LAND ROVER FREELANDER 2001 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 881 of 1007

HEATING AND VENTILATION

80-16REPAIRS

Relay - power - positive temperature co-

efficient (PTC) - Td4 models

$% 80.20.34

Remove

1.Disconnect battery earth lead.

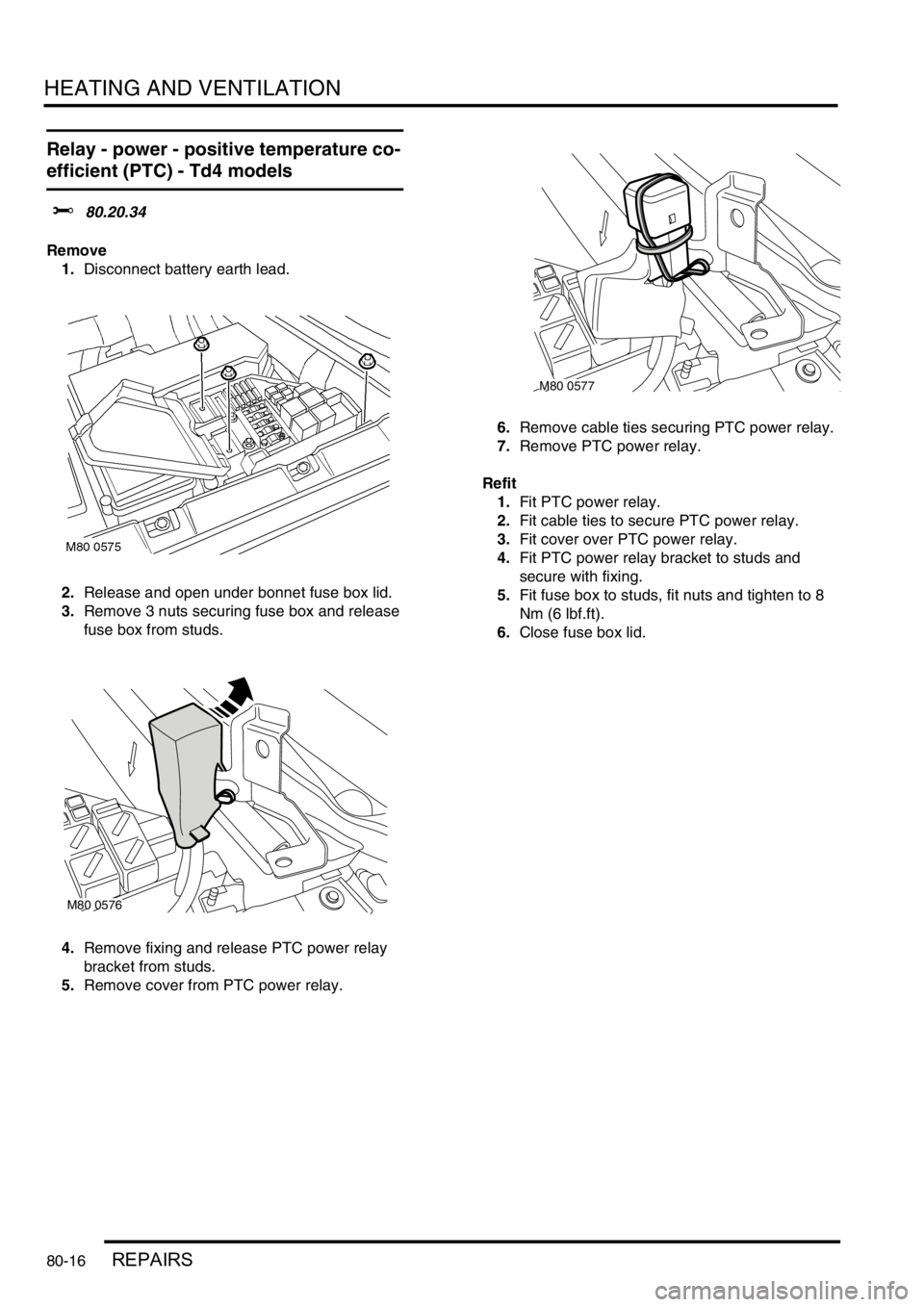

2.Release and open under bonnet fuse box lid.

3.Remove 3 nuts securing fuse box and release

fuse box from studs.

4.Remove fixing and release PTC power relay

bracket from studs.

5.Remove cover from PTC power relay.6.Remove cable ties securing PTC power relay.

7.Remove PTC power relay.

Refit

1.Fit PTC power relay.

2.Fit cable ties to secure PTC power relay.

3.Fit cover over PTC power relay.

4.Fit PTC power relay bracket to studs and

secure with fixing.

5.Fit fuse box to studs, fit nuts and tighten to 8

Nm (6 lbf.ft).

6.Close fuse box lid.

M80 0576

M80 0577

Page 882 of 1007

HEATING AND VENTILATION

REPAIRS 80-17

Relay - control - positive temperature co-

efficient (PTC) - Td4 models

$% 80.20.35

Remove

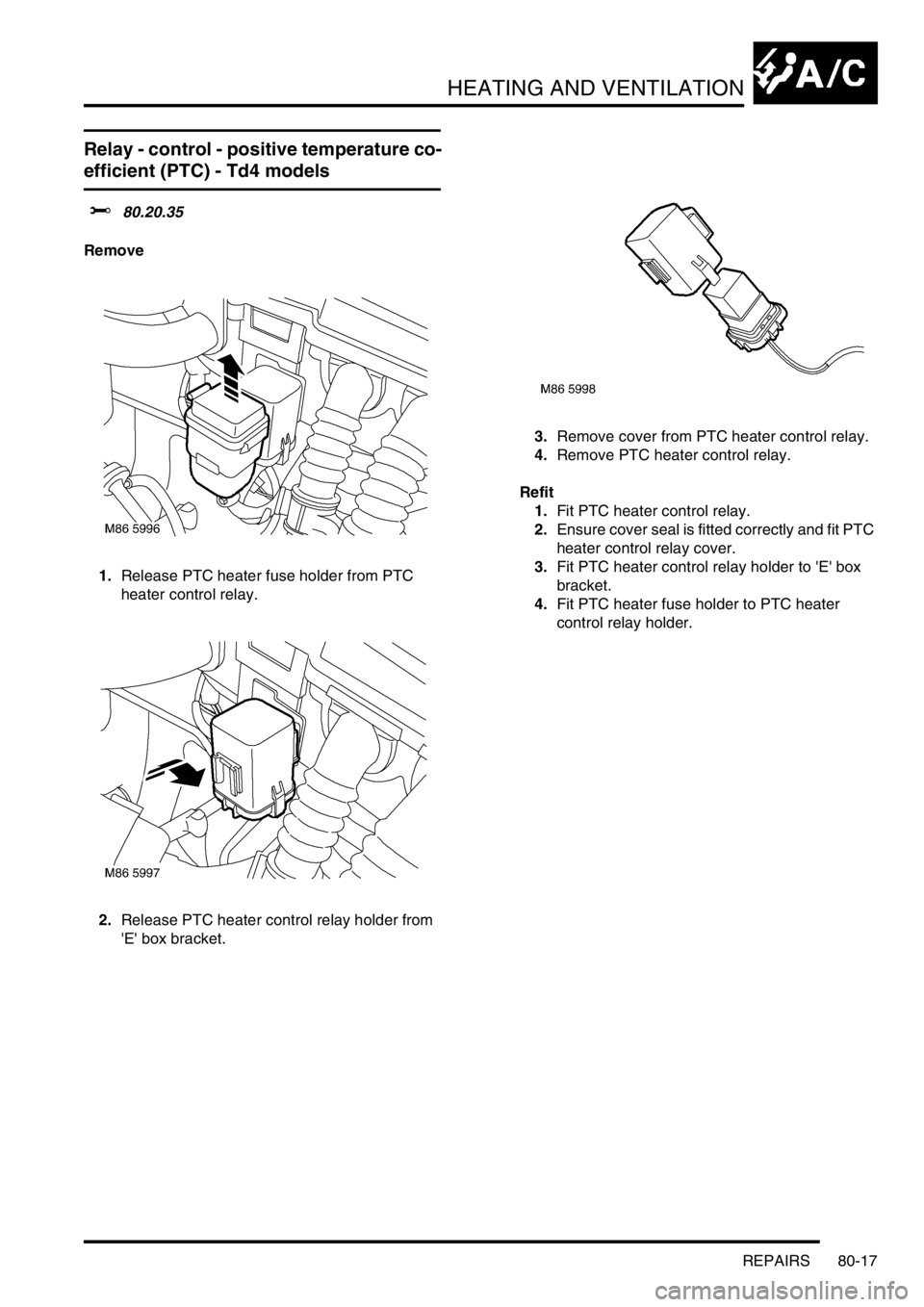

1.Release PTC heater fuse holder from PTC

heater control relay.

2.Release PTC heater control relay holder from

'E' box bracket.3.Remove cover from PTC heater control relay.

4.Remove PTC heater control relay.

Refit

1.Fit PTC heater control relay.

2.Ensure cover seal is fitted correctly and fit PTC

heater control relay cover.

3.Fit PTC heater control relay holder to 'E' box

bracket.

4.Fit PTC heater fuse holder to PTC heater

control relay holder.

Page 883 of 1007

HEATING AND VENTILATION

80-18REPAIRS

Fuel burning heater (FBH)

$% 80.40.01

Remove

1.Disconnect battery earth lead.

2.Remove front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

3.Drain coolant.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

4.Position container to collect coolant spillage.

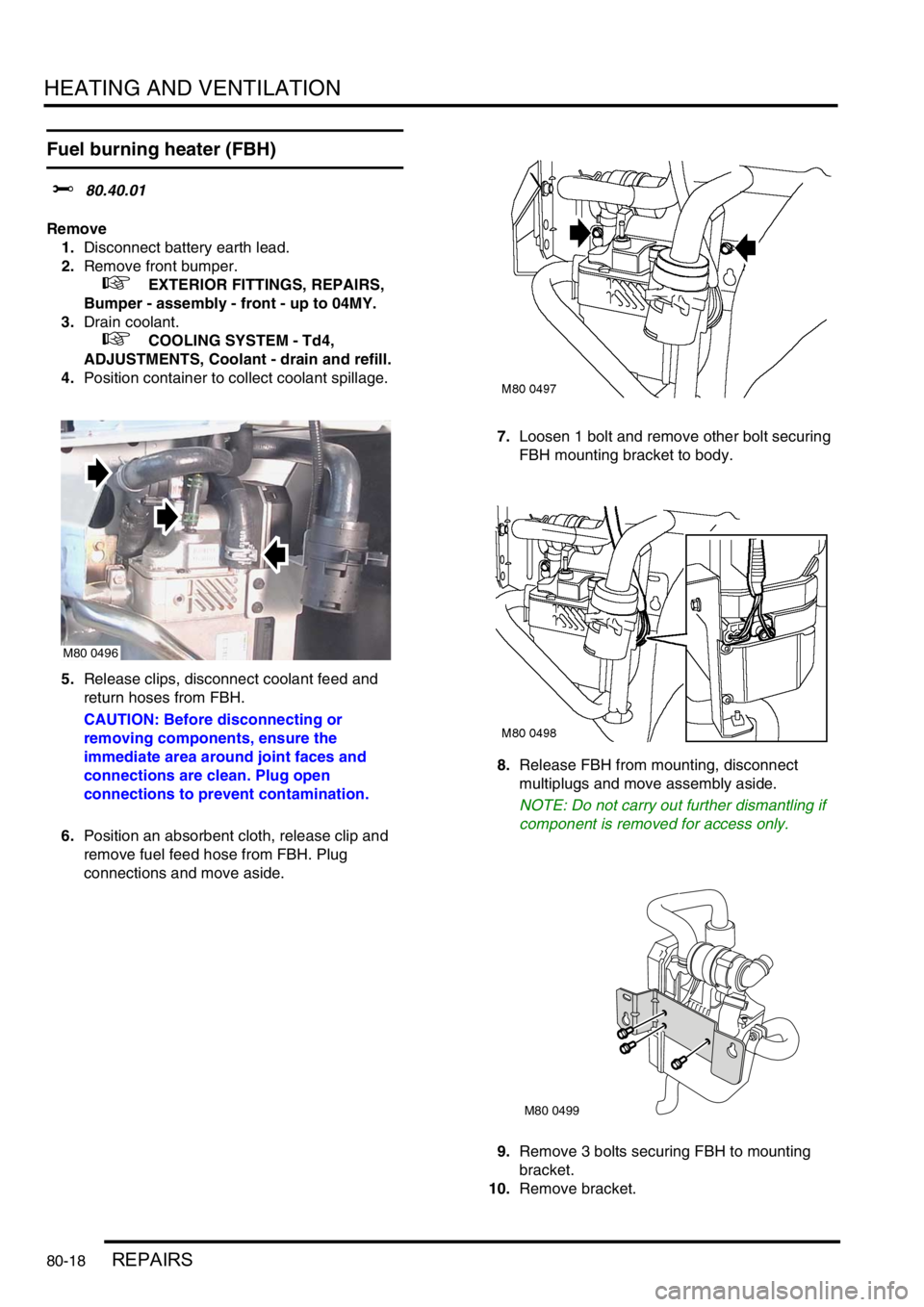

5.Release clips, disconnect coolant feed and

return hoses from FBH.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

6.Position an absorbent cloth, release clip and

remove fuel feed hose from FBH. Plug

connections and move aside.7.Loosen 1 bolt and remove other bolt securing

FBH mounting bracket to body.

8.Release FBH from mounting, disconnect

multiplugs and move assembly aside.

NOTE: Do not carry out further dismantling if

component is removed for access only.

9.Remove 3 bolts securing FBH to mounting

bracket.

10.Remove bracket.

M80 0496

M80 0499

Page 884 of 1007

HEATING AND VENTILATION

REPAIRS 80-19

11.Release clip securing air intake hose to FBH,

release clamp from exhaust manifold.

12.Remove 2 bolts securing air intake and exhaust

assembly to FBH and move aside.

Refit

1.Fit exhaust pipe, air intake hose and bracket

assembly to FBH.

2.Fit and tighten bolts to 10 Nm (7.5 lbf.ft).

3.Tighten exhaust pipe clamp to 5 Nm (3.5 lbf.ft).

4.Align air intake hose with mark on casing and

secure with clip.

5.Fit mounting bracket to FBH and tighten bolts to

10 Nm (7.5 lbf.ft).

6.Connect multiplugs to FBH.

7.Fit FBH to body, tighten bolts to 10 Nm (7.5

lbf.ft).

8.Fit coolant hoses to FBH and secure with clips.

9.Fit fuel feed hose to FBH and secure with clip.

10.Refill cooling system.

+ COOLING SYSTEM - Td4,

ADJUSTMENTS, Coolant - drain and refill.

11.Fit front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

12.Connect battery earth lead.

Sensor - outside temperature (OT)

$% 80.40.31

Remove

1.Remove front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

2.Disconnect multiplug from OT sensor.

3.Remove OT sensor from mounting bracket,

collect rubber washer and spacer.

Refit

1.Clean OT mounting bracket and sensor.

2.Fit OT sensor to mounting bracket, fit rubber

washer and spacer, connect multiplug.

3.Fit front bumper.

+ EXTERIOR FITTINGS, REPAIRS,

Bumper - assembly - front - up to 04MY.

Page 885 of 1007

HEATING AND VENTILATION

80-20REPAIRS

Fuel pump - fuel burning heater - up to

03MY

$% 80.40.40

Remove

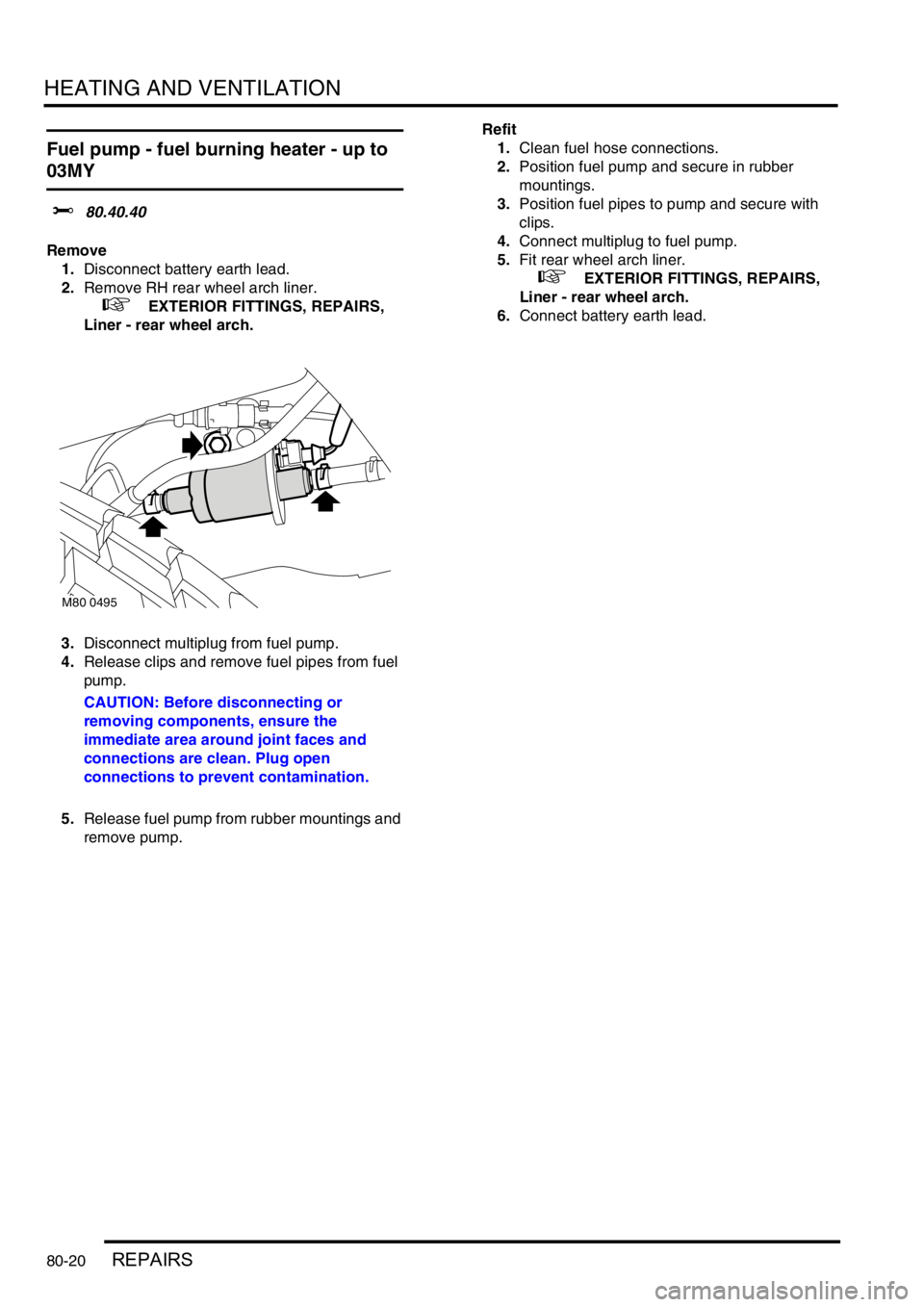

1.Disconnect battery earth lead.

2.Remove RH rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

3.Disconnect multiplug from fuel pump.

4.Release clips and remove fuel pipes from fuel

pump.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

5.Release fuel pump from rubber mountings and

remove pump.Refit

1.Clean fuel hose connections.

2.Position fuel pump and secure in rubber

mountings.

3.Position fuel pipes to pump and secure with

clips.

4.Connect multiplug to fuel pump.

5.Fit rear wheel arch liner.

+ EXTERIOR FITTINGS, REPAIRS,

Liner - rear wheel arch.

6.Connect battery earth lead.

M80 0495

Page 886 of 1007

HEATING AND VENTILATION

REPAIRS 80-21

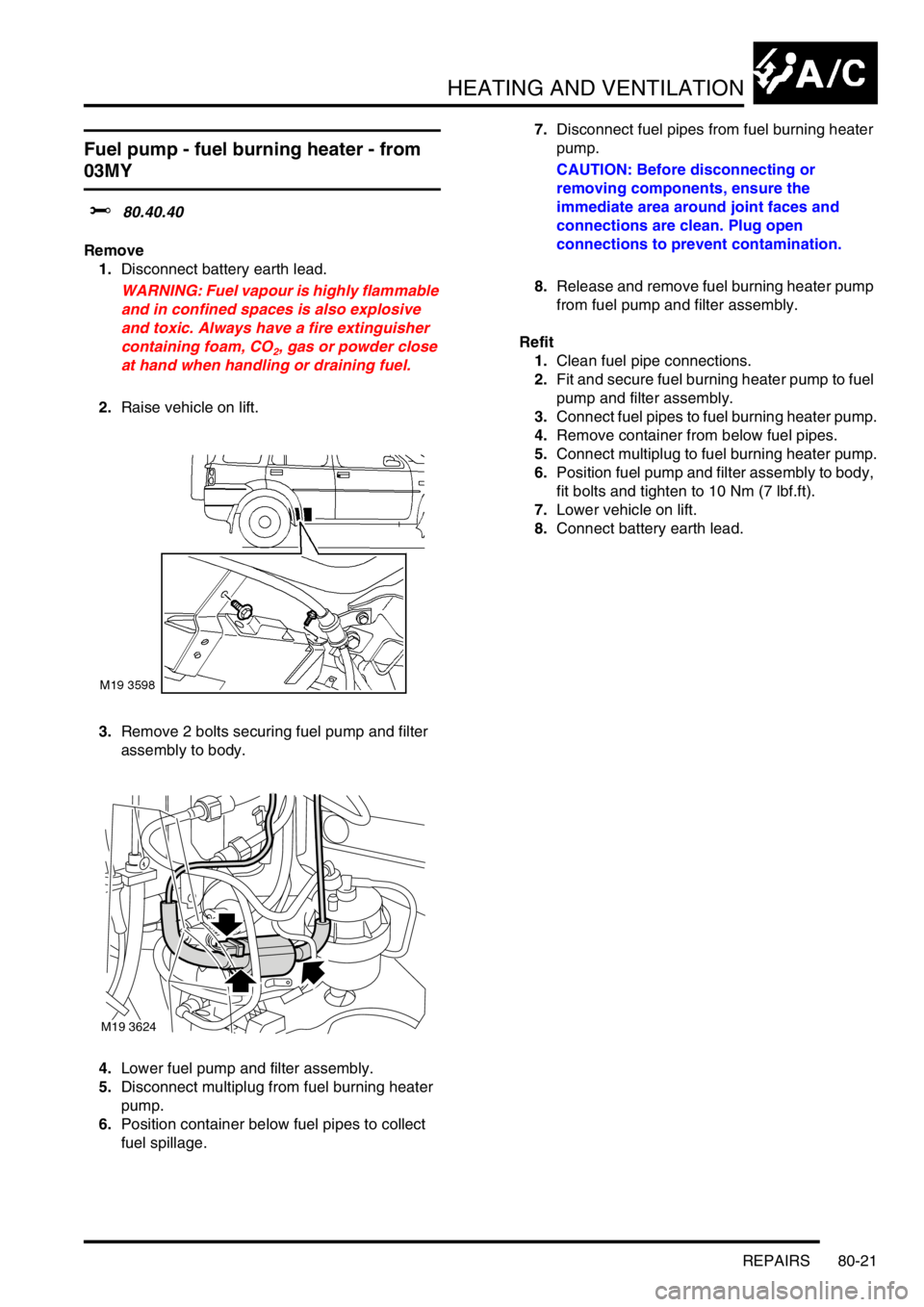

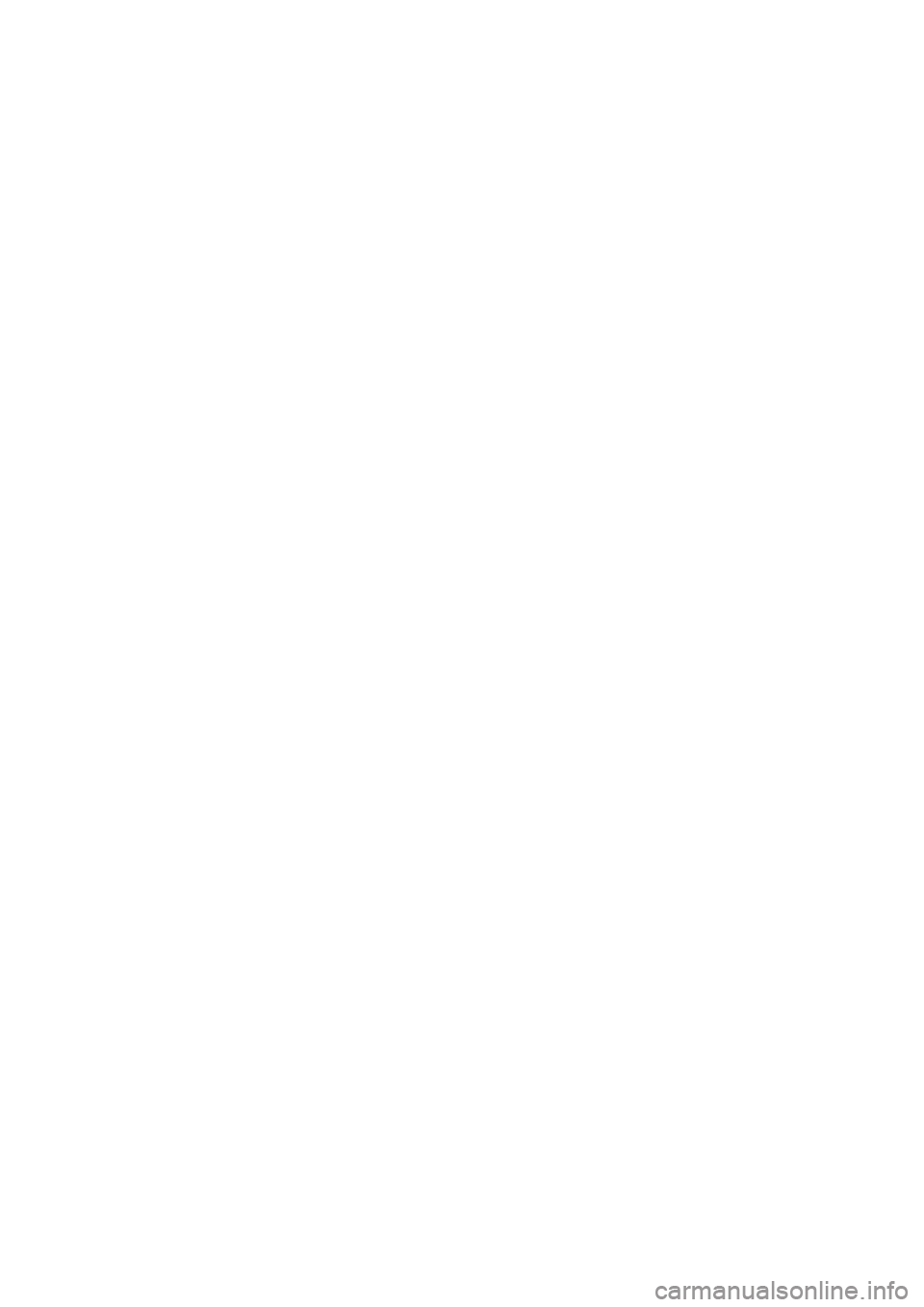

Fuel pump - fuel burning heater - from

03MY

$% 80.40.40

Remove

1.Disconnect battery earth lead.

WARNING: Fuel vapour is highly flammable

and in confined spaces is also explosive

and toxic. Always have a fire extinguisher

containing foam, CO

2, gas or powder close

at hand when handling or draining fuel.

2.Raise vehicle on lift.

3.Remove 2 bolts securing fuel pump and filter

assembly to body.

4.Lower fuel pump and filter assembly.

5.Disconnect multiplug from fuel burning heater

pump.

6.Position container below fuel pipes to collect

fuel spillage.7.Disconnect fuel pipes from fuel burning heater

pump.

CAUTION: Before disconnecting or

removing components, ensure the

immediate area around joint faces and

connections are clean. Plug open

connections to prevent contamination.

8.Release and remove fuel burning heater pump

from fuel pump and filter assembly.

Refit

1.Clean fuel pipe connections.

2.Fit and secure fuel burning heater pump to fuel

pump and filter assembly.

3.Connect fuel pipes to fuel burning heater pump.

4.Remove container from below fuel pipes.

5.Connect multiplug to fuel burning heater pump.

6.Position fuel pump and filter assembly to body,

fit bolts and tighten to 10 Nm (7 lbf.ft).

7.Lower vehicle on lift.

8.Connect battery earth lead.

M19 3624

Page 887 of 1007

Page 888 of 1007

AIR CONDITIONING

REFRIGERANT RECOVERY, RECYCLING AND RECHARGING 82-1

AIR CONDITIONING REFRIGERANT RECOVERY, RECYCLING AND RECHARGING

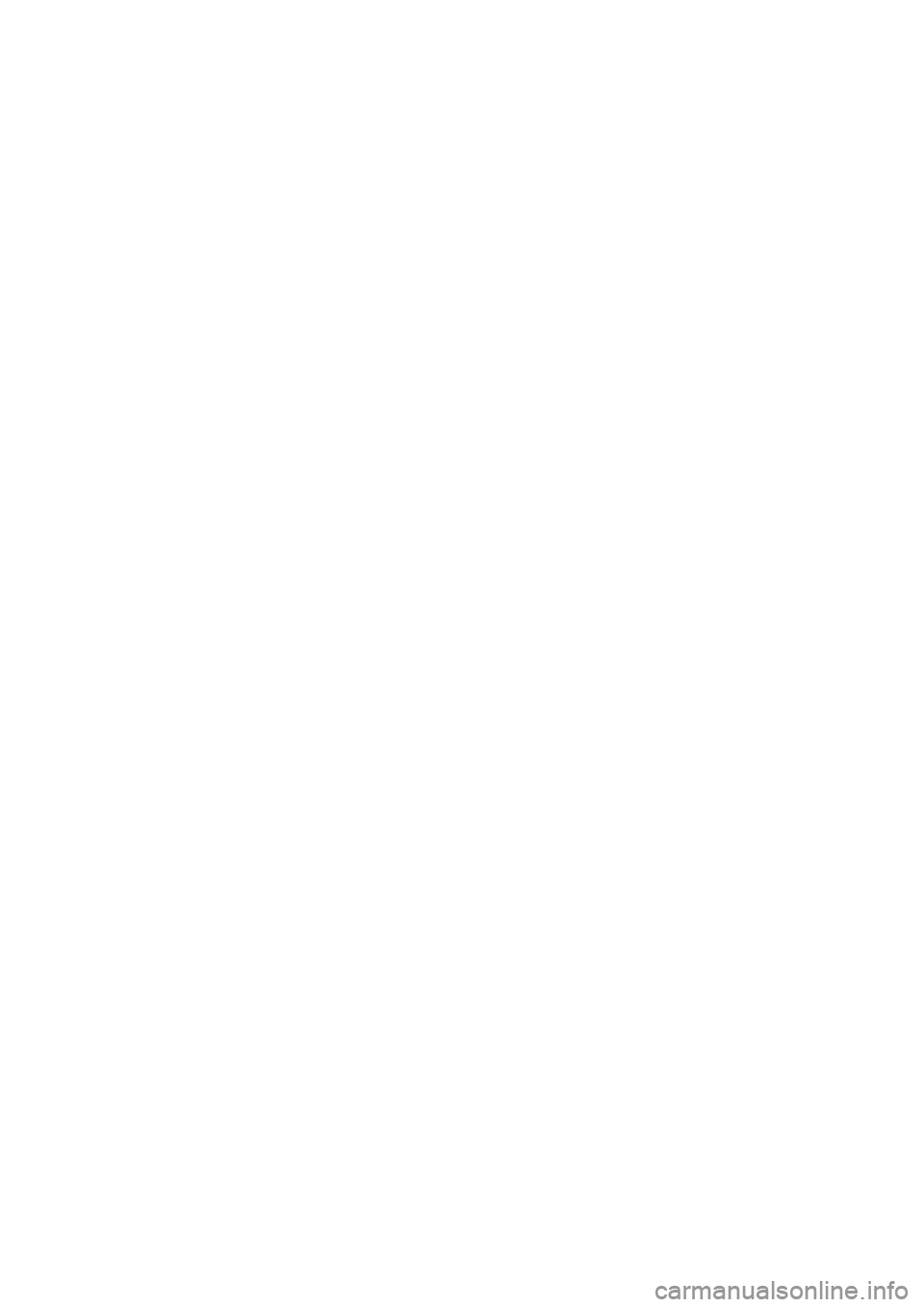

Refrigerant recovery - recycling and

recharge

$% 82.30.02

Refrigerant recovery

WARNING: Servicing must only be carried

out by personnel familiar with both the

vehicle system and the charging and testing

equipment. All operations must be carried

out in a well ventilated area away from open

flame and heat sources.

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to recover refrigerant from

system.

WARNING: Refrigerant must always be

recycled before re-use to ensure that the

purity of the refrigerant is high enough for

safe use in the air conditioning system.

Recycling should always be carried out with

equipment which is in compliance with SAE

J2210. Other equipment may not recycle

refrigerant to the required level of purity. A

R134a Refrigerant Recovery Recycling

Recharging Station must not be used with

any other type of refrigerant. Refrigerant

R134a from domestic and commercial

sources must not be used in motor vehicle

air conditioning systems.

8.Close valves on refrigerant station.9.Turn main switch to 'OFF'.

10.Close valves on connectors.

11.Disconnect high and low pressure connectors.

12.Fit dust caps to connectors.

13.Open tap at rear of station to drain refrigerant

oil.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn main switch to 'ON'.

7.Allow station to evacuate system.

Recharging

CAUTION: The system must be evacuated

immediately before recharging

commences. Delay between evacuation and

recharging is not permitted.

1.Close valves on refrigerant station.

2.Close valve on oil charger.

3.Disconnect yellow hose from refrigerant

station.

4.Remove lid from oil charger.

5.Pour correct quantity of refrigerant oil into oil

charger.

+ GENERAL DATA, Air Conditioning.

6.Fit lid to oil charger.

7.Connect yellow hose to refrigerant station.

8.Open valve on oil charger.

9.Move pointer on refrigerant gauge to mark

position of refrigerant drop.

10.Slowly open correct valve on refrigerant station

and allow vacuum to pull refrigerant into

system.

11.Close valve on refrigerant station when correct

amount of refrigerant has been drawn into air

conditioning system.

+ GENERAL DATA, Air Conditioning.

12.Turn main switch to 'OFF'.

13.Close valves on connectors.

14.Disconnect high and low pressure connectors.

15.Fit dust caps to connectors.

M82 0728

Page 889 of 1007

Page 890 of 1007

AIR CONDITIONING

ADJUSTMENTS 82-3

ADJUST ME NTS

Drive belt - compressor - Td4

$% 82.10.01

Check

1.Disconnect battery earth lead.

2.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

3.Turn steering on RH lock.

4.Remove 3 bolts and RH splash shield.

5.Check condition of drive belt. Renew a drive

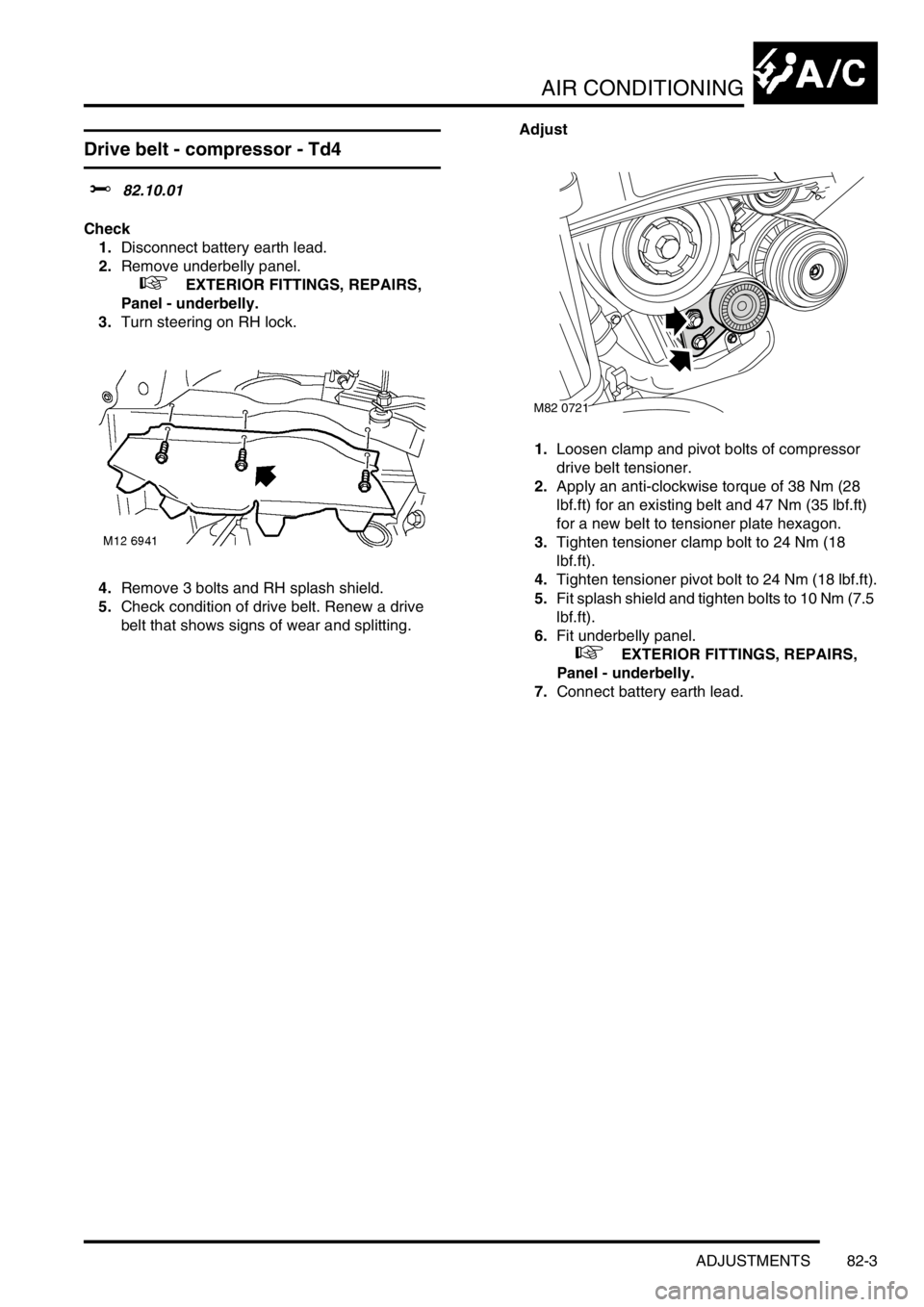

belt that shows signs of wear and splitting.Adjust

1.Loosen clamp and pivot bolts of compressor

drive belt tensioner.

2.Apply an anti-clockwise torque of 38 Nm (28

lbf.ft) for an existing belt and 47 Nm (35 lbf.ft)

for a new belt to tensioner plate hexagon.

3.Tighten tensioner clamp bolt to 24 Nm (18

lbf.ft).

4.Tighten tensioner pivot bolt to 24 Nm (18 lbf.ft).

5.Fit splash shield and tighten bolts to 10 Nm (7.5

lbf.ft).

6.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

7.Connect battery earth lead.

M82 0721