belt LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2484 of 3229

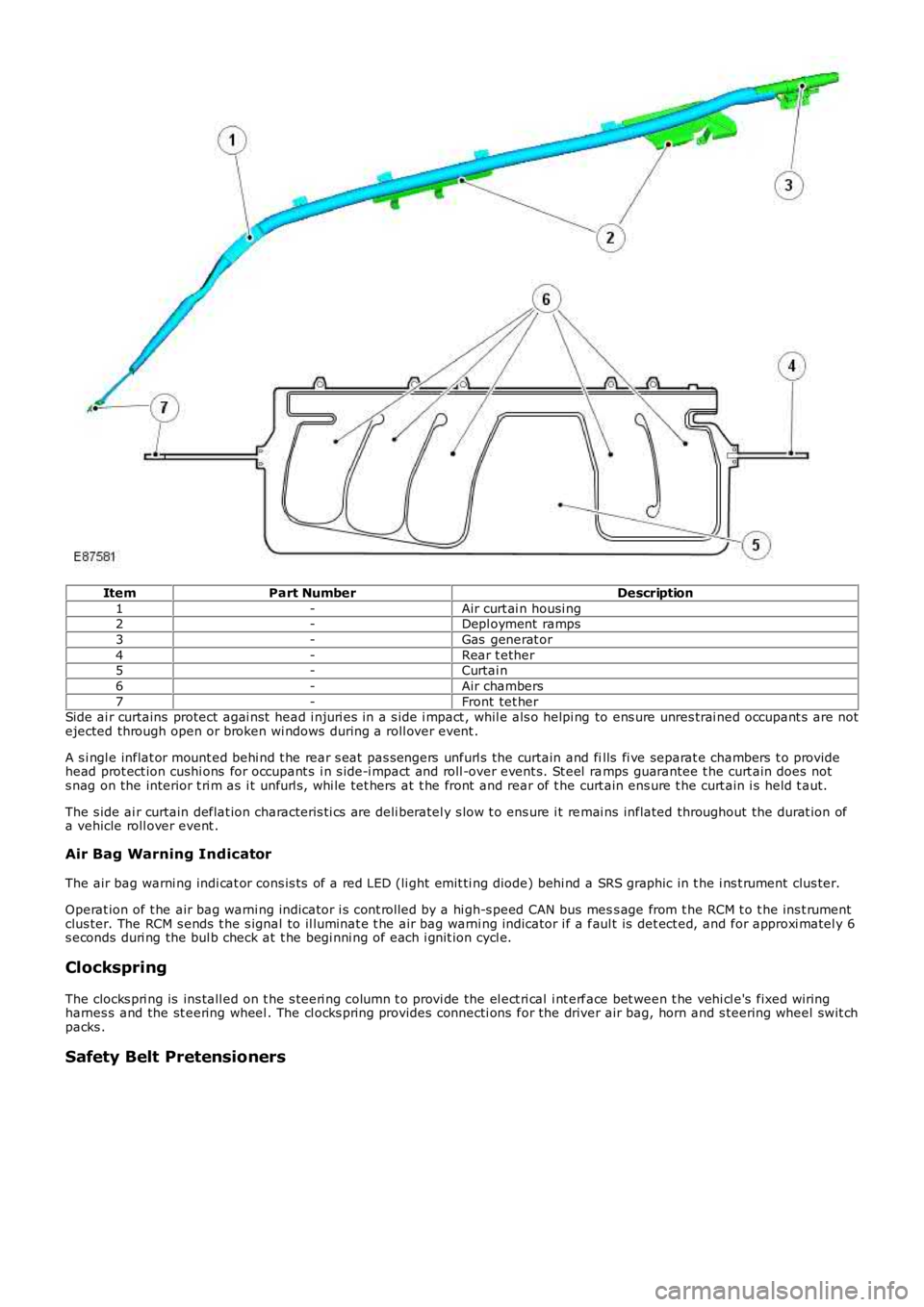

ItemPart NumberDescription

1-Air curt ai n housi ng2-Depl oyment ramps

3-Gas generat or

4-Rear t ether5-Curtai n

6-Air chambers

7-Front tet herSide ai r curtains protect agai nst head i njuri es in a s ide i mpact , whil e als o helpi ng to ens ure unres trai ned occupant s are notejected through open or broken wi ndows during a roll over event .

A s i ngl e inflat or mount ed behi nd t he rear s eat pas s engers unfurl s the curtain and fills fi ve separat e chambers t o providehead prot ect ion cushi ons for occupant s i n s ide-i mpact and roll -over event s. St eel ramps guarantee t he curt ain does nots nag on the interior t ri m as i t unfurl s , whi le tet hers at t he front and rear of t he curt ain ens ure t he curt ain i s held t aut.

The s ide ai r curtain deflat ion characteris ti cs are deli beratel y s low t o ens ure i t remai ns inflated throughout the durat ion ofa vehicle roll over event .

Air Bag Warning Indicator

The air bag warni ng indi cat or cons is ts of a red LED (li ght emit ti ng diode) behi nd a SRS graphic in t he i ns t rument clus ter.

Operat ion of t he air bag warni ng indicator i s cont rol led by a hi gh-s peed CAN bus mess age from t he RCM t o t he ins t rumentclus ter. The RCM s ends t he s ignal to il luminat e t he air bag warni ng indicator i f a faul t is det ect ed, and for approxi matel y 6s econds duri ng the bul b check at t he begi nni ng of each i gnit ion cycl e.

Clockspring

The clocks pri ng is ins tall ed on t he s teeri ng column t o provi de the el ect ri cal i nt erface bet ween t he vehi cl e's fixed wiringharnes s and the st eering wheel . The cl ocks pring provides connecti ons for the driver air bag, horn and s teering wheel swit chpacks .

Safety Belt Pretensioners

Page 2485 of 3229

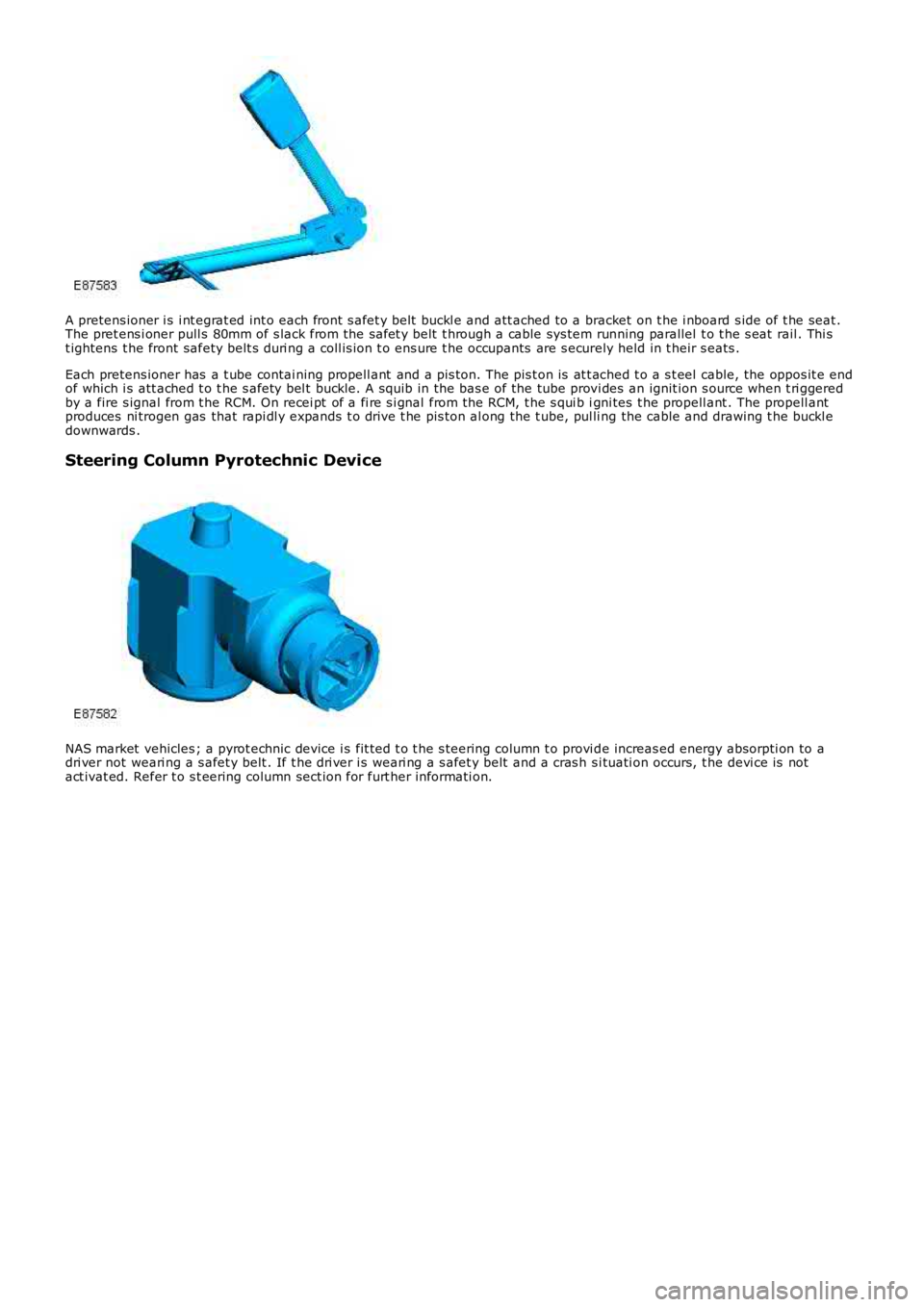

A pretens ioner i s i nt egrat ed int o each front s afet y belt buckl e and att ached to a bracket on t he i nboard s ide of t he seat .The pret ens i oner pull s 80mm of s lack from the safet y belt t hrough a cable sys tem running parallel t o t he s eat rail . Thi st ightens t he front safety belt s duri ng a coll is ion t o ens ure t he occupants are s ecurely held in t heir s eats .

Each pretens ioner has a t ube contai ning propell ant and a pis ton. The pis t on is at t ached t o a s t eel cable, the oppos it e endof which i s att ached t o t he s afety bel t buckle. A squib in the bas e of the tube provi des an ignit ion s ource when t ri ggeredby a fire s ignal from t he RCM. On recei pt of a fi re s i gnal from the RCM, t he s qui b igni tes t he propell ant . The propell antproduces ni trogen gas that rapi dl y expands t o dri ve t he pis ton al ong the t ube, pul ling the cable and drawing t he buckl edownwards .

Steering Column Pyrotechnic Device

NAS market vehicles ; a pyrot echnic device i s fit ted t o t he s teering column t o provi de increas ed energy absorpti on to adri ver not weari ng a s afet y belt . If t he dri ver i s weari ng a s afet y belt and a cras h s i tuati on occurs, t he devi ce is notact ivat ed. Refer t o s t eering column sect ion for furt her informati on.

Page 2510 of 3229

In addi ti on t o the short st roke s aw, t he reciprocati ng s aw can be us ed. W it h t his , it i s poss i bl e t o make narrow ands traight cut s t o an exact depth.

Carrying out the repairs

Butt joint

• NOTE: The s everance cut s houl d always be kept as s hort as poss i bl e on s ecti onal repl acement. Onl y cut at t he s everanceli nes shown in t he repair chapters.

Do not make any cuts near rei nforcements or pre-determined folding lines .

Prepare parts remaini ng on t he vehi cl e/new parts .- Res hape t he adjoi ni ng s urface of any dented body part s t hat are t o remai n on t he vehicle us ing a hammer anda count erhold (ens ure t hat the ol d part mat ches the s hape of the new part ). Grind off left over s pot wel ds ors eams wit h an angle grinder.- Cut the new part s to s hape.- If neces sary punch or drill holes for mig plug wel di ng.-• NOTE: Do not us e a wel ding t orch t o remove pai nt res idue (the heat coul d caus e t he met al to deform).

Gri nd all joining flanges to bare met al on both s i des . Do not us e an angle grinder for t hi s purpos e (this couldweaken the met al and damage the zi nc layer). Sui table tools : rot ati ng wi re brush, belt s ander or plas t ic dis c.- Apply wel di ng pri mer li berall y to all weld flanges .- The pri mer mus t be well s t irred before us e.

• NOTE: W hen us ing aerosol s, t ake care not t o cont aminat e adjacent part s wi th spray mi st .

Fit t he new part .

It must be ens ured that t he new part fit s exact ly t o t he s pecified di mensi ons. Suit able equipment :- Ali gnment jig.- Univers al meas uring s ys tem.- Jig s ys tem.- Ruler or tape meas ure.- Compass .- Frame dimens ions can be found i n t he model-specific repai r manual s.• NOTE: Any att ached body part s t hat require accurat e ali gnment and fit t ing mus t be i ncorporat ed i n t hi s s tep; forins t ance bumpers , s eal s , headlamps , rear l amps and lock as sembl y components . If thi s is not done careful ly i t mayres ult i n wat er l eaks , wi nd noi s es and subs tant ial fol low-on work.

Ensure t hat edges li ne up wi th adjacent part s and check t hat gaps are cons is t ent (compare l eft and right-hands ides ). Make s ure that the shape of t he vehi cl e is ret ai ned.

Secure t he new part

• NOTE: The need for s ubsequent foll ow-on work can be s ignificantl y reduced if ali gni ng and t ack-wel ding arecarri ed out wit h due care.

Dependi ng on acces si bili ty the foll owing met hods for s ecuri ng are avai lable:

Page 2512 of 3229

Sli di ng hammer- If the damaged panel i s only acces s ibl e from t he outs i de, us e a sl iding hammer to pul l i t back into shape. Thedis cs or st uds needed t o mount t he s li di ng hammer are welded onto the bare s urface. Dent s i n t he panel can befl att ened out us ing cont roll ed appl icati on of the s l iding hammer.

Heat-treatment of panels

It is us ually inevi tabl e that s ome parts of t he body panels show exces s material as a resul t of mechanical st rai n. Ift here are any areas of exces s material t hi s wi ll caus e l ocali s ed ins tabil it ies due to di fferences i n t ens ion. Theselocali sed i nst abil it ies can be s tabil is ed by applying heat -t reat ment techni ques .• NOTE: This does not appl y t o high-s t rength low al loy s t eel , ult ra hi gh s trengt h s teel and alumi nium.

Rule: Flat tening panels by heat -t reat ment reduces t he amount of excess material by more than t hey were origi nal lys tretched.

Different heat -t reatment t echni ques .

• NOTE: Different heat -t reat ment techni ques are us ed depending on the amount of exces s mat erial .

Flat tening us ing a fl ame.- A wel ding t orch i s used if t he material exces s extends over a larger area (t orch size 0.5 - 1.0 mm). Us e a s oftfl ame.- The s urface of t he met al i s bri efl y s pot -heat ed and then i mmediat ely cooled wi th a wet s ponge.- Requi rement : Abili ty to handle a weldi ng torch safely and knowledge of anneali ng col ours of s teel .- Advant age: No damage to the s urface of the met al.Flat tening us ing a fl ame, support ed by hammer and count erhold.-• NOTE: The flatt ening effect is i ncreas ed by s peedi ng up t he heat ing and cooli ng s tages .

If the mat eri al excess is concentrated, t hen the flat tening effect can be increas ed aft er heat ing by carefullyus ing an al uminium or wooden hammer.- Requi rement : Abili ty to recognis e material tens ion by feeling the s urface that is to be fl att ened.Flat tening us ing a carbon electrode.- If panel areas are onl y acces s ible from one s ide, or the panel is onl y s light ly des tabil is ed, then t he preferredmet hod is flat tening us ing a carbon electrode.- Requi rement : Bare met al s urface.- Dis advant age: Scarring and hardening of t he s urface.Flat tening us ing a copper electrode.- Small , s harp dents t hat face outwards can be worked on wi th a copper electrode.Flat tening us ing a fl ame and body fi les .-• NOTE: W hen appli ed correct ly, thi s method can be us ed wi th al l the at t ached part s s ti ll i n place (roofheadl ining, wi ring harnes s es etc.).

Small , soft dent s (onl y s li ght s t ret chi ng): W orki ng at t he edges of t he dent i n an inward s piral pat tern, the dentis heat ed wit h an oxyacet yl ene torch (t orch s ize 1 - 2 mm, exces s gas fl ame) to approx. 250° C.- W orking rapi dly wi th a body fi le ext racts heat from the edge area unt il t he dent is flat tened. Preferabl yalt ernate bet ween t wo files . This i ncreas es t he amount of heat t hat can be ext racted.

Safety measures

The electroni c cont rol modules (ECM) fi tt ed t o vehicles make i t advi sable to foll ow s uit able precauti ons prior t ocarryi ng out wel ding repai r operati ons . Hars h condit ions of heat and vibrati on may be generat ed during t heseoperati ons which coul d caus e damage t o t he modules . In part icul ar, i t is es s ent ial to fol low the appropriateprecaut ions when di sconnect ing or removi ng the ai rbag RCM.Do not all ow electronic modules or l ines t o come int o contact wit h t he ground connecti on or the wel ding elect rode.Seat bel t anchorages are a s afety crit ical. W hen maki ng repairs i n t hes e areas , it is es s ent ial t o fol low des igns pecificati ons. Not e t hat ext ra s t rength low al loy s t eel may be us ed for seat belt anchorages . W here poss i bl e, theori ginal product ion as s embl y s houl d be us ed, compl et e wi th it s s eat bel t anchorages, or t he cut line should be soarranged t hat the origi nal s eat bel t anchorage i s not dis turbed.All wel ds wit hin 250mm (9.842) of s eat bel t anchorages mus t be careful ly checked for weld quali ty, includings pacing of s pot welds .Remove the bat tery before carryi ng out wel ding work in it s vicinit y.Ut most care mus t be taken when wel di ng near the fuel t ank or other components that cont ain fuel. If the t ank fi ll erneck or a fuel li ne mus t be detached to al low access for weldi ng work, then t he fuel t ank mus t be drained andremoved.Never wel d, on components of a fi lled ai r condit ioning sys tem. The same appl ies i f there is a ri sk of t he aircondi ti oni ng s ys t em heati ng up.

Page 2527 of 3229

Clean t he affect ed s eam and re-t reat any expos ed met al areas wit h a sui table et ch phos phate primer.Treat affect ed area wit h an et ch-aci d pri mer.Apply appropri ate seam seal er as necess ary.appl y appropri ate colour coat (and under body s ealer as appl icable).

Provided acces s i s adequat e, apply seam seal er t o bot h s ides of a repai r joint . W here access is l imi ted to one s i de onl y,(e.g. box secti on), t reat t he affect ed box member wit h cavi ty wax.

Cavity Wax

Aft er repairs, al ways re-treat t hese areas wit h an approved cavit y wax. In addit ion, t reat all int eri or s urfaces whi ch havebeen dis turbed during repai rs whet her they have been treat ed i n product ion or not . Thi s includes all box members, cavit iesand door i nteriors .

Before wax inject ion, ensure t hat t he cavi ty to be treat ed i s free from any contaminati on or forei gn mat ter. W hereneces s ary, cl ear out any debri s.

Ensure t hat cavit y wax is appl ied after t he fi nal paint proces s and before refit ti ng any trim components .

Duri ng appl icati on ensure t hat t he wax covers all flanges and seam areas and t hat i t is adequately appl ied t o all repai redareas of both new and exi s ti ng panel s.

It should be not ed t hat new panel as sembl ies and complet e body shel ls are s uppl ied wi thout wax inject ion t reat ment.Ensure t hat s uch t reatment i s carri ed out aft er repairs .

Effect ive cavit y wax prot ect ion i s vit al. Always obs erve t he fol lowing poi nts :

Complet e all paint refini sh operati ons before wax appli cat ion.Check t he s pray pat tern of inject ion equipment.Mas k all areas not t o be waxed.Remove body fi xi ngs , s uch as s eat belt retract ors , if contami nati on is at al l l ikely.Move door gl ass es t o ful ly cl os ed pos it ion before t reati ng door interiors .Treat body areas normal ly covered by t ri m before refi tt ing i tems .Check t hat body and door drai n holes are cl ear after t he prot ect ive wax has dried.Keep all equipment cl ean, es peci ally wax inject ion nozzl es.

Page 2532 of 3229

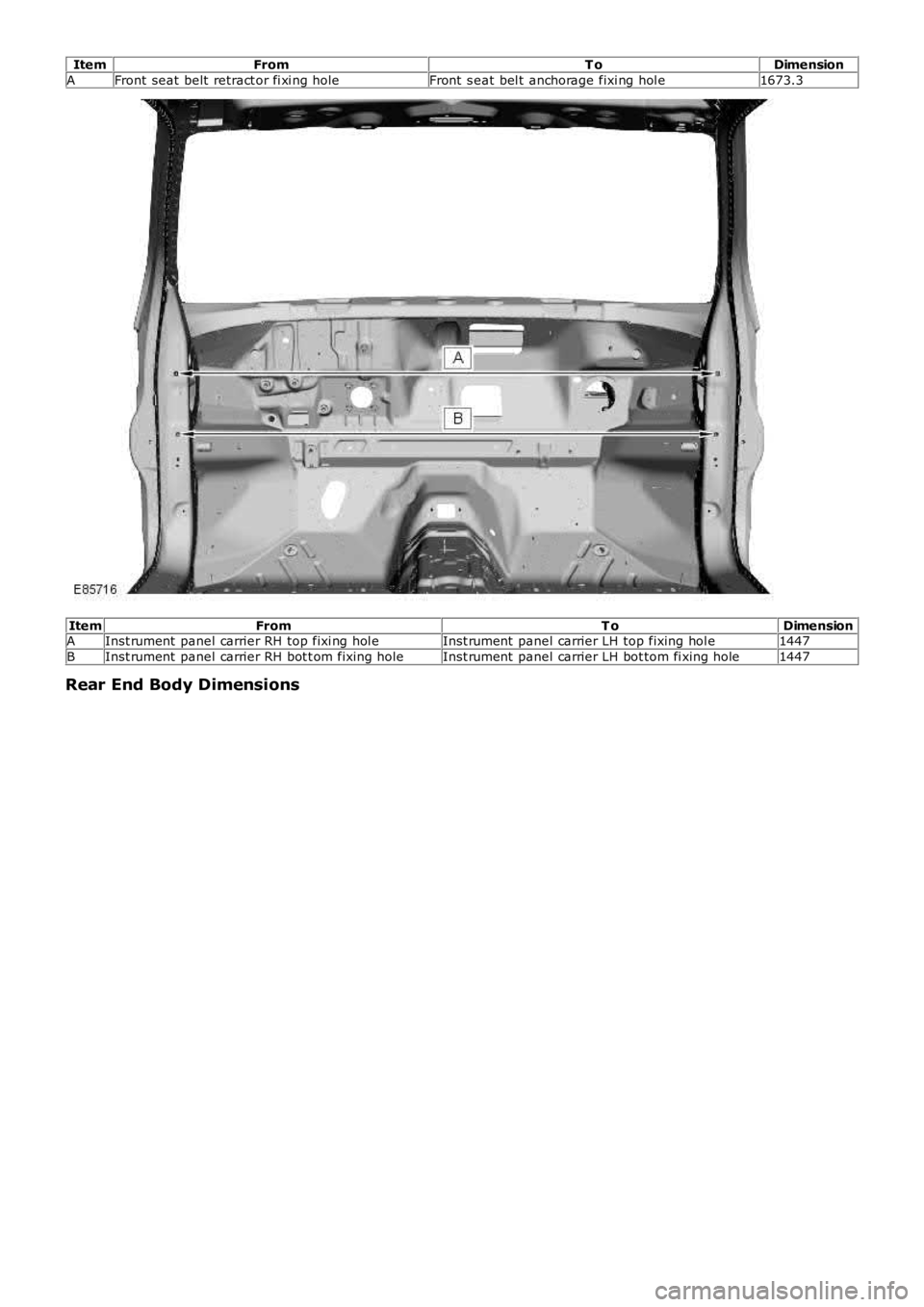

ItemFromT oDimension

AFront seat belt retract or fi xi ng holeFront s eat bel t anchorage fixi ng hol e1673.3

ItemFromT oDimensionAInst rument panel carrier RH top fixi ng hol eInst rument panel carrier LH top fixing hol e1447

BInst rument panel carrier RH bot t om fixing holeInst rument panel carrier LH bot tom fi xing hole1447

Rear End Body Dimensions

Page 2561 of 3229

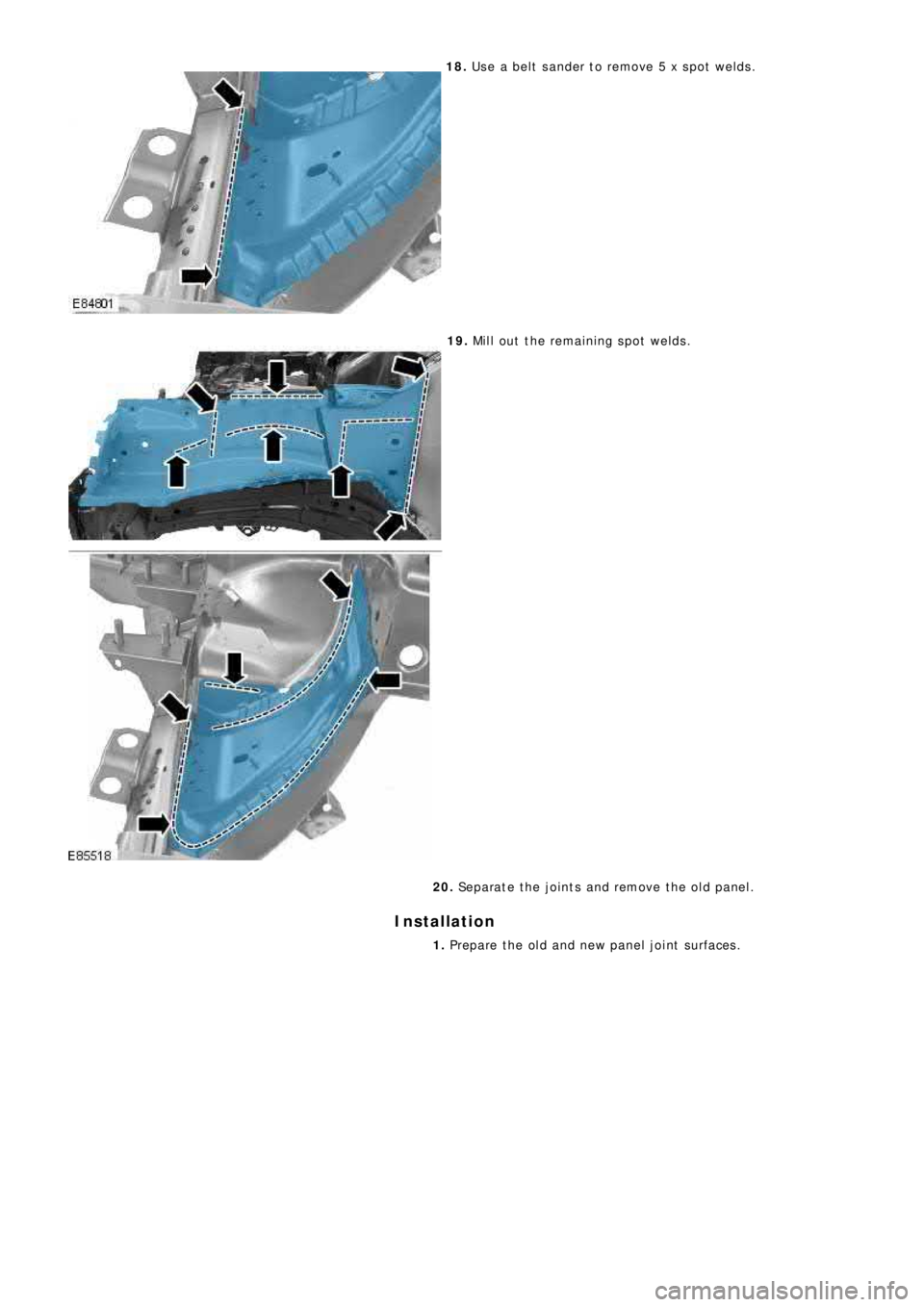

18. Use a belt sander to remove 5 x spot welds.

19. Mill out the remaining spot welds.

20. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

Page 2568 of 3229

Publ is hed: 11-May-2011

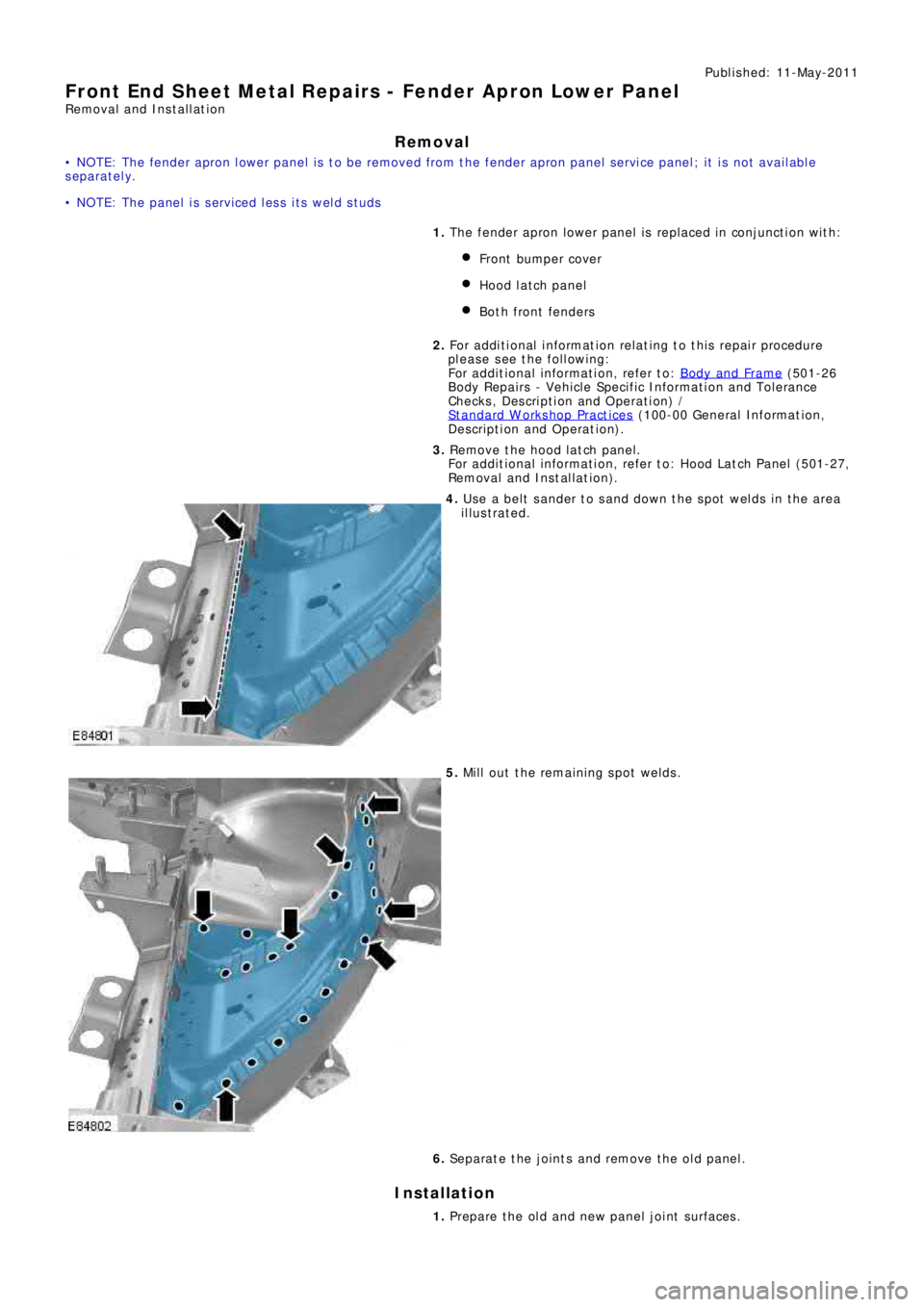

Front End Sheet Metal Repairs - Fender Apron Lower Panel

Removal and Installation

Removal

• NOTE: The fender apron lower panel is to be removed from the fender apron panel service panel; it is not available

separately.

• NOTE: The panel is serviced less its weld studs

1. T he f e nd e r a p ro n l o we r p a ne l i s re p l a ce d i n co nj unct i o n w i t h:

Front bumper cover

Hood lat ch panel

Both front fenders

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove t he hood l at ch panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : H o o d L a t ch P a ne l (501-27,

Removal and Installation).

4. Use a belt sander to sand down the spot welds in the area

illustrated.

5. Mill out the remaining spot welds.

6. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

Page 2580 of 3229

Publ is hed: 11-May-2011

Roof Sheet Metal Repairs - Roof PanelVehicles Without: Sliding Roof

Opening Panel

Removal and Installation

Removal

• NOTE: The roof is serviced as a separate weld on panel, less its reinforcements.

• NOTE: Along the RH and LH sides of the panel, spot welds should be installed adjacent to the originals and not in the

same locations.

1. The roof panel is replaced in conjunction with:

Liftgate

Windshield

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Disconnect both battery cables.

4. Remove the liftgate.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Liftgate

(501-03 Body

Closures, Removal and Installation).

5. Remove the windshield glass.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Glass

(501-11

Glass, Frames and Mechanisms, Removal and Installation).

6. Remove both front seats.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Seat

(501-10

Seating, Removal and Installation).

7. Remove the rear seat.

8. Remove bot h side air curt ain modules.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Side Air Bag Module

(501-20B Suppl ement al Res t rai nt Sys t em, Removal and

Installation).

9. Remove both front safety belt retractors.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Safety Belt Retractor

(501-20A Safe t y Bel t Sys t em, Removal and Ins t al l at i on).

10. Remove both rear safety belt retractors.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Safety Belt Retractor

(501-20A Safe t y Bel t Sys t em, Removal and Ins t al l at i on).

11. Release and lay aside the wiring harness.

Page 2584 of 3229

Publ is hed: 11-May-2011

Roof Sheet Metal Repairs - Roof Front PanelVehicles With: Sliding Roof

Opening Panel

Removal and Installation

Removal

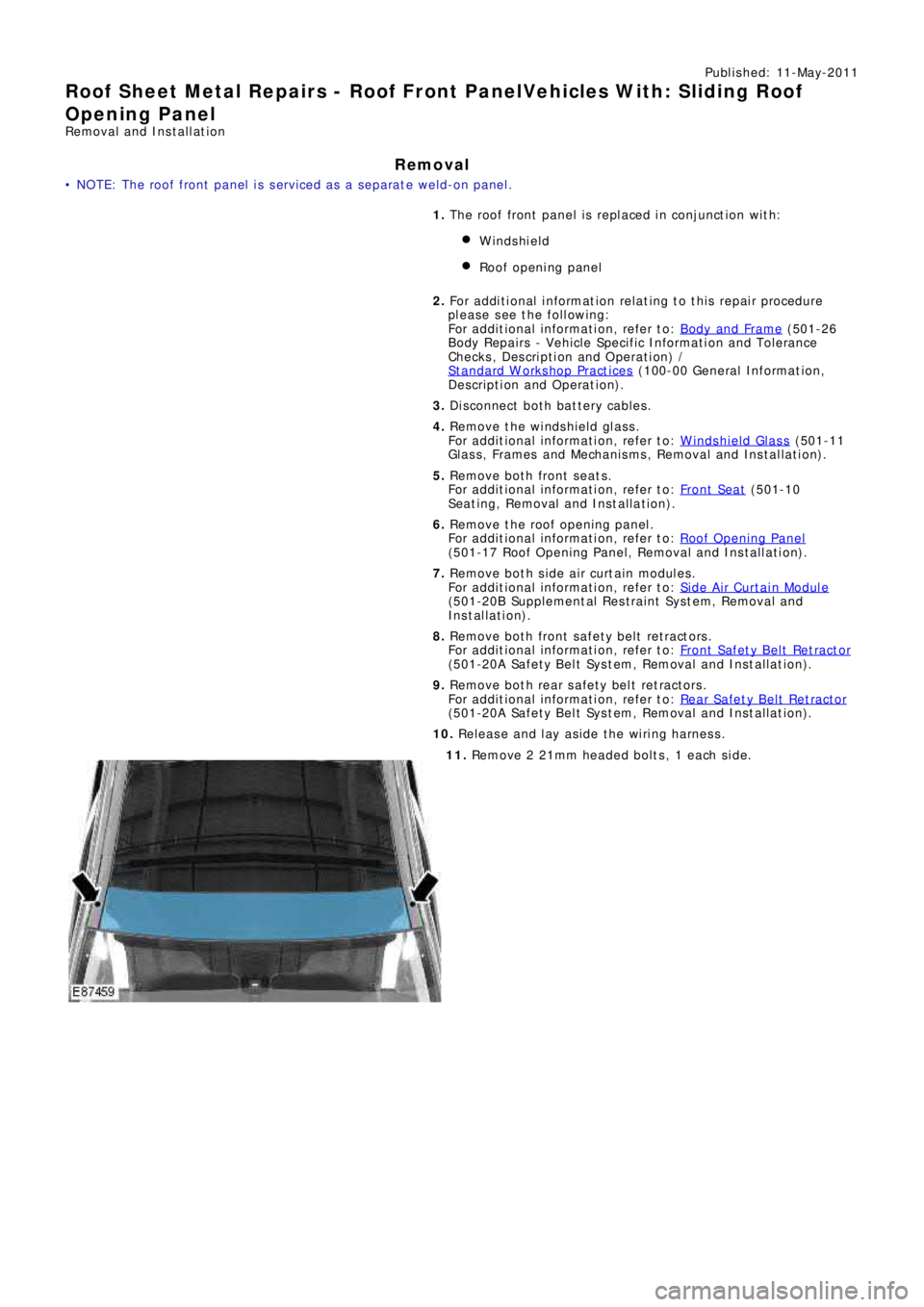

• NOTE: The roof front panel is serviced as a separate weld-on panel.

1. The roof front panel is replaced in conjunction with:

Windshield

Roof opening panel

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Disconnect both battery cables.

4. Remove the windshield glass.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Glass

(501-11

Glass, Frames and Mechanisms, Removal and Installation).

5. Remove both front seats.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Seat

(501-10

Seating, Removal and Installation).

6. Remove the roof opening panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Roof Opening Panel

(501-17 Roof O peni ng Panel , Removal and Ins t al l at i on).

7. Remove bot h side air curt ain modules.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Si d e A i r Curt a i n Mo d ul e

(501-20B Suppl ement al Res t rai nt Sys t em, Removal and

Installation).

8. Remove both front safety belt retractors.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Safety Belt Retractor

(501-20A Safe t y Bel t Sys t em, Removal and Ins t al l at i on).

9. Remove both rear safety belt retractors.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Rear Safety Belt Retractor

(501-20A Safe t y Bel t Sys t em, Removal and Ins t al l at i on).

10. Release and lay aside the wiring harness.

11. Re mo ve 2 21mm he a de d bo l t s , 1 e a ch s i de .