LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2551 of 3229

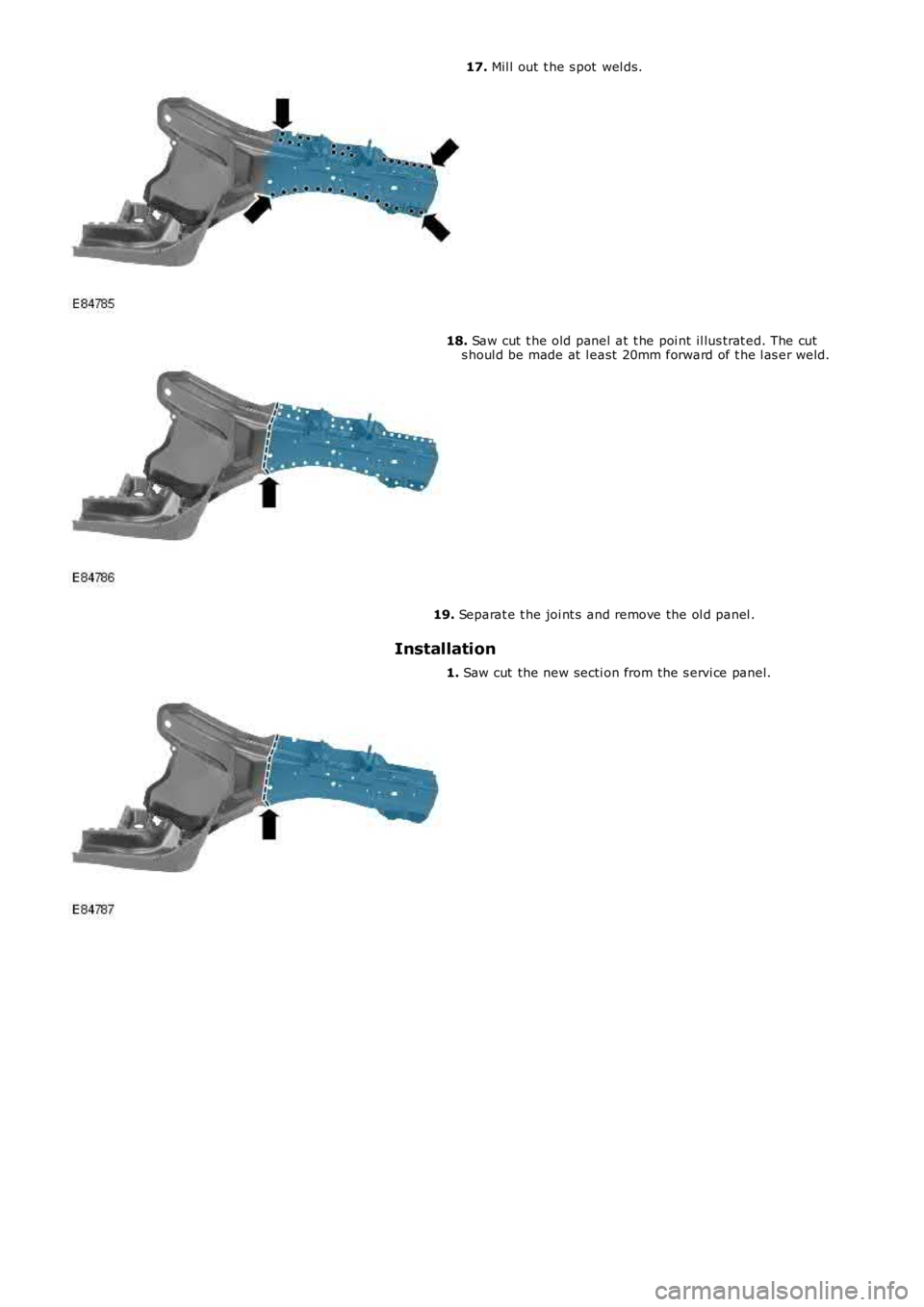

17. Mil l out t he s pot wel ds.

18. Saw cut t he old panel at t he poi nt il lus trat ed. The cuts houl d be made at l east 20mm forward of t he l as er weld.

19. Separat e t he joi nt s and remove the ol d panel .

Installation

1. Saw cut the new secti on from the s ervi ce panel.

Page 2552 of 3229

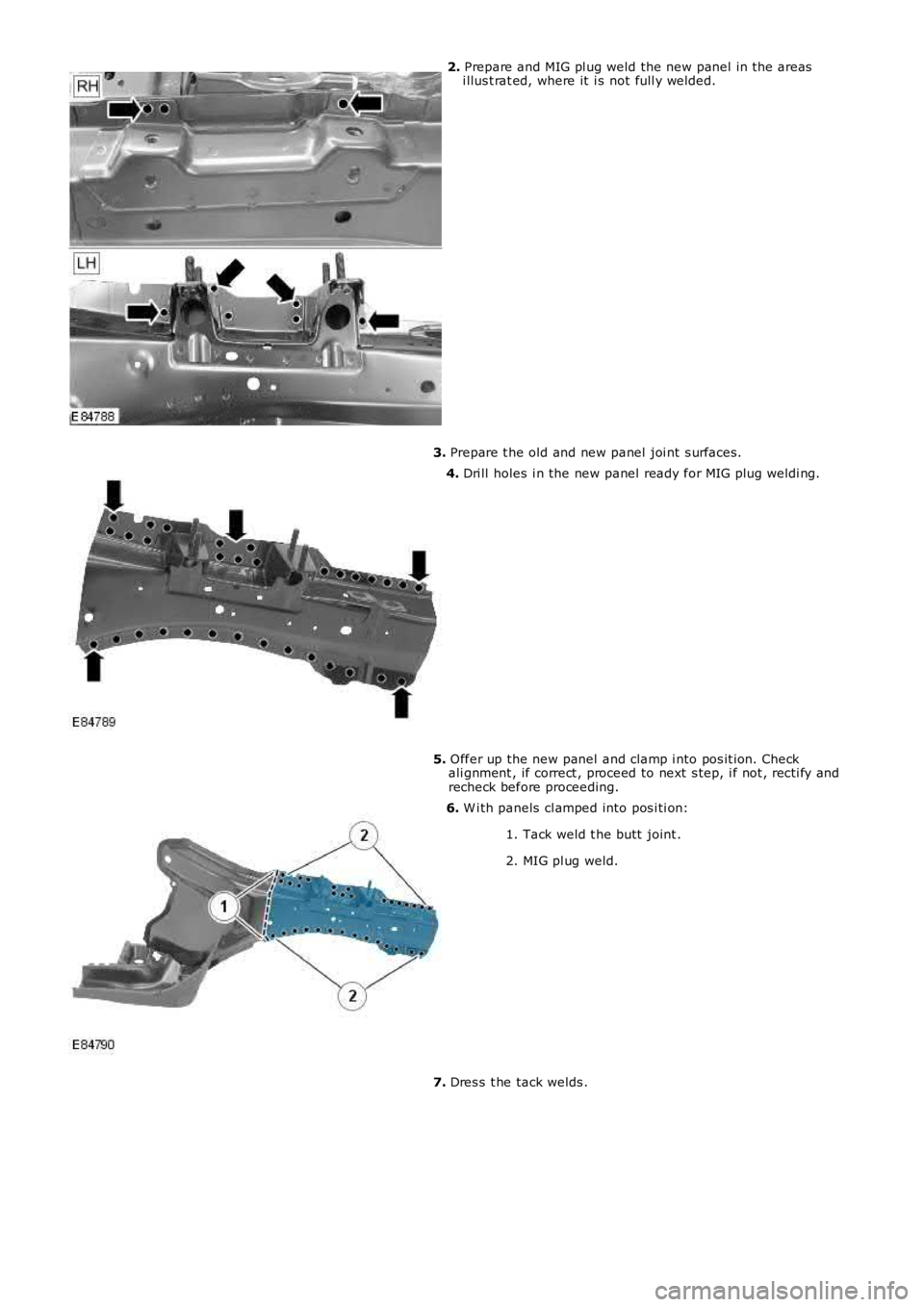

2. Prepare and MIG pl ug weld the new panel in the areasi llus t rat ed, where it i s not full y welded.

3. Prepare t he old and new panel joi nt s urfaces.

4. Dri ll holes i n the new panel ready for MIG plug wel di ng.

5. Offer up the new panel and clamp i nto pos it ion. Checkali gnment , if correct , proceed to next s tep, i f not , recti fy andrecheck before proceeding.

6. W i th panels cl amped into pos i ti on:

1. Tack weld t he butt joint .

2. MIG pl ug weld.

7. Dres s t he tack welds .

Page 2553 of 3229

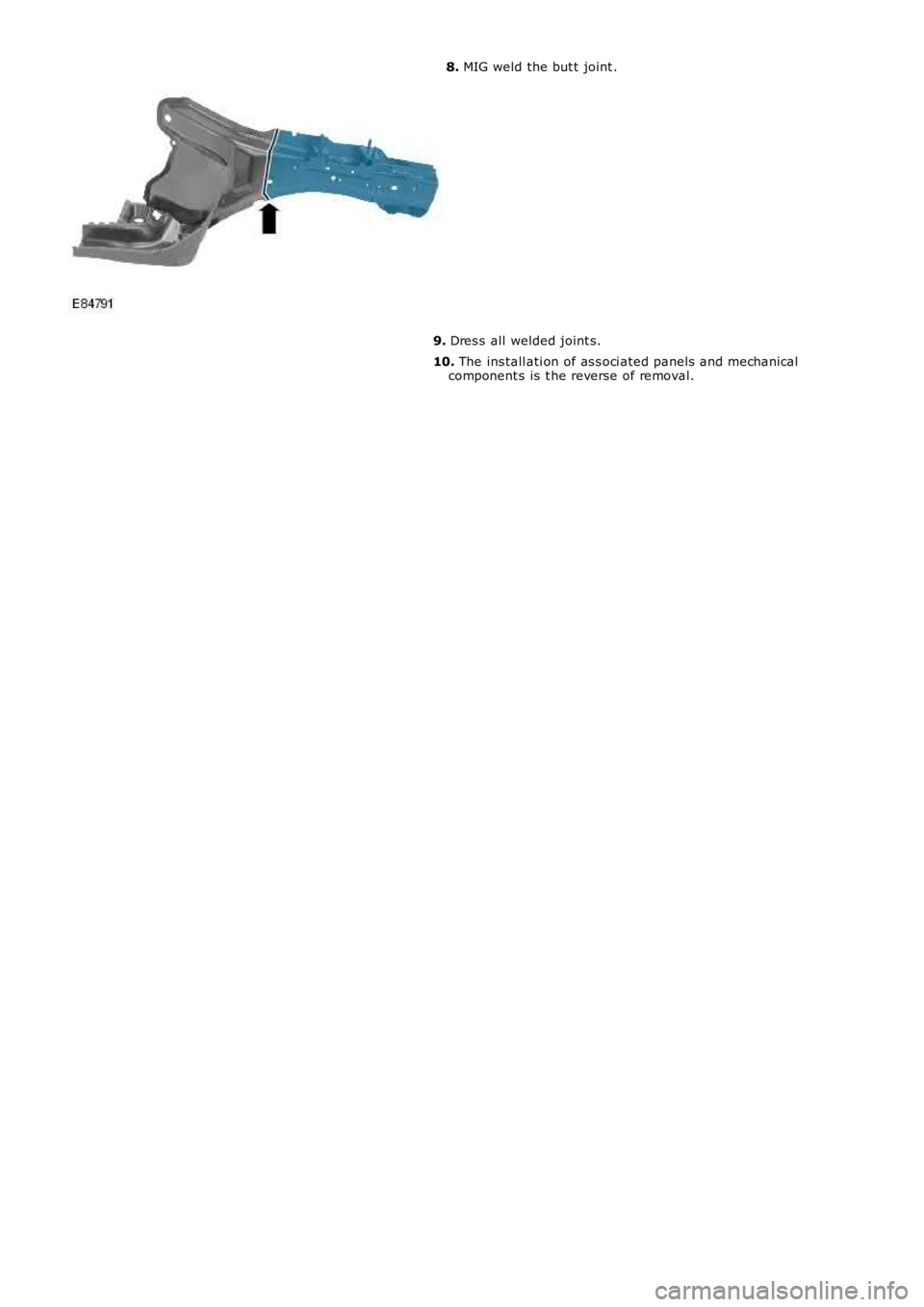

8. MIG weld the but t joint .

9. Dres s all welded joint s.

10. The ins tall ati on of as s oci ated panels and mechanicalcomponent s is t he reverse of removal.

Page 2554 of 3229

Publi s hed: 11-May-2011

Front End Sheet Metal Repairs - Suspension Top Mount

Removal and Inst all ati on

Removal

• NOTE: The s uspens ion t op mount is s ervi ced as a s eparate wel d-on panel.

• NOTE: The s ervice panel is not ful ly wel ded.

• NOTE: The panel i s s erviced les s i ts wel d s t uds

1. The sus pens i on top mount i s repl aced i n conjunct ion wi th:

Front bumper cover

Front bumper armature

Hood

Hood lat ch panel

Both front fenders

Fender apron upper panel

Fender apron panel

Ins t rument panel

• NOTE: It is al so neces sary t o remove t he engine and s us pens ion as an as s embly.

2. For addit ional informati on rel at ing to this repair procedurepleas e s ee t he foll owing:For addi ti onal informat ion, refer t o: Body and Frame (501-26Body Repai rs - Vehi cl e Speci fic Informat ion and ToleranceChecks , Descripti on and Operat ion) /Standard W orks hop Practi ces (100-00 General Informat ion,Des cript ion and Operat ion).

3. Remove the fender apron panel.For addi ti onal informat ion, refer t o: Fender Apron Panel(501-27 Front End Sheet Met al Repairs , Removal andIns t allat ion).

4. Remove the i nst rument panel.For addi ti onal informat ion, refer t o: Ins t rument Panel - TD42.2L Di esel (501-12 Ins t rument Panel and Cons ole, Removaland Ins t allat ion).

5. Remove the rocker panel i nner t ri m panel.

6. Remove the B-pill ar lower trim panel .For addi ti onal informat ion, refer t o: B-Pi ll ar Lower Tri m Panel(501-05 Int eri or Trim and Ornament ati on, Removal andIns t allat ion).

7. Remove the engine and front s uspens ion as an as s embly.

8. RH Side: Remove t he pedal box.

9. RH Side: Remove t he brake mas ter cylinder.For addi ti onal informat ion, refer t o: Brake Mas t er Cyli nder(206-06 Hydraulic Brake Actuati on, Removal and Ins t al lat ion).

10. Rel eas e and l ay as ide t he carpet and ins ul ati ng mat erial att he inner bul khead.

11. Rel eas e and l ay as ide t he wiring harnes s .

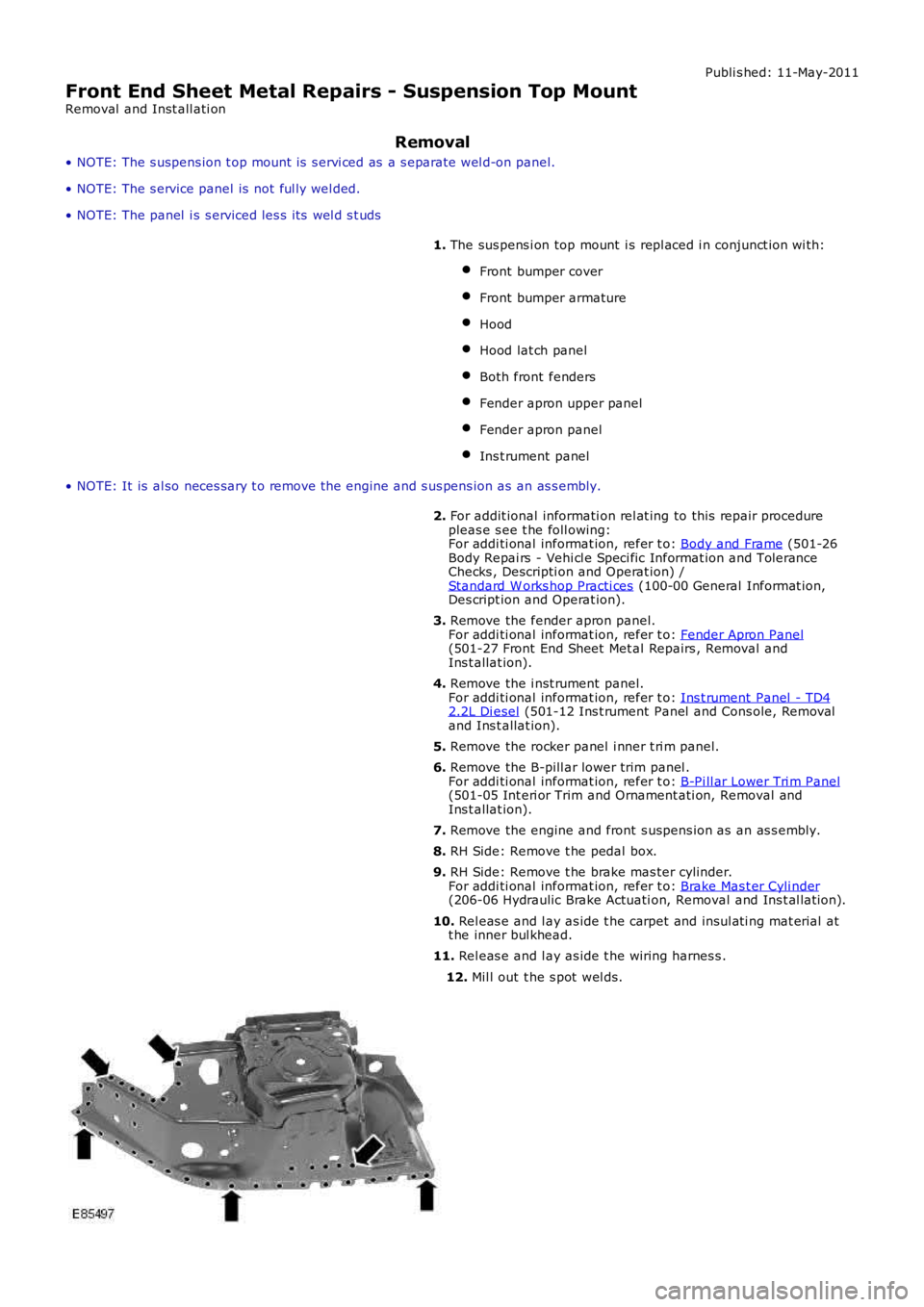

12. Mil l out t he s pot wel ds.

Page 2555 of 3229

13. Separat e t he joi nt s and remove the ol d panel .

Installation

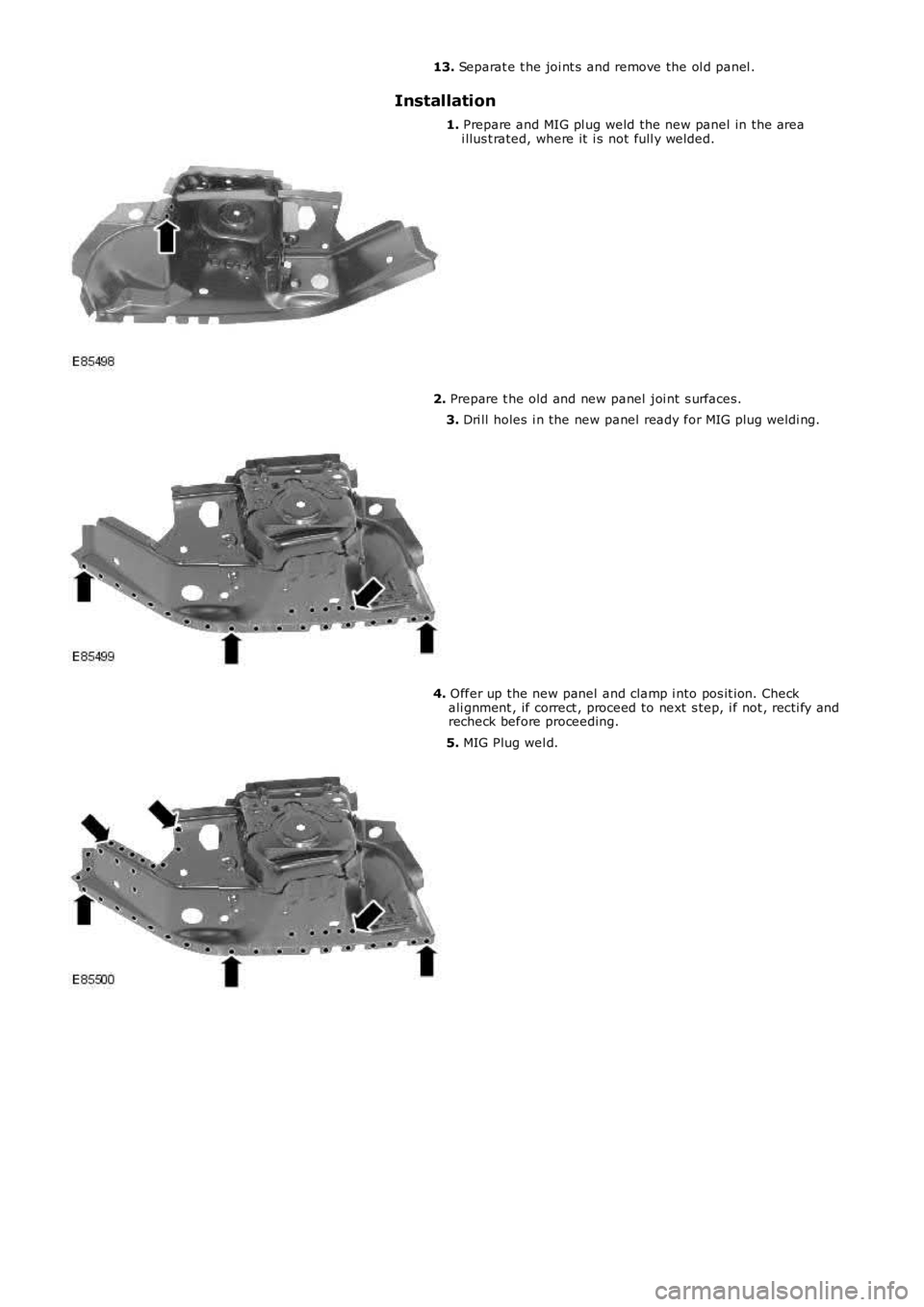

1. Prepare and MIG pl ug weld the new panel in the areai llus t rated, where it i s not full y welded.

2. Prepare t he old and new panel joi nt s urfaces.

3. Dri ll holes i n the new panel ready for MIG plug wel di ng.

4. Offer up the new panel and clamp i nto pos it ion. Checkali gnment , if correct , proceed to next s tep, i f not , recti fy andrecheck before proceeding.

5. MIG Plug wel d.

Page 2556 of 3229

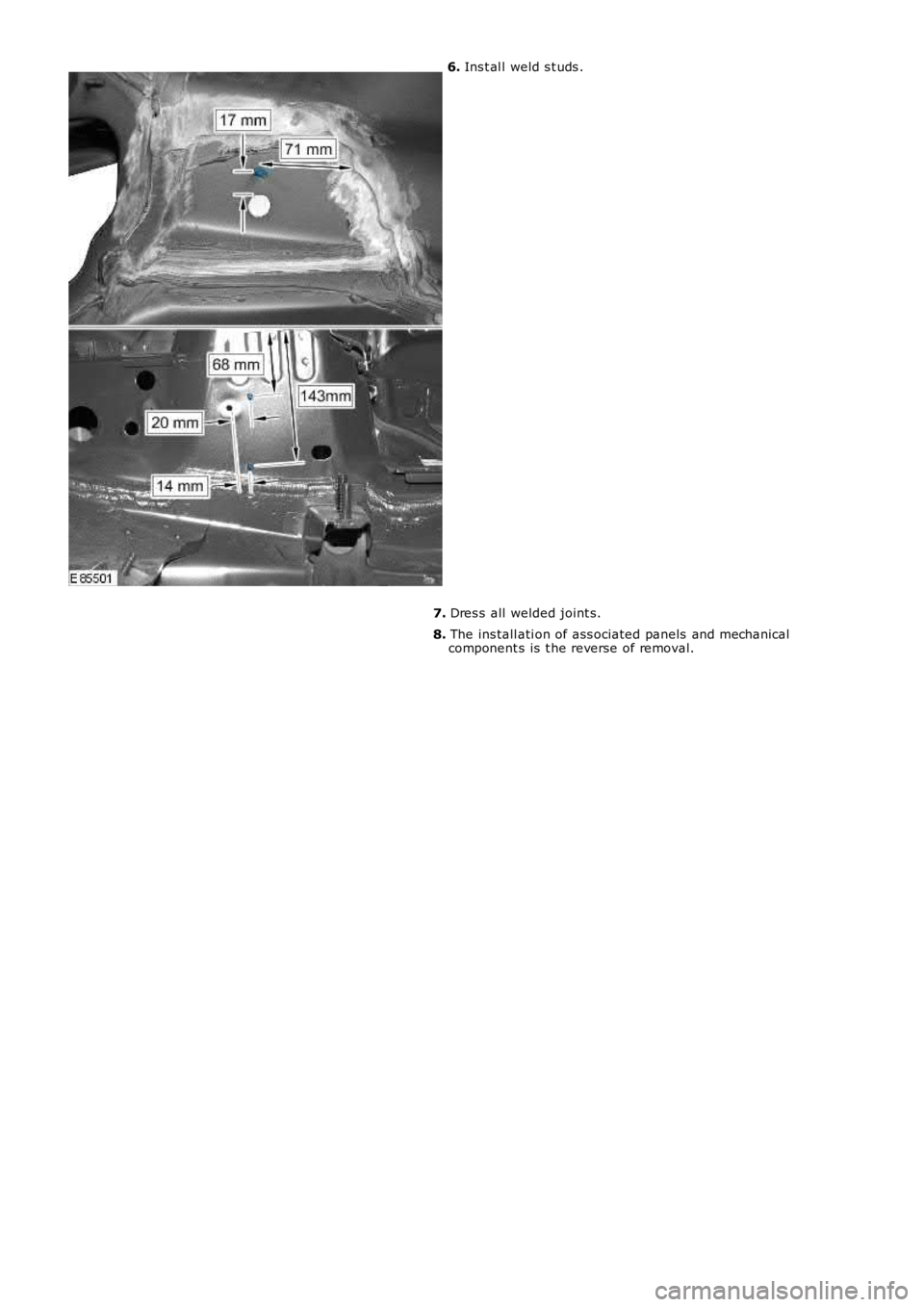

6. Ins t al l weld s t uds .

7. Dres s all welded joint s.

8. The ins tall ati on of ass ociated panels and mechanicalcomponent s is t he reverse of removal.

Page 2557 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Front Side Member Section

Removal and Installation

Removal

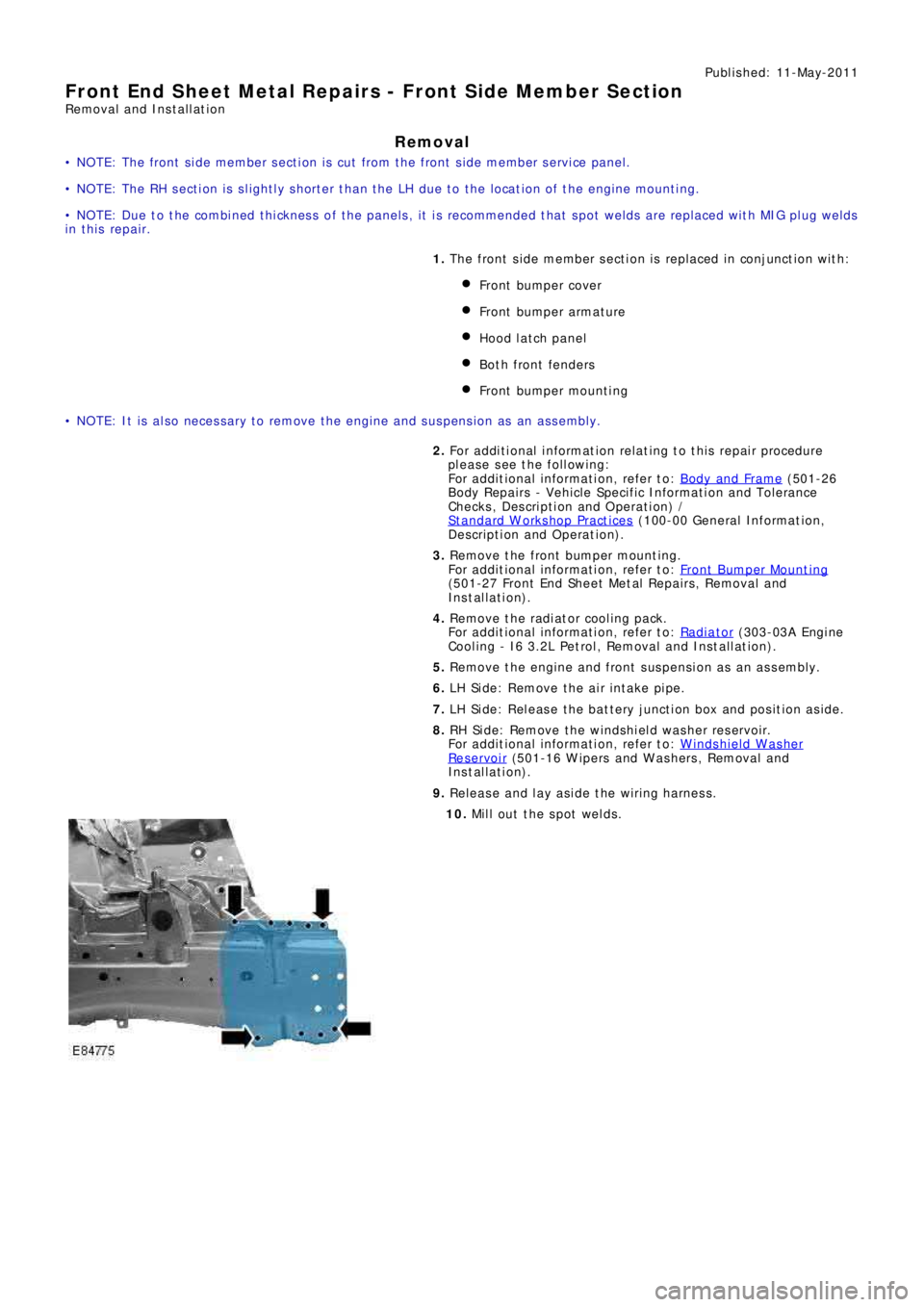

• NOTE: The front side member section is cut from the front side member service panel.

• NOTE: The RH section is slightly shorter than the LH due to the location of the engine mounting.

• NOTE: Due to the combined thickness of the panels, it is recommended that spot welds are replaced with MIG plug welds

in this repair.

1. The front s ide member s ect ion is replaced in conjunct ion wit h:

Front bumper cover

Front bumpe r a rma t ure

Hood lat ch panel

Both front fenders

Front bumpe r mount i ng

• NOTE: It is also necessary to remove the engine and suspension as an assembly.

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Re move t he f ront bumpe r mount i ng.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Bumper Mount ing

(501-27 Front End Sheet Met al Re pai rs , Removal and

Installation).

4. Remove the radiator cooling pack.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Radiator

(303-03A Engi ne

Cooling - I6 3.2L Petrol, Removal and Installation).

5. Remove the engine and front suspension as an assembly.

6. LH Side: Remove the air intake pipe.

7. LH Side: Release the battery junction box and position aside.

8. RH Side: Remove the windshield washer reservoir.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Washer

Res ervoi r (501-16 W i pers and W as hers , Removal and

Installation).

9. Release and lay aside the wiring harness.

10. Mill out the spot welds.

Page 2558 of 3229

11. Saw cut the old panel at the point illustrated.

12. Separate the joints and remove the old panel.

Installation

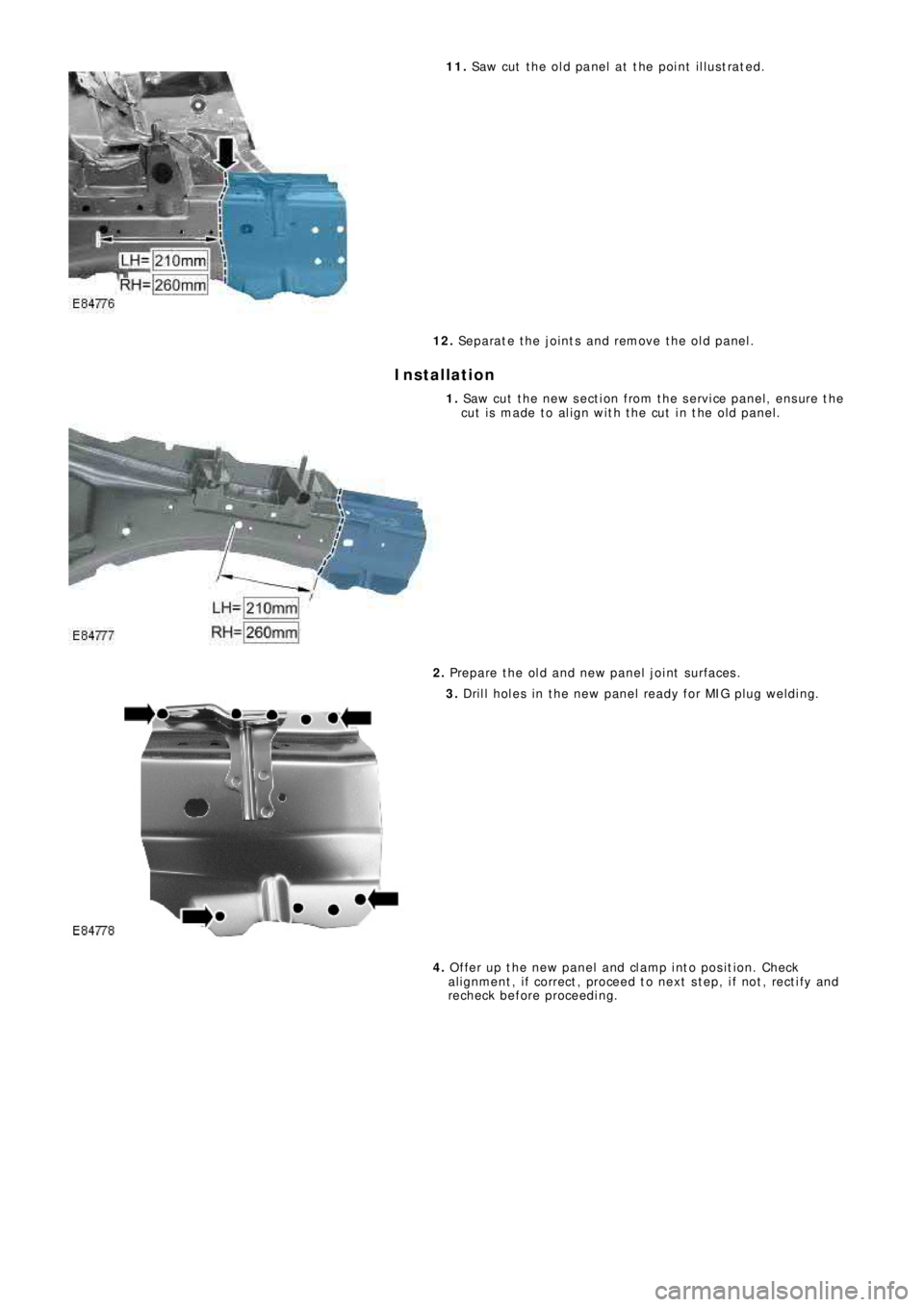

1. Saw cut the new section from the service panel, ensure the

cut is made to align with the cut in the old panel.

2. Prepare the old and new panel joint surfaces.

3. Drill holes in the new panel ready for MIG plug welding.

4. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

Page 2559 of 3229

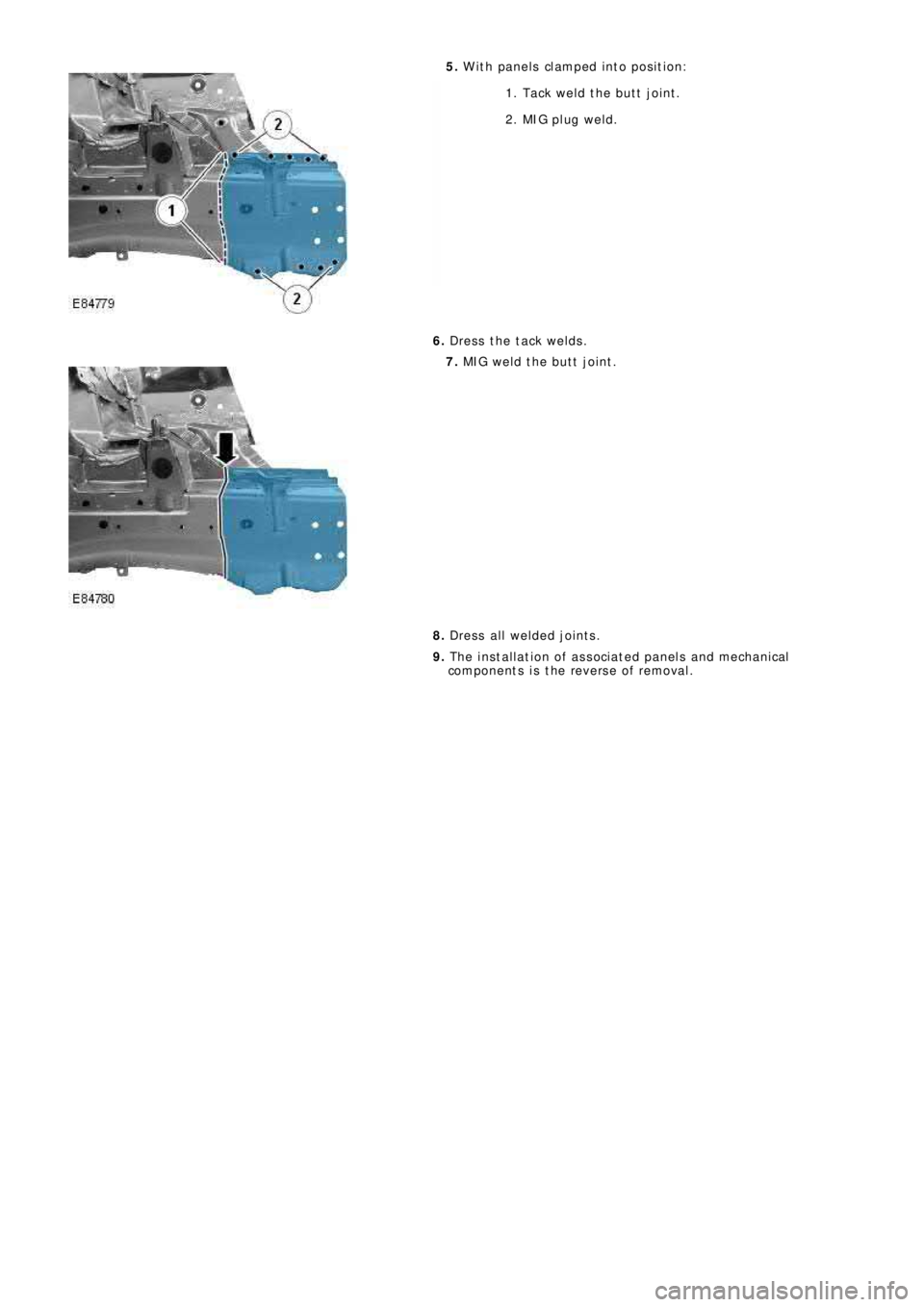

5. W ith panels clamped into position:

1. Tack weld the butt joint.

2. MIG pl ug wel d.

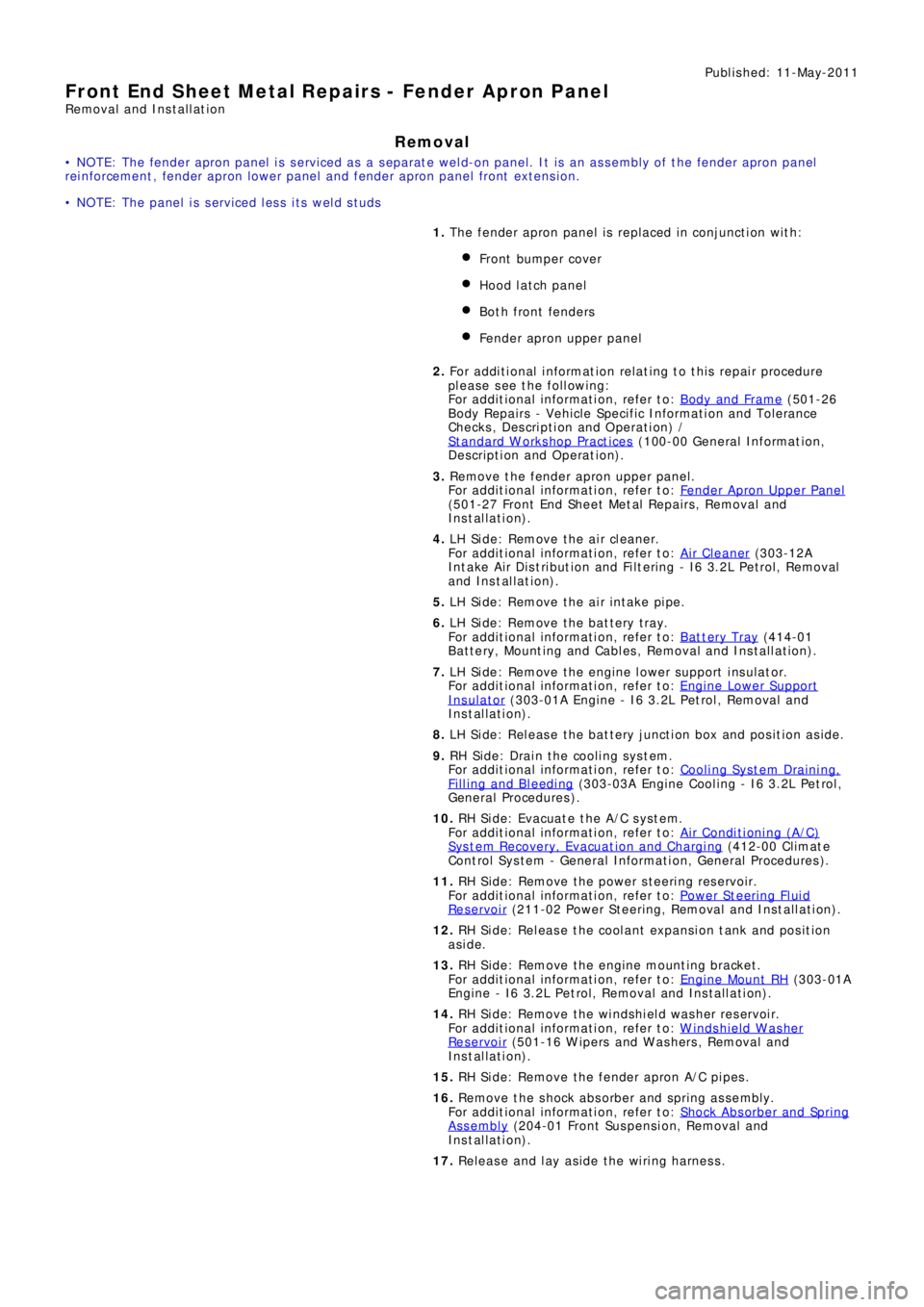

6. Dress the tack welds.

7. MIG weld the butt joint.

8. Dress all welded joints.

9. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2560 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Fender Apron Panel

Removal and Installation

Removal

• NOTE: The fender apron panel is serviced as a separate weld-on panel. It is an assembly of the fender apron panel

reinforcement, fender apron lower panel and fender apron panel front extension.

• NOTE: The panel is serviced less its weld studs

1. The fender apron panel is replaced in conjunction with:

Front bumper cover

Hood lat ch panel

Both front fenders

Fender apron upper panel

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the fender apron upper panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Fender Apron Upper Panel

(501-27 Front End Sheet Met al Re pai rs , Removal and

Installation).

4. L H Si d e : Re mo ve t he a i r cl e a ne r.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Air Cleaner

(303-12A

I nt a ke A i r Di s t ri b ut i o n a nd Fi l t e ri ng - I 6 3. 2L P e t ro l , Re mo va l

and Installation).

5. LH Side: Remove the air intake pipe.

6. LH Side: Remove the bat tery t ray.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Battery Tray

(414-01

Battery, Mounting and Cables, Removal and Installation).

7. LH Side: Remove the engine lower support insulator.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Lower Support

Insulator (303-01A Engi ne - I6 3.2L Pet rol, Removal and

Installation).

8. LH Side: Release the battery junction box and position aside.

9. RH Side: Drain the cooling system.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Cooling Sys tem Draining,

Filling and Bleeding (303-03A Engine Cooling - I6 3.2L Petrol,

General Procedures ).

10. RH Side: Evacuate the A/C system.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Air Conditioning (A/C)

System Recovery, Evacuation and Charging (412-00 Cl i mat e

Co nt ro l Sys t e m - Ge ne ra l I nf o rma t i o n, Ge ne ra l P ro ce d ure s ).

11. RH Si d e : Re mo ve t he p o we r s t e e ri ng re s e rvo i r.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : P o we r St e e ri ng Fl ui d

Res ervoi r (211-02 Power St eeri ng, Removal and Ins t al lat i on).

12. RH Side: Release the coolant expansion tank and position

aside.

13. RH Side: Remove the engine mounting bracket.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Mount RH

(303-01A

Engine - I6 3.2L Petrol, Removal and Installation).

14. RH Side: Remove the windshield washer reservoir.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Washer

Res ervoi r (501-16 W i pers and W as hers , Removal and

Installation).

15. RH Side: Remove the fender apron A/C pipes.

16. Remove the shock absorber and spring assembly.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Sho ck A b s o rb e r a nd Sp ri ng

Assembly (204-01 Front Sus pens i on, Removal and

Installation).

17. Release and lay aside the wiring harness.