LAND ROVER FRELANDER 2 2006 Repair Manual

Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 2561 of 3229

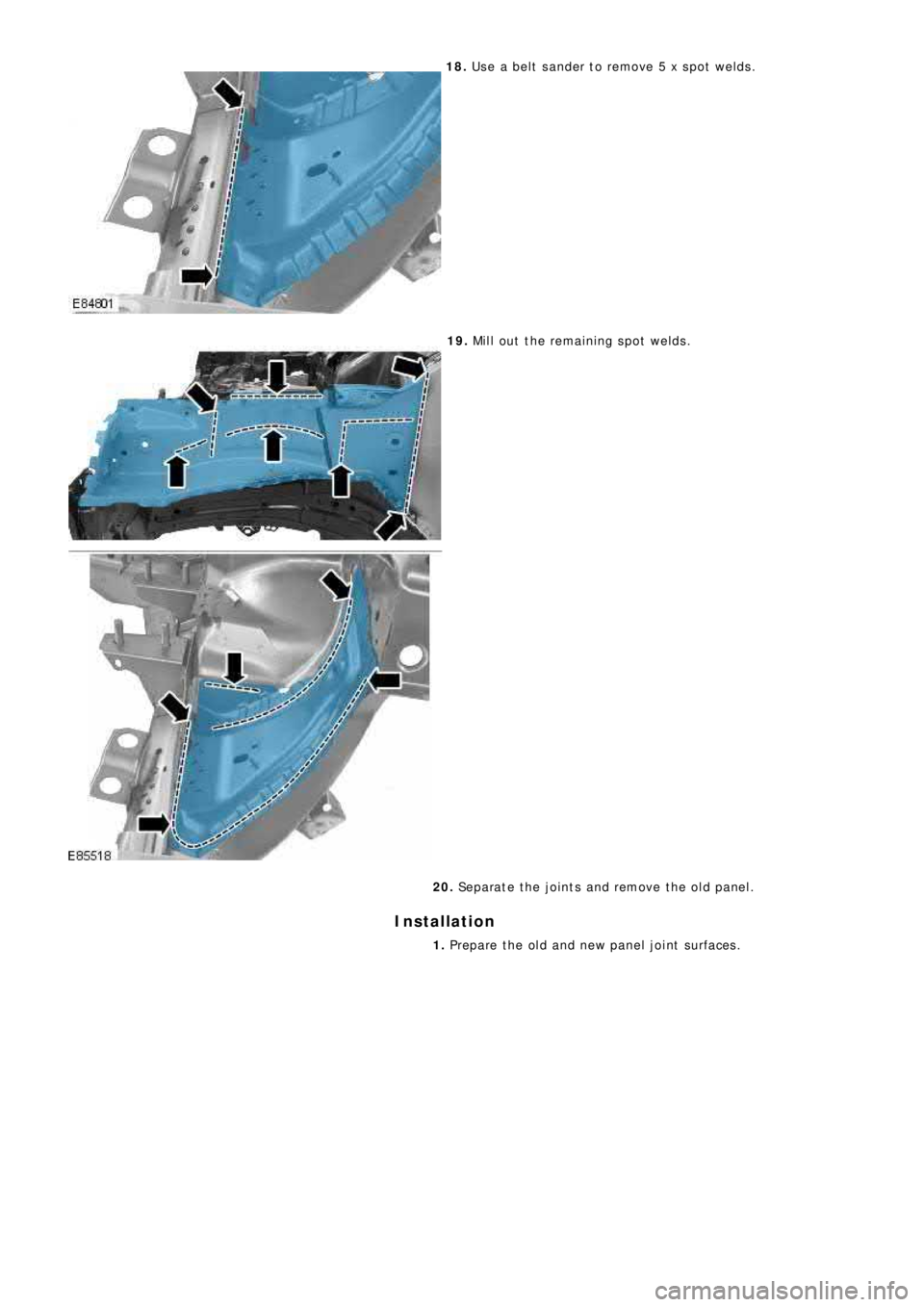

18. Use a belt sander to remove 5 x spot welds.

19. Mill out the remaining spot welds.

20. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

Page 2562 of 3229

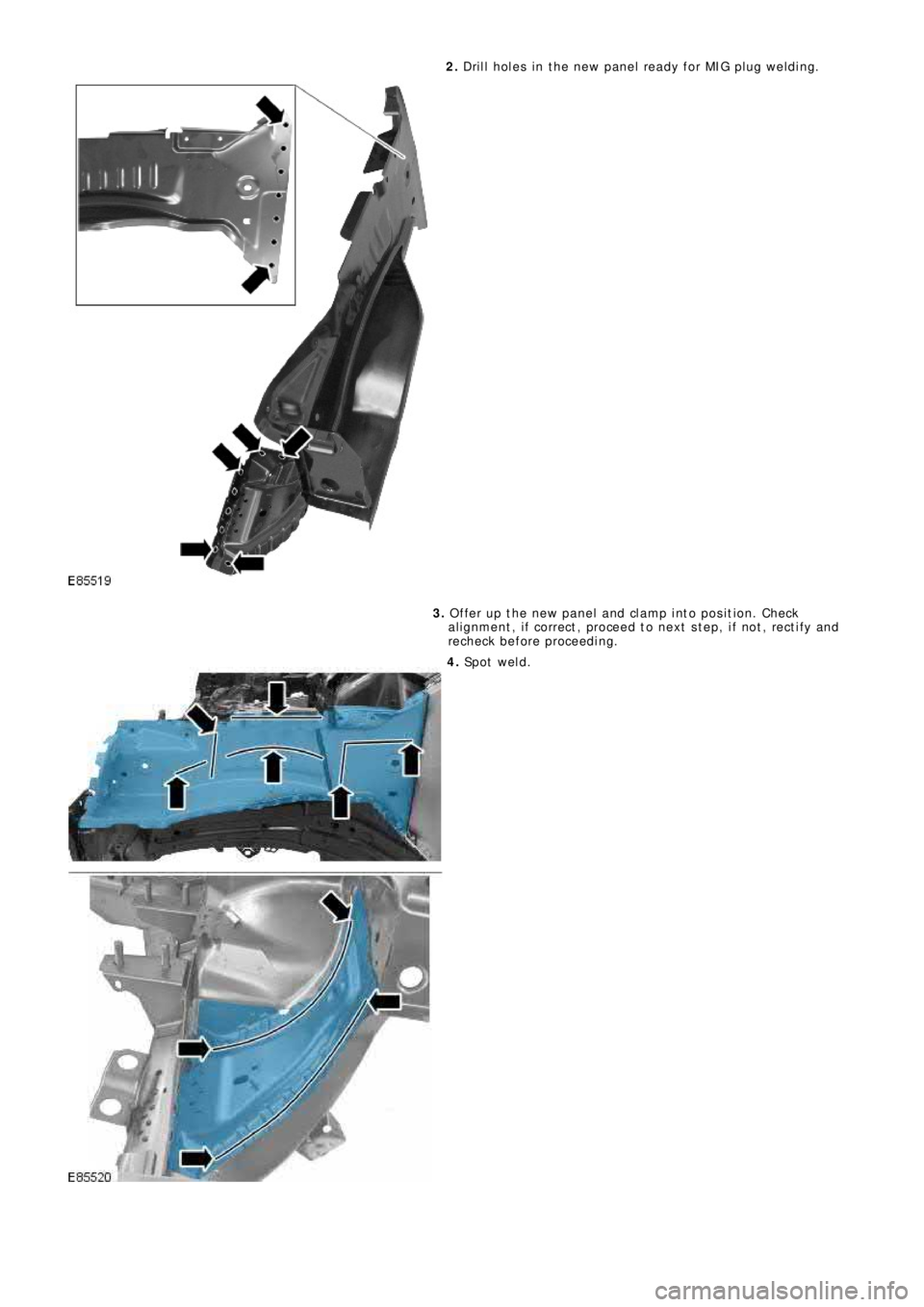

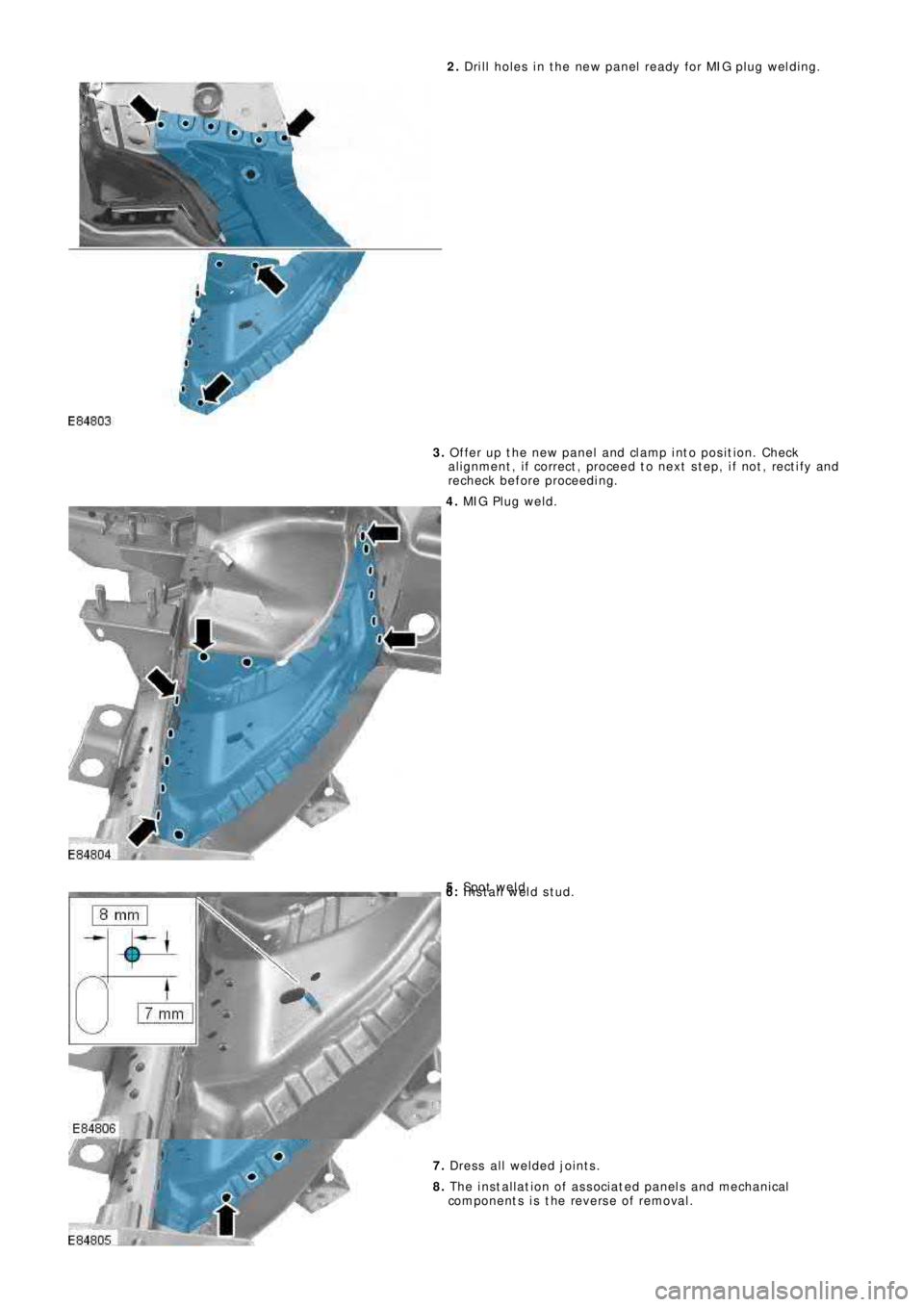

2. Drill holes in the new panel ready for MIG plug welding.

3. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

4. Sp o t we l d .

Page 2563 of 3229

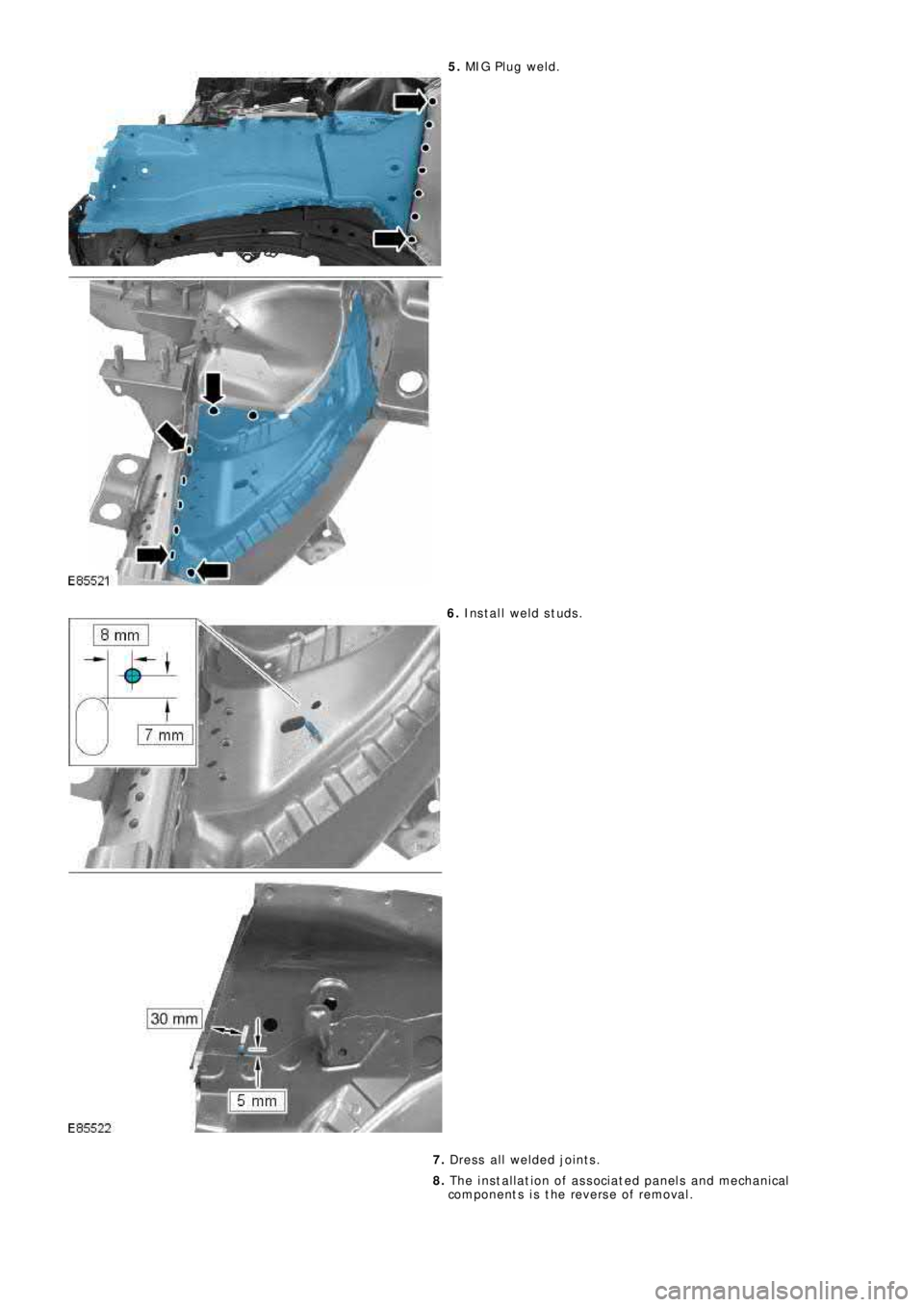

5. MIG P l ug we l d.

6. Install weld studs.

7. Dress all welded joints.

8. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2564 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Fender Apron Panel Reinforcement

Removal and Installation

Removal

• NOTE: The fender apron panel reinforcement has to be unpicked from the fender apron panel service panel, it is not

available separately.

• NOTE: The RH panel is serviced less its weld studs 1. T he f e nd e r a p ro n p a ne l re i nf o rce me nt i s re p l a ce d i n

conjunct ion wit h:

Front bumper cover

Hood lat ch panel

Both front fenders

Fender apron upper panel

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove the fender apron upper panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Fender Apron Upper Panel

(501-27 Front End Sheet Met al Re pai rs , Removal and

Installation).

4. Remove the front shock absorber.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Front Shock Abs orber

(204-01 Front Suspension, Removal and Installation).

5. LH Side: Remove the engine support insulator.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Upper Support

Insulator (303-01B Engi ne - TD4 2.2L Di es el, Removal and

Installation).

6. LH Side: Remove the bat tery t ray.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Battery Tray

(414-01

Battery, Mounting and Cables, Removal and Installation).

7. LH Side: Remove the air intake pipe.

8. LH Side: Release the battery junction box and position aside.

9. RH Side: Remove the windshield washer reservoir.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Windshield Washer

Res ervoi r (501-16 W i pers and W as hers , Removal and

Installation).

10. RH Side: Remove the engine mounting bracket.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Engine Mount RH

(303-01B

Engine - TD4 2.2L Diesel, Removal and Installation).

11. RH Side: Release the coolant expansion tank and lay it

aside.

12. RH Side: Evacuate the A/C system.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Air Conditioning (A/C)

System Recovery, Evacuation and Charging (412-00 Cl i mat e

Co nt ro l Sys t e m - Ge ne ra l I nf o rma t i o n, Ge ne ra l P ro ce d ure s ).

13. RH Side: Remove the fender apron A/C pipes.

14. RH Side: Release and lay aside the insulating material at the

bulkhead.

15. Release and lay aside the wiring harness.

Page 2565 of 3229

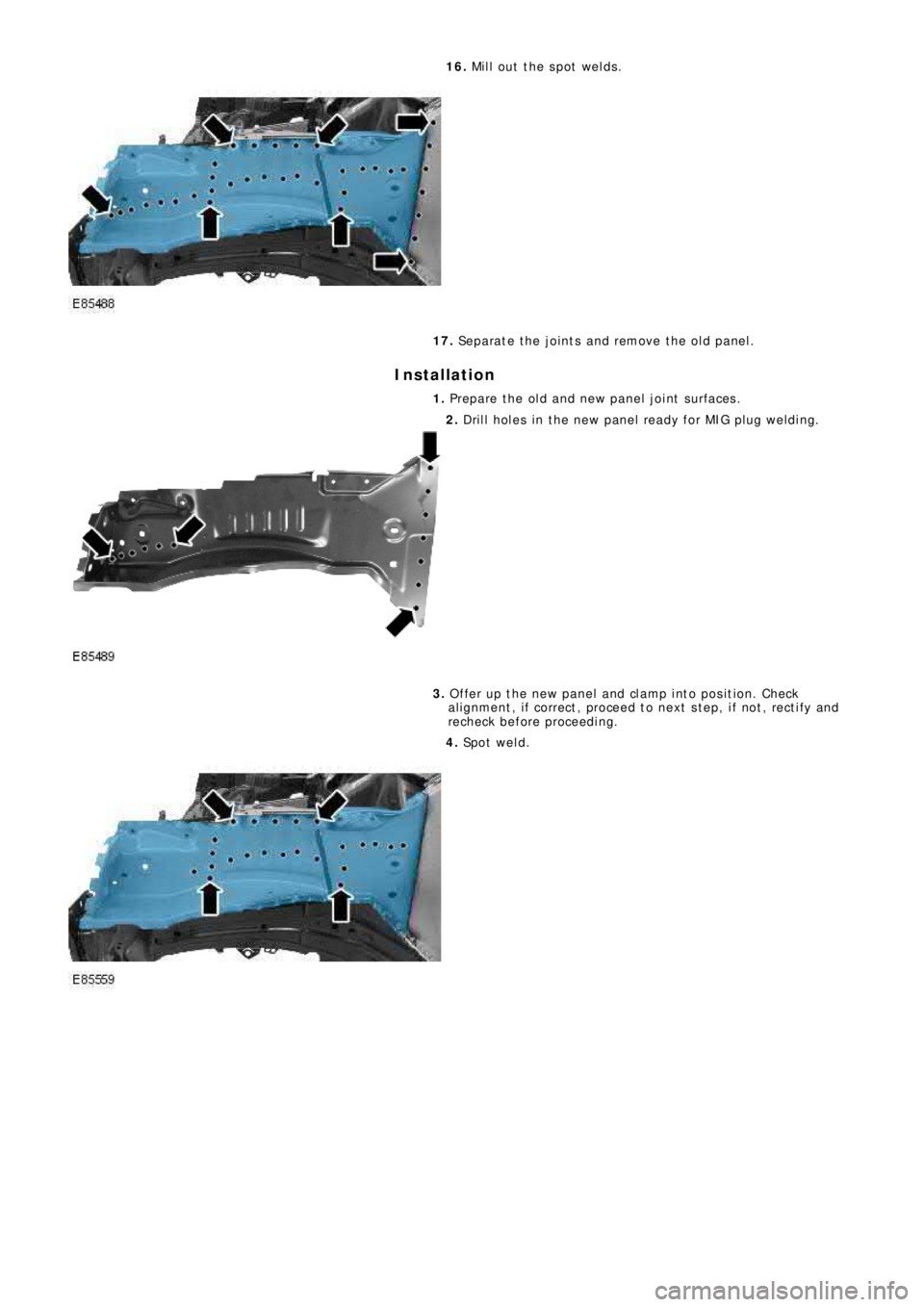

16. Mill out the spot welds.

17. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

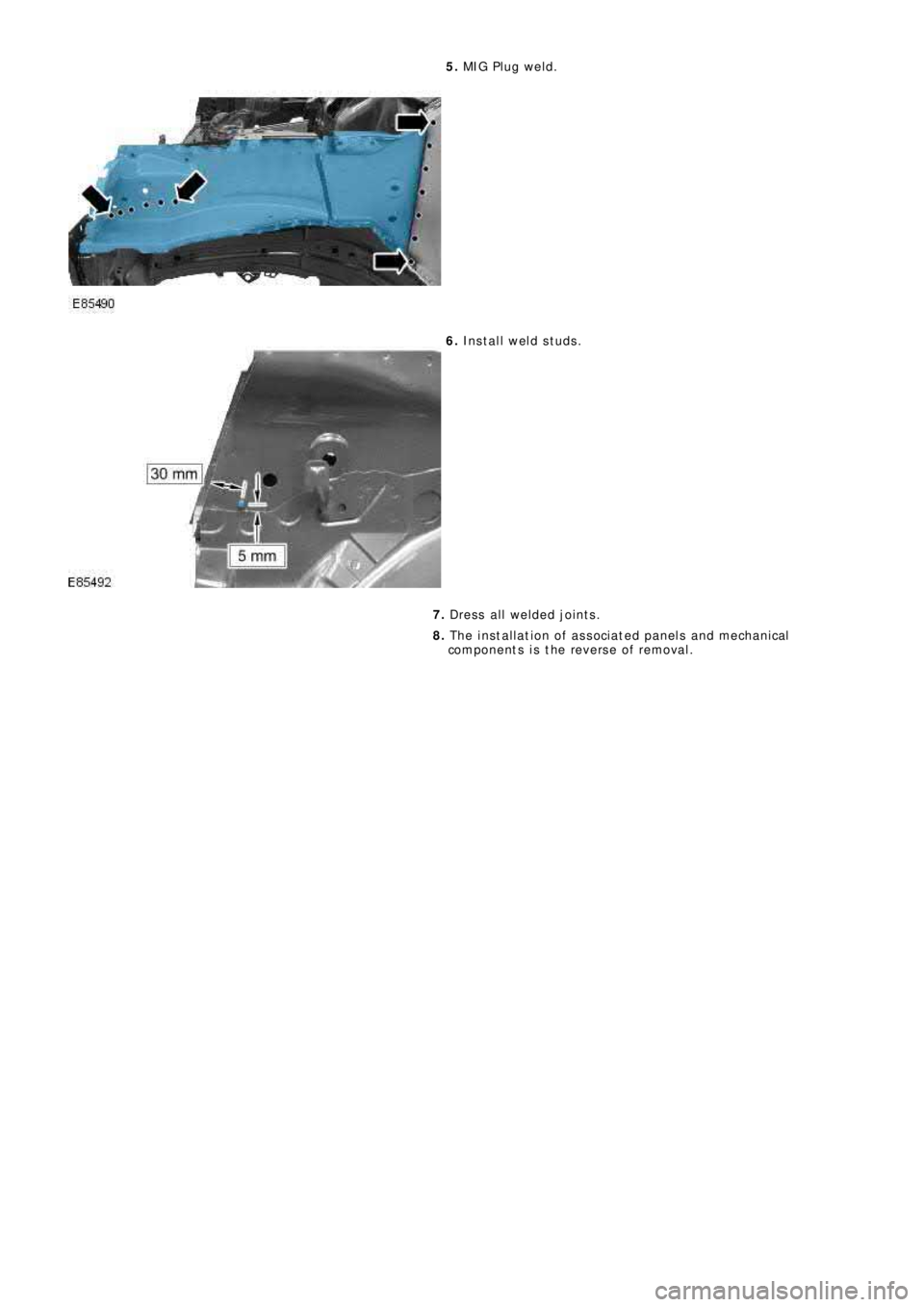

2. Drill holes in the new panel ready for MIG plug welding.

3. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

4. Sp o t w e l d .

Page 2566 of 3229

5. MIG P l ug we l d.

6. Install weld studs.

7. Dress all welded joints.

8. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2567 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Fender Apron Panel Front Extension

Removal and Installation

Removal

• NOTE: The fender apron panel front extension has to be unpicked from the fender apron panel, it is not serviced

separately.

1. The fender apron panel front extension is replaced in

conjunct ion wit h:

Front bumper cover

Hood lat ch panel

Both front fenders

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove t he hood l at ch panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : H o o d L a t ch P a ne l (501-27,

Removal and Installation).

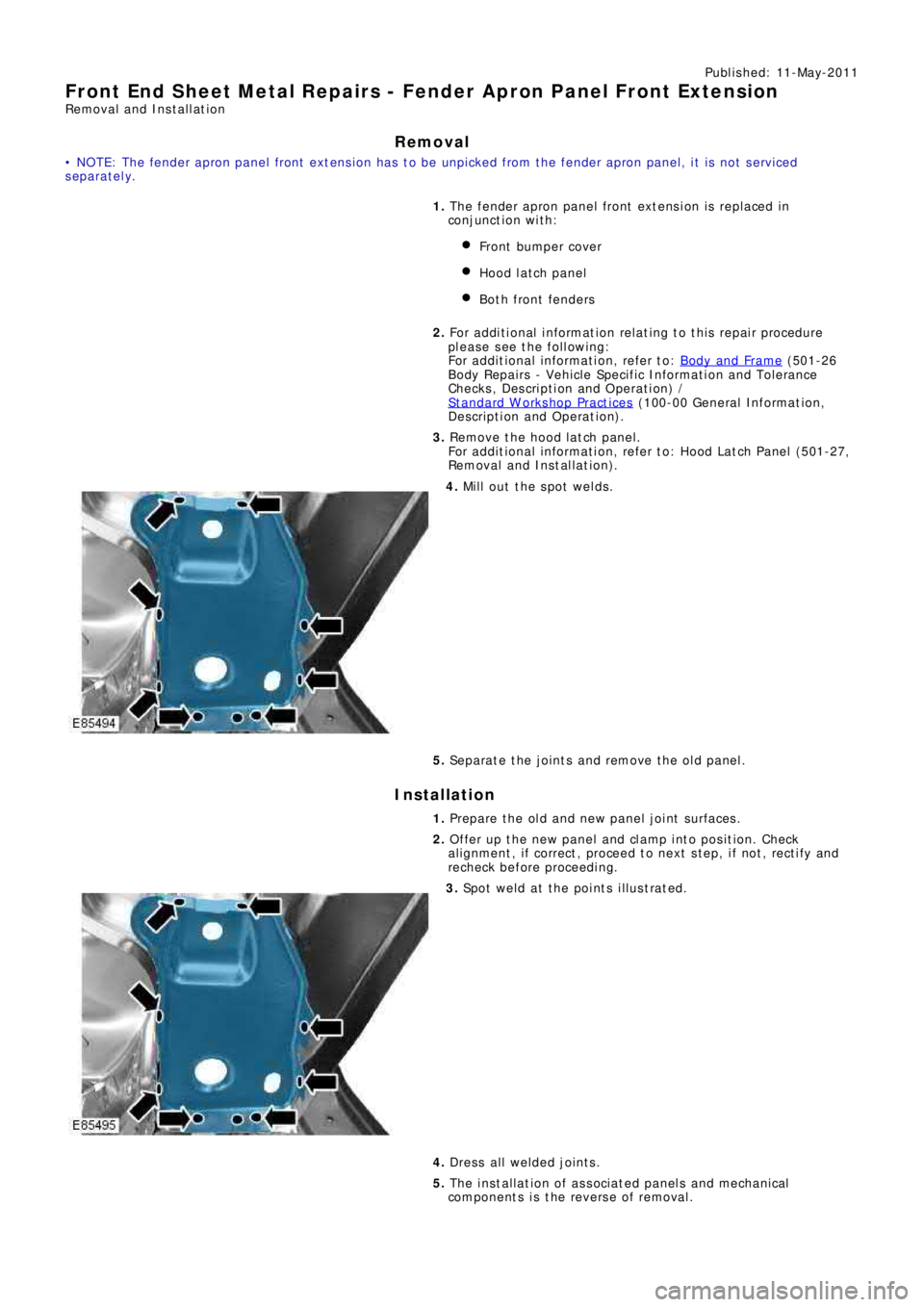

4. Mill out the spot welds.

5. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

2. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

3. Spot weld at the points illustrated.

4. Dress all welded joints.

5. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2568 of 3229

Publ is hed: 11-May-2011

Front End Sheet Metal Repairs - Fender Apron Lower Panel

Removal and Installation

Removal

• NOTE: The fender apron lower panel is to be removed from the fender apron panel service panel; it is not available

separately.

• NOTE: The panel is serviced less its weld studs

1. T he f e nd e r a p ro n l o we r p a ne l i s re p l a ce d i n co nj unct i o n w i t h:

Front bumper cover

Hood lat ch panel

Both front fenders

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove t he hood l at ch panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : H o o d L a t ch P a ne l (501-27,

Removal and Installation).

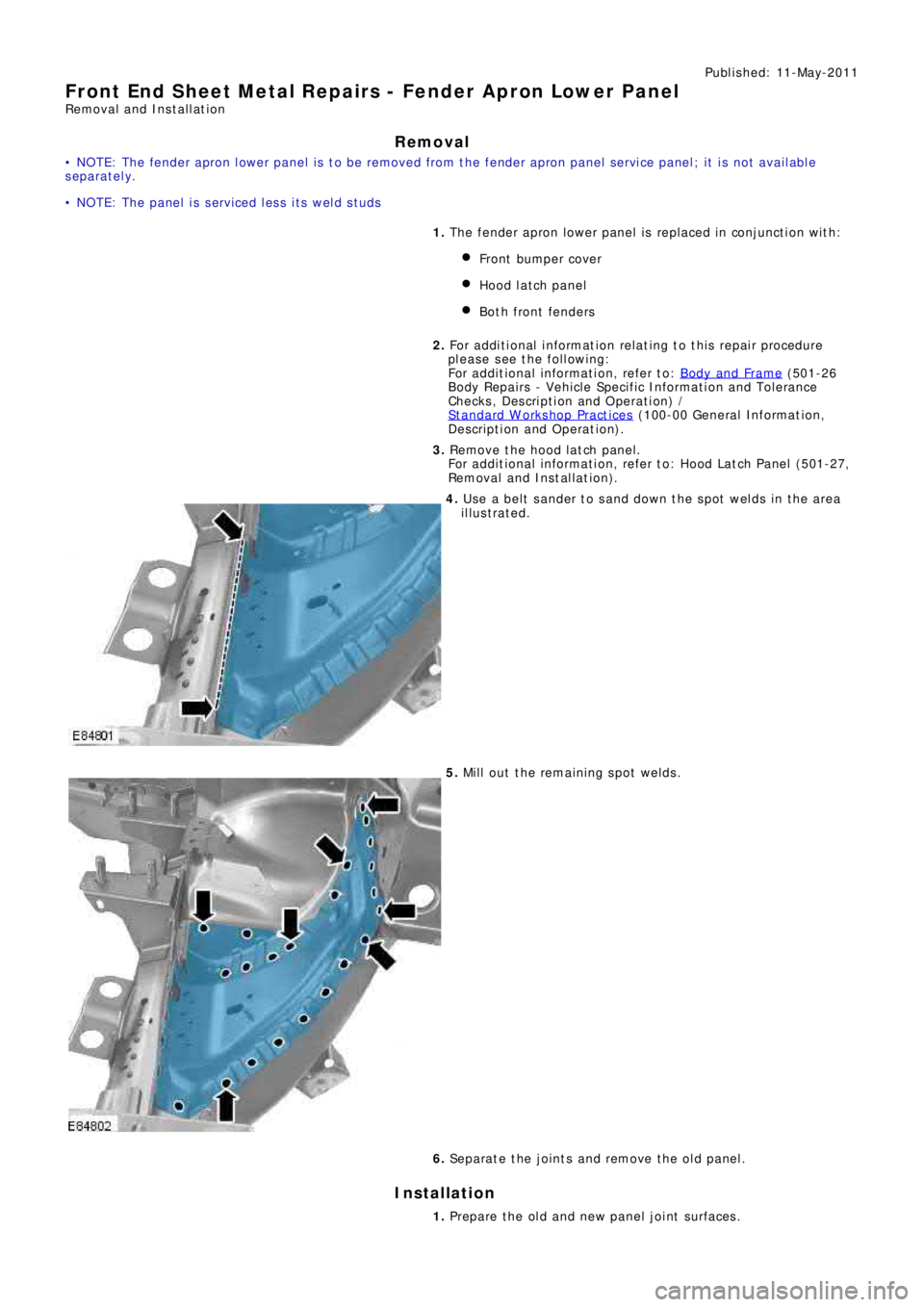

4. Use a belt sander to sand down the spot welds in the area

illustrated.

5. Mill out the remaining spot welds.

6. Separate the joints and remove the old panel.

Installation

1. Prepare the old and new panel joint surfaces.

Page 2569 of 3229

2. Drill holes in the new panel ready for MIG plug welding.

3. Offer up the new panel and clamp into position. Check

al ignment , i f correct , proceed t o next s t ep, i f not , rect i fy and

recheck before proceeding.

4. MIG P l ug we l d.

5. Sp o t w e l d .6. Install weld stud.

7. Dress all welded joints.

8. The installation of associated panels and mechanical

components is the reverse of removal.

Page 2570 of 3229

Publ is hed: 11-May-2011

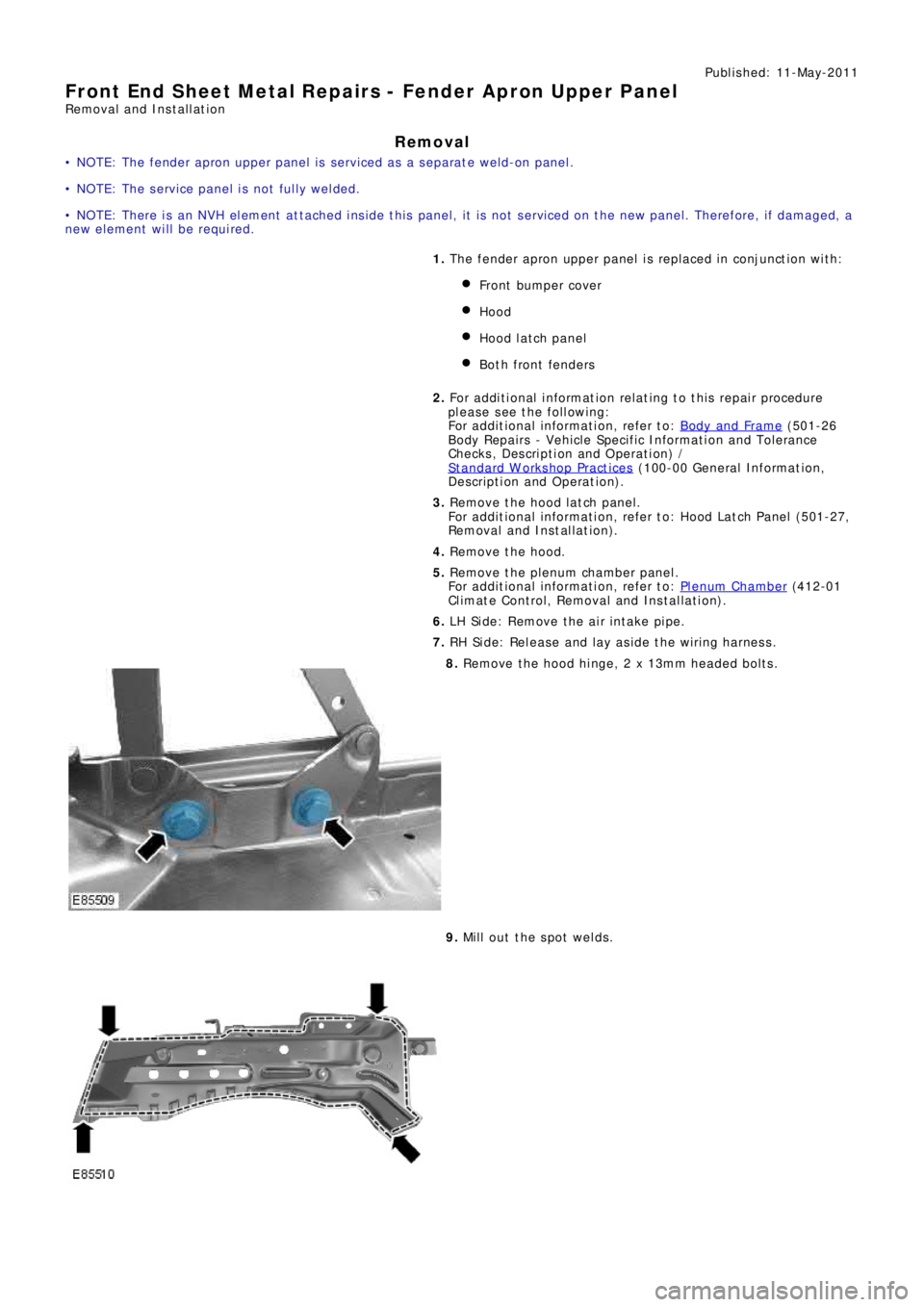

Front End Sheet Metal Repairs - Fender Apron Upper Panel

Removal and Installation

Removal

• NOTE: The fender apron upper panel is s erviced as a s eparat e weld-on panel.

• NOTE: The service panel is not fully welded.

• NOTE: There is an NVH element attached inside this panel, it is not serviced on the new panel. Therefore, if damaged, a

new element will be required.

1. The fender apron upper panel is replaced in conjunct ion wit h:

Front bumper cover

Hood

Hood lat ch panel

Both front fenders

2. Fo r a d d i t i o na l i nf o rma t i o n re l a t i ng t o t hi s re p a i r p ro ce d ure

please see the following:

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Body and Frame

(501-26

Body Repairs - Vehicle Specific Information and Tolerance

Checks, Description and Operation) /

St a nd a rd W o rks ho p P ra ct i ce s

(100-00 Ge ne ra l I nf o rma t i o n,

Description and Operation).

3. Remove t he hood l at ch panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : H o o d L a t ch P a ne l (501-27,

Removal and Installation).

4. Remove the hood.

5. Remove the plenum chamber panel.

Fo r a d d i t i o na l i nf o rma t i o n, re f e r t o : Plenum Chamber

(412-01

Climate Control, Removal and Installation).

6. LH Side: Remove the air intake pipe.

7. RH Side: Release and lay aside the wiring harness.

8. Remove t he hood hi nge, 2 x 13mm headed bol t s .

9. Mill out the spot welds.