sensor LAND ROVER FRELANDER 2 2006 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 639 of 3229

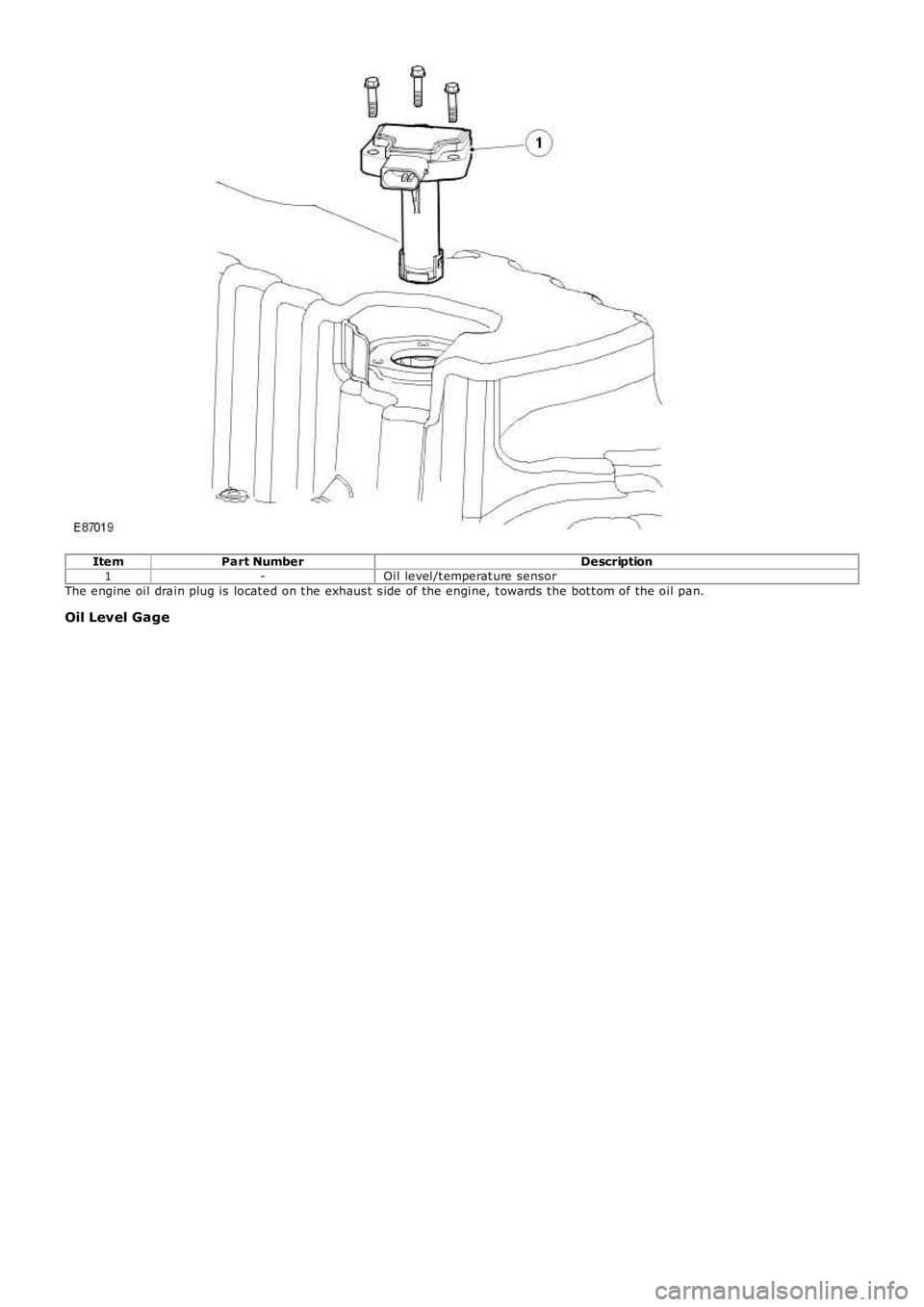

ItemPart NumberDescription1-Oil level/t emperat ure sensorThe engine oil drain plug is locat ed on t he exhaus t s ide of the engine, t owards t he bot t om of the oil pan.

Oil Level Gage

Page 667 of 3229

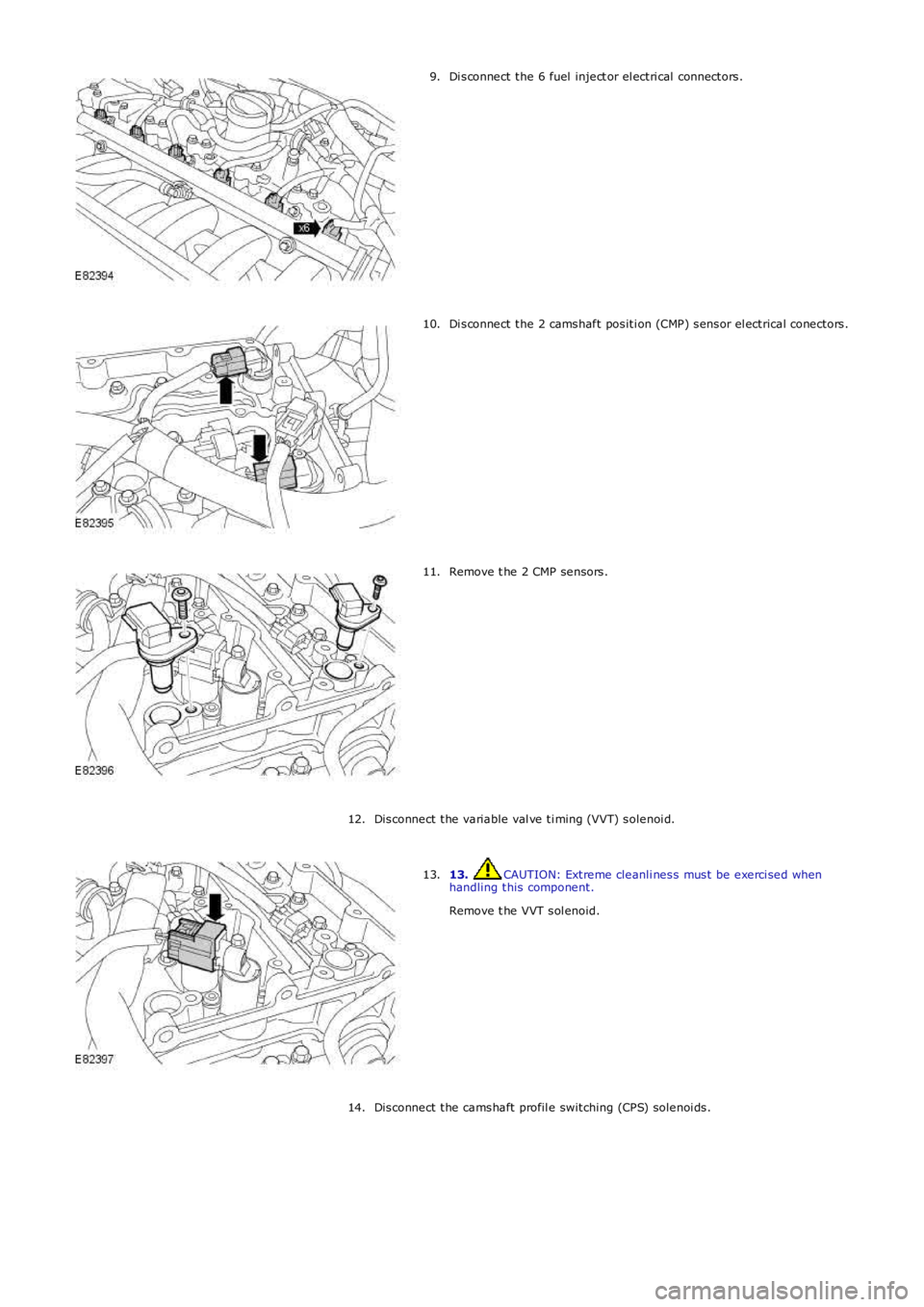

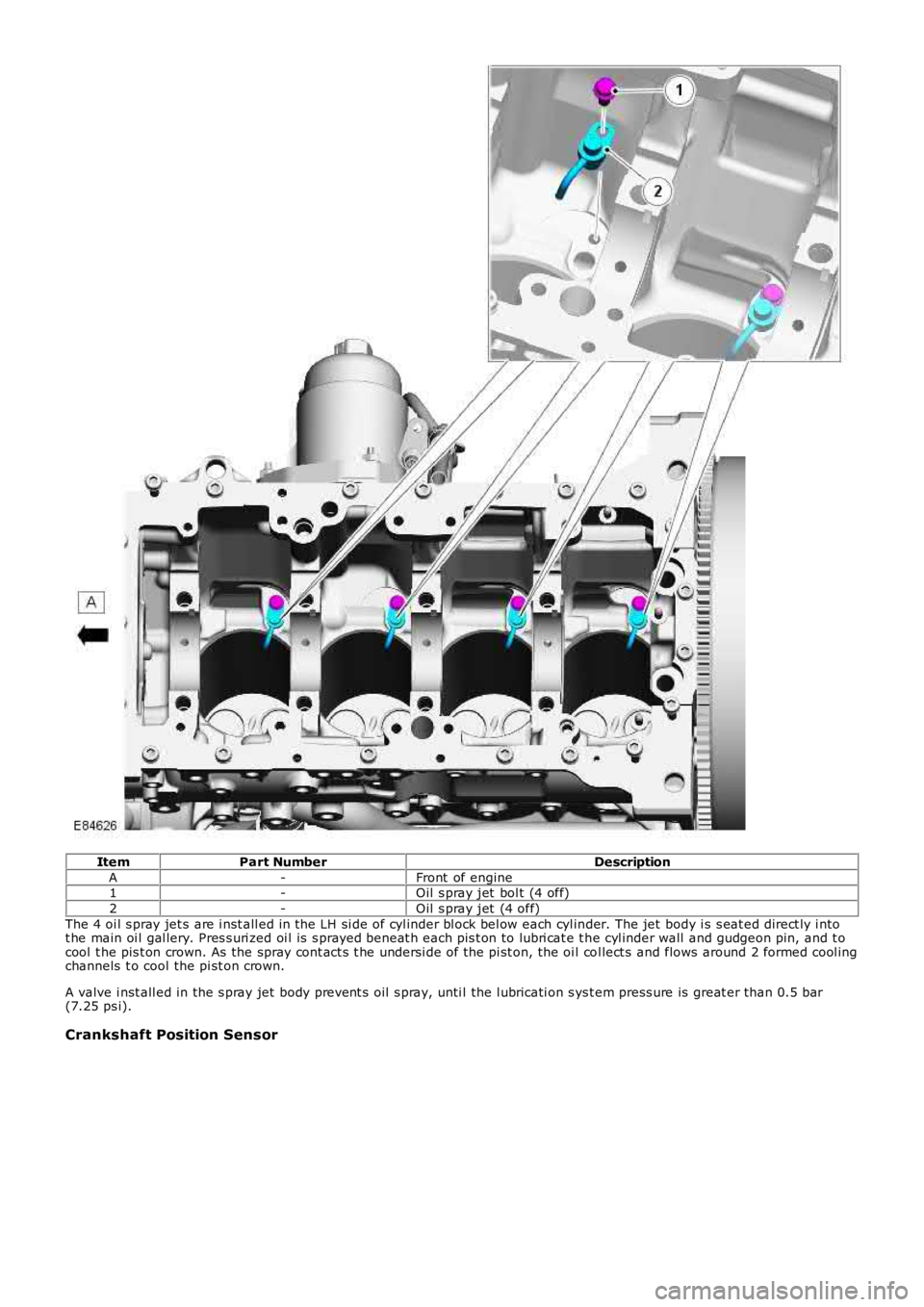

Di sconnect the 6 fuel inject or el ectri cal connectors.

9. Di sconnect the 2 camshaft positi on (CMP) sensor el ectrical conectors.

10. Remove t he 2 CMP sensors.

11.

Disconnect the variable val ve ti ming (VVT) solenoi d.

12. 13. CAUTION: Extreme cleanli ness must be exerci sed when

handling this component.

Remove t he VVT sol enoid.

13.

Disconnect the camshaft profil e switching (CPS) solenoi ds.

14.

Page 671 of 3229

Torque:

6 Nm 13.

CAUTIONS: Extreme cleanli ness must be exerci sed when handli ng this component.

A new O-ring seal is t o be instal led.

Install the CPS solenoids.

Torque: 10 Nm 13.

Connect the CPS solenoi ds.

14.

15. CAUTIONS: Apply clean engi ne oil to t he VVT sol enoid shaft.

Extreme cleanli ness must be exerci sed when handli ng this component.

A new O-ring seal is t o be instal led.

Install the VVT solenoid.

Torque: 10 Nm 15.

Connect the VVT solenoid.

16.

Install the CMP sensors.

Torque: 10 Nm 17.

Connect and secure the CMP sensor electrical connectors.

18.

Connect the fuel i nj ector electrical connectors.

19.

Connect the ground cabl e.

Torque: 6 Nm 20.

Install the engine mount.

Refer to: Engine Mount RH (303-01A Engi ne - I6 3.2L Petrol, Removal and

Installation).

21.

Install the i gniti on coil-on-pl ugs.

Refer to: Igni tion Coil-On-Plug (303-07A Engine Igni tion, Removal and

Installation).

22.

Install the crankcase vent oil separator.

Refer to: Crankcase Vent Oi l Separator (303-08A Engine Emi ssi on Control - I6 3.2L

Petrol, Removal and Installation).

23.

Install the ti ming component housi ng.

Refer to: Timing Components Housing (303-01A Engine - I6 3.2L Pet rol , Removal

and Install ati on).

24.

Connect the battery ground cable and instal l the cover.

Refer to: Specifi cati ons (414-00 Battery and Charging System - General

Information, Specifi cati ons).

25.

Page 763 of 3229

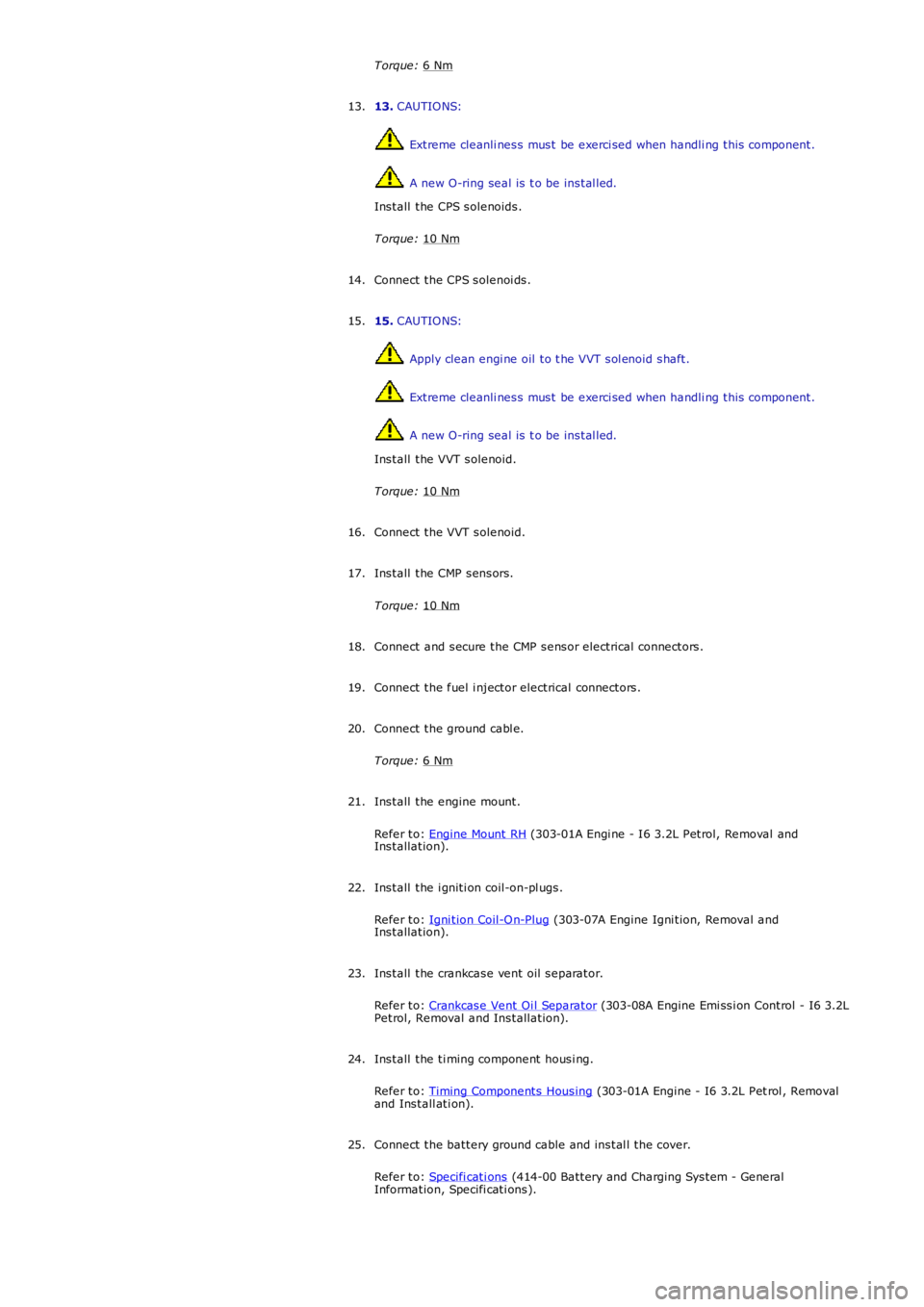

ItemPart NumberDescription

A-Front of engine1-Oil s pray jet bol t (4 off)

2-Oil s pray jet (4 off)

The 4 oi l s pray jet s are i nst all ed in the LH si de of cyl inder bl ock bel ow each cyl inder. The jet body i s s eat ed direct ly i ntot he main oi l gal lery. Pres s uri zed oi l is s prayed beneat h each pis t on to lubri cat e t he cyl inder wall and gudgeon pin, and t ocool t he pis t on crown. As the spray cont act s t he undersi de of the pi st on, the oi l col lect s and flows around 2 formed cool ingchannels t o cool the pi st on crown.

A valve i nst all ed in the s pray jet body prevent s oil s pray, unti l the l ubricati on s ys t em press ure is great er than 0.5 bar(7.25 ps i).

Crankshaft Position Sensor

Page 775 of 3229

ItemPart NumberDescription

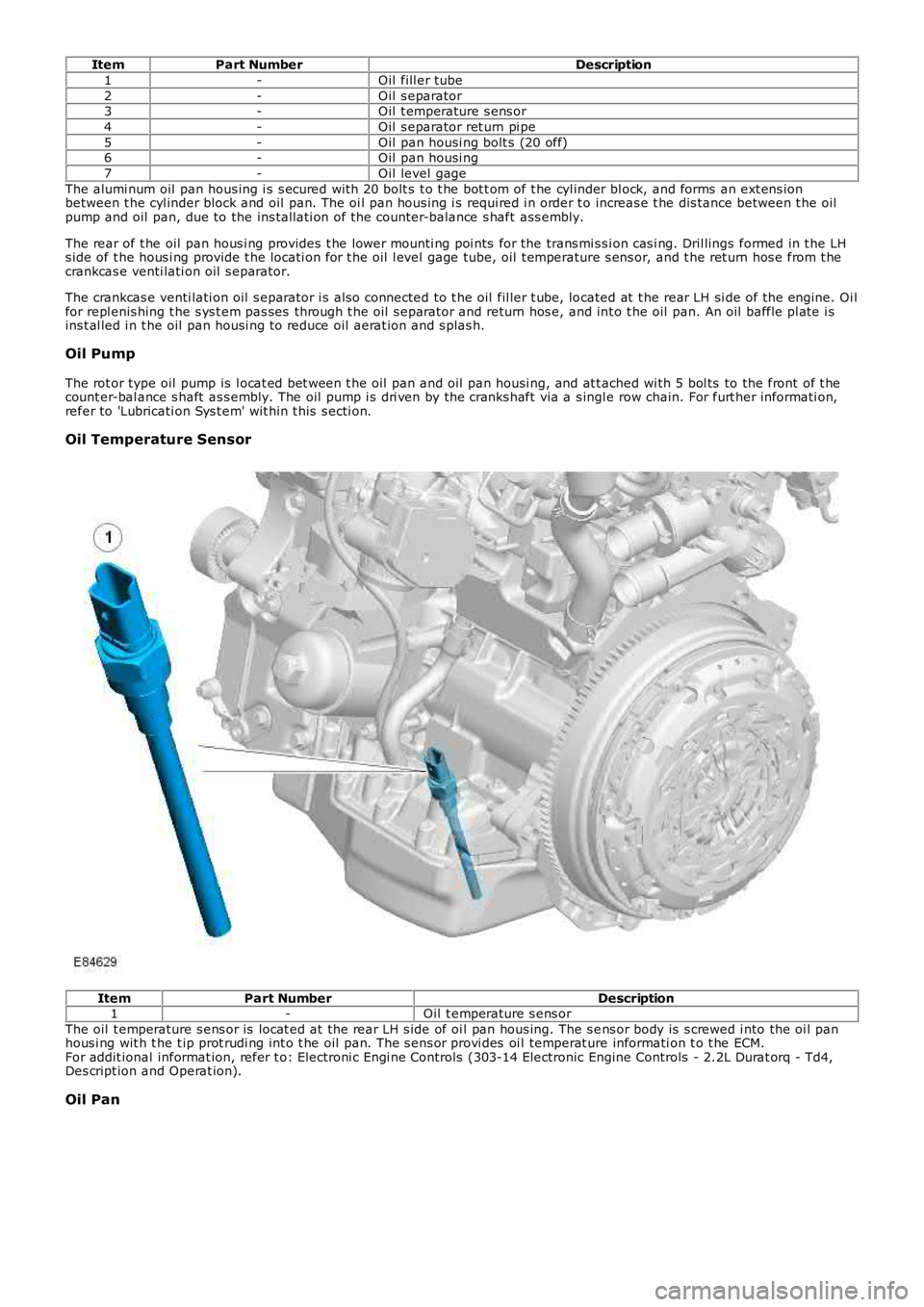

1-Oil fill er tube

2-Oil s eparator3-Oil t emperature s ens or

4-Oil s eparator ret urn pi pe

5-Oil pan housi ng bolt s (20 off)6-Oil pan housi ng

7-Oil level gage

The alumi num oil pan hous ing i s s ecured wit h 20 bolt s t o t he bot t om of t he cyl inder bl ock, and forms an ext ens ionbetween t he cyl inder block and oil pan. The oi l pan hous ing i s requi red i n order t o increas e t he dis tance between t he oilpump and oil pan, due to the ins tall ati on of the counter-balance s haft ass embly.

The rear of t he oil pan hous i ng provides t he lower mounti ng poi nts for the trans mi s si on cas i ng. Dril lings formed in t he LHs ide of t he hous i ng provide t he locati on for t he oil l evel gage tube, oil t emperature s ens or, and t he ret urn hos e from t hecrankcas e venti lati on oil s eparator.

The crankcas e venti lati on oil s eparator i s als o connected to t he oil fil ler t ube, located at t he rear LH si de of the engine. Oi lfor repl enis hing t he s ys t em pas ses through t he oil s eparator and return hos e, and int o t he oil pan. An oil baffle pl ate i sins t al led i n t he oil pan housi ng to reduce oil aerat ion and s plas h.

Oil Pump

The rot or type oil pump is l ocat ed bet ween t he oil pan and oil pan housi ng, and at t ached wi th 5 bol ts to the front of t hecount er-bal ance s haft as s embly. The oil pump i s dri ven by the cranks haft via a s ingle row chain. For furt her informati on,refer to 'Lubricati on Sys t em' wit hin t his s ecti on.

Oil Temperature Sensor

ItemPart NumberDescription1-Oil t emperature s ens or

The oil t emperature s ens or is locat ed at t he rear LH s ide of oi l pan hous ing. The s ens or body is s crewed i nto the oi l panhous i ng wit h t he t ip prot rudi ng int o t he oil pan. The s ens or provi des oi l temperat ure informati on t o t he ECM.For addit ional informat ion, refer t o: Electroni c Engi ne Controls (303-14 Electronic Engine Controls - 2.2L Durat orq - Td4,Des cript ion and Operat ion).

Oil Pan

Page 785 of 3229

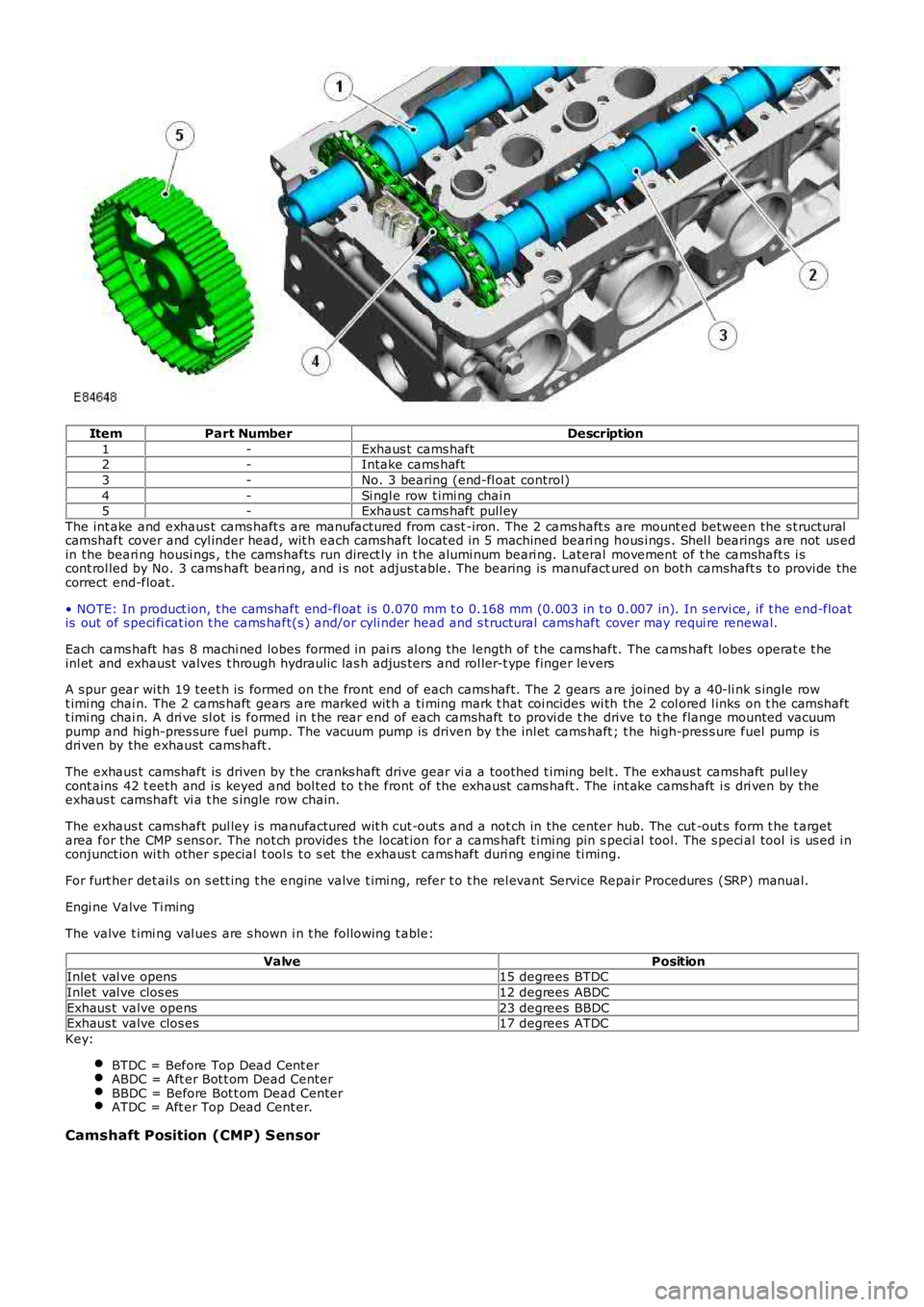

ItemPart NumberDescription

1-Exhaus t cams haft2-Intake cams haft

3-No. 3 bearing (end-fl oat control)

4-Si ngl e row t imi ng chai n5-Exhaus t cams haft pull ey

The int ake and exhaus t cams haft s are manufactured from cast -iron. The 2 cams haft s are mount ed between the s t ructuralcamshaft cover and cyl inder head, wit h each camshaft locat ed i n 5 machined beari ng hous i ngs . Shel l bearings are not us edin the beari ng housi ngs , t he camshafts run direct ly in t he alumi num beari ng. Lateral movement of t he camshaft s i scont rol led by No. 3 cams haft beari ng, and i s not adjust able. The bearing is manufactured on both camshaft s t o provi de thecorrect end-float.

• NOTE: In product ion, t he camshaft end-fl oat i s 0.070 mm t o 0.168 mm (0.003 in t o 0.007 in). In s ervi ce, if t he end-floatis out of s peci fi cat ion t he cams haft(s ) and/or cyli nder head and s t ructural cams haft cover may requi re renewal.

Each cams haft has 8 machi ned lobes formed in pai rs al ong the length of t he cams haft. The cams haft lobes operat e t heinl et and exhaust valves t hrough hydraulic las h adjus ters and rol ler-t ype finger levers

A s pur gear wi th 19 teet h is formed on t he front end of each cams haft. The 2 gears are joined by a 40-li nk s ingle rowt imi ng chai n. The 2 cams haft gears are marked wit h a ti ming mark t hat coi ncides wi th the 2 col ored l inks on t he camshaftt imi ng chai n. A dri ve sl ot is formed in t he rear end of each camshaft to provi de t he drive to t he flange mounted vacuumpump and high-pres sure fuel pump. The vacuum pump is driven by t he inl et cams haft ; the hi gh-pres s ure fuel pump isdri ven by the exhaust cams haft .

The exhaus t camshaft is driven by t he cranks haft drive gear vi a a toothed t iming belt . The exhaus t camshaft pul leycont ains 42 t eeth and is keyed and bol ted to t he front of the exhaust cams haft . The int ake cams haft i s dri ven by theexhaus t camshaft vi a t he s ingle row chain.

The exhaus t camshaft pul ley i s manufactured wit h cut-out s and a not ch in the center hub. The cut -out s form t he t argetarea for the CMP s ens or. The not ch provides the locat ion for a cams haft t imi ng pin speci al tool. The s peci al tool is us ed i nconjunct ion wi th other s pecial t ool s t o s et the exhaus t cams haft duri ng engi ne ti ming.

For furt her det ail s on s ett ing t he engine valve t imi ng, refer t o t he rel evant Service Repair Procedures (SRP) manual.

Engi ne Valve Ti ming

The valve t imi ng val ues are s hown i n t he fol lowing t able:

ValvePositionInlet val ve opens15 degrees BTDC

Inlet val ve clos es12 degrees ABDC

Exhaus t valve opens23 degrees BBDCExhaus t valve clos es17 degrees ATDC

Key:

BTDC = Before Top Dead Cent erABDC = Aft er Bot t om Dead CenterBBDC = Before Bot t om Dead CenterATDC = Aft er Top Dead Cent er.

Camshaft Position (CMP) Sensor

Page 805 of 3229

1

2

3

4

5

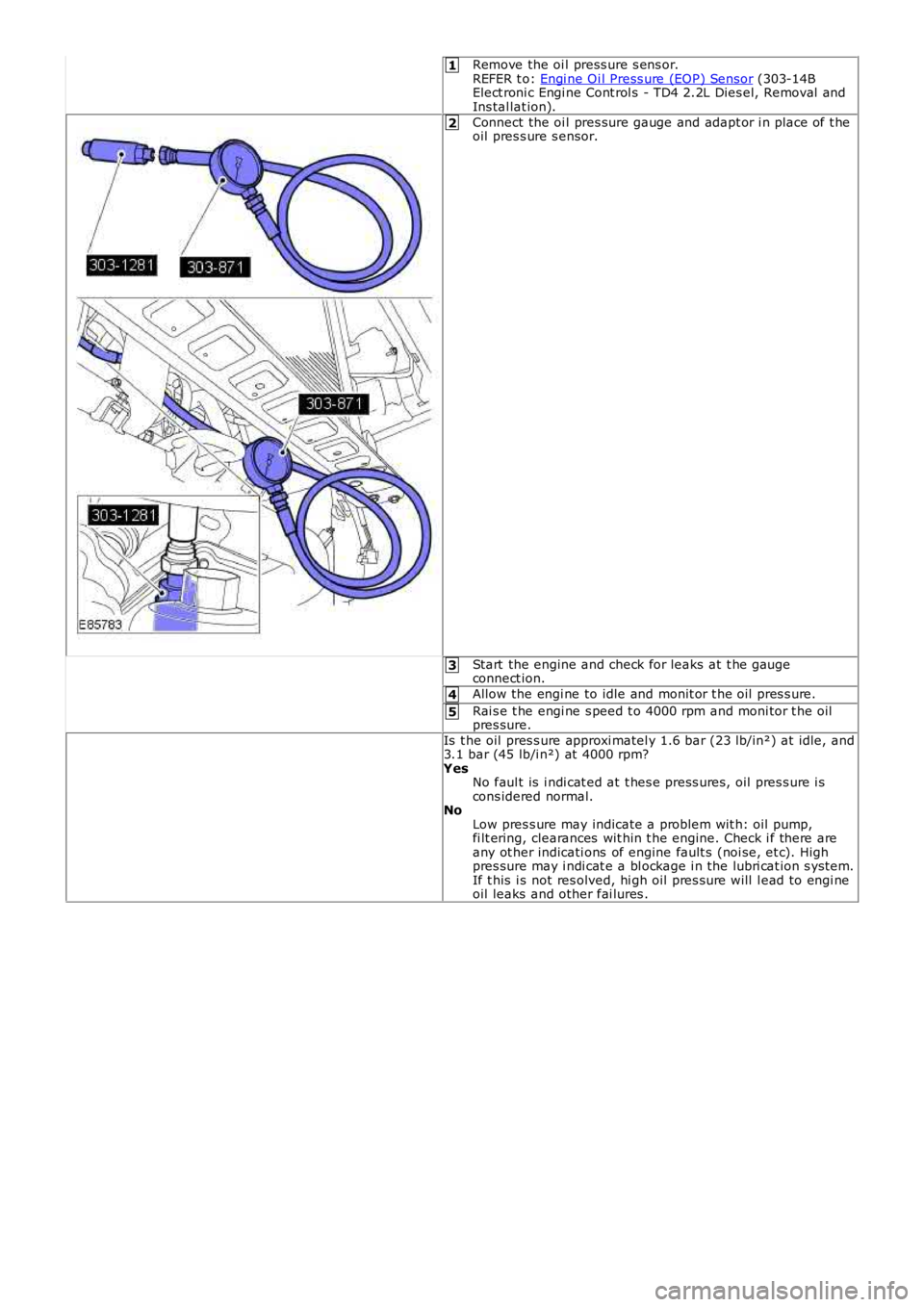

Remove the oi l press ure s ens or.REFER t o: Engi ne Oi l Press ure (EOP) Sensor (303-14BElect roni c Engi ne Cont rol s - TD4 2.2L Dies el, Removal andIns tal lat ion).

Connect the oi l pres sure gauge and adapt or i n place of t heoil pres s ure s ensor.

Start the engine and check for leaks at t he gaugeconnect ion.

Allow the engi ne to idle and monit or t he oil pres s ure.

Rai s e t he engi ne s peed t o 4000 rpm and moni tor t he oilpres sure.

Is t he oil pres s ure approxi matel y 1.6 bar (23 lb/in²) at idle, and3.1 bar (45 lb/i n²) at 4000 rpm?YesNo faul t is i ndi cat ed at t hes e press ures , oil pres s ure i scons idered normal.NoLow pres s ure may indicate a problem wit h: oil pump,fi lt ering, clearances wit hin t he engine. Check i f there areany ot her indicati ons of engine fault s (noi se, et c). Highpres sure may i ndi cat e a bl ockage i n the lubri cat ion s ys tem.If t his i s not res olved, hi gh oil pres s ure will l ead to engi neoil leaks and other fai lures .

Page 914 of 3229

1

2

DT CDescriptionPossible CauseAction

res is t anceEngi ne cool ant t emperat ure(ECT) s ens or fai lure

new s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011621Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude les s than minimum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011622Engine coolant temperature s ens or 1circui t range/performance - s ignalampl it ude greater t han maxi mum

Engi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011700Engine coolant temperature s ens or 1circui t lowEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o groundEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P011800Engine coolant temperature s ens or 1circui t highEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: shortci rcuit t o powerEngi ne cool ant t emperat ure(ECT) s ens or 1 circui t: openci rcuitEngi ne cool ant t emperat ure(ECT) s ens or fai lure

Check t he ECT s ensor and circui ts .Refer to the el ect ri cal guides . Ins tal l anew s ens or as requi red.REFER to: Engine Coolant Temperature(ECT) Sensor (303-14A Electroni cEngi ne Cont rol s - I6 3.2L Pet rol,Removal and Inst all at ion).

P012500Insuffi ci ent coolant t emperature forclos ed-l oop fuel cont rolDamaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P012800Coolant t hermos tat (coolantt emperat ure below thermost atregul ati ng temperat ure)

Damaged/Faul ty coolantthermost atCool ing fan faul tEngi ne cool ant t emperat ures ens or ci rcuit : highres is t anceEngi ne cool ant t emperat ures ens or fai lure

Check t he cool ing s ys tem operati on.Rect ify as neces s ary. Check for DTCsindicati ng a coolant temperat ures ens or fault .

P145C68Fan s yst em component errorCool ing fan cont rol moduletemperat ure fail ureNo acti on neces sary. Code forinformat ion only.

P145D68Fan s yst em component error BCool ing fan cont rol modulehigh t emperature i ndi cat ionNo acti on neces sary. Code forinformat ion only.

Pinpoint Tests

PINPOINT TEST A : LOSS OF COOLANT

T ESTCO NDIT IONSDET AILS/RESULT S/ACT IONS

A1: VISUAL INSPECT IONVis ually ins pect for l oss of coolant .

Carry out a s ys t em press ure tes t. See component t es ts i n t his s ecti on.

Is the engine cooli ng sys t em l eaking?YesRect ify t he leak as i ndi cat ed by t he tes t res ult . Top-up and fil l t he cooling sys tem t o the correctlevel wit h t he correct s pecificati on fl uid as necess ary.REFER to: Speci fi cat ions (303-03A Engi ne Cool ing - I6 3.2L Petrol , Specificati ons) /Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, GeneralProcedures).TEST the s ys tem for correct operat ion.NoVeri fy t he cust omer compl aint.

Page 947 of 3229

Publi s hed: 11-May-2011

Engine Cooling - TD4 2.2L Diesel - Engine Cooling

Diagnosi s and Tes ti ng

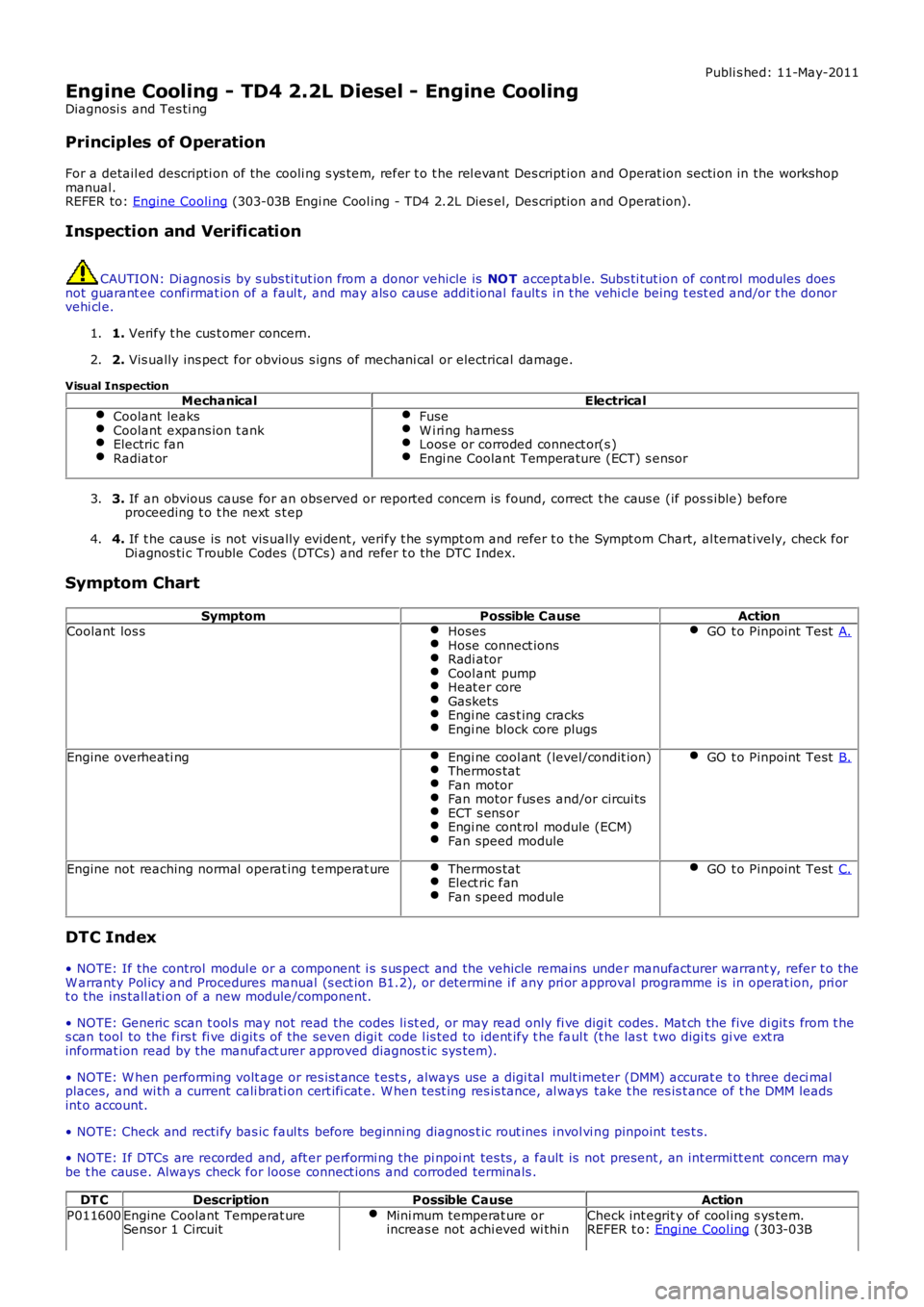

Principles of Operation

For a detail ed descripti on of the cooli ng s ys t em, refer t o t he rel evant Des cript ion and Operat ion secti on in the workshop

manual.

REFER to: Engine Cooli ng (303-03B Engi ne Cool ing - TD4 2.2L Dies el, Des cript ion and Operat ion).

Inspection and Verification CAUTION: Di agnos is by s ubs ti tut ion from a donor vehicle is

NO T acceptabl e. Subs ti tut ion of cont rol modules does

not guarant ee confirmat ion of a faul t, and may als o caus e addit ional fault s i n t he v ehi cl e being t est ed and/or t he donor

vehi cl e.

1. Verify t he cus t omer concern.

1.

2. Vis ually ins pect for obvious s igns of mechani cal or electrical damage.

2.

Visual Inspection Mechanical Electrical

Coolant leaks Coolant expans ion t ank

Electric fan

Radiat or Fuse

W i ri ng harness

Loos e or corroded connect or(s )

Engi ne Coolant Temperature (ECT) s ensor

3.

If an obvious cause for an obs erved or report ed concern is found, correct t he caus e (if pos s ible) before

proceeding t o t he next s t ep

3.

4. If t he caus e is not vis ually evi dent , verify t he sympt om and refer t o t he Sympt om Ch art, al ternat ively, check for

Di agnos ti c Trouble Codes (DTCs) and refer t o t he DTC Index.

4.

Symptom Chart Symptom Possible CauseAction

Coolant los s Hoses Hose connect ions

Radi ator

Cool ant pump

Heat er core

Gaskets

Engi ne cas t ing cracks

Engi ne block core plugs GO t o Pinpoint Test

A.Engine overheati ng

Engi ne cool ant (level/condit ion) Thermos tat

Fan motor

Fan motor fus es and/or circui ts

ECT s ens or

Engi ne cont rol module (ECM)

Fan speed module GO t o Pinpoint Test

B.Engine not reaching normal operat ing t emperat ure

Thermos tat Elect ric fan

Fan speed module GO t o Pinpoint Test

C.DTC Index

• NOTE: If the control modul e or a component i s s us pect and the vehicle remains unde r manufacturer warrant y, refer t o the

W arranty Pol icy and Procedures manual (s ect ion B1.2), or determine i f any pri or appr oval programme is in operat ion, pri or

t o the ins tall ati on of a new module/component.

• NOTE: Generic scan t ool s may not read the codes li st ed, or may read only fi ve digi t codes . Mat ch the five di git s from t he

s can tool to the firs t fi ve di git s of the seven digi t code l is ted to ident ify t he fa ul t (t he las t t wo digi ts gi ve ext ra

informat ion read by the manufact urer approved diagnos t ic s ys tem).

• NOTE: W hen performing volt age or res is t ance t est s , always use a digi tal mult imeter (DMM) accurat e t o t hree deci mal

places, and wi th a current cali brati on cert ifi cat e. W hen t est ing res is tance, al ways take t he res is t ance of t he DMM leads

int o account.

• NOTE: Check and recti fy bas ic faul ts before beginni ng diagnos t ic rout ines i nvol vi n g pinpoint t es t s.

• NOTE: If DTCs are recorded and, aft er performi ng the pi npoi nt tes ts , a fault is no t present , an int ermi tt ent concern may

be t he caus e. Always check for loose connect ions and corroded terminals .

DT C Description Possible Cause Action

P011600 Engine Coolant Temperat ure

Sensor 1 Circuit Mini mum temperat ure or

increas e not achi eved wi thi n Check int egrit y of cool ing s ys tem.

REFER t o: Engi ne Cool ing (303-03B

Page 948 of 3229

1

2

1

1

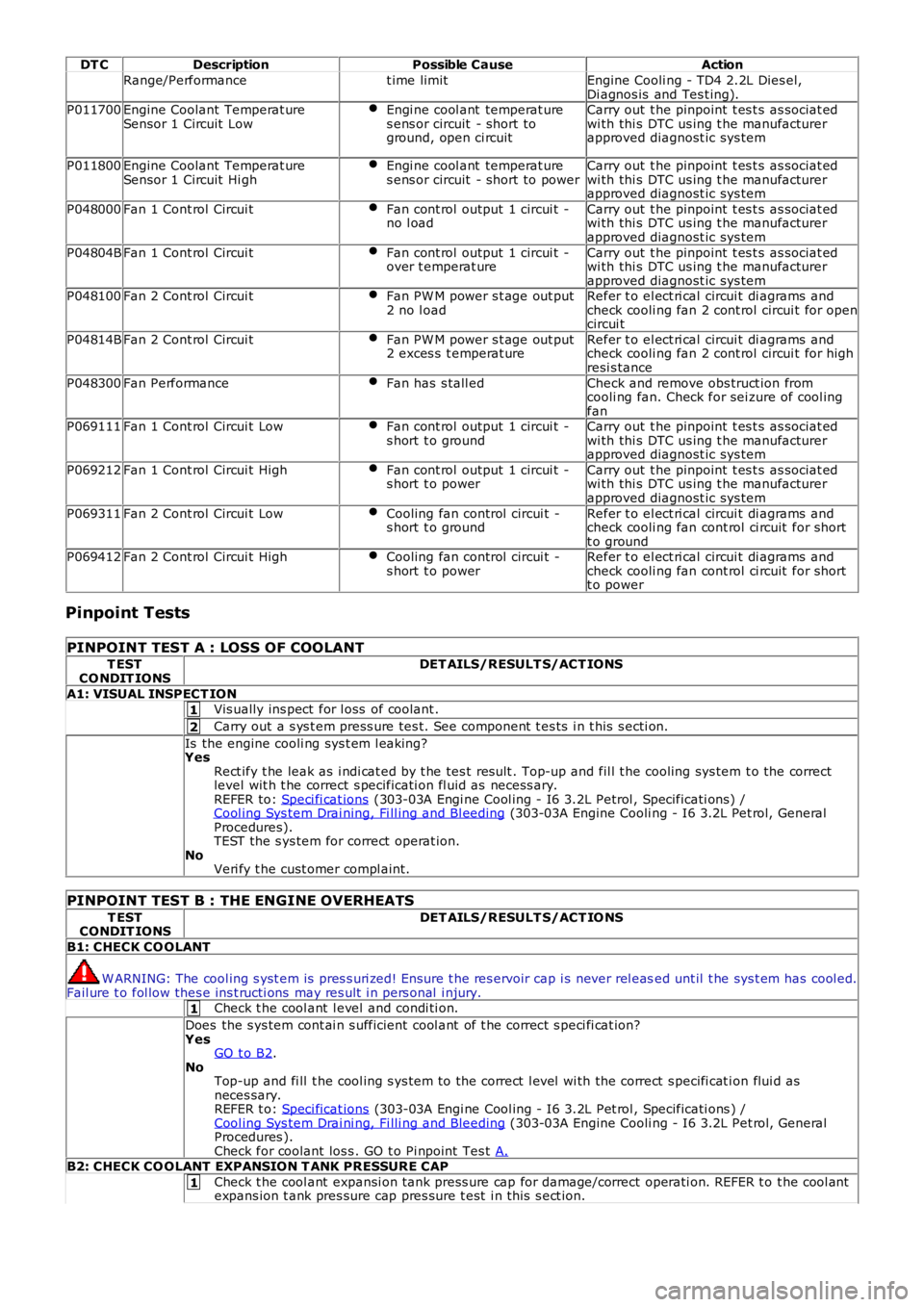

DT C

Description Possible Cause Action

Range/Performance t ime limitEngine Cooli ng - TD4 2.2L Dies el,

Di agnos is and Tes t ing).

P011700 Engine Coolant Temperat ure

Sensor 1 Circuit Low Engi ne cool ant temperat ure

s ens or circuit - short to

ground, open ci rcuit Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P011800 Engine Coolant Temperat ure

Sensor 1 Circuit Hi gh Engi ne cool ant temperat ure

s ens or circuit - short to power Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P048000 Fan 1 Cont rol Circui t Fan cont rol output 1 circui t -

no l oad Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P04804B Fan 1 Cont rol Circui t Fan cont rol output 1 circui t -

over t emperat ure Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P048100 Fan 2 Cont rol Circui t Fan PW M power s t age out put

2 no l oad Refer t o el ect ri cal circui t di agrams and

check cooli ng fan 2 cont rol circui t for open

circui t

P04814B Fan 2 Cont rol Circui t Fan PW M power s t age out put

2 exces s t emperat ure Refer t o el ect ri cal circui t di agrams and

check cooli ng fan 2 cont rol circui t for high

resi s tance

P048300 Fan Performance Fan has s tall ed Check and remove obs truct ion from

cooli ng fan. Check for sei zure of cool ing

fan

P069111 Fan 1 Cont rol Circui t Low Fan cont rol output 1 circui t -

s hort t o ground Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P069212 Fan 1 Cont rol Circui t High Fan cont rol output 1 circui t -

s hort t o power Carry out t he pinpoint t es t s as sociat ed

wi th thi s DTC us ing t he manufacturer

approved diagnost ic sys tem

P069311 Fan 2 Cont rol Circui t Low Cooling fan control circui t -

s hort t o ground Refer t o el ect ri cal circui t di agrams and

check cooli ng fan cont rol ci rcuit for short

t o ground

P069412 Fan 2 Cont rol Circui t High Cooling fan control circui t -

s hort t o power Refer t o el ect ri cal circui t di agrams and

check cooli ng fan cont rol ci rcuit for short

t o power

Pinpoint Tests

PINPOINT TEST A : LOSS OF COOLANT T EST

CO NDIT IONS DET AILS/RESULT S/ACT IONS

A1: VISUAL INSPECT ION Vis ually ins pect for l oss of coolant .

Carry out a s ys t em press ure tes t. See component t es ts i n t his s ecti on.

Is the engine cooli ng sys t em l eaking?

Yes

Rect ify t he leak as i ndi cat ed by t he tes t res ult . Top-up and fil l t he cooling sys tem t o the correct

level wit h t he correct s pecificati on fl uid as necess ary.

REFER to: Speci fi cat ions (303-03A Engi ne Cool ing - I6 3.2L Petrol , Specificati ons) /

Cool ing Sys tem Drai ning, Fi ll ing and Bl eeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, General

Procedures).

TEST the s ys tem for correct operat ion.

No Veri fy t he cust omer compl aint.

PINPOINT TEST B : THE ENGINE OVERHEATS T EST

CONDIT IONS DET AILS/RESULT S/ACT IO NS

B1: CHECK CO OLANT W ARNING: The cool ing s yst em is pres s uri zed! Ensure t he res ervoir cap i s never rel eas

ed unt il t he sys t em has cool ed.

Fail ure t o fol low thes e ins t ructi ons may res ult i n pers onal i njury.

Check t he cool ant l evel and condi ti on.

Does the s ys tem cont ai n s ufficient cool ant of t he correct s peci fi cat ion?

Yes GO t o B2 .

No Top-up and fi ll t he cool ing s ys tem to the correct l evel wi th the correct s pecifi cat i on flui d as

neces sary.

REFER t o: Speci ficat ions (303-03A Engi ne Cool ing - I6 3.2L Pet rol , Specificati ons ) /

Cool ing Sys tem Drai ni ng, Fi lli ng and Bleeding (303-03A Engine Cooli ng - I6 3.2L Pet rol, General

Procedures ).

Check for coolant los s . GO t o Pi npoint Tes t A.B2: CHECK CO OLANT EXPANSION T ANK PRESSURE CAP

Check t he cool ant expansi on tank press ure cap for damage/correct operati on. REFER t o t he cool ant

expans ion t ank pres sure cap pres sure t est i n t his s ect ion.