light LAND ROVER FRELANDER 2 2006 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 113 of 3229

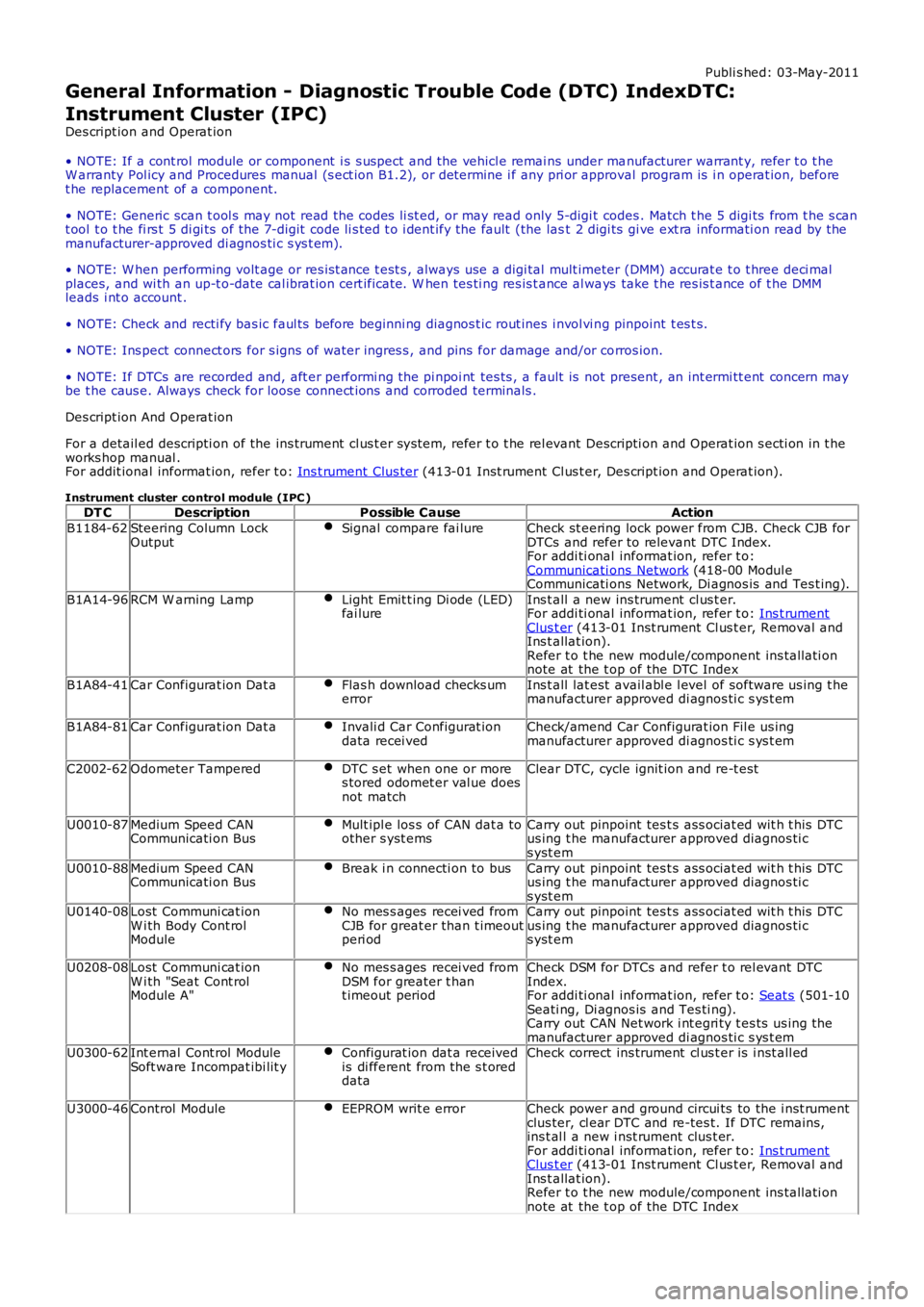

Publi s hed: 03-May-2011

General Information - Diagnostic Trouble Code (DTC) IndexDTC:

Instrument Cluster (IPC)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under manufacturer warrant y, refer t o t heW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval program is i n operat ion, beforet he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t codes . Match t he 5 digi ts from t he s cant ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the last 2 digi ts gi ve ext ra informati on read by themanufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the ins trument cl us t er sys tem, refer t o t he rel evant Descripti on and Operat ion s ecti on in t heworks hop manual .For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

Instrument cluster control module (IPC )DT CDescriptionPossible CauseAction

B1184-62Steering Column LockOutputSignal compare fai lureCheck st eering lock power from CJB. Check CJB forDTCs and refer to relevant DTC Index.For addi ti onal informat ion, refer t o:Communicati ons Network (418-00 Modul eCommunicati ons Network, Di agnos is and Tes t ing).

B1A14-96RCM W arning LampLight Emit t ing Di ode (LED)fai lureIns t all a new ins trument cl us t er.For addi ti onal informat ion, refer t o: Ins t rumentClus t er (413-01 Inst rument Cl us t er, Removal andIns t allat ion).Refer t o t he new module/component ins tall ati onnote at the t op of the DTC Index

B1A84-41Car Configurat ion Dat aFlas h download checks umerrorIns t all lat est avail abl e l evel of software us ing t hemanufacturer approved di agnos ti c s ys t em

B1A84-81Car Configurat ion Dat aInvali d Car Configurat iondata recei vedCheck/amend Car Configurat ion Fil e us ingmanufacturer approved di agnos ti c s ys t em

C2002-62Odometer TamperedDTC s et when one or mores tored odomet er val ue doesnot match

Clear DTC, cycle ignit ion and re-t est

U0010-87Medium Speed CANCommunicati on BusMult ipl e los s of CAN dat a toother s yst emsCarry out pinpoint tes t s ass ociat ed wit h t his DTCus ing t he manufacturer approved diagnos ti cs yst em

U0010-88Medium Speed CANCommunicati on BusBreak i n connecti on to busCarry out pinpoint tes t s ass ociat ed wit h t his DTCus ing t he manufacturer approved diagnos ti cs yst emU0140-08Lost Communi cat ionW i th Body Cont rolModule

No mes s ages recei ved fromCJB for great er than t imeoutperi od

Carry out pinpoint tes t s ass ociat ed wit h t his DTCus ing t he manufacturer approved diagnos ti cs yst em

U0208-08Lost Communi cat ionW i th "Seat Cont rolModule A"

No mes s ages recei ved fromDSM for greater t hant imeout period

Check DSM for DTCs and refer t o rel evant DTCIndex.For addi ti onal informat ion, refer t o: Seat s (501-10Seati ng, Di agnos is and Tes ti ng).Carry out CAN Net work i nt egri ty t es ts us ing themanufacturer approved di agnos ti c s ys t emU0300-62Int ernal Cont rol ModuleSoft ware Incompat ibi lit yConfigurat ion dat a receivedis di fferent from the s t oreddata

Check correct ins trument cl us t er is i nst all ed

U3000-46Control ModuleEEPROM writ e errorCheck power and ground circui ts to the i nst rumentclus ter, cl ear DTC and re-tes t. If DTC remains ,ins t al l a new i nst rument clus t er.For addi ti onal informat ion, refer t o: Ins t rumentClus t er (413-01 Inst rument Cl us t er, Removal andIns t allat ion).Refer t o t he new module/component ins tall ati onnote at the t op of the DTC Index

Page 151 of 3229

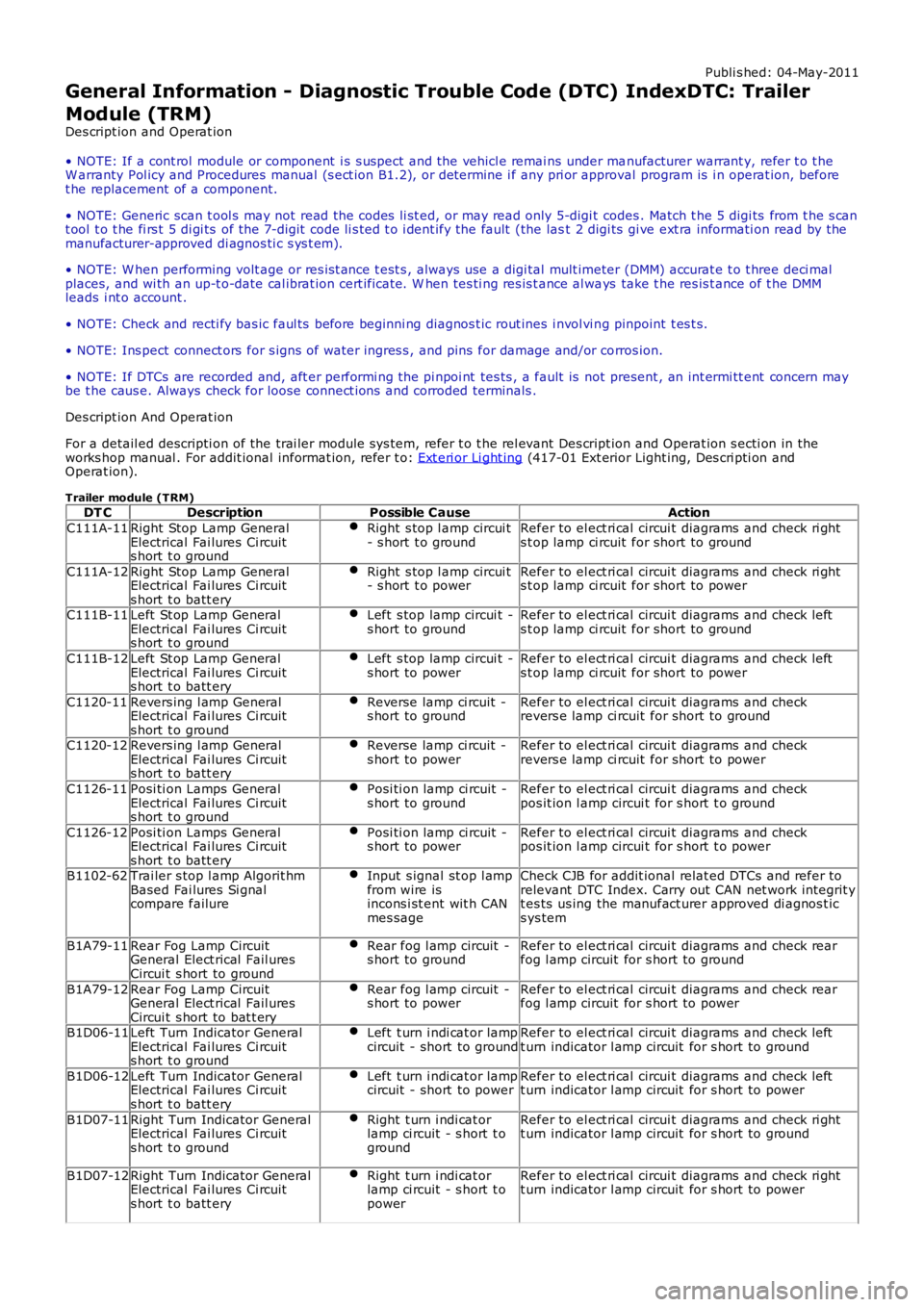

Publi s hed: 04-May-2011

General Information - Diagnostic Trouble Code (DTC) IndexDTC: Trailer

Module (TRM)

Des cript ion and Operat ion

• NOTE: If a cont rol module or component i s s uspect and the vehicl e remai ns under ma nufacturer warrant y, refer t o t he

W arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or appr oval program is i n operat ion, before

t he replacement of a component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only 5-digi t c odes . Match t he 5 digi ts from t he s can

t ool t o t he fi rs t 5 di gi ts of the 7-digit code li s ted t o i dent ify the fault (the las t 2 digi ts gi ve ext ra informati on read by the

manufacturer-approved di agnos ti c s ys t em).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci mal

places, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al wa ys take t he res is t ance of t he DMM

leads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi n g pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or co rros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is no t present , an int ermi tt ent concern may

be t he caus e. Always check for loose connect ions and corroded terminals .

Des cript ion And Operat ion

For a detail ed descripti on of the trai ler module sys tem, refer t o t he rel evant Des cr ipt ion and Operat ion s ecti on in the

works hop manual . For addit ional informat ion, refer t o: Ext eri or Li ght ing (417-01 Ext erior Light ing, Des cri pti on and

Operat ion).

Trailer module (TRM) DT C Description Possible Cause Action

C111A-11 Right Stop Lamp General

Electrical Fai lures Ci rcuit

s hort t o ground Right s top l amp circui t

- s hort t o ground Refer to el ect ri cal circui t diagrams and check ri ght

s t op lamp ci rcuit for short to ground

C111A-12 Right Stop Lamp General

Electrical Fai lures Ci rcuit

s hort t o batt ery Right s top l amp circui t

- s hort t o power Refer to el ect ri cal circui t diagrams and check ri ght

s t op lamp ci rcuit for short to power

C111B-11 Left St op Lamp General

Electrical Fai lures Ci rcuit

s hort t o ground Left s top lamp circui t -

s hort to ground Refer to el ect ri cal circui t diagrams and check left

s t op lamp ci rcuit for short to ground

C111B-12 Left St op Lamp General

Electrical Fai lures Ci rcuit

s hort t o batt ery Left s top lamp circui t -

s hort to power Refer to el ect ri cal circui t diagrams and check left

s t op lamp ci rcuit for short to power

C1120-11 Revers ing l amp General

Electrical Fai lures Ci rcuit

s hort t o ground Reverse lamp ci rcuit -

s hort to ground Refer to el ect ri cal circui t diagrams and check

revers e lamp ci rcuit for short to ground

C1120-12 Revers ing l amp General

Electrical Fai lures Ci rcuit

s hort t o batt ery Reverse lamp ci rcuit -

s hort to power Refer to el ect ri cal circui t diagrams and check

revers e lamp ci rcuit for short to power

C1126-11 Posi ti on Lamps General

Electrical Fai lures Ci rcuit

s hort t o ground Posi ti on lamp ci rcuit -

s hort to ground Refer to el ect ri cal circui t diagrams and check

pos it ion l amp circui t for s hort t o ground

C1126-12 Posi ti on Lamps General

Electrical Fai lures Ci rcuit

s hort t o batt ery Posi ti on lamp ci rcuit -

s hort to power Refer to el ect ri cal circui t diagrams and check

pos it ion l amp circui t for s hort t o power

B1102-62 Trai ler s top l amp Algorit hm

Based Fai lures Si gnal

compare failure Input s ignal st op l amp

from wire is

incons i st ent wit h CAN

mes sage Check CJB for addit ional relat ed DTCs and refer to

relevant DTC Index. Carry out CAN net work integrit y

t es ts us ing the manufact urer approved di agnos t ic

s ys tem

B1A79-11 Rear Fog Lamp Circuit

General Elect rical Fail ures

Circui t s hort to ground Rear fog l amp circuit -

s hort to ground Refer to el ect ri cal circui t diagrams and check rear

fog l amp circuit for s hort to ground

B1A79-12 Rear Fog Lamp Circuit

General Elect rical Fail ures

Circui t s hort to bat t ery Rear fog l amp circuit -

s hort to power Refer to el ect ri cal circui t diagrams and check rear

fog l amp circuit for s hort to power

B1D06-11 Left Turn Indicator General

Electrical Fai lures Ci rcuit

s hort t o ground Left t urn i ndi cat or lamp

circuit - short to ground Refer to el ect ri cal circui t diagrams and check left

t urn indicator l amp circuit for s hort to ground

B1D06-12 Left Turn Indicator General

Electrical Fai lures Ci rcuit

s hort t o batt ery Left t urn i ndi cat or lamp

circuit - short to power Refer to el ect ri cal circui t diagrams and check left

t urn indicator l amp circuit for s hort to power

B1D07-11 Right Turn Indicator General

Electrical Fai lures Ci rcuit

s hort t o ground Right t urn i ndi cat or

lamp ci rcuit - s hort t o

ground Refer to el ect ri cal circui t diagrams and check ri ght

t urn indicator l amp circuit for s hort to ground

B1D07-12 Right Turn Indicator General

Electrical Fai lures Ci rcuit

s hort t o batt ery Right t urn i ndi cat or

lamp ci rcuit - s hort t o

power Refer to el ect ri cal circui t diagrams and check ri ght

t urn indicator l amp circuit for s hort to power

Page 297 of 3229

If a fault occurs i n t he Terrai n Res pons e rot ary cont rol, al l rotary cont rol i con amber Light Emi tt ing Di odes (LED's ) wil l bet urned off and rotat ion of t he rot ary control i s ignored. The i ns t rument clus ter mess age cent er will di spl ay a mes s age'SY STEM FAULT SPECIAL PROGRAMS NOT AVAILABLE' when t he fault occurs , if t he fault i s pres ent and the driver att emptst o s el ect a s pecial program (if t he cont rol module is able to do thi s) or at t he next i gni ti on mode 2 (on) cycle.

The Terrai n Res pons e rotary cont rol and t he cont rol module are an i nt egral unit . If a fault occurs in eit her component , thewhole uni t wil l requi re replacement. ENSURE T HAT T HE FAULT IS WIT H T HE T ERRAIN RESPONSE CO NT ROL MO DULEAND NOT IN A SUB-SYST EM MODULE BEFO RE REPLACING T HE MODULE.

If a CAN faul t exi s ts and prevent s Terrai n Res pons e s yst em operat ion, all of t he Terrai n Res pons e rotary cont rol icon LED'swil l be il lumi nat ed and rot ati on of the rot ary cont rol i s ignored.

If the i nst rument clus ter does not receive a Terrain Res ponse s ys t em CAN mess age from the Terrain Res ponse cont rolmodule, t he mes sage 'SY STEM FAULT SPECIAL PROGRAMS NO T AVAILABLE' wi ll be dis played when t he faul t occurs and willbe repeat ed at every ignit ion mode 2 (on) cycl e.

User Error

The fol lowing incorrect us age of t he s yst em may be mi si nterpreted as a s ys t em fault :

Engi ne not running - Program changes and driver advi s ory mes s ages are only avail abl e wi th the engine runni ngSpeci al program change att empted wi th DSC or ABS acti ve (t his i ncl udes ABS cycling which is operat ional when HDCis bei ng used on s lippery or l oose surfaces)Speci al program change att empted wi th overheat condi ti on pres ent on the act ive on-demand coupling.

Page 409 of 3229

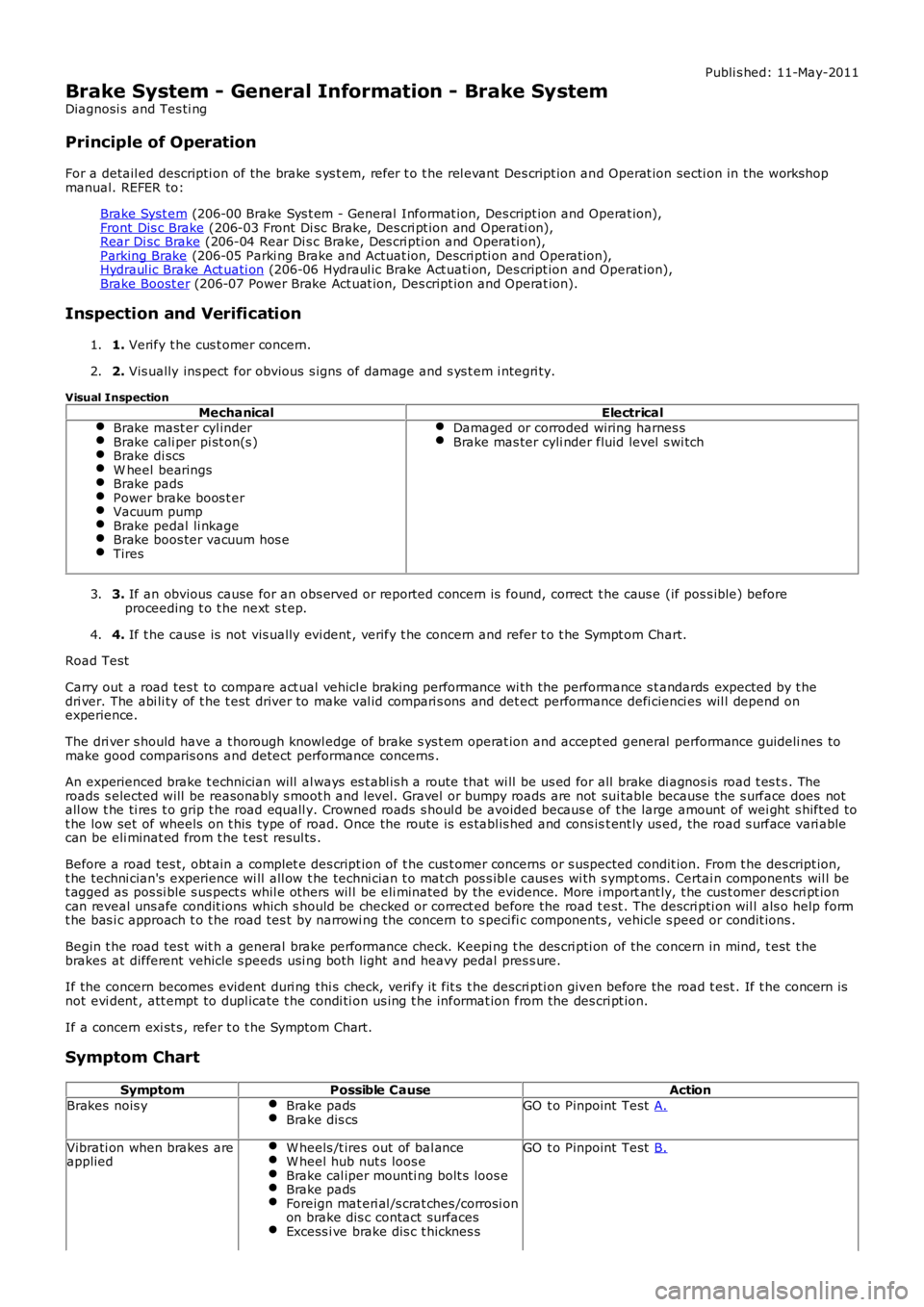

Publi s hed: 11-May-2011

Brake System - General Information - Brake System

Diagnosi s and Tes ti ng

Principle of Operation

For a detail ed descripti on of the brake s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshopmanual. REFER to:

Brake Syst em (206-00 Brake Sys t em - General Informat ion, Des cript ion and Operat ion),Front Dis c Brake (206-03 Front Di sc Brake, Des cri pt ion and Operati on),Rear Di sc Brake (206-04 Rear Di s c Brake, Des cri pti on and Operati on),Parking Brake (206-05 Parki ng Brake and Actuat ion, Descri pti on and Operat ion),Hydraul ic Brake Act uati on (206-06 Hydraul ic Brake Act uati on, Des cript ion and Operat ion),Brake Boost er (206-07 Power Brake Act uat ion, Des cript ion and Operat ion).

Inspection and Verification

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.2.

Visual Inspection

MechanicalElectricalBrake mast er cyl inderBrake cali per pi st on(s )Brake di scsW heel bearingsBrake padsPower brake boos t erVacuum pumpBrake pedal li nkageBrake boos ter vacuum hos eTires

Damaged or corroded wiring harnes sBrake mas ter cyli nder fluid level s wi tch

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep.3.

4. If t he caus e is not vis ually evi dent , verify t he concern and refer t o t he Sympt om Chart.4.

Road Test

Carry out a road tes t to compare act ual vehicl e braking performance wi th the performance s t andards expected by t hedri ver. The abi li ty of t he t est driver to make val id compari s ons and det ect performance defi cienci es wil l depend onexperience.

The dri ver s hould have a t horough knowl edge of brake s ys t em operat ion and accept ed general performance guideli nes tomake good comparis ons and detect performance concerns .

An experienced brake t echnician will al ways es t abl is h a route that wi ll be us ed for all brake di agnos is road t es t s . Theroads s elected will be reasonably s moot h and level. Gravel or bumpy roads are not sui table because the s urface does notall ow t he ti res t o grip t he road equall y. Crowned roads s houl d be avoided becaus e of t he large amount of wei ght s hifted tot he low set of wheels on t his type of road. Once the route is es tabl is hed and cons ist ent ly us ed, the road s urface vari ablecan be eli minat ed from t he t es t resul ts .

Before a road tes t, obt ain a compl et e des cript ion of t he cus t omer concerns or s uspected condit ion. From t he des cript ion,t he techni cian's experience wi ll all ow t he techni cian t o mat ch pos s ibl e caus es wi th s ympt oms. Certai n components wil l bet agged as pos si ble s us pect s whil e others wil l be eli minated by the evidence. More i mport ant ly, t he cus t omer des cri pt ioncan reveal uns afe condit ions which s hould be checked or correct ed before the road t est . The descri pti on wil l als o help formt he bas i c approach t o t he road tes t by narrowi ng t he concern t o s peci fi c components , vehicle s peed or condit ions .

Begin t he road tes t wit h a general brake performance check. Keepi ng t he des cri pti on of the concern in mind, t est t hebrakes at different vehicle s peeds usi ng both light and heavy pedal pres s ure.

If the concern becomes evident duri ng thi s check, verify it fit s t he descri pti on given before the road t est . If t he concern isnot evi dent , att empt to dupl icate t he condi ti on us ing t he informat ion from the des cri pt ion.

If a concern exi st s , refer t o t he Symptom Chart.

Symptom Chart

SymptomPossible CauseAction

Brakes nois yBrake padsBrake dis csGO t o Pinpoint Test A.

Vibrati on when brakes areappliedW heels /t ires out of bal anceW heel hub nut s loos eBrake cal iper mounti ng bolt s loos eBrake padsForeign mat eri al /s crat ches /corrosi onon brake dis c contact surfacesExcess i ve brake dis c t hicknes s

GO t o Pinpoint Test B.

Page 416 of 3229

brake boos ter.

5. Operate the engine for a minimum of 10 s econds at a fast i dle. Stop the engine and al low t he vehicle t o s t andfor 10 mi nut es. Then, appl y the brake pedal wi th approxi mately 89 N (20lb) of force. The pedal feel (brakeappli cat ion) s houl d be t he s ame as t hat not ed wit h t he engine runni ng. If the brake pedal feel s hard (no poweras s is t), ins t al l a new valve and t hen repeat t he tes t. If t he brake pedal s t ill feels hard, i ns t all a new brakeboos ter. If t he brake pedal movement feel s s pongy, bleed t he brake s ys t em.REFER t o: Brake Syst em Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ) /Brake Sys t em Pres s ure Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ).

5.

Brake Master Cylinder

Us ual ly, t he fi rs t and s tronges t indicat or of anything wrong i n t he brake s ys t em i s a feeling through t he brake pedal. Indiagnosi ng the condit ion of t he brake mas t er cyli nder, check pedal feel as evidence of a brake concern. Check for brakewarni ng lamp ill uminat ion and t he brake fluid level i n t he brake mas t er cyli nder reservoi r.

Normal Condit ions

The fol lowing condit ions are cons idered normal and are not i ndi cat ions t hat t he brake mast er cyl inder i s i n need of repair.

Modern brake sys tems are des igned t o produce a pedal effort that is not as hard as in the pas t . Compl aint s of lightpedal effort s s houl d be compared t o t he pedal efforts of another vehi cl e of t he s ame model and year.The fl uid l evel wi ll fal l wit h brake pad wear.

Abnormal Condi ti ons

Changes i n t he brake pedal feel or brake pedal travel are indicators t hat s omet hi ng coul d be wrong in the brake sys tem.The diagnost ic procedure and techni ques us e brake pedal feel , warning i ndi cat or il lumi nat ion and l ow brake flui d level asindicat ors t o diagnosi ng brake s yst em concerns . The foll owing condi ti ons are consi dered abnormal and indi cat e t hat t hebrake mas t er cyli nder i s in need of repai r:

• NOTE: Pri or to carrying out any diagnosi s , ens ure the brake sys tem warni ng indicator i s functi onal .

Brake pedal goes down fast . This could be caus ed by an external or int ernal leak.Brake pedal goes down s l owl y. Thi s coul d be caused by an int ernal or external l eak.Brake pedal is l ow or feels spongy. Thi s condit ion may be caus ed by no fl ui d i n the brake mas ter cylinder, reservoi rcap vent holes cl ogged or air i n t he hydraul ic s ys tem.Brake pedal effort is excess ive. This may be caus ed by a bi nd or obs t ructi on in the pedal/li nkage, a faul tynon-ret urn val ve, boost er or ins ufficient boos t er vacuum.Rear brakes lock up during light pedal force. Thi s may be caus ed by damaged brake pads , a parti ally appl ied parkingbrake, a damaged ABS s ens or or bearing fail ure.Brake pedal effort errat ic. This condit ion could be caus ed by the brake boos t er or incorrectl y ins tal led brake pads .Brake warning i ndi cat or is on. This may be caus ed by low fl uid l evel or fl oat as s embly damaged.

Non Pressure Leaks

Any reduced fl uid volume in t he brake mast er cyl inder res ervoi r may be caused by two types of none pres sure externalleaks .

Type 1: An ext ernal leak may occur at the brake mast er cyl inder res ervoir cap because of incorrect posi ti oning of t hegasket and cap. Repos it ion cap and gasket .

Type 2: An ext ernal leak may occur at the brake mast er cyl inder res ervoir mounti ng seal s. Repair s uch a l eak by ins tall ingnew s eals and make s ure that t he brake mas t er cyli nder reservoi r ret ai ning bolt i s correct ly i nst all ed.

Page 500 of 3229

1

2

Publi s hed: 11-May-2011

Anti-Lock Control - Anti-Lock Control

Diagnosi s and Tes ti ng

Principles of Operation

For a detail ed descripti on of the Ant i-lock Braking Sys t em (ABS), refer to the relevant Des cri pt ion and Operati on s ect ion i nt he works hop manual . REFER t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

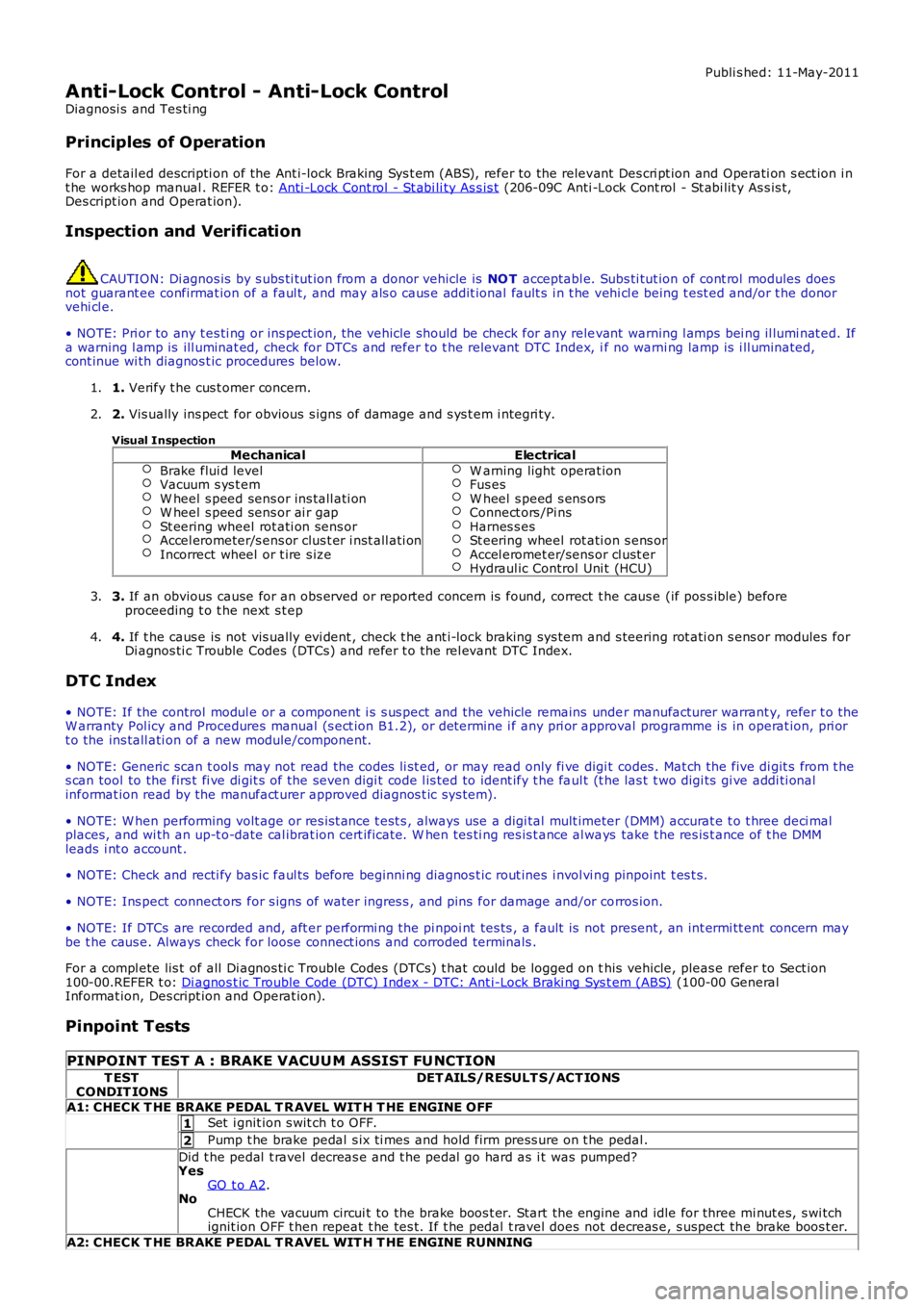

Inspection and Verification

CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is NO T acceptabl e. Subs ti tut ion of cont rol modules doesnot guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he vehi cl e being t est ed and/or t he donorvehi cl e.

• NOTE: Pri or to any t es ti ng or ins pect ion, the vehicle should be check for any relevant warning l amps bei ng il lumi nat ed. Ifa warning l amp is ill uminat ed, check for DTCs and refer to t he relevant DTC Index, if no warni ng lamp is i ll uminated,cont inue wi th diagnos t ic procedures below.

1. Verify t he cus t omer concern.1.

2. Vis ually ins pect for obvious s igns of damage and s ys t em i ntegri ty.

Visual InspectionMechanicalElectrical

Brake flui d levelVacuum s ys t emW heel s peed sens or ins tall ati onW heel s peed sens or ai r gapSt eering wheel rot ati on sens orAccel erometer/s ens or clus t er i nst all ati onIncorrect wheel or t ire s ize

W arning light operat ionFus esW heel s peed s ens orsConnect ors /Pi nsHarnes s esSt eering wheel rot ati on s ens orAccel eromet er/sens or cl ust erHydraul ic Control Uni t (HCU)

2.

3. If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) beforeproceeding t o t he next s t ep3.

4. If t he caus e is not vis ually evi dent , check t he ant i-lock braking sys tem and s teering rot ati on s ens or modules forDi agnos ti c Trouble Codes (DTCs) and refer t o t he rel evant DTC Index.4.

DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains under manufacturer warrant y, refer t o theW arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or approval programme is in operat ion, pri ort o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digit codes . Mat ch the five di git s from t hes can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he faul t (t he las t t wo digi ts gi ve addi ti onalinformat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci malplaces, and wi th an up-t o-date cal ibrat ion cert ificate. W hen tes ti ng res is t ance al ways take t he res is t ance of t he DMMleads i nt o account .

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi ng pinpoint t es t s.

• NOTE: Ins pect connect ors for s igns of water ingres s , and pins for damage and/or corros ion.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is not present , an int ermi tt ent concern maybe t he caus e. Always check for loose connect ions and corroded terminals .

For a compl ete lis t of all Di agnos ti c Trouble Codes (DTCs) t hat could be logged on this vehicle, pleas e refer to Sect ion100-00.REFER t o: Di agnos t ic Trouble Code (DTC) Index - DTC: Ant i-Lock Braki ng Sys t em (ABS) (100-00 GeneralInformat ion, Des cript ion and Operat ion).

Pinpoint Tests

PINPOINT TEST A : BRAKE VACUU M ASSIST FU NCTION

T ESTCONDIT IONSDET AILS/RESULT S/ACT IO NS

A1: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE OFF

Set i gnit ion s wit ch t o OFF.

Pump t he brake pedal s ix ti mes and hold firm press ure on t he pedal .

Did t he pedal t ravel decreas e and t he pedal go hard as i t was pumped?YesGO t o A2.NoCHECK the vacuum circui t to the brake boos t er. Start the engine and idle for three mi nut es, s wi tchignit ion OFF t hen repeat t he tes t. If t he pedal t ravel does not decreas e, s uspect the brake boos t er.

A2: CHECK T HE BRAKE PEDAL T R AVEL WIT H T HE ENGINE RUNNING

Page 588 of 3229

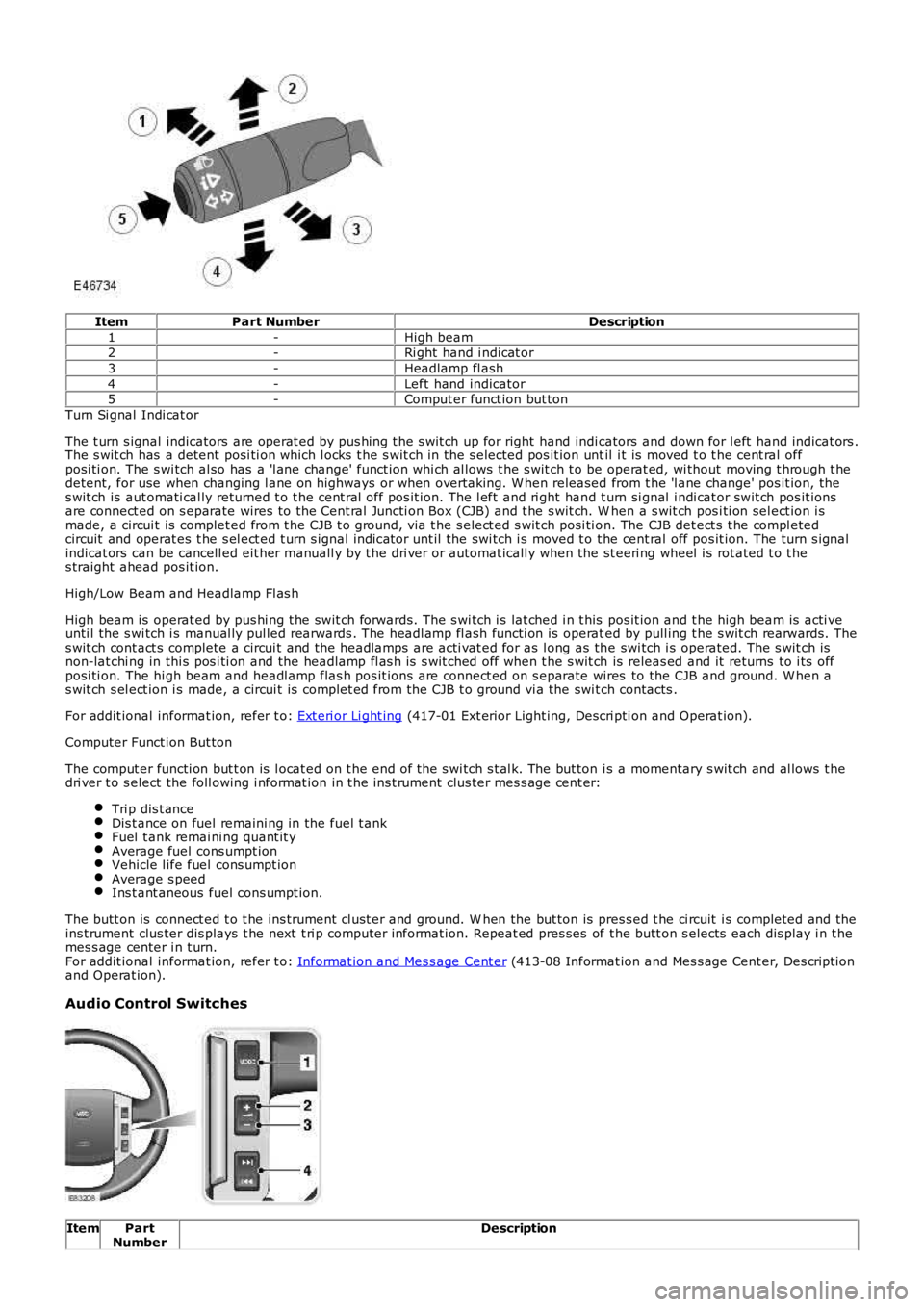

ItemPart NumberDescription

1-High beam2-Ri ght hand i ndicat or

3-Headlamp fl ash

4-Left hand indicator5-Comput er funct ion but ton

Turn Si gnal Indi cat or

The t urn s ignal indicators are operat ed by pus hing t he s wit ch up for right hand indicators and down for l eft hand indicat ors .The s wit ch has a detent posi ti on which l ocks t he s wit ch in the s elected pos it ion until i t is moved t o t he cent ral offposi ti on. The s wi tch al so has a 'l ane change' funct ion whi ch al lows t he s wit ch t o be operat ed, wi thout moving t hrough t hedetent, for use when changing l ane on highways or when overtaking. W hen released from t he 'l ane change' pos it ion, thes wit ch is aut omati cal ly returned t o t he cent ral off pos it ion. The l eft and ri ght hand t urn si gnal i ndi cat or swit ch pos it ionsare connect ed on s eparate wires to the Cent ral Juncti on Box (CJB) and t he s wit ch. W hen a s wit ch pos i ti on sel ect ion i smade, a circui t is complet ed from t he CJB t o ground, vi a t he s elect ed s wit ch posi ti on. The CJB det ect s t he compl etedcircuit and operat es t he s el ect ed t urn s ignal indicator unt il the swi tch i s moved t o t he cent ral off pos it ion. The turn s ignalindicat ors can be cancell ed eit her manuall y by t he dri ver or automat icall y when t he st eeri ng wheel i s rot ated t o t hes traight ahead pos it ion.

High/Low Beam and Headlamp Fl as h

High beam is operat ed by pus hi ng t he swit ch forwards. The s wi tch i s lat ched i n t his pos it ion and t he high beam is acti veunti l the s wi tch i s manual ly pul led rearwards . The headl amp fl ash functi on is operated by pull ing t he s wit ch rearwards. Thes wit ch cont act s complete a circui t and the headlamps are acti vat ed for as l ong as the swi tch i s operated. The s wit ch isnon-lat chi ng in thi s pos i ti on and the headlamp fl as h is s wit ched off when t he s wit ch is releas ed and it returns to i ts offposi ti on. The hi gh beam and headl amp flas h pos it ions are connect ed on s eparate wires to the CJB and ground. W hen as wit ch s el ect ion i s made, a circui t is complet ed from the CJB t o ground vi a the swi tch contacts .

For addit ional informat ion, refer t o: Ext eri or Li ght ing (417-01 Ext erior Light ing, Descri pti on and Operat ion).

Computer Funct ion But ton

The comput er functi on but t on is l ocat ed on t he end of the s wi tch s t al k. The but ton is a momentary s wit ch and al lows t hedri ver t o s elect the foll owing i nformat ion in t he ins t rument clus ter mes s age cent er:

Tri p dis t anceDis t ance on fuel remaini ng in the fuel t ankFuel t ank remai ni ng quant it yAverage fuel cons umpt ionVehicle l ife fuel cons umpt ionAverage s peedIns t ant aneous fuel cons umpt ion.

The butt on is connect ed t o t he ins trument cl ust er and ground. W hen the but ton is pres s ed t he ci rcuit i s completed and theins t rument clus ter dis plays t he next t ri p computer informat ion. Repeat ed pres ses of t he butt on s elects each dis play i n t hemes s age center i n t urn.For addit ional informat ion, refer t o: Informat ion and Mes s age Cent er (413-08 Informat ion and Mes s age Cent er, Des cript ionand Operat ion).

Audio Control Switches

ItemPartNumberDescription

Page 606 of 3229

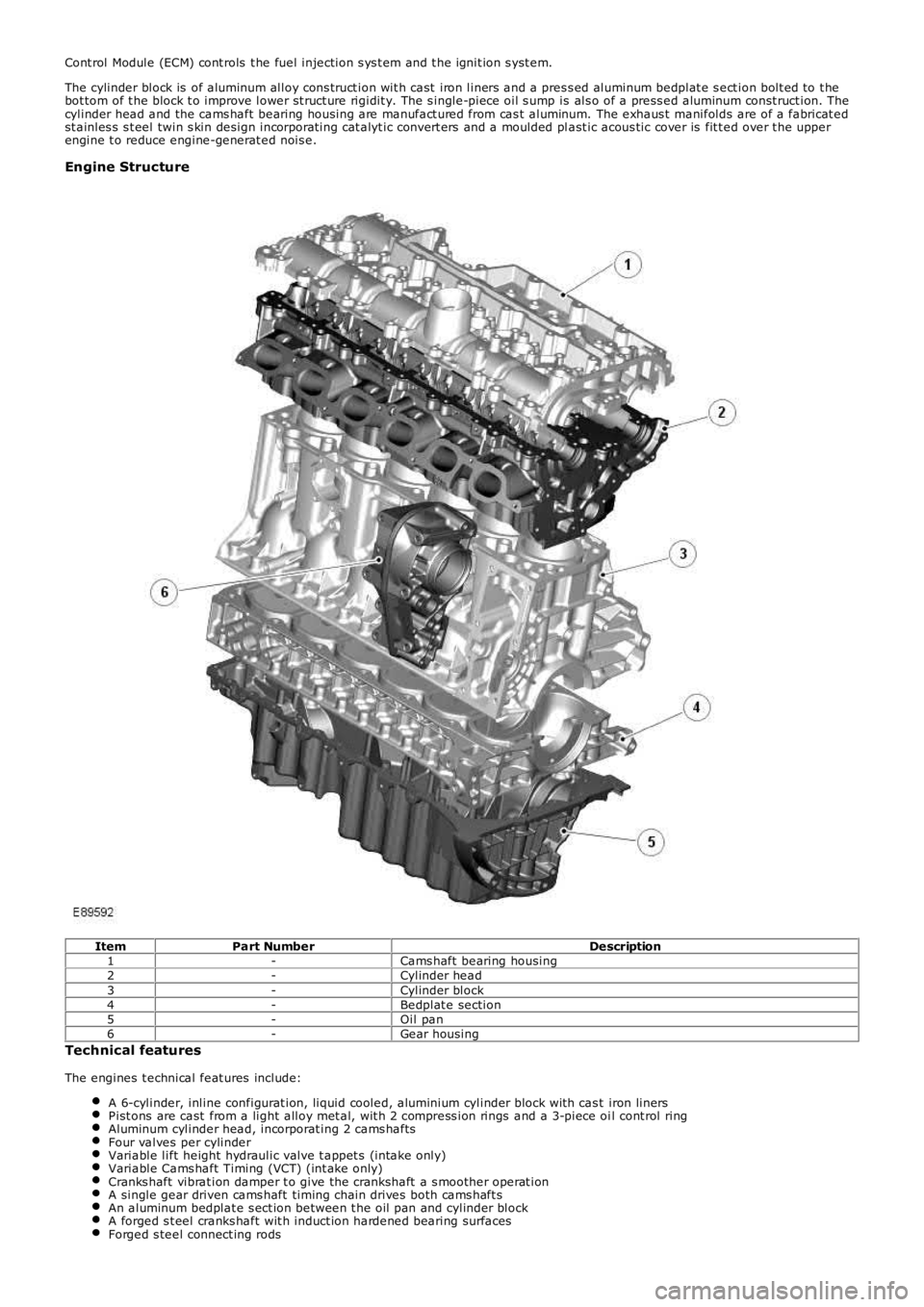

Cont rol Module (ECM) cont rols t he fuel injection s ys t em and t he ignit ion s yst em.

The cylinder block is of aluminum alloy cons truct ion wit h cast iron liners and a pres s ed aluminum bedplat e s ect ion bolt ed to t hebot tom of t he block t o improve lower st ruct ure rigidit y. The s ingle-piece oil s ump is als o of a press ed aluminum const ruct ion. Thecylinder head and the cams haft bearing housing are manufact ured from cas t aluminum. The exhaus t manifolds are of a fabricat edst ainles s s t eel twin s kin design incorporat ing cat alyt ic convert ers and a moulded plast ic acous tic cover is fit t ed over t he upperengine t o reduce engine-generat ed nois e.

Engine Structure

ItemPart NumberDescription1-Cams haft bearing housing2-Cylinder head3-Cylinder block4-Bedplat e section5-Oil pan6-Gear housing

Technical features

The engines t echnical feat ures include:

A 6-cylinder, inline configurat ion, liquid cooled, aluminium cylinder block wit h cast iron linersPist ons are cast from a light alloy met al, wit h 2 compress ion rings and a 3-piece oil cont rol ringAluminum cylinder head, incorporat ing 2 cams haftsFour valves per cylinderVariable lift height hydraulic valve t appet s (intake only)Variable Cams haft Timing (VCT) (int ake only)Cranks haft vibrat ion damper t o give the crankshaft a s moother operat ionA single gear driven cams haft timing chain drives both cams haft sAn aluminum bedplat e s ect ion between t he oil pan and cylinder blockA forged s t eel cranks haft wit h induct ion hardened bearing surfacesForged s teel connect ing rods

Page 609 of 3229

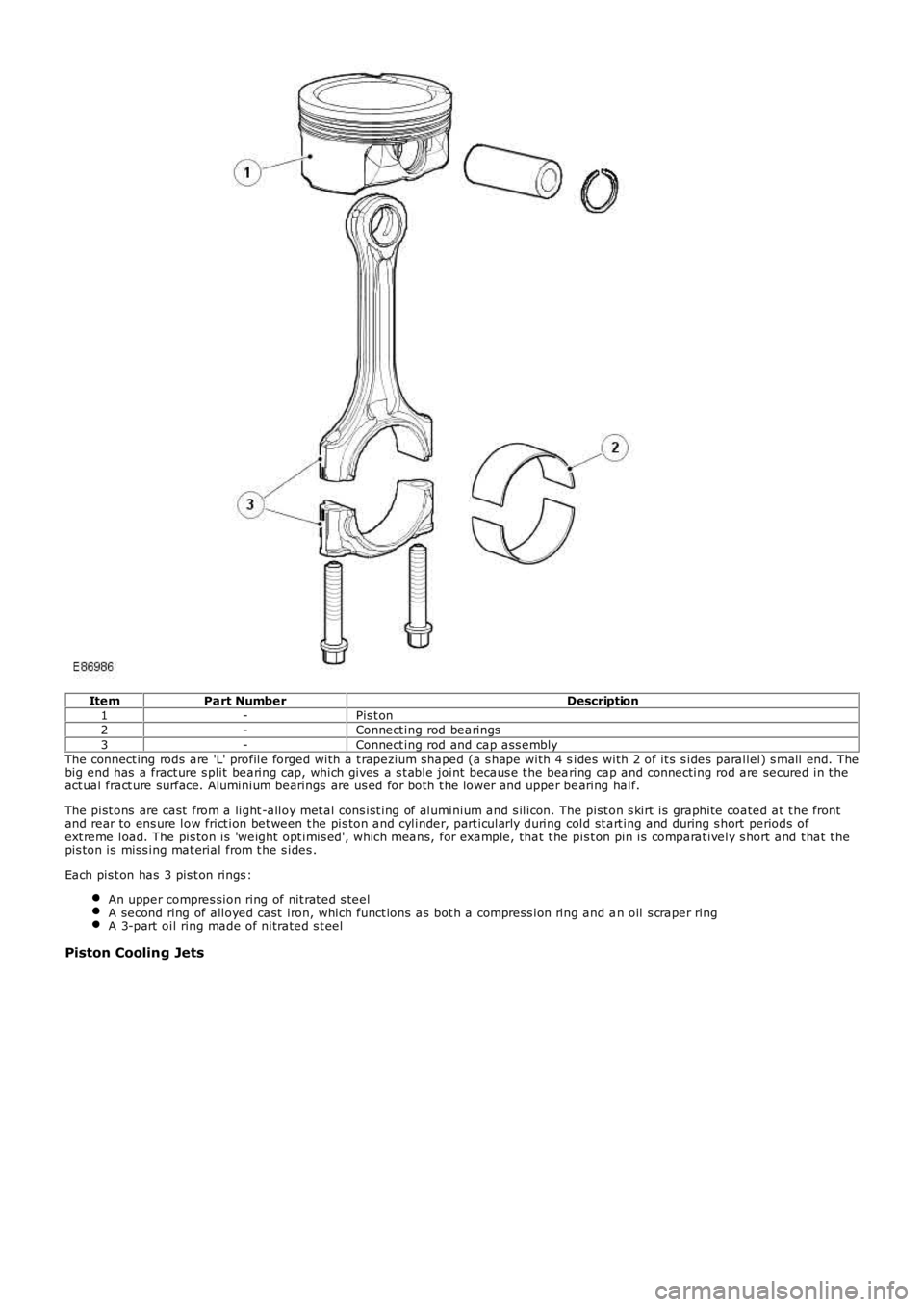

ItemPart NumberDescription1-Pis t on2-Connect ing rod bearings3-Connect ing rod and cap ass emblyThe connect ing rods are 'L' profile forged with a t rapezium shaped (a s hape with 4 sides with 2 of it s s ides parallel) s mall end. Thebig end has a fract ure s plit bearing cap, which gives a s t able joint becaus e t he bearing cap and connecting rod are secured in t heact ual fract ure surface. Aluminium bearings are us ed for both t he lower and upper bearing half.

The pist ons are cast from a light -alloy met al cons ist ing of aluminium and s ilicon. The pist on s kirt is graphite coated at t he frontand rear to ens ure low frict ion bet ween t he pis ton and cylinder, part icularly during cold st art ing and during s hort periods ofext reme load. The pis ton is 'weight opt imis ed', which means, for example, that t he pis t on pin is comparat ively s hort and t hat t hepis ton is miss ing mat erial from t he s ides .

Each pis t on has 3 pis t on rings :

An upper compres sion ring of nit rat ed s teelA second ring of alloyed cast iron, which funct ions as bot h a compress ion ring and an oil s craper ringA 3-part oil ring made of nitrated s t eel

Piston Cooling Jets

Page 617 of 3229

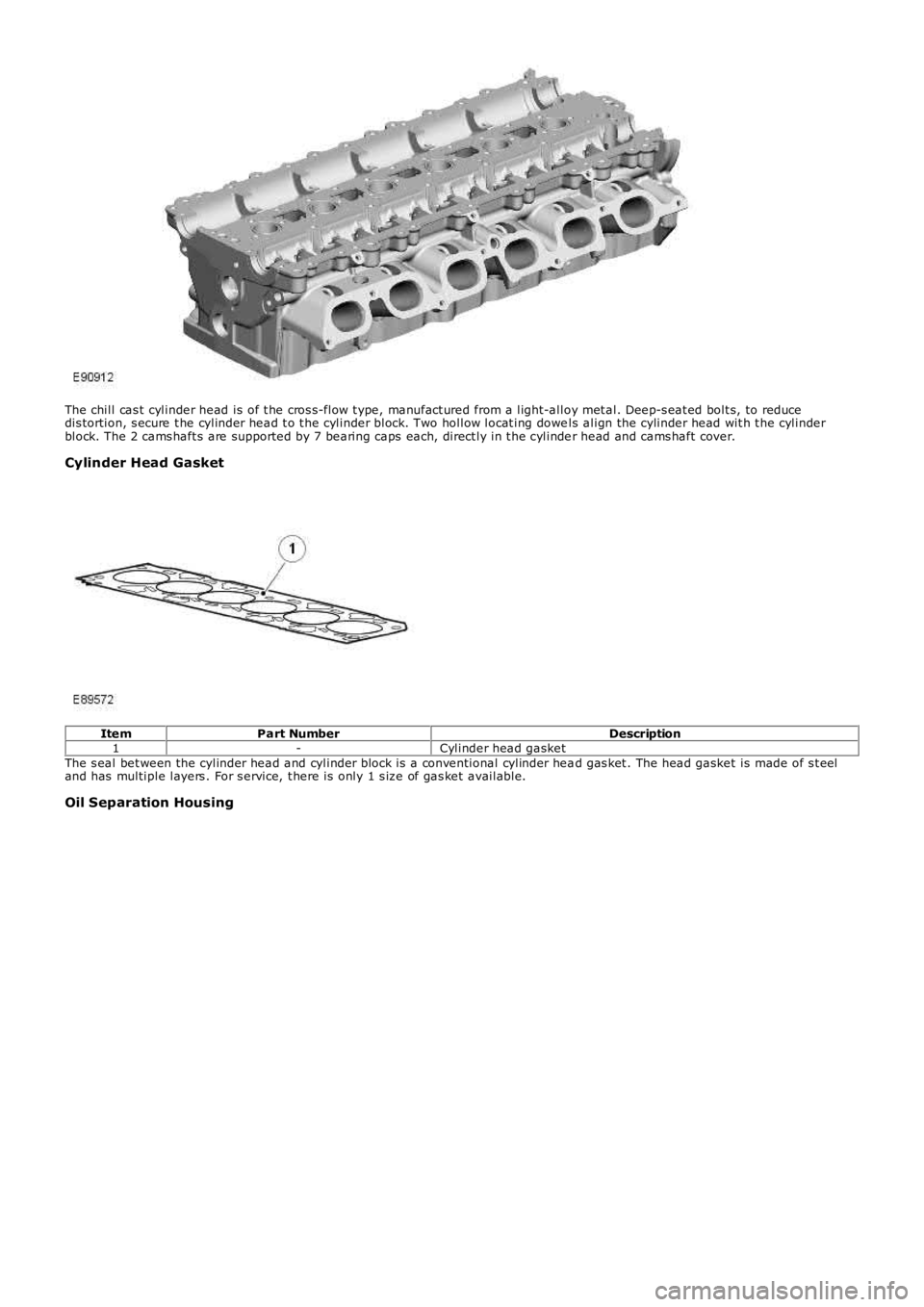

The chill cas t cylinder head is of t he cros s-flow t ype, manufact ured from a light-alloy met al. Deep-s eat ed bolt s, to reducedis tortion, s ecure t he cylinder head t o t he cylinder block. Two hollow locat ing dowels align the cylinder head wit h t he cylinderblock. The 2 cams haft s are supported by 7 bearing caps each, direct ly in t he cylinder head and cams haft cover.

Cylinder Head Gasket

ItemPart NumberDescription1-Cylinder head gasketThe s eal bet ween the cylinder head and cylinder block is a conventional cylinder head gas ket . The head gasket is made of s t eeland has multiple layers . For s ervice, t here is only 1 s iz e of gas ket available.

Oil Separation Housing