LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2521 of 3229

Description - UsageSupplierProduct Number

Bodyguard s tonechi p coat ing (fl at) can - bl ack3M08158

Bodyguard s tonechi p coat ing (fl at) can - grey3M08159Anti chip coat ing s mooth - grey3M08886

Terot ex record bl ack 1L canTeroson122.48N

Terot ex record l ight 1L canTeroson165.53STerot ex ant i chi p compound light (UBC) 1L canTeroson191.08V

Terot ex ant i chi p compound bl ack (UBC) 1L canTeroson191.32V

T rim Adhesive--Auto adhes ive - aeros ol - clear (t ri m)3M08080

Auto adhes ive - brushable - cl ear (t ri m)3M08150

Contact adhes ive - aerosol - amber3M08090Corrosion Protection--

Zinc s pray3M09113

Zinc s prayTeroson158.18TAnti Corrosive Agent--

Terot ex HV 350 1L canTeroson141.78L

Terot ex HV 350 10L canTeroson160.02TTerot ex HV 350 60L barrelTeroson160.01S

Sound Deadening--

Sound deadening s heets3M08840Terodem SP 100 aluTeroson190.33

Terodem SP 200Teroson190.55M

Terodem SP 300 50 x 50Teroson145.28RTerodem SP 300 100 x 50Teroson134.29X

Flexible Part Repair--

Flexibl e part repai r material (FPRM)3M05900Adhesives / T hread Locking--

Lock N Seal 243 thread l ocki ngLocti te13701

Lock N Seal 243 thread l ocki ngLocti te14131Lock N Seal 243 thread l ocki ngLocti te25684

St ud N Beari ng fi t 271Locti te13704

St ud N Beari ng fi t 271Locti te14130St ud N Beari ng fi t 271Locti te25685

Pipe sealant 577Locti te16604

Pipe sealant 577Locti te25689Pipe sealant 55Locti te31899

Gasket--

Mult i gasketLocti te25688Sil icone copperLocti te19245

Sil icone copperLocti te82046

Sil icone 596 blackLocti te19242Sil icone 596 blackLocti te59875

3020 gasket adhes i veLocti te31458

NVH Baffle--Sikabaffle 278SIKA

Approved Service Material Supplier - Contact Details

3M

3M Uni ted Ki ngdom PLC3M Cent reCain RoadBracknel lBerks hireRG12 8HTTelephone (01344) 858000www.3m.com

Cooper Pegler

Burges s Hil lSuss exRH 15 9LATelephone (014446) 42526

Sika Lt d

W at chmeadW el wyn Garden Cit yHert fordshi reAL7 1BQTelephone (01707) 394444www.si ka.co.uk

SATA Spray Equipment

Minden Indus t ri al equipment16 Greyfri ars RoadMoret on Hall

Page 2522 of 3229

Bury St EdmundsSuffol kIP32 7DXTelephone (01284) 760791www.sat a.com

Henkel Loct it e Adhesi ves Li mi ted

Technologies Hous eW ood Lane EndHemel Hempst eadHert fordshi reHP2 4RQTelephone (01442) 278000www.locti te.co.uk

Teros on

Henkel LtdApollo Court2 Bi shops Square Bus ines s ParkHatfiel dHert fordshi reAL10 9EYTelephone (01707) 635000www.henkel.co.uk

Underbody sealer

Under floor areas and t he front part of the spare wheel wel l are t reat ed wit h a pl ast is ol PVC underbody sealer. Thi smat erial i s not sui table for re-treatment . W hen repairing areas of underbody s ealer, s t ri p t he factory-appl ied underbodys eal er back t o a s uit able break poi nt. Ens ure t hat a clean met al s urface is expos ed and that t he edge of t he exis t ingadheres s oundly to the panel.

Apply new underbody s eal er bet ween pri mer and s urface paint operat ions . Appl y s eam seal er as neces sary beforeappl icati on of underbody s ealer. Ens ure that blanking plugs and grommets in t he floor pan (except t hose used for waxinject ion) are fi tt ed before underbody s ealer appl icati on. Refit any heat-fus ibl e plugs which have been dis t urbed in repairwit h t he aid of a hot ai r blower, or repl ace wit h rubber grommet s

CAUTION: Ens ure t hat sus pens i on uni ts , wheels , ti res , power uni t, drive s haft s, exhaus t and brakes (including al lmounti ng points ) are s hi elded pri or to appl icat ion of fres h underbody s eal er.

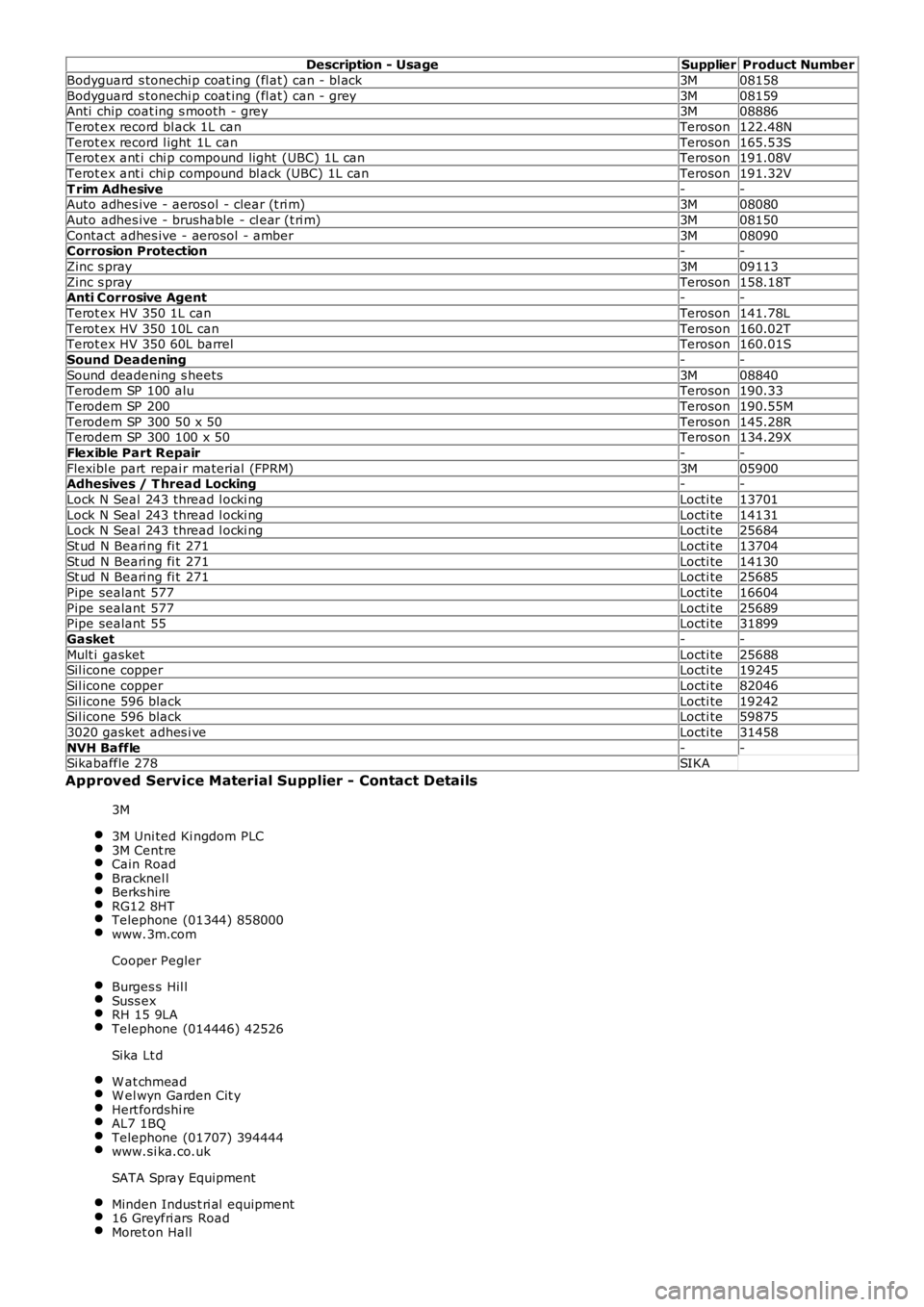

Area of Underbody Sealer Appl icati on - Floor Pan

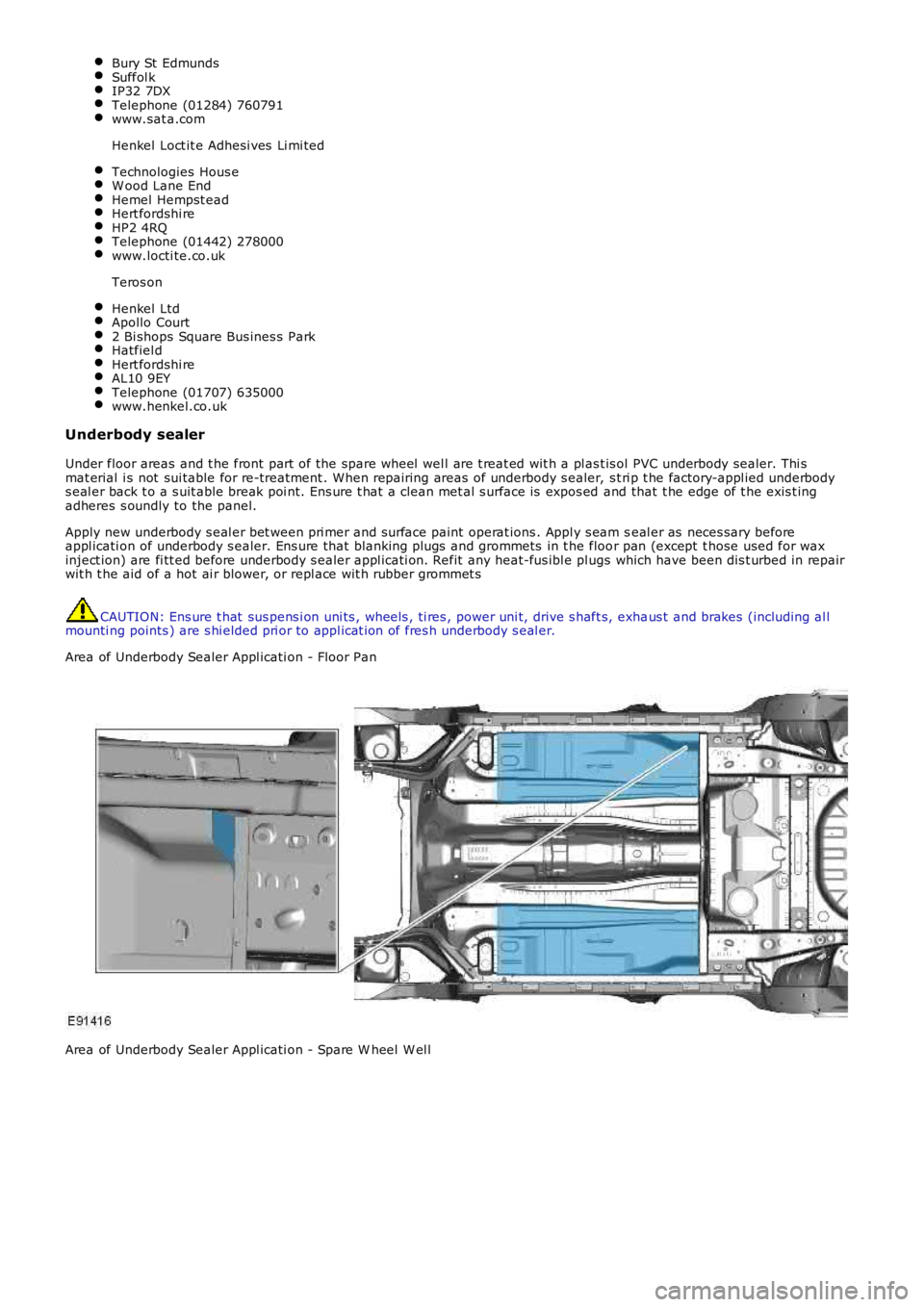

Area of Underbody Sealer Appl icati on - Spare W heel W el l

Page 2523 of 3229

Precautions During Body Repairs and Handling

Take care when handl ing t he vehicle i n t he works hop. Underbody s ealers , s eam s ealers, underbody wax and body panelsmay be damaged i f the vehicle is carel es s ly lifted.

Proprietary Anti-corrosion Treatments

The appl icati on of propri etary ant i corros ion treat ments in addit ion t o t he fact ory-appli ed treatment could i nval idate thecorros ion warrant y and s houl d be dis couraged. This does not apply t o approved, compat ible, pres ervati ve waxes which maybe applied on top of exis t ing coati ngs .

Fitting Approved Accessories

W hen fit ti ng acces s ories ens ure t hat the vehicle corros ion protecti on is not affected, eit her by breaki ng the protecti vecoat ing or by i ntroducing a mois t ure t rap.

Do not s crew s elf-t apping s crews direct ly int o body panels . Fit s uit able pl as t ic i nserts to t he panel beforehand. Alwaysensure t hat t he edges of hol es dril led i nto panels , chas s is members and ot her body part s are prot ect ed wit h a sui tablezinc rich or aci d et ch primer, and fol low wit h a prot ect ive wax coat ing brus hed onto the s urroundi ng area.

Do not att ach painted metal s urfaces of any acces sory direct ly t o t he vehicle's bodywork unles s s uit ably prot ect ed. W heremet al s urfaces are bolt ed t oget her al ways interpos e a s ui table int erface mat eri al s uch as weldable zi nc ri ch pri mer,extruded s t ri p, or zi nc tape.

Steam Cleaning

Due t o t he high pres s ure/temperat ure generat ed by s team cl eani ng equi pment, t here i s a ris k t hat certain adhes ives andcorros ion prevent ion mat eri al may become softened or li qui fi ed.

Take care not to allow the st eam jet to dwel l on one area, and keep the nozzle at l eas t 300mm from t he panel s urface.

CAUTION: Do not remove wax or lacquer from underbody areas during repai rs .

Inspection During Maintenance Servicing

It is a requirement of t he corros ion warrant y t hat t he vehicle i s ins pect ed for corros ion by a Land Rover Aut hori sed Repairerduri ng a rout ine s ervi ce, t o ensure t hat t he fact ory-appli ed prot ect ion remains effecti ve.

Rect ify any bodywork damage or evi dence of corros i on found duri ng ins pect ion as s oon as i s practi cable, bot h to mini mis et he ext ent of t he damage and t o ensure t he long t erm effect iveness of t he fact ory-appli ed corros ion prevent ion t reat ment.

Underbody Protection Repairs

W henever body repairs have been carri ed out, ens ure t hat full s ealing and corros ion prot ecti on treat ment s are reins tat ed.This appli es bot h t o t he damaged areas and als o t o areas where prot ect ion has been indi rectl y impai red, as a resul t eit herof accident damage or repair operat ions.

Remove corros ion protecti on from the damaged areas before s traighteni ng or panel beat ing. This appli es in parti cul ar t opanel s coat ed wi th wax, PVC underbody s eal er, s ound deadening pads etc.

CAUTION: Do not us e oxy-acet ylene t o remove corros ion preventi on mat erial . Large volumes of fumes and gas es areli berated by thes e mat erial s when t hey burn.

The mos t common met hod of removal i s by means of a hot air bl ower wi th an int egral scraper. High t emperatures can begenerated wi th thi s equi pment which may cause fumes . Take care duri ng it s us e.

Page 2524 of 3229

Structural Adhesive

CAUTION: W hen separat ing a joint wi th metal t o met al adhes ive, it is important to avoi d dis t orti on. Heat graduall yunti l the bond weakens suffi ci ent ly to permit panel separat ion - do not apply excessi ve heat .

• NOTE: W hen s pot weldi ng through metal to metal adhesi ve, t ake part icul ar care t o adjus t the equipment s ett ing toensure a s uit able wel d.

Metal t o met al adhes ive i s appl ied t o cri ti cal joint areas duri ng factory as sembl y. The materi al us ed i s a hi gh temperat ure,heat cured, nit rile phenoli c which s erves t o bond two met al s urfaces and al so to seal t he joi nt agains t ingres s of dus t,mois t ure and fumes . Thi s mat erial i s not sui table for s ervice us e and, during repai r, s houl d be s ubs ti tut ed by an approveds truct ural adhes ive. For panel s pecific i nformati on and to identi fy t he areas of s t ructural adhesi ve appl icati on in repair,refer to the relevant s heet metal removal and ins t al lat ion procedure.

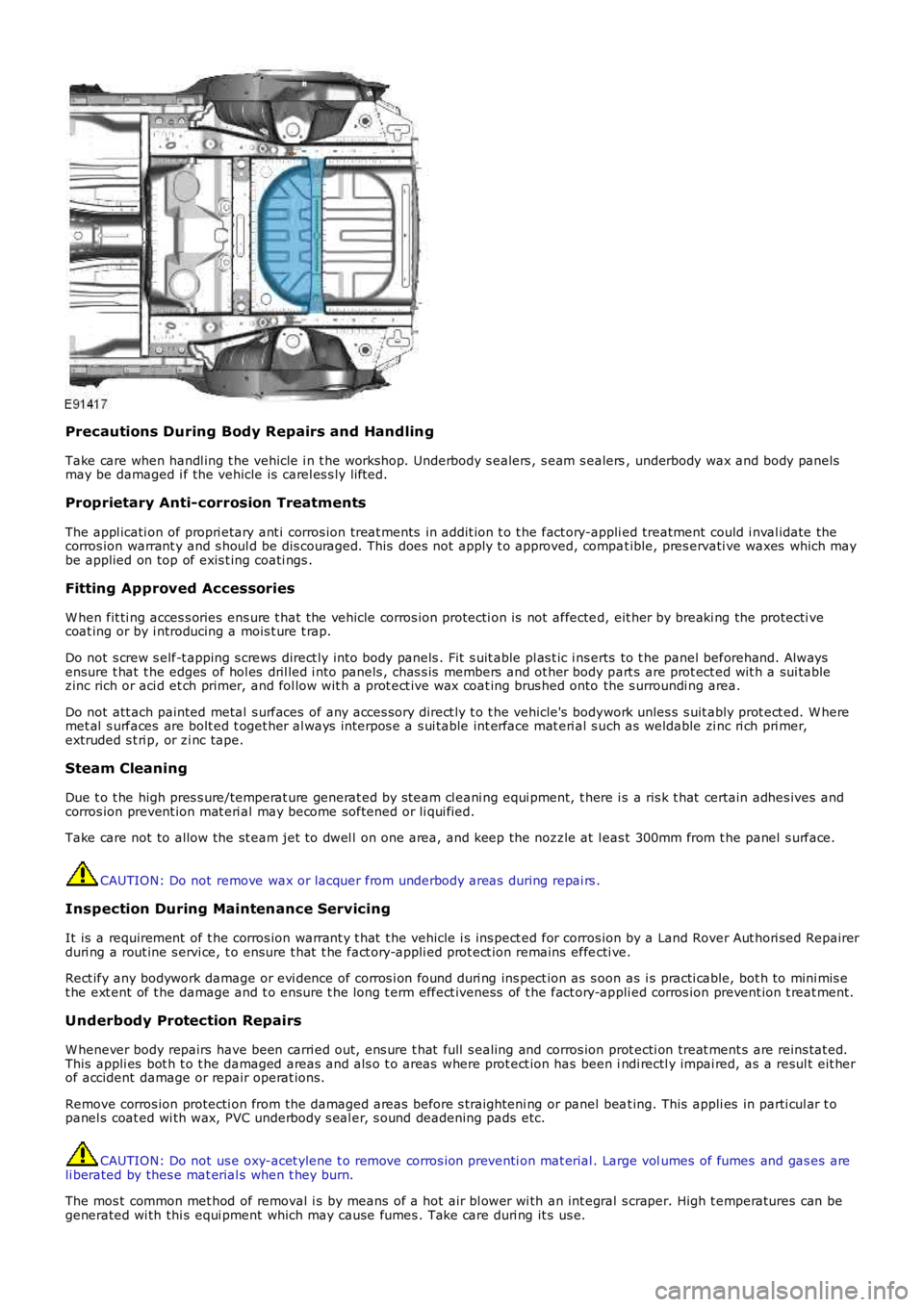

Expanding Foam Acoustic Seals

Expanding foam acoust ic s eals are us ed in various clos ed-s ect ions of t he body to i mprove vehicle refi nement . The s eal sare ins tall ed duri ng the vehicle body manufact ure and expand duri ng the pai nt process up t o t en t imes original s ize, thuslocking t hem i nt o pos it ion. They are l ocat ed s uch t hat they prevent nois e accentuat ion al ong a s ect ion and refl ect airborne nois e away from t he cabi n.

The s eal s have s pi lt funct ionalit y dependi ng on locati on. The s eals locat ed at t he bas e of t he body pill ars have a primaryfuncti on of prevent ing wat er ingres s when wadi ng. Their s econdary funct ion i s t o prevent noi s e and dust i ngres s.

The s eal around t he fuel fil ler has a pri mary functi on of prevent ing bot h fuel and water i ngress . W it h a s econdary funct ionof prevent ing noi se and dus t i ngress .

The remai ning s eals primary functi on is to prevent nois e accent uat ion al ong a s ect ion and refl ect ai r borne nois e awayfrom the cabin.

Another advantage of t he s eal s i s that t hey marginal ly i ncreas e t he overall s t iffness of t he body and it s s t ructuralperformance in cas e of a cras h.

The s eal s are manufact ured from an expandi bl e polymer.

Replacing Expanding Foam Acoustic Seals

As paint oven temperatures us ed i n a repai r works hop are s i gni fi cantl y l ower t han thos e t hat are us ed duri ng manufact ureof the vehicle, (the temperat ures are not suffi ci ent to expand the foam), a different proces s is required to repli cat e t hefoam in repair.

If a repair di st urbs t he expanding foam acoust ic seal it mus t be reins tat ed. If acces s all ows, (whether a new seal is fit t edor the origi nal i s reus ed), acous ti c foam s houl d be i nject ed aft er paint refinis hing. If access is not poss i bl e, or it is notpracti cal t o apply expandi ng foam due to the nat ure of t he repair, a s uit abl e flexible PU s eal er should be appl ied aroundt he seal and t he corres pondi ng body panel/s pri or to as s embly. In all cases t he appli cat ion of foam / s eal er should form as eal bet ween the expandi ng foam acous ti c s eal and any adjacent panelwork.

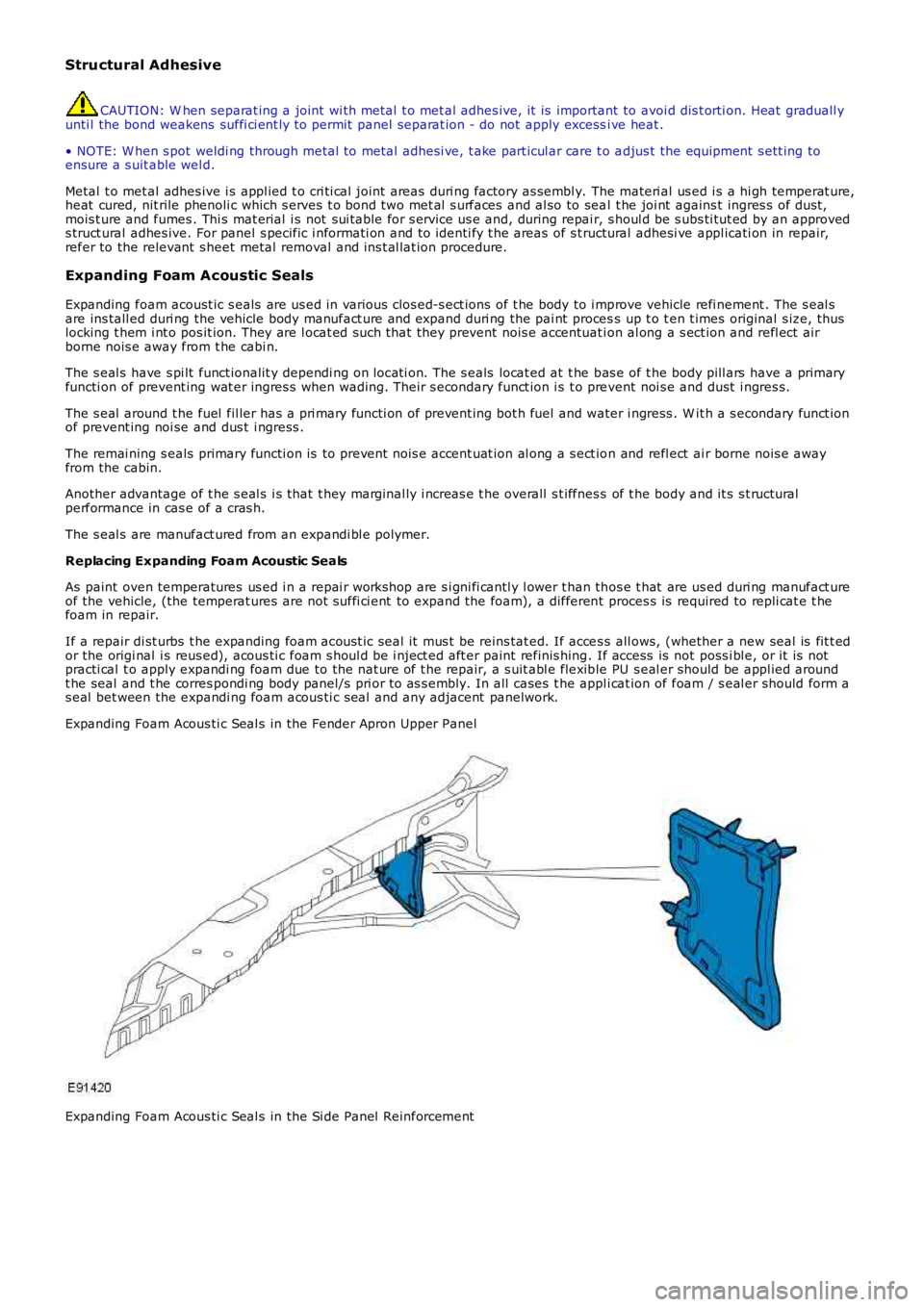

Expanding Foam Acous ti c Seal s in the Fender Apron Upper Panel

Expanding Foam Acous ti c Seal s in the Si de Panel Reinforcement

Page 2525 of 3229

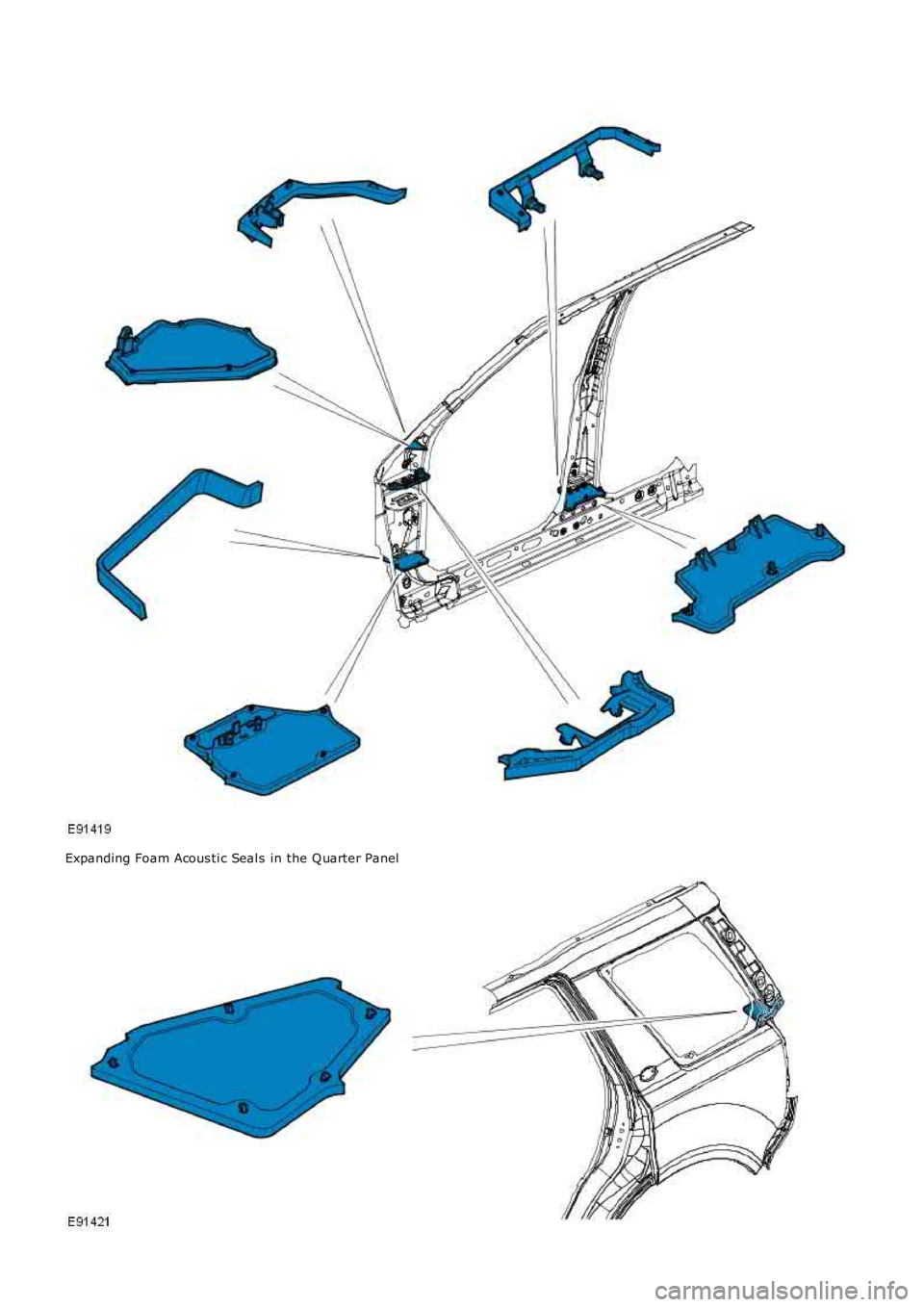

Expanding Foam Acous ti c Seal s in the Q uarter Panel

Page 2526 of 3229

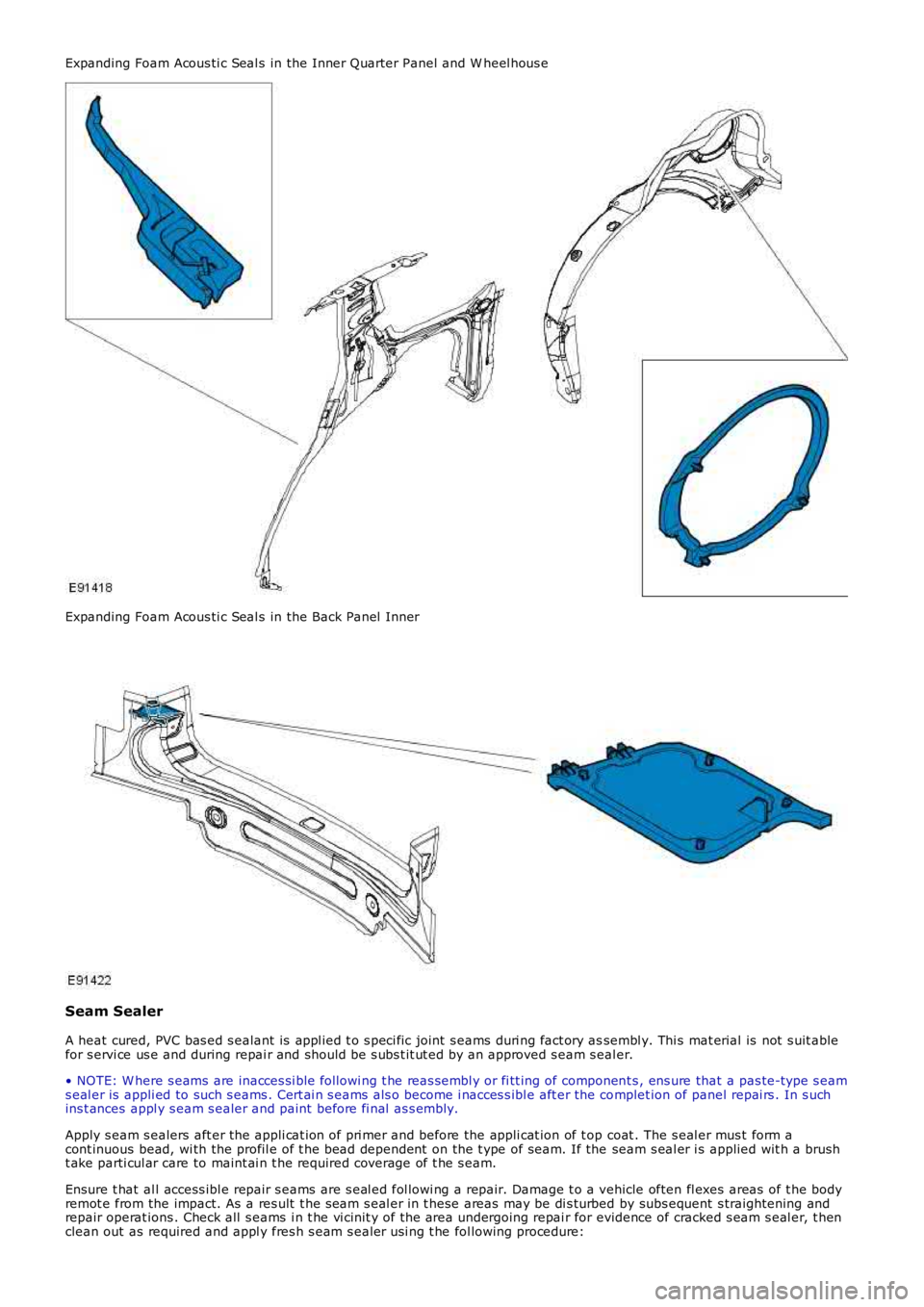

Expanding Foam Acous ti c Seal s in the Inner Quarter Panel and W heel hous e

Expanding Foam Acous ti c Seal s in the Back Panel Inner

Seam Sealer

A heat cured, PVC bas ed s ealant is appl ied t o s peci fic joint s eams duri ng fact ory assembl y. Thi s mat erial is not s uit ablefor s ervi ce us e and during repai r and should be s ubs t it ut ed by an approved s eam s ealer.

• NOTE: W here s eams are inacces si ble followi ng t he reas sembl y or fi tt ing of component s , ens ure that a pas te-type s eams eal er is appli ed to such s eams . Cert ai n s eams als o become i nacces s ibl e aft er the complet ion of panel repai rs . In s uchins t ances appl y s eam s ealer and paint before fi nal as s embly.

Apply s eam s ealers aft er the appli cat ion of pri mer and before the appli cat ion of t op coat . The s eal er mus t form acont inuous bead, wi th the profil e of t he bead dependent on the t ype of seam. If the seam s eal er i s applied wit h a brusht ake parti cul ar care to maint ai n t he required coverage of t he s eam.

Ensure t hat al l access ibl e repair s eams are s eal ed fol lowi ng a repair. Damage t o a vehicle often fl exes areas of t he bodyremot e from the impact. As a res ult t he s eam s eal er in t hese areas may be di s turbed by subs equent s traightening andrepair operat ions . Check all s eams i n t he vi cinit y of the area undergoing repai r for evidence of cracked s eam s eal er, t henclean out as required and appl y fres h s eam s ealer usi ng t he fol lowing procedure:

Page 2527 of 3229

Clean t he affect ed s eam and re-t reat any expos ed met al areas wit h a sui table et ch phos phate primer.Treat affect ed area wit h an et ch-aci d pri mer.Apply appropri ate seam seal er as necess ary.appl y appropri ate colour coat (and under body s ealer as appl icable).

Provided acces s i s adequat e, apply seam seal er t o bot h s ides of a repai r joint . W here access is l imi ted to one s i de onl y,(e.g. box secti on), t reat t he affect ed box member wit h cavi ty wax.

Cavity Wax

Aft er repairs, al ways re-treat t hese areas wit h an approved cavit y wax. In addit ion, t reat all int eri or s urfaces whi ch havebeen dis turbed during repai rs whet her they have been treat ed i n product ion or not . Thi s includes all box members, cavit iesand door i nteriors .

Before wax inject ion, ensure t hat t he cavi ty to be treat ed i s free from any contaminati on or forei gn mat ter. W hereneces s ary, cl ear out any debri s.

Ensure t hat cavit y wax is appl ied after t he fi nal paint proces s and before refit ti ng any trim components .

Duri ng appl icati on ensure t hat t he wax covers all flanges and seam areas and t hat i t is adequately appl ied t o all repai redareas of both new and exi s ti ng panel s.

It should be not ed t hat new panel as sembl ies and complet e body shel ls are s uppl ied wi thout wax inject ion t reat ment.Ensure t hat s uch t reatment i s carri ed out aft er repairs .

Effect ive cavit y wax prot ect ion i s vit al. Always obs erve t he fol lowing poi nts :

Complet e all paint refini sh operati ons before wax appli cat ion.Check t he s pray pat tern of inject ion equipment.Mas k all areas not t o be waxed.Remove body fi xi ngs , s uch as s eat belt retract ors , if contami nati on is at al l l ikely.Move door gl ass es t o ful ly cl os ed pos it ion before t reati ng door interiors .Treat body areas normal ly covered by t ri m before refi tt ing i tems .Check t hat body and door drai n holes are cl ear after t he prot ect ive wax has dried.Keep all equipment cl ean, es peci ally wax inject ion nozzl es.

Page 2528 of 3229

Publi s hed: 11-May-2011

Body Repairs - Vehicle Specific Information and Tolerance Checks - Body

and Frame

Des cript ion and Operat ion

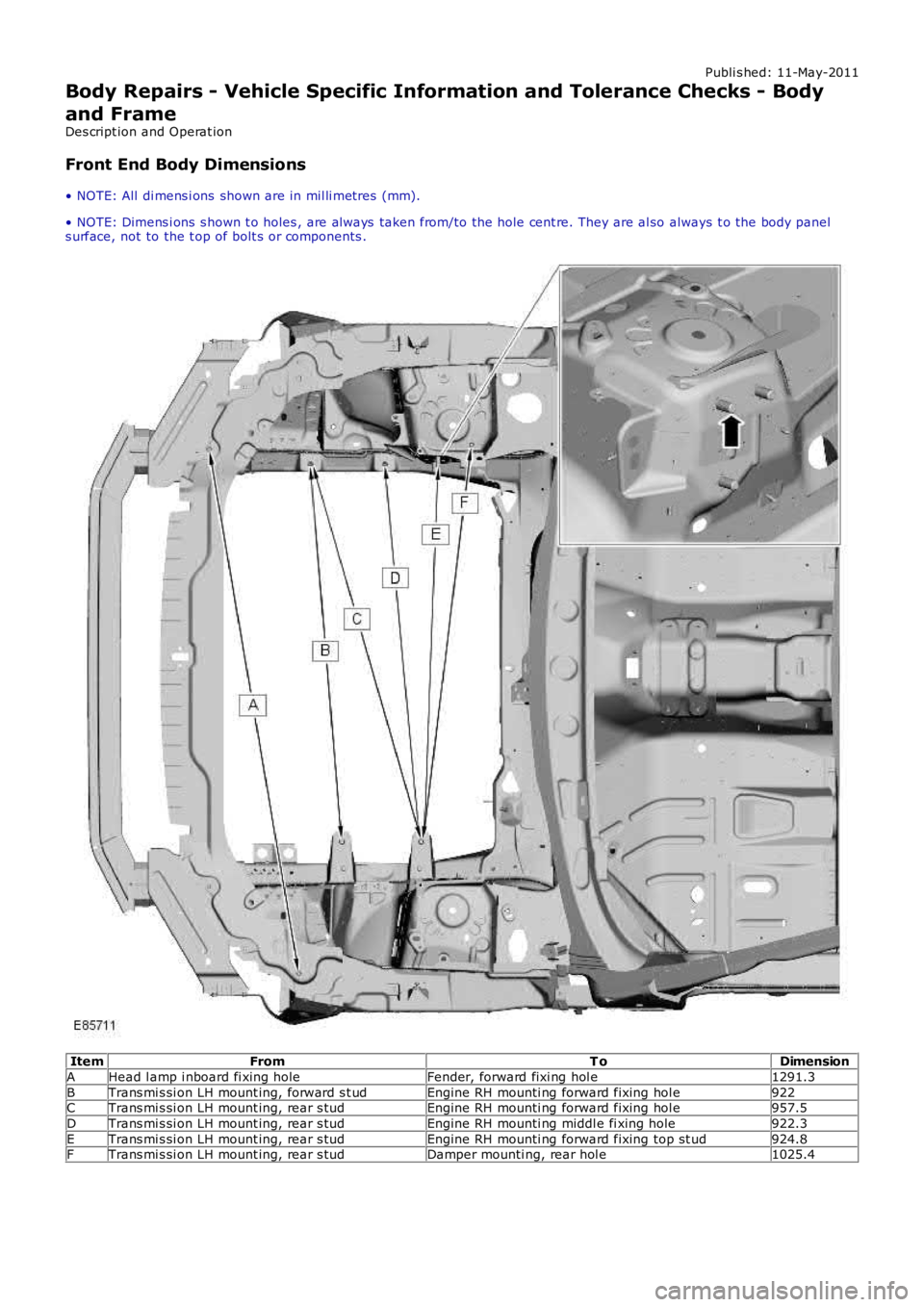

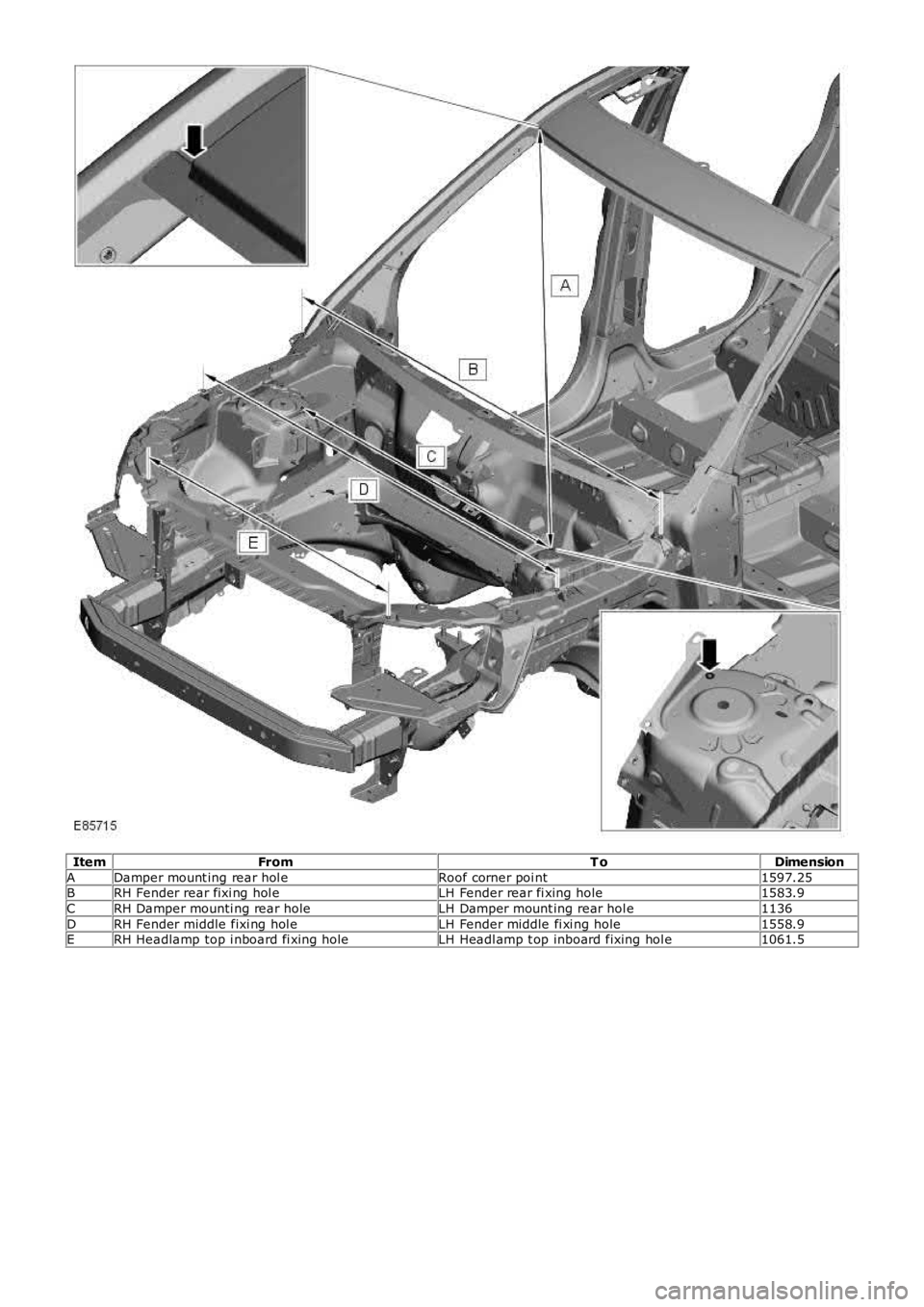

Front End Body Dimensions

• NOTE: All di mens i ons shown are in mil li metres (mm).

• NOTE: Dimens i ons s hown t o holes , are al ways taken from/to the hole cent re. They are al so always t o the body panels urface, not to the t op of bolt s or components .

ItemFromT oDimension

AHead l amp i nboard fi xing holeFender, forward fixi ng hol e1291.3

BTrans mi s si on LH mount ing, forward s t udEngine RH mounti ng forward fixing hol e922CTrans mi s si on LH mount ing, rear s tudEngine RH mounti ng forward fixing hol e957.5

DTrans mi s si on LH mount ing, rear s tudEngine RH mounti ng middl e fi xing hole922.3

ETrans mi s si on LH mount ing, rear s tudEngine RH mounti ng forward fixing top s t ud924.8FTrans mi s si on LH mount ing, rear s tudDamper mounti ng, rear hol e1025.4

Page 2529 of 3229

ItemFromT oDimension

ADamper mount ing rear hol eRoof corner poi nt1597.25BRH Fender rear fixi ng hol eLH Fender rear fi xing hole1583.9

CRH Damper mounti ng rear holeLH Damper mount ing rear hol e1136

DRH Fender middle fixi ng hol eLH Fender middle fi xi ng hole1558.9ERH Headlamp top i nboard fi xing holeLH Headl amp t op inboard fixing hol e1061.5

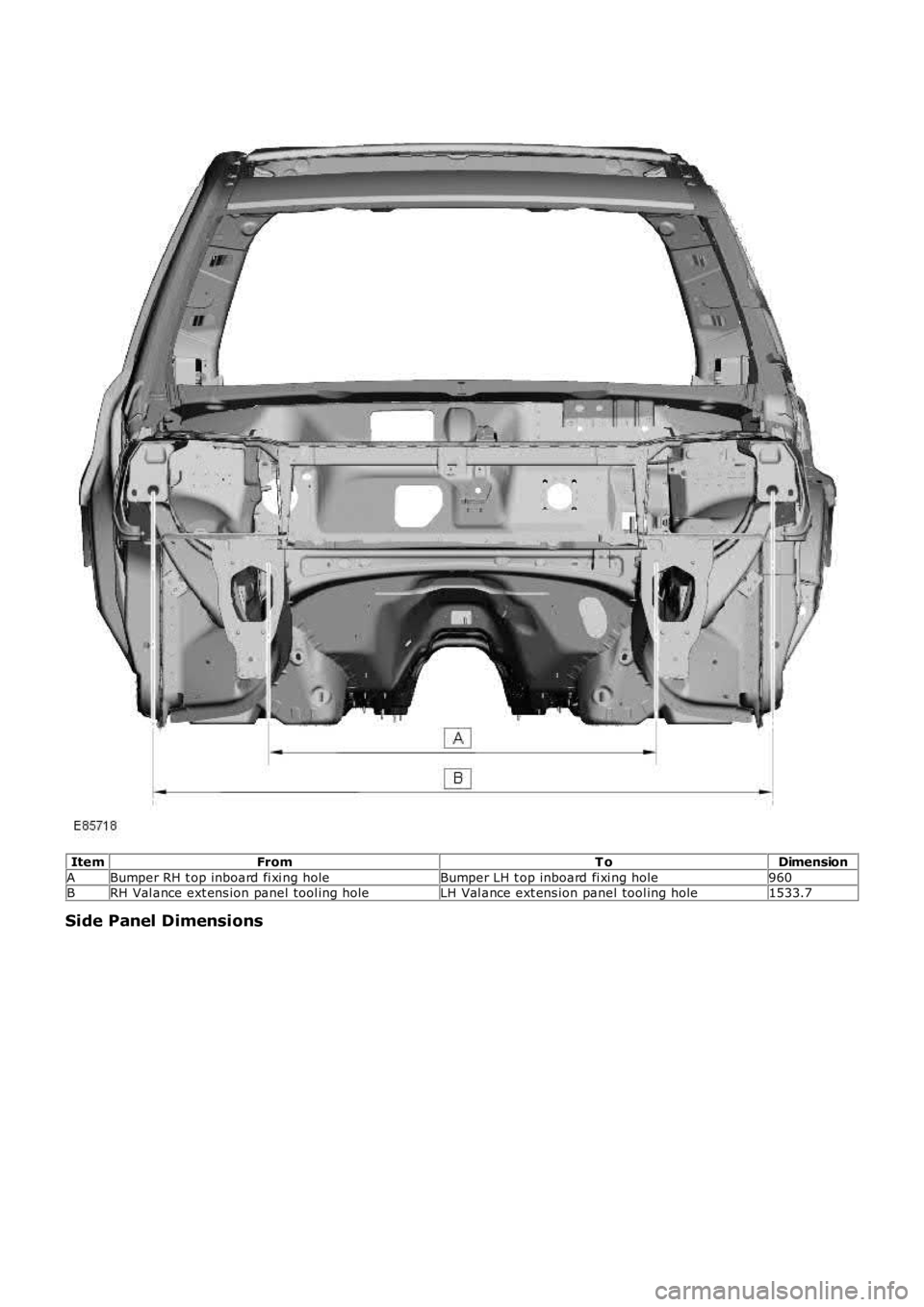

Page 2530 of 3229

ItemFromT oDimension

ABumper RH t op inboard fi xi ng holeBumper LH t op inboard fi xi ng hole960BRH Val ance ext ens ion panel tool ing holeLH Val ance ext ens ion panel tool ing hole1533.7

Side Panel Dimensions