ABS LAND ROVER FRELANDER 2 2006 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2059 of 3229

The pass i ve ant i-theft sys t em us es the foll owing component s:

Remote hands et trans ponderCJBECMStart cont rol moduleIns t rument clus terABS moduleElectric s t eering column lock (if enabl ed).

• NOTE: On North Ameri can Specificat ion (NAS) vehi cles , a running change was int roduced during 2008 Model Y ear (MY ) t odis able t he electric st eering col umn lock. Under t he change, the i nternal elect ronics (print ed circuit board (PCB), motor,etc.) of t he l ock have been removed and t he lock has been dis abled i n t he car configurat ion fi le. The change i sincorporat ed on VIN (vehi cl e identi fi cat ion number) 082896, 085531, 085622, 085685, 085832, 085891, 085942, 085987,086049, 086081, 086123, 086178, 086276, 086287, 086309, 086363, 086383, 086389, 086398, 086403 and 091770onwards .

The s ys t em i s automat ic and requi res no input from t he dri ver. The engi ne management s yst em wil l onl y allow engi necrank when an aut horizati on data mess age is received from t he CJB. The engi ne st art s ys tem is init iat ed when thes tart/s top s wi tch and t he brake pedal (automat ic t rans mis s ion) or t he cl utch pedal (manual trans mi ss i on) are pres s eds imul taneous l y.

The engi ne management s ys tem (ECM) wi ll only al low engi ne crank, s park (petrol models only) and inject or funct ions whent he foll owing condit ions are met:

A hardwi red Park/Neutral si gnal i s received from the Trans mi ss i on Cont rol Module (TCM) (aut omati c t ransmis s iononly)A hardwi red ignit ion s ignal is recei ved from t he CJBA hardwi red crank reques t s ignal is recei ved from t he CJBEncrypt ed data exchange bet ween t he ins trument cl ust er and the ECM is verifi ed.

Before the CJB will s end t he hardwired igni ti on si gnal , it mus t s ati s factori ly complet e t he fol lowi ng:

Exchanged encrypt ed data wit h the st art control modul e t o validat e t he remot e hands et .

Addit ional ly, before the CJB will s end t he hardwired crank reques t s ignal i t mus t receive t he fol lowing si gnal s:

Brake s ignal from t he brake s wi tch (automat ic t rans mis s ion) or clutch s i gnal from the clut ch s wit ch (manualt ransmis s ion)Hardwi red t rans mis s ion in Park (P) s ignal from t he s elector lever ass embl y (aut omatic trans mi s si on only).

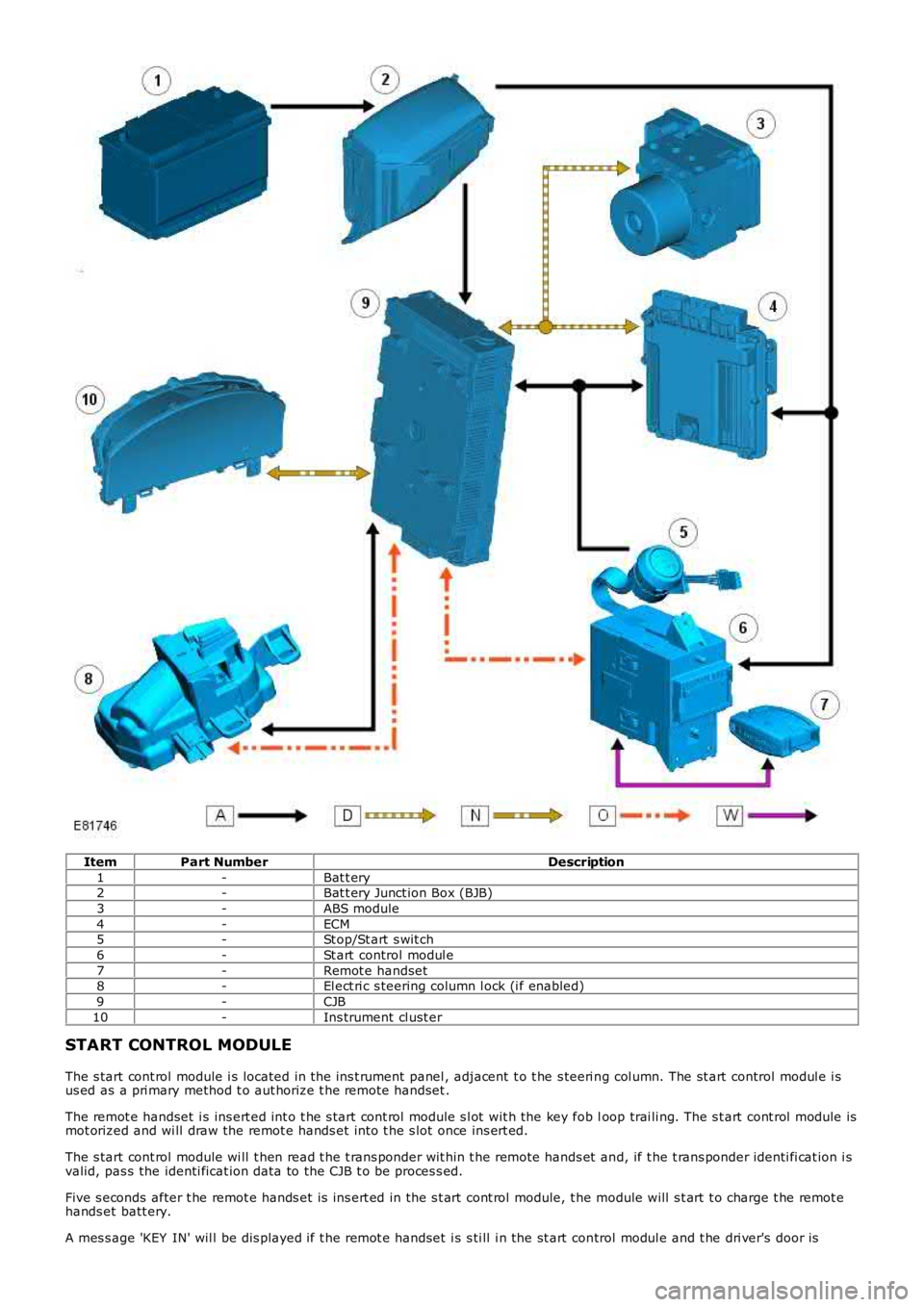

CONTROL DIAGRAM

• NOTE: A = Hardwi red; D = High speed CAN bus ; N = Medium s peed CAN bus ; O = LIN bus ; W = LF t rans mis s ion

Page 2060 of 3229

ItemPart NumberDescription

1-Bat t ery2-Bat t ery Junct ion Box (BJB)

3-ABS module

4-ECM5-St op/St art s wit ch

6-St art control modul e

7-Remot e handset8-El ect ri c s teering column l ock (i f enabled)

9-CJB

10-Ins trument cl ust er

START CONTROL MODULE

The s tart cont rol module i s located in t he ins t rument panel , adjacent t o t he s teeri ng col umn. The st art control modul e i sus ed as a pri mary method t o aut horize t he remot e handset .

The remot e handset i s ins ert ed int o t he s tart cont rol module s l ot wit h the key fob loop trai li ng. The s t art cont rol module ismot orized and wi ll draw the remot e hands et int o t he s lot once ins ert ed.

The s tart cont rol module wi ll t hen read t he t rans ponder wit hin t he remote hands et and, if t he t rans ponder identi fi cat ion i svalid, pas s the identi ficat ion data to the CJB t o be proces s ed.

Five s econds after t he remot e hands et is ins ert ed in the s t art cont rol module, t he module will s t art t o charge t he remot ehands et batt ery.

A mes s age 'KEY IN' wil l be dis played if t he remot e handset i s s ti ll i n the st art control modul e and t he dri ver's door is

Page 2062 of 3229

Publi s hed: 11-May-2011

Anti-Theft - Passive - Anti-Theft - Passive

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Pas s ive Ant i-Theft Sys t em (PATS), refer t o t he relevant Des cript ion and Operat ion secti onin the workshop manual.REFER to: Ant i-Theft - Pas s ive (419-01B Anti -Theft - Pas s ive, Descripti on and Operat ion).

Inspection and Verification

The best method t o confirm the correct operat ion of t he Pass i ve Ant i-Theft Syst em (PATS) is t o check t he LED (located i nt he cent er of t he ins t rument panel ). The LED s hould i ll uminate sol id for 3 s econds , when the i gnit ion s tat us is set t o ON,and t hen ext inguis h. Thi s validat es all PATS functi ons (i .e. the key t rans ponder matches a st ored key code, thechal lenge/res ponse sequence bet ween t he res pect ive modules was succes s ful res ult ing in t he EMS being enabled).

Ignition Fails to Operate

Check t hat the key i s correct ly i nserted i nto the s t art cont rol unit (SCU) and that i t is t he correct key for t he vehi cle (Keywil l be ejected from t he SCU i f it is not programmed or from anot her vehicl e). If the vehicle is an aut omati c, ens ure t hatt he Park pos it ion i s s el ect ed and if manual, ens ure it is in t he Neutral pos i ti on.

Check t hat the st art but ton circui t to the Cent ral Juncti on Box (CJB) i s not open circui t or s hort to ground.

Check t hat the CAN network is not mal functi oni ng, i .e. open circuit or s hort circui t. This woul d mean t hat the CJB, ECM andIns t rument Clus t er woul d be unabl e t o communicate. Check thes e modules for relat ed DTCs and refer t o relevant DTCIndex.

Engine Fails to Crank

The immobili zer s t atus i ndi cat ion LED i s dis played i n the bot tom left of the i nst rument pack. W hen the key i s i ns ert ed i nt ot he SCU, t he LED wi ll be t urned on for 3 s econds and t hen turned off. The LED will flas h s lowl y (once every 2 seconds ) i ft he vehi cl e is immobi lis ed (t ransponder not approved). Addit ionall y the di agnos ti c syst em s hould be us ed t o check forDiagnost ic Troubl e Codes (DTCs ) from the CJB, ins trument cl ust er, ECM and the ABS modul e.

One potent ial occurrence for the vehicl e fai ling to crank on an Automat ic Trans mi s sion coul d be due t o t he Locked in parks wit ch.

Check t he Crank reques t circui t from t he CJB t o ECM for short ci rcuit or open circuit .

Check t he St art er Rel ay Circuit .

Check t hat the St eeri ng Col umn Lock (SCL) is operat ing correctl y. Ins erti ng t he key should drive t he SCL t o un-l ock ands teeri ng wheel should move freel y.

Check t he CAN net work i s not malfunct ioning, i.e. the CAN ci rcuit i s open or short ci rcuit . Thi s would mean that t he CJB,ins t rument clus ter, ECM or ABS module would not be abl e t o communicate res ul ti ng in no chal lenge being made from t hemodules for the Immobil is ati on data.

Als o on an Aut omat ic, check the CAN network between t he CJB and the Transmis s ion Control Modul e (TCM). The CJB usest he "LockedInP" s ignal transmit ted by t he TCM to det ermi ne if t he t rans mis s ion i s in Park before all owing crank, the CJBus es a value of 0x01, i f the CJB s ees a value l ess than t his i t wil l not al low crank, and key wil l not be ejected from SCU.

For a manual gearbox t he clut ch pedal has to be de-pres s ed, hence check t he CAN network between t he CJB and t he ECMt o ensure t he cl utch i s depress ed, Clut chPedal Swit ch75pct = TRUE and Cl ut chPedalPress ed2 = True. The Vehicl e wil l notcrank unti l thes e s ignals are s et.

On an Aut omati c vehi cl e, check t he CAN network between t he ABS module and the CJB. The CJB uses a s ignal"BrakePedalActi ve" t o det ermi ne if t he brake pedal has been depres sed in order t o allow t he engine t o crank. The CJB us esa value = TRUE i f the CJB does not receive t hi s s ignal, i t wil l not al low t he crank reques t output.

Engine Cranks But Will Not Start

If the engine i s cranking i t means that t he EMS has pass ed t he authori s at ion required wit h t he CJB. If thi s authori s at ionfai led, the ECM would not engage the s t art er relay. Thi s coul d be confi rmed by verifyi ng t he LED in the l eft of t heIns t rument pack bei ng il lumi nat ed for 3 seconds on Key ins ert ion, or by reading DTCs from t he CJB or t he ECM.

In all cases of s us pected non-st art i s sues , the most l ogical fail ure modes s houl d be el imi nat ed first . i.e.

1. Check al l relevant suppli es and grounds to the relevant modul es are ok.2. Note any unus ual behavi our from other s yst ems /funct ionali ty.3. Note any funct ions t hat are not operati ng as expect ed.

Fault Codes/DTCs

For the vari ous PATS modes of operat ion/fail ures l is ted i n t he t abl e, t he CJB wi ll store a DTC whi ch wil l not be shown t ot he cus t omer.

W hen t he Key i s ins ert ed and ignit ion st atus ON is achieved, if t he s tart aut horis ation pas ses , the LED in t he bott om leftof the ins trument cl us t er will i ll uminate for 3 s econds t hen go off. If st art aut horis ati on fai ls , the LED wil l conti nue to fl as hevery 2 s econds . Pleas e s ee tabl e below for a li s t of fault codes that wil l be s tored under cert ain condi ti ons. For addi ti onalinformat ion.REFER to: St art ing Syst em (303-06A St art ing Sys tem - I6 3.2L Petrol, Di agnos is and Tes ti ng) /

Page 2072 of 3229

3-Touch Screen Dis play (TAD)

4-Integrat ed Head Unit (IHU) - Hi-Li ne

5-Bl uet ooth phone module6-Ampl ifier/t uner

7-Di git al Audio Broadcas t (DAB) recei ver

8-Navigat ion computer

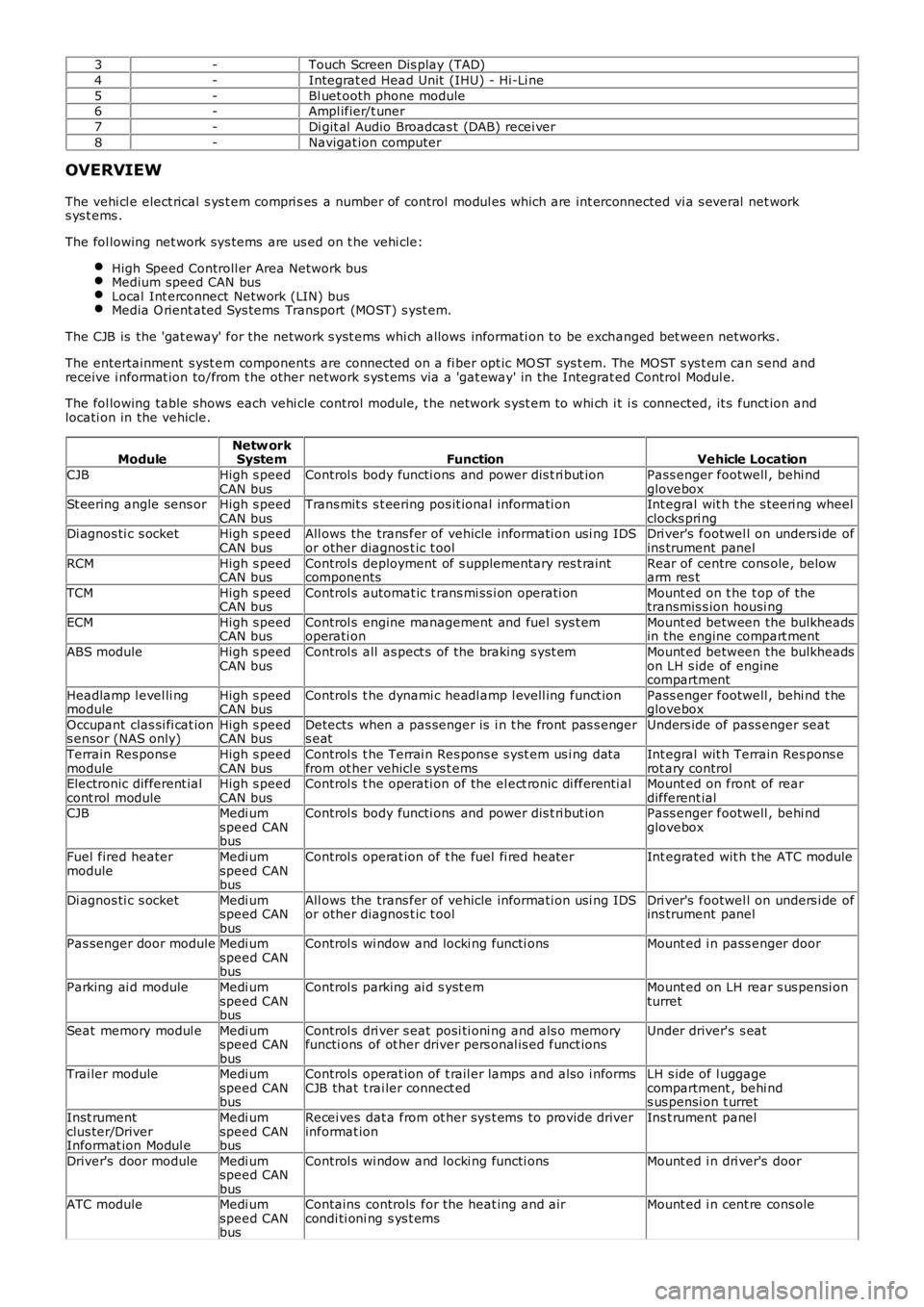

OVERVIEW

The vehi cl e elect rical s ys t em compri s es a number of control modul es which are int erconnected vi a s everal net works ys t ems .

The fol lowing net work sys tems are us ed on t he vehi cle:

High Speed Controll er Area Network busMedium speed CAN busLocal Int erconnect Network (LIN) busMedia O rient ated Sys tems Transport (MOST) s yst em.

The CJB is the 'gat eway' for the net work s yst ems whi ch allows informati on to be exchanged bet ween networks .

The entertainment s yst em components are connected on a fi ber opt ic MO ST sys t em. The MOST s ys t em can s end andreceive i nformat ion to/from t he other network s ys t ems via a 'gat eway' in the Integrat ed Control Modul e.

The fol lowing table shows each vehi cle control modul e, t he network s yst em to whi ch it i s connected, it s funct ion andlocati on in the vehicle.

ModuleNetw orkSystemFunctionVehicle Location

CJBHigh s peedCAN busControl s body functi ons and power dis t ri but ionPass enger footwell , behi ndgloveboxSt eering angle sens orHigh s peedCAN busTrans mit s s t eering pos it ional informati onInt egral wit h t he s teeri ng wheelclocks pri ngDi agnos ti c s ocketHigh s peedCAN busAll ows the trans fer of vehicle informati on usi ng IDSor other diagnos t ic t oolDri ver's footwel l on unders i de ofins trument panel

RCMHigh s peedCAN busControl s deployment of s upplementary res t raintcomponentsRear of centre cons ole, belowarm res t

TCMHigh s peedCAN busControl s automat ic t rans mi ss i on operati onMount ed on t he t op of thetransmis s ion housi ng

ECMHigh s peedCAN busControl s engine management and fuel sys t emoperati onMount ed between the bulkheadsin the engine compart ment

ABS moduleHigh s peedCAN busControl s all as pect s of the braking s yst emMount ed between the bulkheadson LH s ide of enginecompartment

Headlamp l evel li ngmoduleHigh s peedCAN busControl s t he dynami c headl amp l evell ing funct ionPass enger footwell , behi nd t heglovebox

Occupant clas si fi cat ions ensor (NAS only)High s peedCAN busDetects when a pas senger is i n t he front pas s engers eatUnders ide of pass enger seat

Terrain Res pons emoduleHigh s peedCAN busControl s t he Terrai n Res pons e s yst em us i ng dat afrom ot her vehicl e s ys t emsInt egral wit h Terrain Res pons erot ary controlElectronic different ialcont rol moduleHigh s peedCAN busControl s t he operati on of the el ect ronic di fferenti alMount ed on front of reardifferent ialCJBMedi umspeed CANbus

Control s body functi ons and power dis t ri but ionPass enger footwell , behi ndglovebox

Fuel fired heatermoduleMedi umspeed CANbus

Control s operat ion of t he fuel fi red heaterInt egrated wit h t he ATC module

Di agnos ti c s ocketMedi umspeed CANbus

All ows the trans fer of vehicle informati on usi ng IDSor other diagnos t ic t oolDri ver's footwel l on unders i de ofins trument panel

Pas senger door moduleMedi umspeed CANbus

Control s wi ndow and locki ng functi onsMount ed i n pass enger door

Parking ai d moduleMedi umspeed CANbus

Control s parking ai d s yst emMount ed on LH rear s us pensi onturret

Seat memory modul eMedi umspeed CANbus

Control s dri ver s eat posi ti oni ng and als o memoryfuncti ons of ot her driver pers onal is ed funct ionsUnder driver's s eat

Trai ler moduleMedi umspeed CANbus

Control s operat ion of t rail er lamps and als o i nformsCJB that t rai ler connect edLH s ide of l uggagecompartment , behi nds us pensi on t urret

Inst rumentclus ter/DriverInformat ion Modul e

Medi umspeed CANbus

Recei ves dat a from ot her sys t ems to provide driverinformat ionIns t rument panel

Driver's door moduleMedi umspeed CANbus

Control s wi ndow and locki ng functi onsMount ed i n dri ver's door

ATC moduleMedi umspeed CANbus

Contains controls for the heat ing and aircondi ti oni ng s ys t emsMount ed i n cent re cons ole

Page 2260 of 3229

Publi s hed: 11-May-2011

Instrument Panel and Console - Instrument Panel

Des cript ion and Operat ion

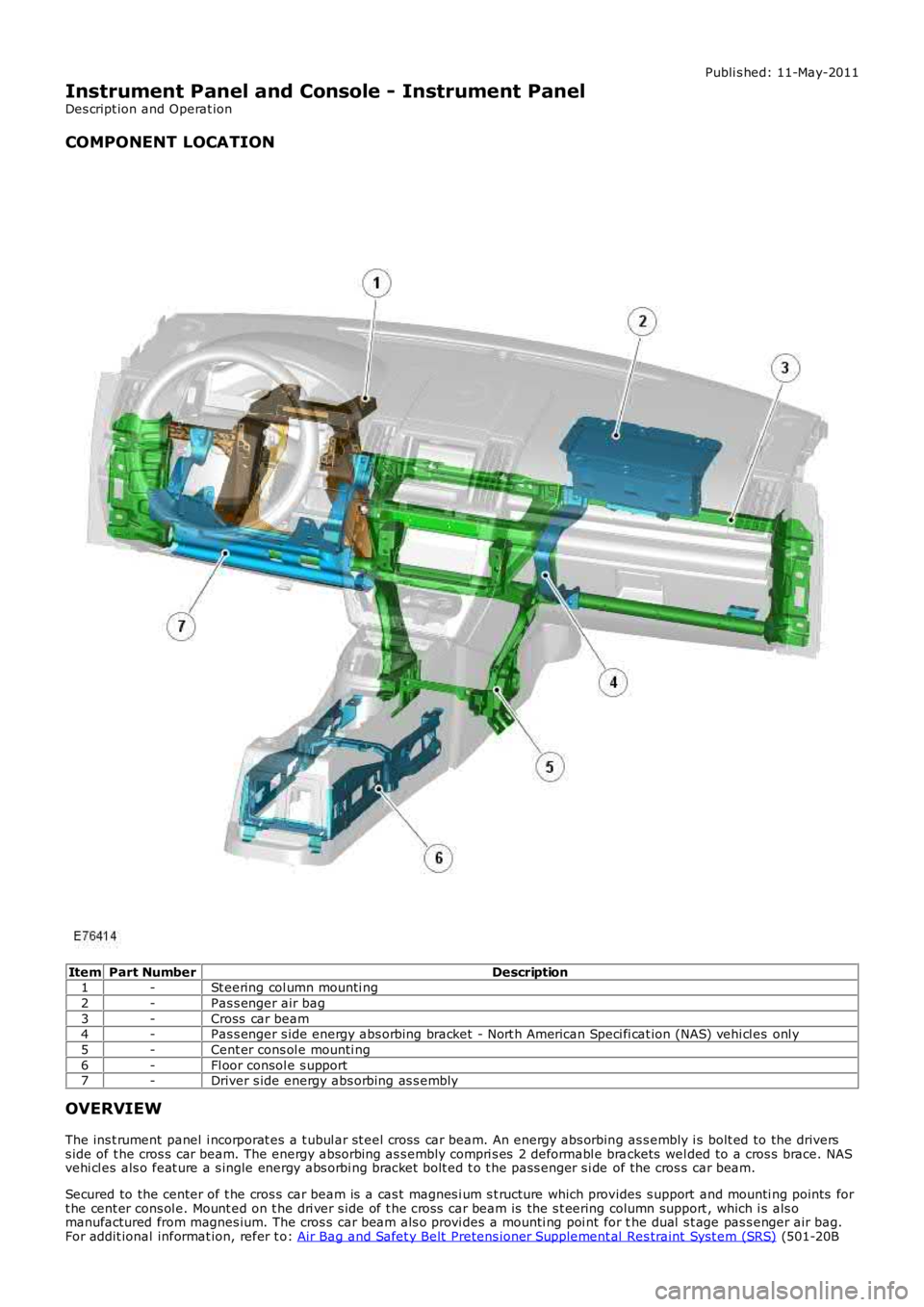

COMPONENT LOCATION

ItemPart NumberDescription1-St eering col umn mounti ng

2-Pas s enger air bag

3-Cross car beam4-Pas s enger s ide energy abs orbing bracket - Nort h American Speci fi cat ion (NAS) vehi cl es onl y

5-Cent er cons ol e mounti ng

6-Fl oor consol e s upport7-Driver s ide energy abs orbing as s embly

OVERVIEW

The ins t rument panel i ncorporat es a t ubul ar st eel cross car beam. An energy abs orbing as s embly i s bolt ed to the driverss ide of t he cros s car beam. The energy abs orbing as s embly compri s es 2 deformabl e brackets wel ded to a cros s brace. NASvehi cl es als o feat ure a s ingle energy abs orbi ng bracket bolt ed t o t he pass enger s i de of the cros s car beam.

Secured to the center of t he cros s car beam is a cas t magnes i um s t ructure which provides s upport and mounti ng points fort he cent er cons ol e. Mount ed on t he dri ver s ide of t he cros s car beam is the s t eering column support , which i s als omanufactured from magnes ium. The cros s car beam als o provi des a mounti ng poi nt for the dual s t age pas s enger air bag.For addit ional informat ion, refer t o: Air Bag and Safet y Belt Pretens ioner Supplement al Res traint Syst em (SRS) (501-20B

Page 2369 of 3229

The rear glas s panel i s fixed in pos i ti on and bonded t o t he roof openi ng panel frame us i ng a PU adhes ive. The forwardglas s panel i s dri ven into pos i ti on by a pair of heli xed cables . The helixed cables are abl e t o pus h or pul l the forward glas spanel i nt o t he requi red pos it ion.

The roof openi ng panel al so cont ai ns 2 i nt egral, manuall y operat ed sunbli nds and 2 drai n hoses . The drai n hoses areconnected t o t he cent er of the frame above t he B pi ll ars . The drain hos es run through the cant rail s and down t he C pi llarst o all ow water coll ect ed in the frame to escape.

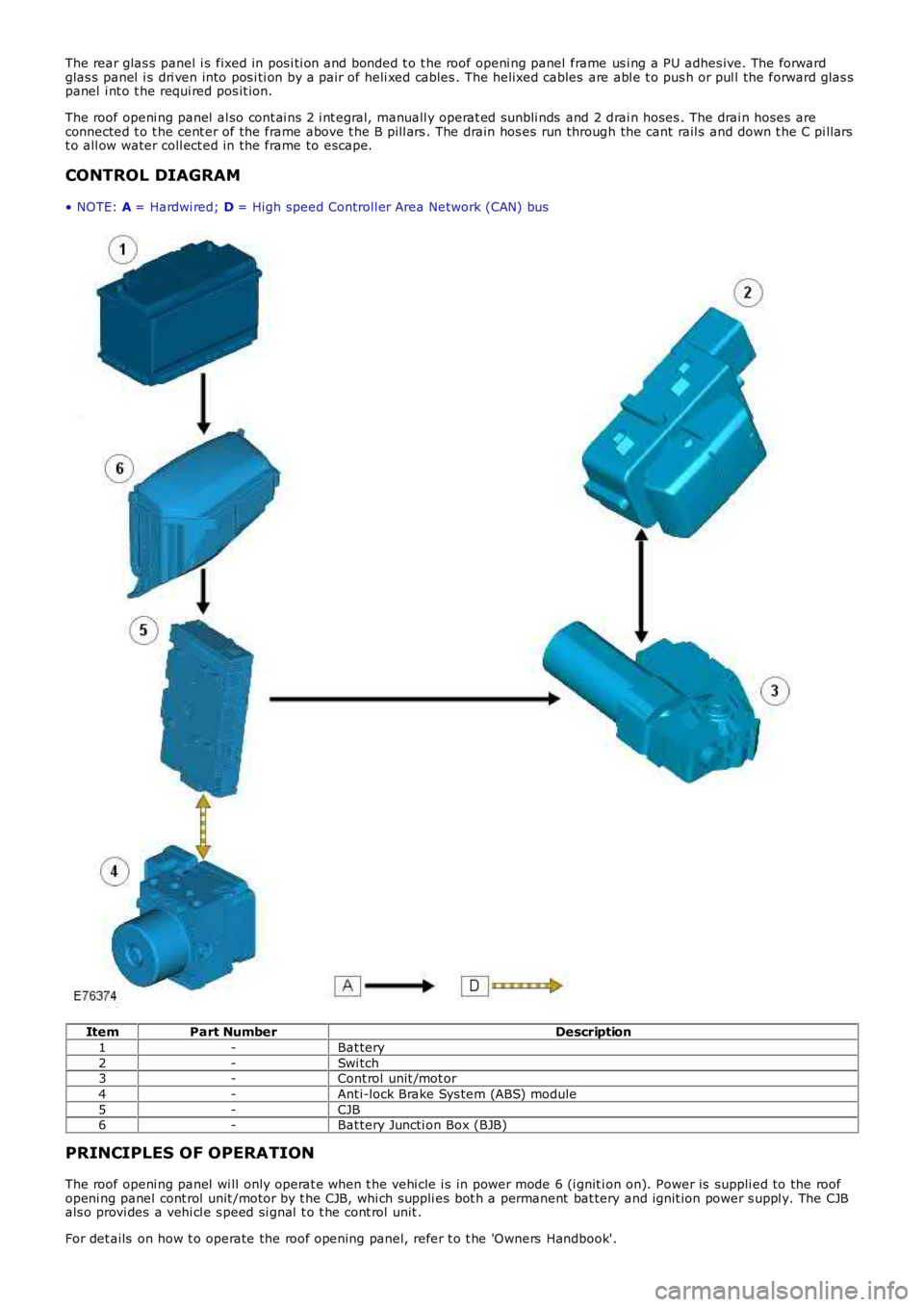

CONTROL DIAGRAM

• NOTE: A = Hardwi red; D = High speed Controll er Area Network (CAN) bus

ItemPart NumberDescription

1-Bat tery

2-Swi tch3-Cont rol unit /mot or

4-Ant i-lock Brake Sys tem (ABS) module

5-CJB6-Bat tery Juncti on Box (BJB)

PRINCIPLES OF OPERATION

The roof openi ng panel wi ll only operat e when t he vehi cle i s in power mode 6 (i gnit ion on). Power is suppli ed to the roofopeni ng panel cont rol unit /motor by t he CJB, whi ch suppli es bot h a permanent bat tery and ignit ion power s uppl y. The CJBals o provi des a vehi cl e s peed si gnal t o t he cont rol unit .

For det ails on how t o operate the roof opening panel, refer t o t he 'Owners Handbook'.

Page 2370 of 3229

Switch Inputs

The roof openi ng panel rocker s wit ch is mount ed in the roof cons ol e and i s provided 2 si gnal feeds by t he control unit .W hen t he s wit ch is in t he res t (cent ral ) pos it ion, both connect ions from the cont rol uni t are open ci rcuit . W hen t he swit chis pres sed t o open t he glas s panel , the si gnal feed from pin 4 of t he cont rol unit electrical connect or is provi ded a groundpath through t he s wit ch cont act s . W hen t he s wit ch is pres s ed t o clos e t he glas s panel , the s wi tch grounds t he s ignal feedfrom pi n 8 of t he cont rol unit el ect ri cal connector.

W hen t il t operati on is reques t ed, t he s wit ch grounds the si gnal feed from pi n 8 of the cont rol unit electrical connect or asdescribed for 'cl ose' operati on.

Anti-Trap

The roof openi ng panel mot or is cali brat ed to det ect a blockage t hat wil l prevent t he glas s panel from cl osi ng. The forcerequired t o clos e t he glas s panel on a st ati onary vehi cl e wi ll not exceed approximately 100 Newt ons (N). If t his l imit isreached, t he cont rol unit wi ll power the motor in the oppos it e direct ion t o reverse the pos it ion of t he glas s panel by 200mm.

The cont rol unit al so monit ors external forces which may i ncrease the force requi red t o clos e t he glas s panel . The cont rolunit bas es this fi gure on vehicle speed, rough road condit ions, and ext reme ambi ent ai r temperatures and may increas et he maximum force appl ied by t he mot or t o approximat ely 150 N if requi red.

Vehicle Speed Signal

The vehi cl e s peed s ignal i s us ed by the roof openi ng panel cont rol unit t o adjus t t he s ens it ivi ty of t he anti -t rap feature.This s ignal all ows the control uni t to take i nt o account wi nd res is t ance when clos ing the roof opening panel at vehicl es peeds hi gher t han 2.5 mph (4 kph).

The vehi cl e s peed s ignal originat es in t he ABS modul e, and i s broadcas t over the hi gh s peed CAN bus . The CJB convert st he vehi cl e s peed si gnal i nt o a pul sed vol tage s ignal for deli very t o the cont rol uni t. Thi s s ignal puls es at a rate of 8,000puls es per mil e (5,000 puls es per ki lomet er), and has a dut y cycl e of 50% on 50% off.

Calibration

If the bat tery is di sconnect ed, or t he power s upply i s int errupt ed, whils t t he s unroof is part ial ly open i t wil l need t o berecali brated.

Once the bat tery is reconnected, or the power s uppl y is res tored, recal ibrat e t he s unroof as foll ows:

Swit ch the ignit ion on.W i th the s unroof clos ed, press and releas e t he front of t he s wit ch. The s unroof wi ll move t o t he ti lt ed posi ti onready for cali brat ion.Pres s t he front of t he s unroof s wit ch, and hold for twent y s econds .Aft er twent y s econds t he sunroof wi ll begin t o move. Keep the front of t he s wit ch pres sed unt il t he s unroof hasful ly opened, t hen clos ed.Once the open/cl os e cycle has complet ed and the sunroof has s topped moving, rel eas e the s wi tch.

The s unroof can now be operated as normal.

Page 2476 of 3229

Opti mi zat ion of t he depl oyment rest rai nt devi ces and t he reducti on in pot enti al for ai r bag induced injuries .The s ignificant reduct ion i n pas senger ai r bag depl oyment s ; parti cul arl y when pass enger s eats are unoccupied.

There are s even s eparat e air bags, each des igned wit h a specific prot ect ion funct ion:

Dri ver and front pas senger air bags provide head and ches t prot ect ion for front occupant s .Dri ver and front pas senger si de air bags provide protecti on agai nst si de impact.Side ai r curtains provi de prot ect ion agains t head impact and rol l-over eject ion for bot h front and rear occupant s .A driver lower air bag provides protecti on to the driver's legs from the st eering col umn s upport st ruct ures.

In order to s upport t he SRS requi rement s, rest rai nt cont rol archit ect ure i s us ed compris ing the foll owi ng s yst ems orcomponents :

All elect ronic front and s ide cras h s ens ing and advanced res t rai nt s management.Dri ver ai r bag wit h t win st age inflator.Pass enger ai r bag wit h t win st age inflator.Dependi ng on market , a front pas s enger s eat:- occupant cl ass ificati on s ens i ng s ys t em, or- occupant det ect ion sens ing s ys tem.Safet y bel t buckle pret ens ioners .A s eat posi ti on s ens or on t he dri ver s eat.Dependi ng on market ; a pyrot echnic actuat or fit t ed to the s t eering column to provide i ncreas ed energy abs orpti on.

CONTROL DIAGRAM

• NOTE: A = Hardwi red; D = Hi gh s peed controller area net work (CAN) bus .

Page 2485 of 3229

A pretens ioner i s i nt egrat ed int o each front s afet y belt buckl e and att ached to a bracket on t he i nboard s ide of t he seat .The pret ens i oner pull s 80mm of s lack from the safet y belt t hrough a cable sys tem running parallel t o t he s eat rail . Thi st ightens t he front safety belt s duri ng a coll is ion t o ens ure t he occupants are s ecurely held in t heir s eats .

Each pretens ioner has a t ube contai ning propell ant and a pis ton. The pis t on is at t ached t o a s t eel cable, the oppos it e endof which i s att ached t o t he s afety bel t buckle. A squib in the bas e of the tube provi des an ignit ion s ource when t ri ggeredby a fire s ignal from t he RCM. On recei pt of a fi re s i gnal from the RCM, t he s qui b igni tes t he propell ant . The propell antproduces ni trogen gas that rapi dl y expands t o dri ve t he pis ton al ong the t ube, pul ling the cable and drawing t he buckl edownwards .

Steering Column Pyrotechnic Device

NAS market vehicles ; a pyrot echnic device i s fit ted t o t he s teering column t o provi de increas ed energy absorpti on to adri ver not weari ng a s afet y belt . If t he dri ver i s weari ng a s afet y belt and a cras h s i tuati on occurs, t he devi ce is notact ivat ed. Refer t o s t eering column sect ion for furt her informati on.

Page 2503 of 3229

Publi s hed: 11-May-2011

Body Repairs - General Information - Body Repairs

Des cript ion and Operat ion

General Information

Introduction

The body plays a s ignificant role in the i ncreas i ng trend of ever more rapi dl y changing model vari ant s . The differentcus t omer groups are s t rongly i nfl uenced by t he des i gn and s hape of t he body. At t he s ame t ime the s t abi li ty of t he bodyplays t he mos t important part i n ensuring pas senger and driver s afet y. Light weight cons truct ion, alt ernat ive mat erial s,compos i te materi als , plas ti cs and appropriat e joi ning proces ses are all des ign feat ures t hat charact eris e modern LandRover vehicle bodies .

In terms of manufacturing t echnology, modern s afet y cell bodi es can be produced al mos t wit hout any probl ems . LandRover guarant ee high qualit y s t andards by ens uri ng t hat mechanical s t rength propert ies are tried and t es ted i n numerouscomput er s imulat ions , crash tes t s, by t es ti ng materials and by employing s ophi s ti cated manufacturing t echnologies . In theevent of repai rs i t is vi tal t hat t he producti on qual it y s tandards are uphel d. This requires a well -equipped works hop, andplaces part icul ar emphas is on the qual ifi cat ions of t he works hop technicians. Up-to-date knowledge of currentmanufacturing t echnologies and conti nuous t rai ni ng on new repai r met hods and t echniques are vit al for high-quali ty bodyrepairs . The model -s peci fi c repair manuals and the general repair t echni ques provi de val uabl e s upport when undertakingbody repairs.

Always follow the repair ins t ructi ons publi s hed in t his manual. Fail ure t o obs erve this i nst ructi on can res ult i n s eri ousimpai rment of vehi cle s afet y. Al l s pecified s afet y requi rements must be met aft er the work has been carri ed out.

Vehicle design

T he body

The Freelander 2 body is manufact ured l ike a convent ional monocoque. Two monos i des are welded t o t he floor, roof andbulkheads , creati ng a s t rong, si ngl e s truct ure. Dual Phas e (DP), and Bake Hardened (BH), s t eel s are us ed i n t he s ide panelrei nforcements . DP s t eel i s als o us ed for t he rear of t he front si de member, for added st rength in front and s ide impacts .The roof s truct ure can accommodate a roof openi ng panel . W hen a s unroof is not fit ted, t he outer roof panel i s a s i ngl elarge s teel pres si ng wi th s t yled s wages to add st rengt h and prevent boomi ng.

The s afety of the driver and the pas s engers is paramount for every body des ign. There are two key safety as pect sin the body:

Safet y pas s enger cellCrumpl e zones

Safet y pas s enger cell

Stable pill ars , rocker panel and door profil es.Side i mpact protecti on in the doors .Doors are desi gned to open even i n t he event of ext reme deformati on.

Crumpl e zone

Dynamic abs orpti on of deforming forces .Prot ect ion of t he pass enger cell .

Vehicle Design