lock LAND ROVER FRELANDER 2 2006 Manual PDF

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2006, Model line: FRELANDER 2, Model: LAND ROVER FRELANDER 2 2006Pages: 3229, PDF Size: 78.5 MB

Page 359 of 3229

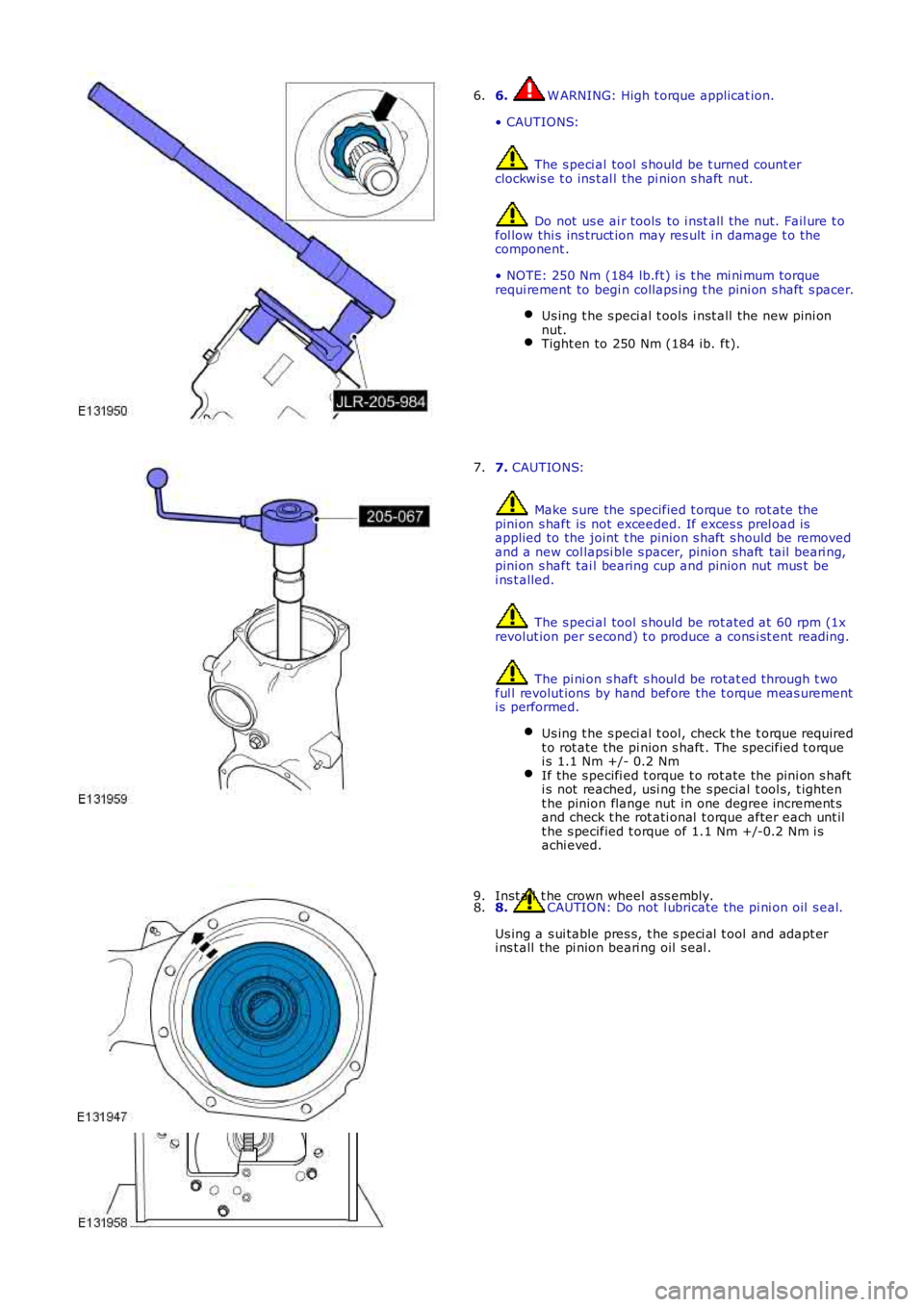

6. W ARNING: High t orque applicat ion.

• CAUTIONS:

The s peci al tool s hould be t urned count erclockwis e t o ins t al l the pi nion s haft nut.

Do not us e ai r tools to i nst all t he nut. Fail ure t ofol low thi s ins truct ion may res ult i n damage t o thecomponent .

• NOTE: 250 Nm (184 lb.ft) i s t he mi ni mum torquerequi rement to begi n collaps ing t he pini on s haft s pacer.

Us ing t he s peci al t ools i nst all t he new pini onnut.Tight en to 250 Nm (184 ib. ft).

6.

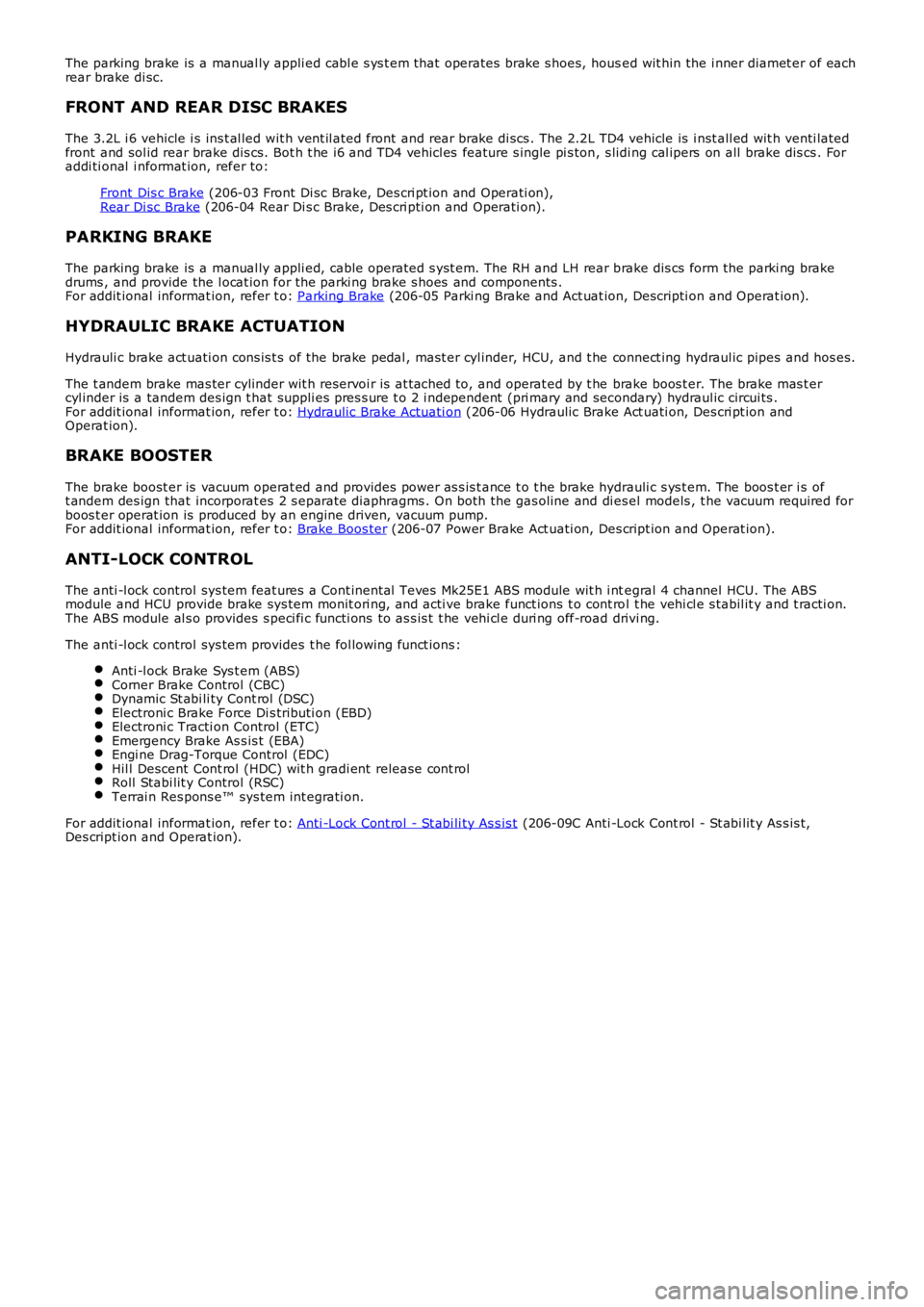

7. CAUTIONS:

Make s ure the specified t orque t o rot ate thepini on s haft is not exceeded. If exces s prel oad isapplied to the joint t he pinion s haft s hould be removedand a new col lapsi ble s pacer, pinion shaft tail beari ng,pini on s haft tai l bearing cup and pinion nut mus t bei ns t alled.

The s peci al tool s hould be rot ated at 60 rpm (1xrevolut ion per s econd) t o produce a cons i st ent reading.

The pi ni on s haft s houl d be rotat ed through t woful l revolut ions by hand before the t orque meas urementi s performed.

Us ing t he s peci al t ool, check t he t orque requiredt o rot ate the pi nion s haft . The specified t orquei s 1.1 Nm +/- 0.2 NmIf the s pecifi ed t orque t o rot ate the pi ni on s hafti s not reached, usi ng t he s pecial t ool s, t ight ent he pinion flange nut in one degree increment sand check t he rot ati onal t orque after each unt ilt he s pecified t orque of 1.1 Nm +/-0.2 Nm i sachi eved.

7.

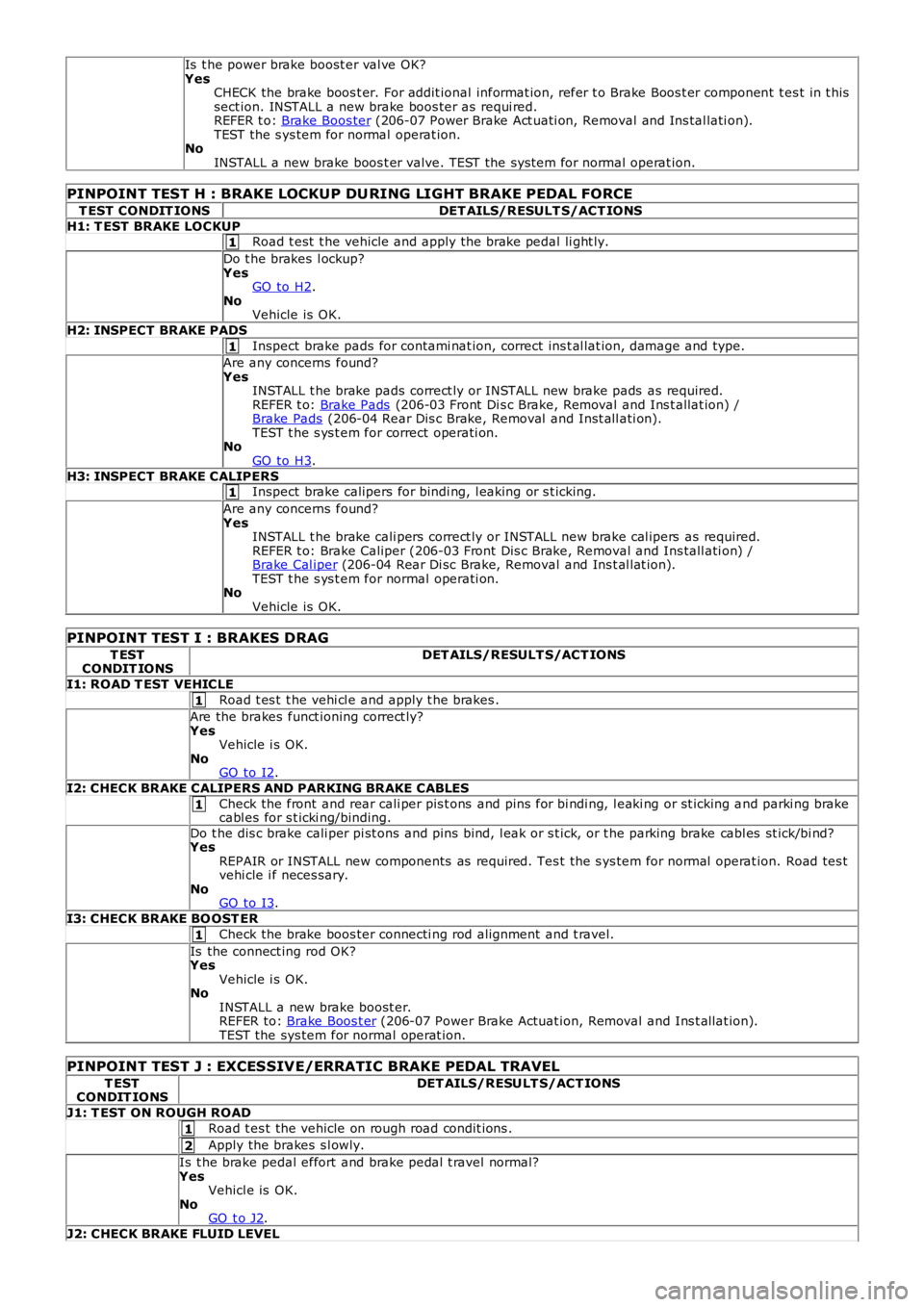

8. CAUTION: Do not l ubricate the pi ni on oil s eal.

Us ing a s ui table pres s, t he s peci al t ool and adapt eri ns t all the pi nion beari ng oil s eal .

8.Inst all t he crown wheel ass embly.9.

Page 408 of 3229

The parking brake is a manual ly appli ed cabl e s ys t em t hat operates brake s hoes, housed wit hin the i nner diamet er of eachrear brake di sc.

FRONT AND REAR DISC BRAKES

The 3.2L i 6 vehicle i s ins t al led wit h vent il ated front and rear brake di scs . The 2.2L TD4 vehicle is i nst all ed wit h venti latedfront and sol id rear brake dis cs. Bot h t he i6 and TD4 vehicl es feature s ingle pi s ton, s lidi ng cal ipers on all brake dis cs . Foraddi ti onal i nformat ion, refer to:

Front Dis c Brake (206-03 Front Di sc Brake, Des cri pt ion and Operati on),Rear Di sc Brake (206-04 Rear Di s c Brake, Des cri pti on and Operati on).

PARKING BRAKE

The parking brake is a manual ly appli ed, cable operat ed s yst em. The RH and LH rear brake dis cs form the parki ng brakedrums , and provide the l ocat ion for the parki ng brake s hoes and components .For addit ional informat ion, refer t o: Parking Brake (206-05 Parki ng Brake and Act uat ion, Descripti on and Operat ion).

HYDRAULIC BRAKE ACTUATION

Hydrauli c brake act uati on cons is t s of the brake pedal , mast er cyl inder, HCU, and t he connect ing hydraul ic pipes and hos es.

The t andem brake mas ter cylinder wit h reservoi r is at tached to, and operat ed by t he brake boos t er. The brake mas t ercyl inder is a tandem des ign t hat suppli es pres s ure t o 2 i ndependent (pri mary and secondary) hydraul ic circui ts .For addit ional informat ion, refer t o: Hydraulic Brake Actuati on (206-06 Hydraulic Brake Act uati on, Des cri pt ion andOperat ion).

BRAKE BOOSTER

The brake boost er is vacuum operat ed and provides power as s is t ance t o t he brake hydrauli c s ys t em. The boos t er i s oft andem des ign that incorporat es 2 s eparate diaphragms . On both the gas oline and di esel models , t he vacuum required forboos t er operat ion is produced by an engine driven, vacuum pump.For addit ional informat ion, refer t o: Brake Boos ter (206-07 Power Brake Act uati on, Des cript ion and Operat ion).

ANTI-LOCK CONTROL

The anti -l ock control sys tem feat ures a Cont inental Teves Mk25E1 ABS module wit h i ntegral 4 channel HCU. The ABSmodule and HCU provide brake sys tem monit ori ng, and acti ve brake funct ions t o cont rol t he vehi cl e s tabil it y and t racti on.The ABS module al s o provides s peci fi c functi ons to as s is t t he vehi cl e duri ng off-road drivi ng.

The anti -l ock control sys tem provides t he fol lowing funct ions :

Anti -l ock Brake Sys t em (ABS)Corner Brake Control (CBC)Dynamic St abi li ty Cont rol (DSC)Electroni c Brake Force Di s tributi on (EBD)Electroni c Tracti on Control (ETC)Emergency Brake As s is t (EBA)Engi ne Drag-Torque Control (EDC)Hil l Descent Cont rol (HDC) wit h gradi ent release cont rolRoll Stabi lit y Control (RSC)Terrai n Res pons e™ sys tem int egrati on.

For addit ional informat ion, refer t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09C Anti -Lock Cont rol - St abi lit y As s is t,Des cript ion and Operat ion).

Page 414 of 3229

1

1

1

1

1

1

1

2

Is t he power brake boost er val ve OK?YesCHECK the brake boos t er. For addit ional informat ion, refer t o Brake Boos t er component t es t in t hissect ion. INSTALL a new brake boos ter as requi red.REFER t o: Brake Boos ter (206-07 Power Brake Act uati on, Removal and Ins tal lati on).TEST the s ys tem for normal operat ion.NoINSTALL a new brake boos t er valve. TEST the sys tem for normal operat ion.

PINPOINT TEST H : BRAKE LOCKUP DU RING LIG HT BRAKE PEDAL FORCE

T EST CONDIT IONSDET AILS/RESULT S/ACT IONS

H1: T EST BRAKE LOCKUPRoad t est t he vehicle and apply the brake pedal li ght ly.

Do t he brakes l ockup?YesGO to H2.NoVehicle is OK.

H2: INSPECT BRAKE PADS

Inspect brake pads for contami nat ion, correct ins t al lat ion, damage and type.

Are any concerns found?YesINSTALL t he brake pads correct ly or INSTALL new brake pads as required.REFER t o: Brake Pads (206-03 Front Di s c Brake, Removal and Ins t allat ion) /Brake Pads (206-04 Rear Dis c Brake, Removal and Inst all ati on).TEST t he s ys t em for correct operati on.NoGO to H3.

H3: INSPECT BRAKE CALIPERSInspect brake calipers for bindi ng, l eaking or s t icking.

Are any concerns found?YesINSTALL t he brake cali pers correct ly or INSTALL new brake cal ipers as required.REFER t o: Brake Caliper (206-03 Front Dis c Brake, Removal and Ins tall ati on) /Brake Cal iper (206-04 Rear Di sc Brake, Removal and Ins t al lat ion).TEST t he s ys t em for normal operati on.NoVehicle is OK.

PINPOINT TEST I : BRAKES DRAG

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

I1: ROAD T EST VEHICLE

Road t es t t he vehi cl e and apply t he brakes .

Are the brakes funct ioning correct ly?YesVehicle i s OK.NoGO to I2.

I2: CHECK BRAKE CALIPERS AND PARKING BRAKE CABLES

Check the front and rear cali per pis t ons and pins for bi ndi ng, l eaki ng or st icking and parki ng brakecabl es for s t icki ng/binding.

Do t he dis c brake cali per pi st ons and pins bind, l eak or s t ick, or t he parking brake cabl es st ick/bi nd?YesREPAIR or INSTALL new components as required. Tes t the s ys tem for normal operat ion. Road tes tvehi cle i f neces sary.NoGO to I3.

I3: CHECK BRAKE BO OST ER

Check the brake boos ter connecti ng rod alignment and t ravel.

Is the connect ing rod OK?YesVehicle i s OK.NoINSTALL a new brake boost er.REFER to: Brake Boos t er (206-07 Power Brake Actuat ion, Removal and Ins t allat ion).TEST the sys tem for normal operat ion.

PINPOINT TEST J : EXCESSIVE/ERRATIC BRAKE PEDAL TRAVEL

T ESTCONDIT IONSDET AILS/RESULT S/ACT IONS

J1: T EST ON ROUGH ROAD

Road t es t the vehicle on rough road condit ions .

Apply the brakes s l owly.

Is t he brake pedal effort and brake pedal t ravel normal?YesVehicl e is OK.NoGO t o J2.

J2: CHECK BRAKE FLUID LEVEL

Page 416 of 3229

brake boos ter.

5. Operate the engine for a minimum of 10 s econds at a fast i dle. Stop the engine and al low t he vehicle t o s t andfor 10 mi nut es. Then, appl y the brake pedal wi th approxi mately 89 N (20lb) of force. The pedal feel (brakeappli cat ion) s houl d be t he s ame as t hat not ed wit h t he engine runni ng. If the brake pedal feel s hard (no poweras s is t), ins t al l a new valve and t hen repeat t he tes t. If t he brake pedal s t ill feels hard, i ns t all a new brakeboos ter. If t he brake pedal movement feel s s pongy, bleed t he brake s ys t em.REFER t o: Brake Syst em Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ) /Brake Sys t em Pres s ure Bl eedi ng (206-00 Brake Syst em - General Informati on, General Procedures ).

5.

Brake Master Cylinder

Us ual ly, t he fi rs t and s tronges t indicat or of anything wrong i n t he brake s ys t em i s a feeling through t he brake pedal. Indiagnosi ng the condit ion of t he brake mas t er cyli nder, check pedal feel as evidence of a brake concern. Check for brakewarni ng lamp ill uminat ion and t he brake fluid level i n t he brake mas t er cyli nder reservoi r.

Normal Condit ions

The fol lowing condit ions are cons idered normal and are not i ndi cat ions t hat t he brake mast er cyl inder i s i n need of repair.

Modern brake sys tems are des igned t o produce a pedal effort that is not as hard as in the pas t . Compl aint s of lightpedal effort s s houl d be compared t o t he pedal efforts of another vehi cl e of t he s ame model and year.The fl uid l evel wi ll fal l wit h brake pad wear.

Abnormal Condi ti ons

Changes i n t he brake pedal feel or brake pedal travel are indicators t hat s omet hi ng coul d be wrong in the brake sys tem.The diagnost ic procedure and techni ques us e brake pedal feel , warning i ndi cat or il lumi nat ion and l ow brake flui d level asindicat ors t o diagnosi ng brake s yst em concerns . The foll owing condi ti ons are consi dered abnormal and indi cat e t hat t hebrake mas t er cyli nder i s in need of repai r:

• NOTE: Pri or to carrying out any diagnosi s , ens ure the brake sys tem warni ng indicator i s functi onal .

Brake pedal goes down fast . This could be caus ed by an external or int ernal leak.Brake pedal goes down s l owl y. Thi s coul d be caused by an int ernal or external l eak.Brake pedal is l ow or feels spongy. Thi s condit ion may be caus ed by no fl ui d i n the brake mas ter cylinder, reservoi rcap vent holes cl ogged or air i n t he hydraul ic s ys tem.Brake pedal effort is excess ive. This may be caus ed by a bi nd or obs t ructi on in the pedal/li nkage, a faul tynon-ret urn val ve, boost er or ins ufficient boos t er vacuum.Rear brakes lock up during light pedal force. Thi s may be caus ed by damaged brake pads , a parti ally appl ied parkingbrake, a damaged ABS s ens or or bearing fail ure.Brake pedal effort errat ic. This condit ion could be caus ed by the brake boos t er or incorrectl y ins tal led brake pads .Brake warning i ndi cat or is on. This may be caus ed by low fl uid l evel or fl oat as s embly damaged.

Non Pressure Leaks

Any reduced fl uid volume in t he brake mast er cyl inder res ervoi r may be caused by two types of none pres sure externalleaks .

Type 1: An ext ernal leak may occur at the brake mast er cyl inder res ervoir cap because of incorrect posi ti oning of t hegasket and cap. Repos it ion cap and gasket .

Type 2: An ext ernal leak may occur at the brake mast er cyl inder res ervoir mounti ng seal s. Repair s uch a l eak by ins tall ingnew s eals and make s ure that t he brake mas t er cyli nder reservoi r ret ai ning bolt i s correct ly i nst all ed.

Page 421 of 3229

Publi s hed: 11-May-2011

Front Disc Brake - Front Disc Brake

Des cript ion and Operat ion

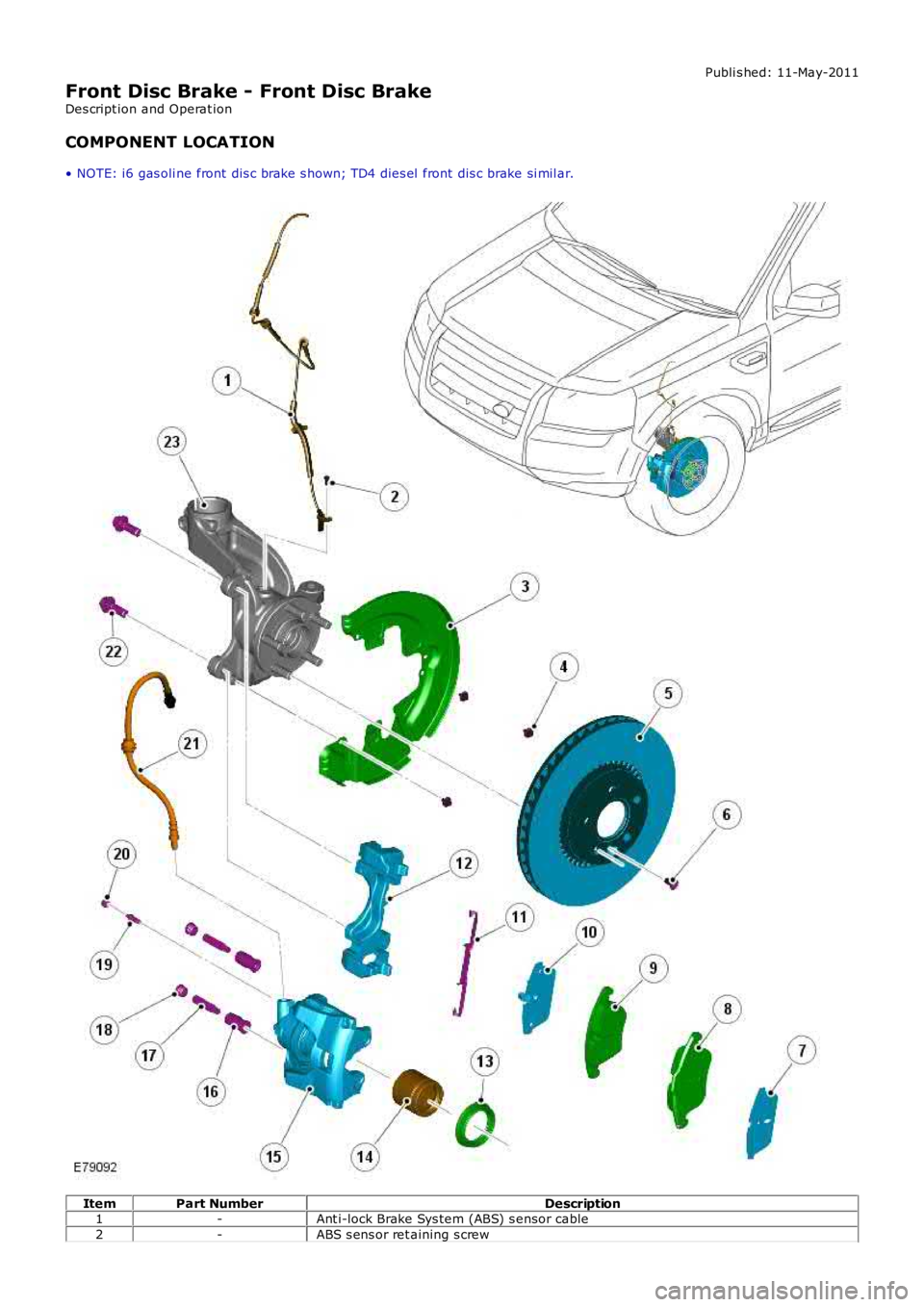

COMPONENT LOCATION

• NOTE: i6 gas oli ne front dis c brake s hown; TD4 dies el front dis c brake si mil ar.

ItemPart NumberDescription1-Ant i-lock Brake Sys tem (ABS) s ensor cable

2-ABS s ens or ret aining s crew

Page 423 of 3229

ItemPart NumberDescription

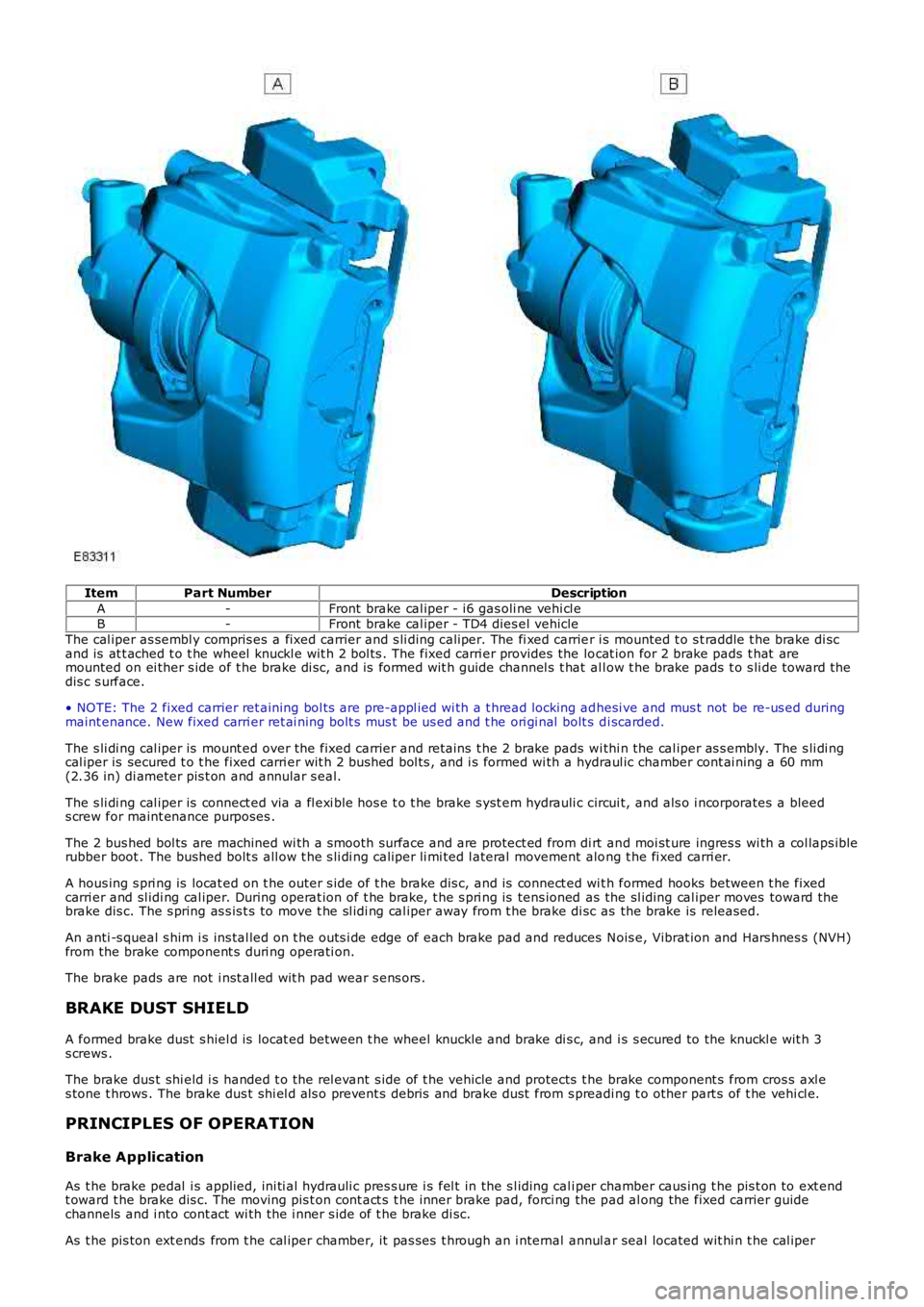

A-Front brake cal iper - i6 gas oli ne vehi cl eB-Front brake cal iper - TD4 dies el vehicle

The cal iper as sembl y compris es a fixed carrier and s li ding caliper. The fi xed carrier i s mounted t o s t raddle t he brake di scand is at t ached t o t he wheel knuckl e wit h 2 bol ts . The fixed carri er provides the locat ion for 2 brake pads t hat aremounted on ei ther s ide of t he brake di sc, and is formed wit h guide channel s t hat al low t he brake pads t o s li de toward t hedis c s urface.

• NOTE: The 2 fixed carrier ret aining bol ts are pre-appl ied wi th a t hread locking adhesi ve and mus t not be re-us ed duringmaint enance. New fixed carri er ret ai ning bolt s mus t be us ed and t he ori gi nal bolt s di scarded.

The s li di ng cal iper is mount ed over the fixed carrier and ret ains t he 2 brake pads wi thi n the cal iper as s embly. The s li di ngcal iper is secured t o t he fixed carri er wit h 2 bus hed bol ts , and i s formed wi th a hydraul ic chamber cont ai ning a 60 mm(2.36 in) di ameter pis t on and annular s eal.

The s li di ng cal iper is connect ed via a fl exi ble hos e t o t he brake s yst em hydrauli c circui t, and als o i ncorporates a bleeds crew for maint enance purposes .

The 2 bus hed bol ts are machined wi th a s mooth surface and are protect ed from di rt and moi st ure ingres s wi th a col laps iblerubber boot . The bushed bolt s all ow t he s li di ng caliper li mi ted l ateral movement along t he fi xed carri er.

A hous ing s pri ng is locat ed on t he outer s ide of t he brake dis c, and is connect ed wit h formed hooks between t he fixedcarri er and sl idi ng cal iper. During operat ion of t he brake, t he s pri ng is tens ioned as the sl iding cal iper moves toward thebrake dis c. The s pring as s is t s to move t he sl idi ng cal iper away from t he brake di sc as the brake is released.

An anti -s queal s him i s ins tal led on t he outs i de edge of each brake pad and reduces Nois e, Vibrat ion and Hars hnes s (NVH)from the brake component s duri ng operati on.

The brake pads are not i nst all ed wit h pad wear s ens ors .

BRAKE DUST SHIELD

A formed brake dust s hiel d is locat ed between t he wheel knuckle and brake di s c, and i s s ecured to the knuckl e wit h 3s crews .

The brake dus t shi eld i s handed t o t he rel evant s ide of t he vehicle and protects t he brake component s from cros s axl es tone t hrows . The brake dus t shi el d als o prevent s debris and brake dust from s preading t o other part s of t he vehi cl e.

PRINCIPLES OF OPERATION

Brake Application

As t he brake pedal i s applied, ini ti al hydrauli c pres s ure i s fel t in the s l iding cali per chamber caus ing t he pis t on to ext endt oward t he brake dis c. The moving pis t on cont act s t he inner brake pad, forci ng the pad al ong the fixed carrier guidechannels and i nto cont act wi th the i nner s ide of t he brake di sc.

As t he pis ton ext ends from t he cal iper chamber, it pas ses t hrough an i nternal annul ar seal located wit hi n t he cal iper

Page 436 of 3229

The brake dis c al so forms t he locati on for t he parking brake component s . The brake d is c i nt ernal diamet er is 185 mm (7.28

in) and i s machined wit h a smoot h s urface to form t he brake drum. An int egral backpl

ate and brake dust s hiel d is mount ed

t o the rear of the brake di s c. The backpl at e enclos es the brake dis c and als o provi d es the mount ing l ocat ion for t he 2

parking brake shoes and operat ing component s.

An apert ure i s formed i n t he dust s hiel d and backplat e t hat al lows t he parking brake cable to protrude t hrough to the i nner

s ide of t he brake dis c, and connect to t he parki ng brake expander uni t. A hol e machi ned i n t he brake dis c outer hub

provides acces s t o t he parking brake manual adjus ter.

For addit ional informat ion, refer t o: Parking Brake (206-05 Parki ng Brake and Act uat ion, Descripti on and Operat ion).

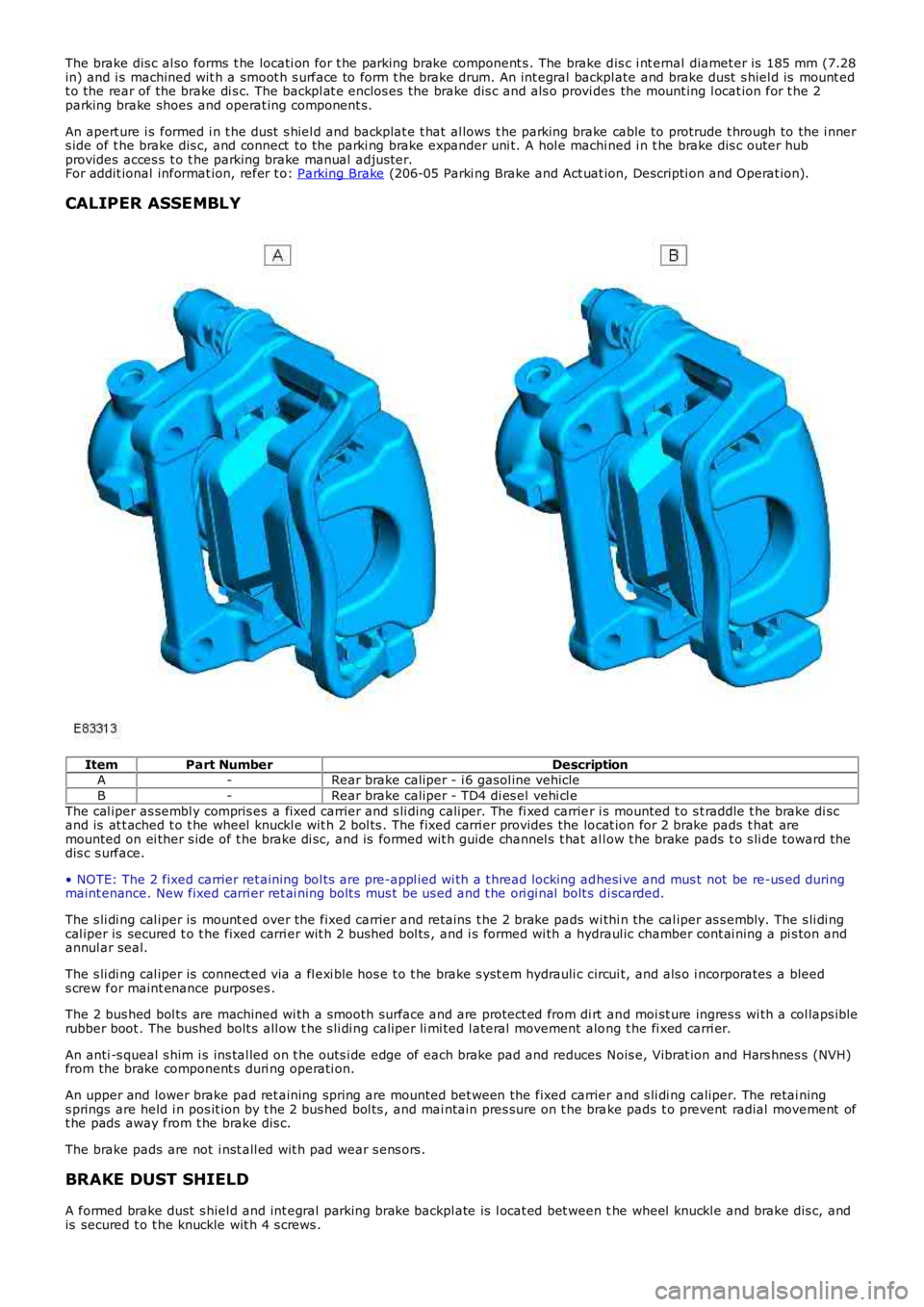

CALIPER ASSEMBLY Item

Part Number Description

A -Rear brake caliper - i 6 gasol ine vehicle

B -Rear brake caliper - TD4 di es el vehi cl e

The cal iper as sembl y compris es a fixed carrier and s li ding caliper. The fi xed carrie r i s mounted t o s t raddle t he brake di sc

and is at t ached t o t he wheel knuckl e wit h 2 bol ts . The fixed carri er provides the lo cat ion for 2 brake pads t hat are

mounted on ei ther s ide of t he brake di sc, and is formed wit h guide channel s t hat al l ow t he brake pads t o s li de toward t he

dis c s urface.

• NOTE: The 2 fixed carrier ret aining bol ts are pre-appl ied wi th a t hread locking ad hesi ve and mus t not be re-us ed during

maint enance. New fixed carri er ret ai ning bolt s mus t be us ed and t he ori gi nal bolt s d i scarded.

The s li di ng cal iper is mount ed over the fixed carrier and ret ains t he 2 brake pads w i thi n the cal iper as s embly. The s li di ng

cal iper is secured t o t he fixed carri er wit h 2 bus hed bol ts , and i s formed wi th a hy draul ic chamber cont ai ning a pi s ton and

annul ar seal.

The s li di ng cal iper is connect ed via a fl exi ble hos e t o t he brake s yst em hydrauli c c ircui t, and als o i ncorporates a bleed

s crew for maint enance purposes .

The 2 bus hed bol ts are machined wi th a s mooth surface and are protect ed from di rt an d moi st ure ingres s wi th a col laps ible

rubber boot . The bushed bolt s all ow t he s li di ng caliper li mi ted l ateral movement alo ng t he fi xed carri er.

An anti -s queal s him i s ins tal led on t he outs i de edge of each brake pad and reduces N ois e, Vibrat ion and Hars hnes s (NVH)

from the brake component s duri ng operati on.

An upper and lower brake pad ret aining spring are mounted bet ween the fixed carrier and s li di ng caliper. The retai ning

s prings are held i n pos it ion by t he 2 bus hed bol ts , and mai ntain pres sure on t he bra ke pads t o prevent radial movement of

t he pads away from t he brake dis c.

The brake pads are not i nst all ed wit h pad wear s ens ors .

BRAKE DUST SHIELD

A formed brake dust s hiel d and int egral parking brake backpl ate is l ocat ed bet ween t he wheel knuckl e and brake dis c, and

is secured t o t he knuckle wit h 4 s crews .

Page 451 of 3229

5-Brake shoe retai ni ng s pri ng

6-Brake shoe return s pri ng

7-Brake shoe mechanical adjust er8-Lower (l eadi ng) brake s hoe

9-Parki ng brake l ever cabl e

10-Parki ng brake cabl e equalizer11-Parki ng brake i nner cabl e

12-Equali zer fas t ener

13-Parki ng brake mi cros wit ch14-Parki ng brake l ever as sembl y

15-Parki ng brake outer cable

16-Brake dus t s hield

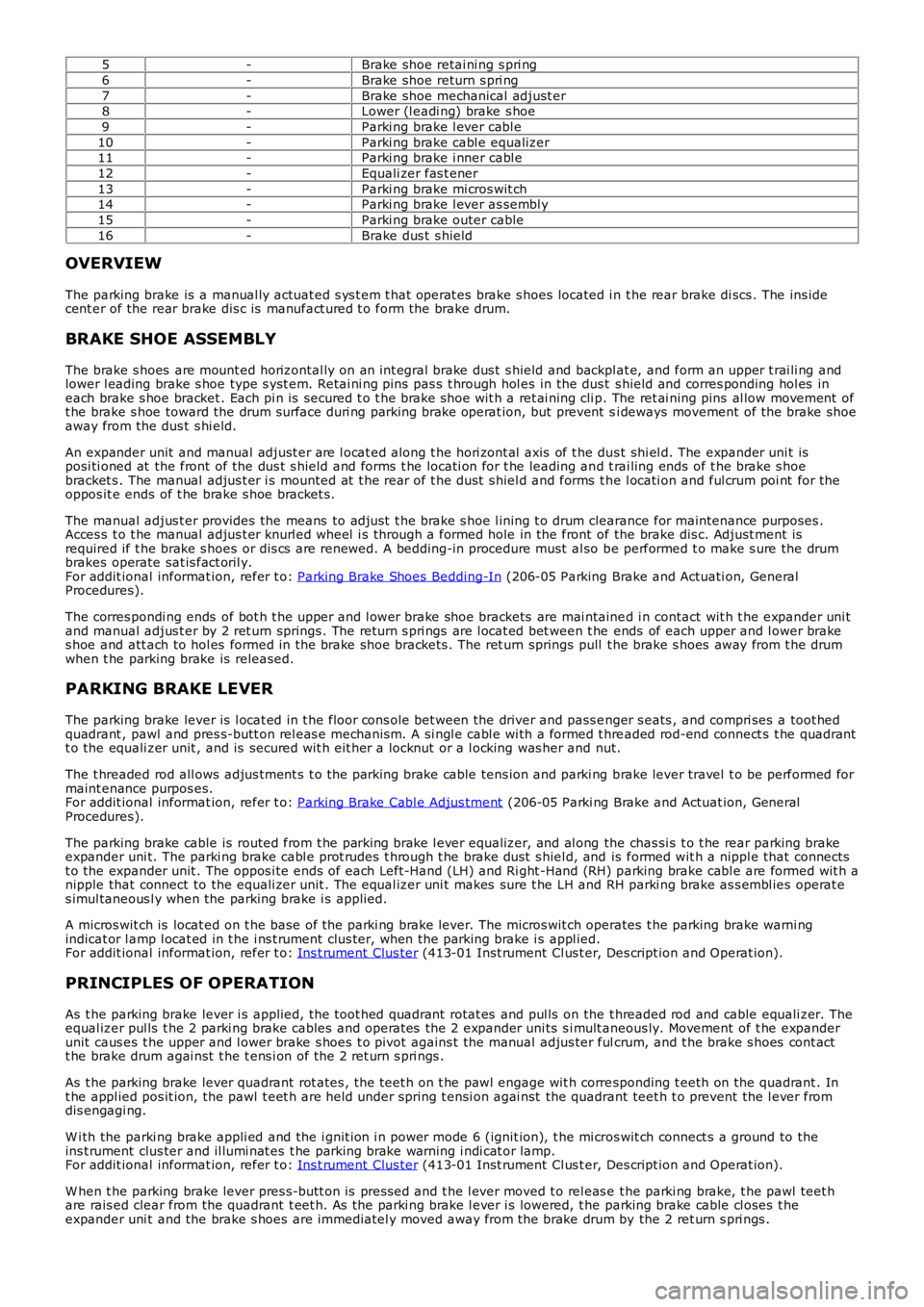

OVERVIEW

The parking brake is a manual ly actuat ed s ys t em t hat operat es brake s hoes located i n t he rear brake di scs . The ins idecent er of the rear brake dis c is manufact ured t o form the brake drum.

BRAKE SHOE ASSEMBLY

The brake s hoes are mount ed horizontal ly on an int egral brake dus t s hield and backplat e, and form an upper t rai li ng andlower l eading brake s hoe type s yst em. Retai ni ng pins pas s t hrough hol es in the dus t s hield and corres ponding hol es ineach brake s hoe bracket . Each pi n is secured t o t he brake s hoe wit h a ret ai ning cli p. The ret ai ning pins al low movement oft he brake s hoe toward the drum surface duri ng parking brake operat ion, but prevent si deways movement of the brake shoeaway from the dus t s hi eld.

An expander unit and manual adjust er are l ocat ed along t he hori zont al axis of t he dus t shi el d. The expander uni t isposi ti oned at the front of the dus t s hield and forms t he locati on for t he leading and t rai ling ends of t he brake s hoebracket s . The manual adjus t er i s mounted at t he rear of t he dust s hiel d and forms t he l ocati on and ful crum poi nt for theoppos it e ends of t he brake s hoe bracket s.

The manual adjus t er provides the means to adjust t he brake s hoe l ining t o drum clearance for maintenance purposes .Acces s t o t he manual adjus t er knurl ed wheel i s t hrough a formed hole in the front of the brake dis c. Adjust ment isrequired if t he brake s hoes or dis cs are renewed. A bedding-in procedure must al so be performed t o make s ure the drumbrakes operate sat is fact oril y.For addit ional informat ion, refer t o: Parking Brake Shoes Bedding-In (206-05 Parking Brake and Actuati on, GeneralProcedures).

The corres pondi ng ends of bot h t he upper and l ower brake shoe brackets are mai ntained i n contact wit h t he expander uni tand manual adjus t er by 2 ret urn springs . The return s pri ngs are l ocat ed bet ween t he ends of each upper and l ower brakes hoe and att ach to hol es formed in the brake shoe brackets . The ret urn springs pull t he brake s hoes away from t he drumwhen t he parking brake is released.

PARKING BRAKE LEVER

The parking brake lever is l ocat ed in t he floor cons ole bet ween the driver and pass enger s eats , and compri ses a toot hedquadrant , pawl and pres s-butt on rel eas e mechanis m. A si ngl e cabl e wi th a formed t hreaded rod-end connect s t he quadrantt o the equali zer unit , and is secured wit h eit her a locknut or a l ocking was her and nut.

The t hreaded rod all ows adjus tment s t o t he parking brake cable tens ion and parki ng brake lever travel t o be performed formaint enance purpos es.For addit ional informat ion, refer t o: Parking Brake Cabl e Adjus tment (206-05 Parki ng Brake and Actuat ion, GeneralProcedures).

The parking brake cable is routed from t he parking brake l ever equalizer, and al ong the chas si s t o t he rear parking brakeexpander uni t. The parki ng brake cabl e prot rudes t hrough t he brake dust s hiel d, and is formed wit h a nippl e that connectst o the expander unit . The oppos i te ends of each Left-Hand (LH) and Ri ght -Hand (RH) parking brake cabl e are formed wit h anipple that connect to the equali zer unit . The equal izer uni t makes sure t he LH and RH parki ng brake as s embl ies operat es imul taneous l y when the parking brake i s applied.

A micros wit ch is locat ed on t he base of the parki ng brake lever. The micros wit ch operates t he parking brake warni ngindicat or l amp l ocat ed in t he i ns t rument clus ter, when the parki ng brake i s appl ied.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

PRINCIPLES OF OPERATION

As t he parking brake lever i s applied, t he toot hed quadrant rotat es and pul ls on the t hreaded rod and cable equali zer. Theequal izer pul ls t he 2 parki ng brake cables and operat es the 2 expander uni ts s i mult aneous ly. Movement of t he expanderunit caus es t he upper and l ower brake s hoes t o pivot agains t the manual adjus ter fulcrum, and t he brake s hoes cont actt he brake drum agai nst t he t ens i on of the 2 ret urn s pri ngs .

As t he parking brake lever quadrant rot ates , t he teet h on t he pawl engage wit h corresponding t eeth on the quadrant . Int he appl ied pos it ion, the pawl t eet h are held under spring t ensi on agai nst the quadrant teet h t o prevent the l ever fromdis engagi ng.

W i th the parki ng brake appli ed and the i gnit ion i n power mode 6 (ignit ion), t he mi cros wit ch connect s a ground to theins t rument clus ter and il lumi nat es t he parking brake warning i ndi cat or lamp.For addit ional informat ion, refer t o: Ins t rument Clus ter (413-01 Inst rument Cl us t er, Des cript ion and Operat ion).

W hen t he parking brake lever pres s-butt on is pres sed and t he l ever moved t o rel eas e t he parki ng brake, t he pawl teet hare rais ed clear from the quadrant t eet h. As the parki ng brake l ever i s lowered, t he parking brake cable cl oses t heexpander uni t and the brake s hoes are immediatel y moved away from the brake drum by the 2 ret urn s pri ngs .

Page 473 of 3229

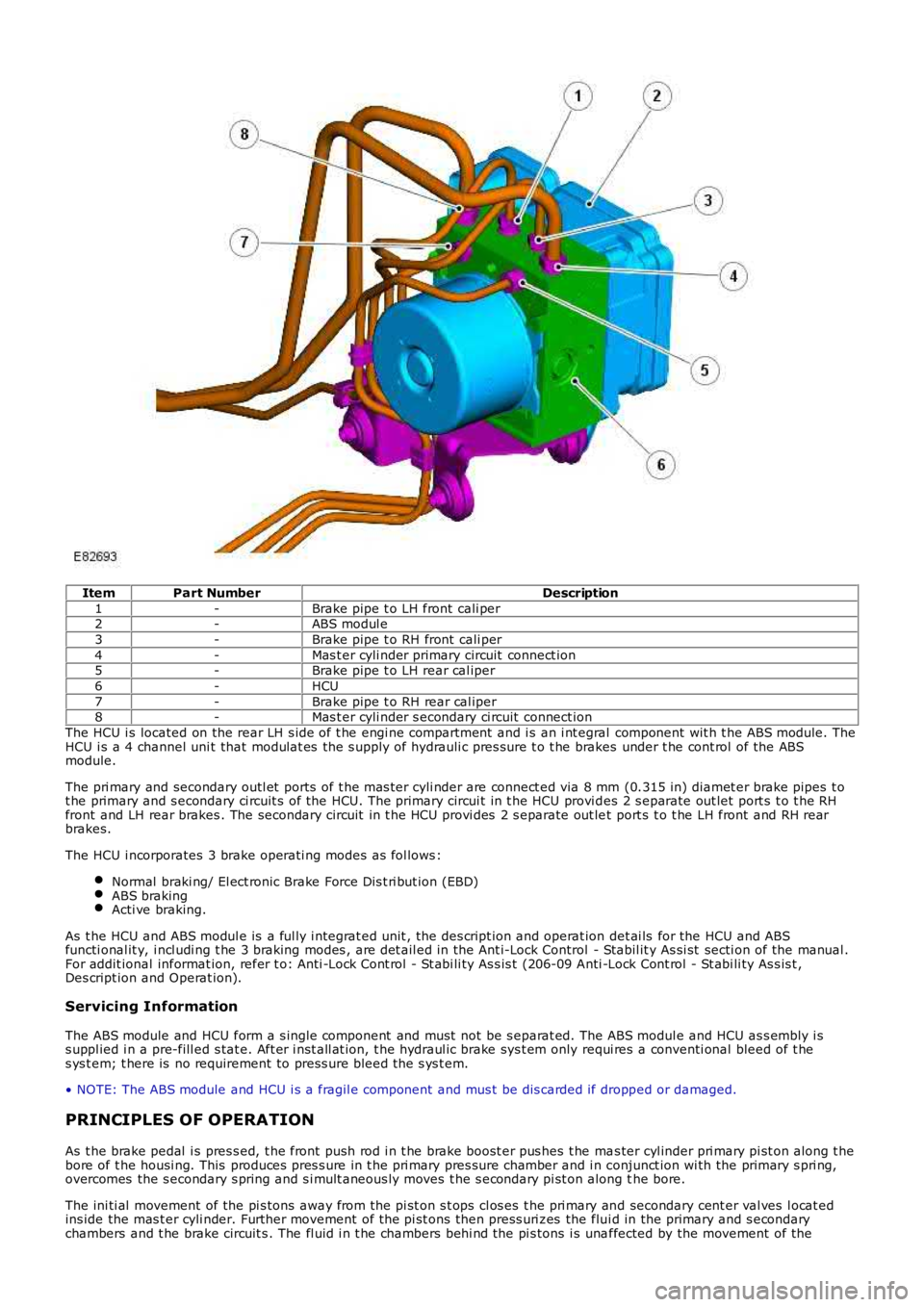

ItemPart NumberDescription

1-Brake pipe t o LH front cali per2-ABS modul e

3-Brake pipe t o RH front cali per

4-Mas t er cyli nder primary circuit connect ion5-Brake pipe t o LH rear cal iper

6-HCU

7-Brake pipe t o RH rear cal iper8-Mas t er cyli nder s econdary ci rcuit connect ion

The HCU i s located on the rear LH s ide of t he engi ne compartment and i s an i nt egral component wit h t he ABS module. TheHCU i s a 4 channel uni t that modulat es the s upply of hydrauli c pres sure t o t he brakes under t he cont rol of the ABSmodule.

The pri mary and secondary outl et ports of t he mas ter cyli nder are connect ed via 8 mm (0.315 in) diamet er brake pipes t ot he primary and s econdary ci rcuit s of the HCU. The primary circui t in t he HCU provi des 2 s eparate out let port s t o t he RHfront and LH rear brakes . The secondary circuit in t he HCU provi des 2 s eparate out let port s t o t he LH front and RH rearbrakes.

The HCU i ncorporates 3 brake operati ng modes as fol lows :

Normal braki ng/ El ect ronic Brake Force Dis t ri but ion (EBD)ABS brakingActi ve braking.

As t he HCU and ABS modul e is a ful ly i ntegrat ed unit , the des cript ion and operat ion det ai ls for the HCU and ABSfuncti onal it y, i ncl udi ng t he 3 braking modes , are det ail ed in the Ant i-Lock Control - Stabil it y As si st secti on of the manual .For addit ional informat ion, refer t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09 Anti -Lock Cont rol - St abi li ty As s is t ,Des cript ion and Operat ion).

Servicing Information

The ABS module and HCU form a s ingle component and must not be s eparat ed. The ABS modul e and HCU as s embly i ss uppl ied i n a pre-fill ed s tat e. Aft er i nst all at ion, t he hydraul ic brake sys t em only requi res a conventi onal bleed of t hes ys t em; t here is no requirement to press ure bleed t he s ys t em.

• NOTE: The ABS module and HCU i s a fragil e component and mus t be dis carded if dropped or damaged.

PRINCIPLES OF OPERATION

As t he brake pedal i s pres s ed, t he front push rod i n t he brake boost er pus hes t he mas ter cyl inder pri mary pi st on along t hebore of t he housi ng. This produces pres s ure in t he pri mary pres sure chamber and i n conjunct ion wi th the primary s pri ng,overcomes the s econdary s pring and s i mult aneous ly moves t he s econdary pi st on along the bore.

The ini ti al movement of the pi s tons away from the pi st on s t ops cl os es t he pri mary and secondary cent er val ves l ocat edins ide the mas t er cyli nder. Further movement of the pi st ons then press uri zes the flui d in the primary and s econdarychambers and t he brake circuit s . The fl uid i n t he chambers behi nd the pi s tons i s unaffected by the movement of the

Page 474 of 3229

pis t ons and will flow unrest ri cted t hrough t he inlet ports , between t he chambers and t he res ervoir.

Pres s urized fluid ent ers the HCU that i s mounted on t he front of the ABS modul e. The HCU t hen modul ates t he s uppl y ofpres s urized fluid to the brakes under cont rol of the ABS modul e.For addit ional informat ion, refer t o: Anti -Lock Cont rol - St abi li ty As s is t (206-09 Anti -Lock Cont rol - St abi li ty As s is t ,Des cript ion and Operat ion).