature.

6. 04MY on: Remove 4 bolts securing armature to

crash cans and remove armature.

7.If fitted, remove 2 scrivets securing LH air

deflector and remove air deflector.8. Td4 models: Remove intercooler.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Intercooler.

9.Remove 4 screws from clamps securing

receiver drier to condenser.

10.Remove receiver drier from condenser.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

11.Discard dust shield and 'O' ring seals.

M76 4176

Page 900 of 1007

AIR CONDITIONING

REPAIRS 82-13

Refit

1.Lubricate new 'O' rings, dust shield and

condenser thread with refrigerant oil.

2.Fit 'O' rings and dust shield to receiver drier.

CAUTION: Do not remove receiver/dryer

from packaging until immediately before

installation.

3.Fit receiver drier to condenser and tighten to 12

Nm (9 lbf.ft).

4.Tighten clamps securing receiver drier to

condenser.

5.If fitted, fit air deflector and secure with scrivets.

6. Td4 models: Fit intercooler.

+ FUEL DELIVERY SYSTEM - DIESEL,

REPAIRS, Intercooler.

7. Up to 04MY: Position armature, fit and tighten

4 nuts and bolts securing armature to body to

25 Nm (18 lbf.ft).

8. 04MY on: Position armature, fit bolts securing

armature to crash cans and tighten bolts to 25

Nm (18 lbf.ft).

9. KV6 models: Align PAS fluid cooler and

tighten bolts to 8 Nm (6 lbf.ft).

10.Fit bumper valance.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

11.Recharge A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery -

recycling and recharge.

12.Connect battery earth lead.

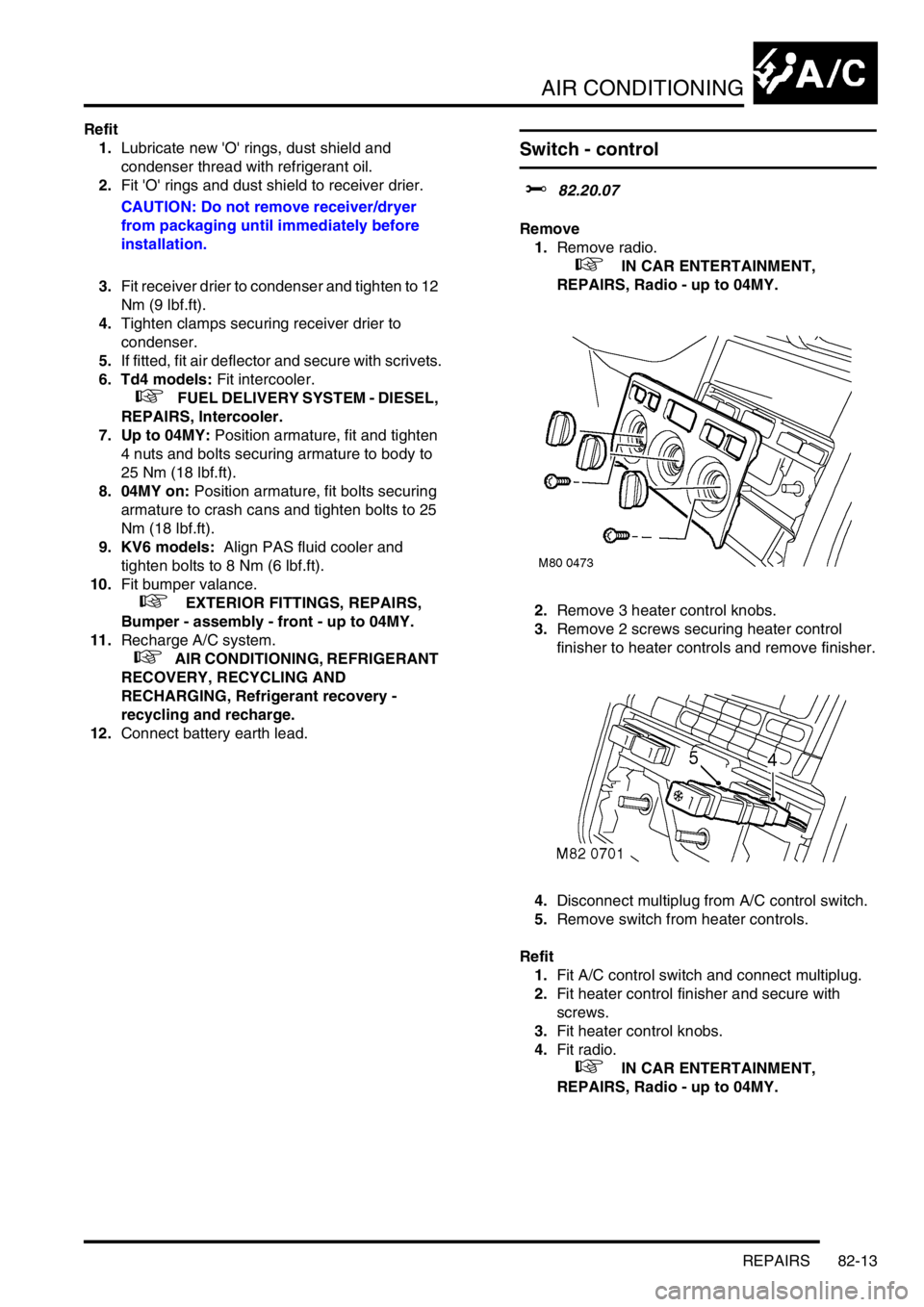

Switch - control

$% 82.20.07

Remove

1.Remove radio.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio - up to 04MY.

2.Remove 3 heater control knobs.

3.Remove 2 screws securing heater control

finisher to heater controls and remove finisher.

4.Disconnect multiplug from A/C control switch.

5.Remove switch from heater controls.

Refit

1.Fit A/C control switch and connect multiplug.

2.Fit heater control finisher and secure with

screws.

3.Fit heater control knobs.

4.Fit radio.

+ IN CAR ENTERTAINMENT,

REPAIRS, Radio - up to 04MY.