LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: Speedometer, steering wheel, power steering, tires, AC Expansion Valve, Air Conditioning Compressor, wiring diagram

Page 111 of 4500

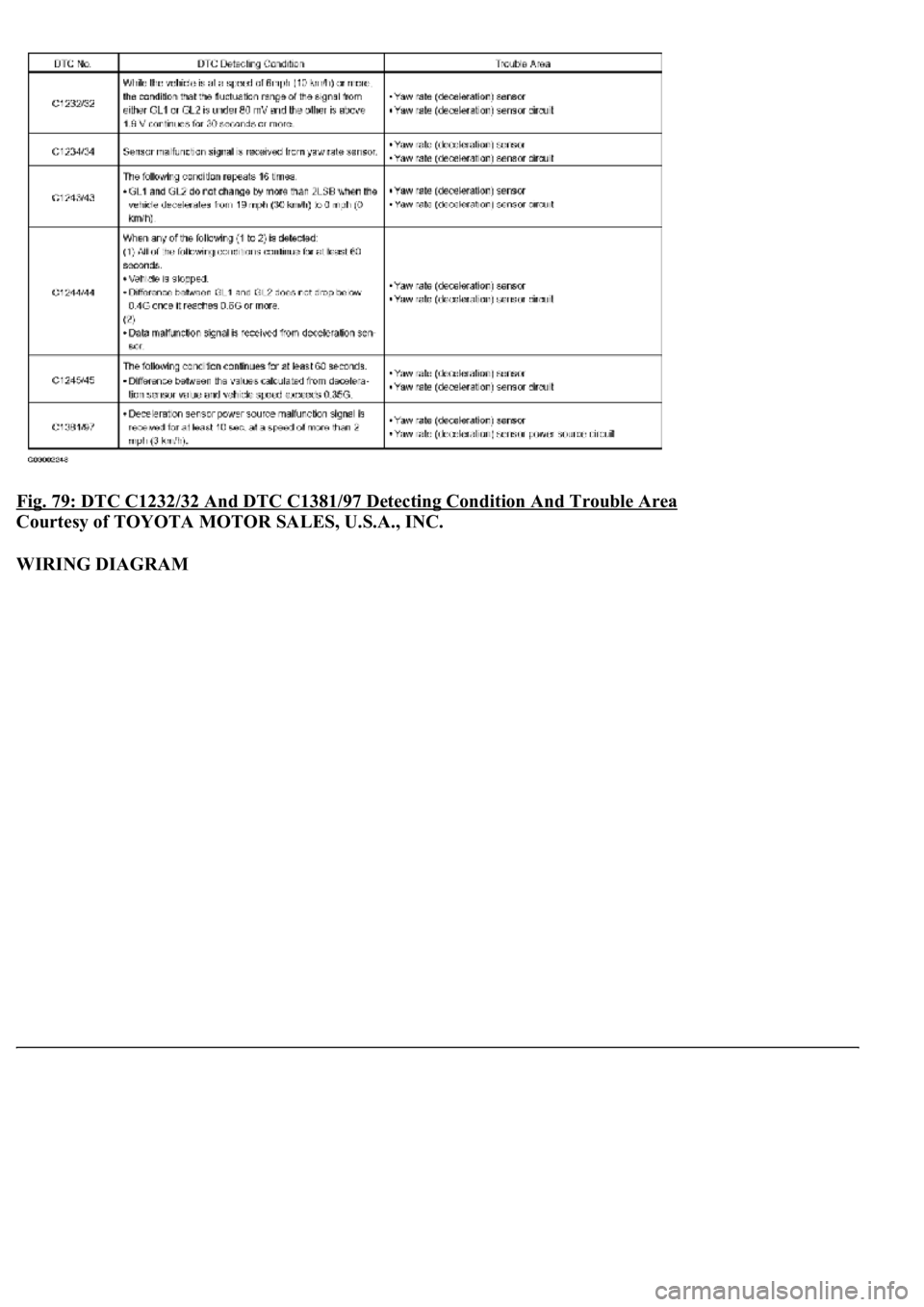

Fig. 79: DTC C1232/32 And DTC C1381/97 Detecting Condition And Trouble Area

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Page 112 of 4500

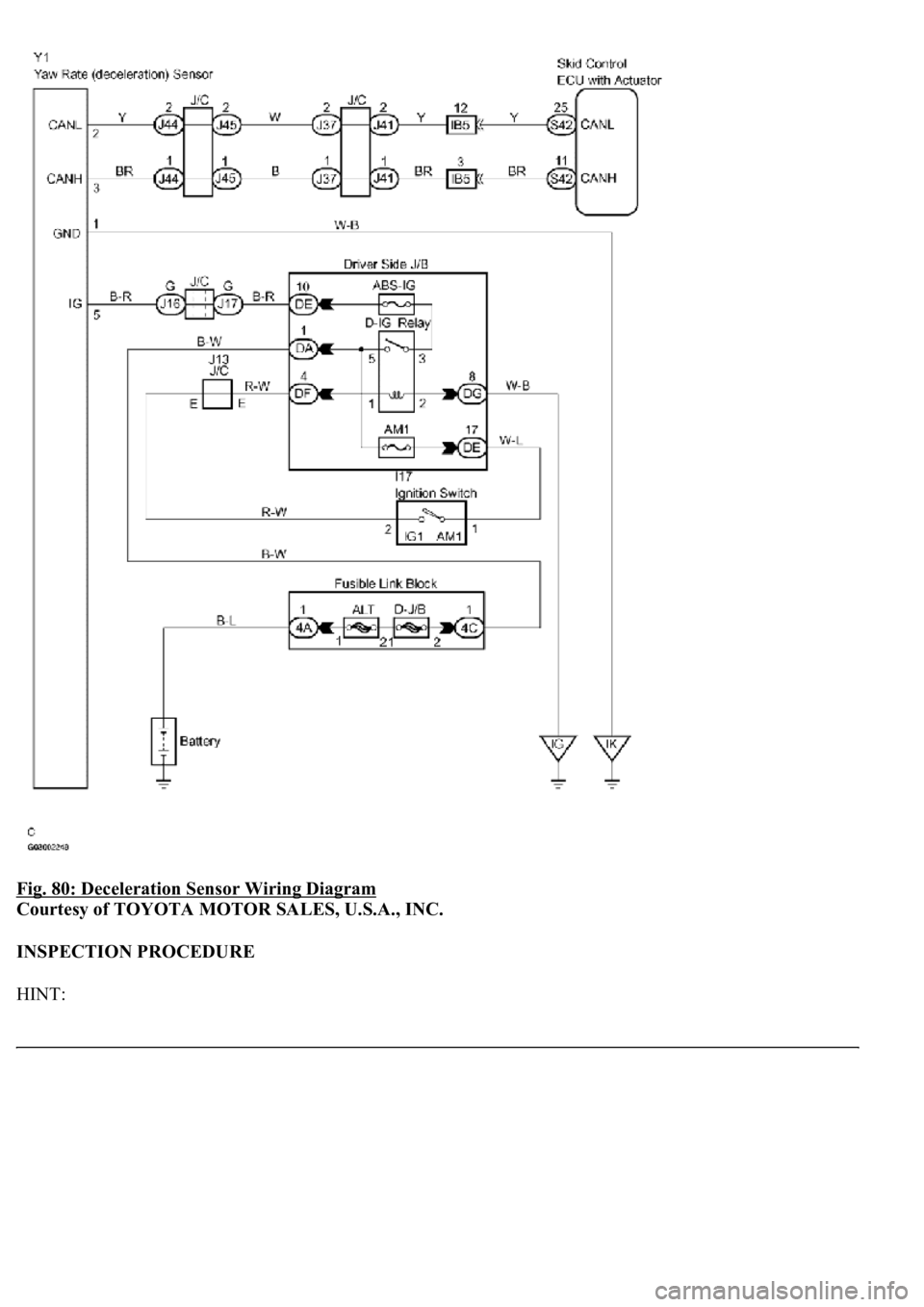

Fig. 80: Deceleration Sensor Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

HINT:

Page 113 of 4500

When U0123/62, U0124/95 or U0126/63 are output together with C1232/32, C1234/34, C1243/43, C1244/44,

C1245/45, and C1381/97 inspect and repair the trouble areas indicated by U0121/94, U0123/62, U0124/95 or

U0126/63 first.

1.CHECK SENSOR INSTALLATION (YAW RATE SENSOR)

a. Check that the yaw rate and deceleration sensor has been installed properly (see

REPLACEMENT

).

OK: Go to next step

The sensor is tightened to the specified torque.

The sensor is not tilted.

NG: INSTALL YAW RATE SENSOR CORRECTLY

OK: Go to next step

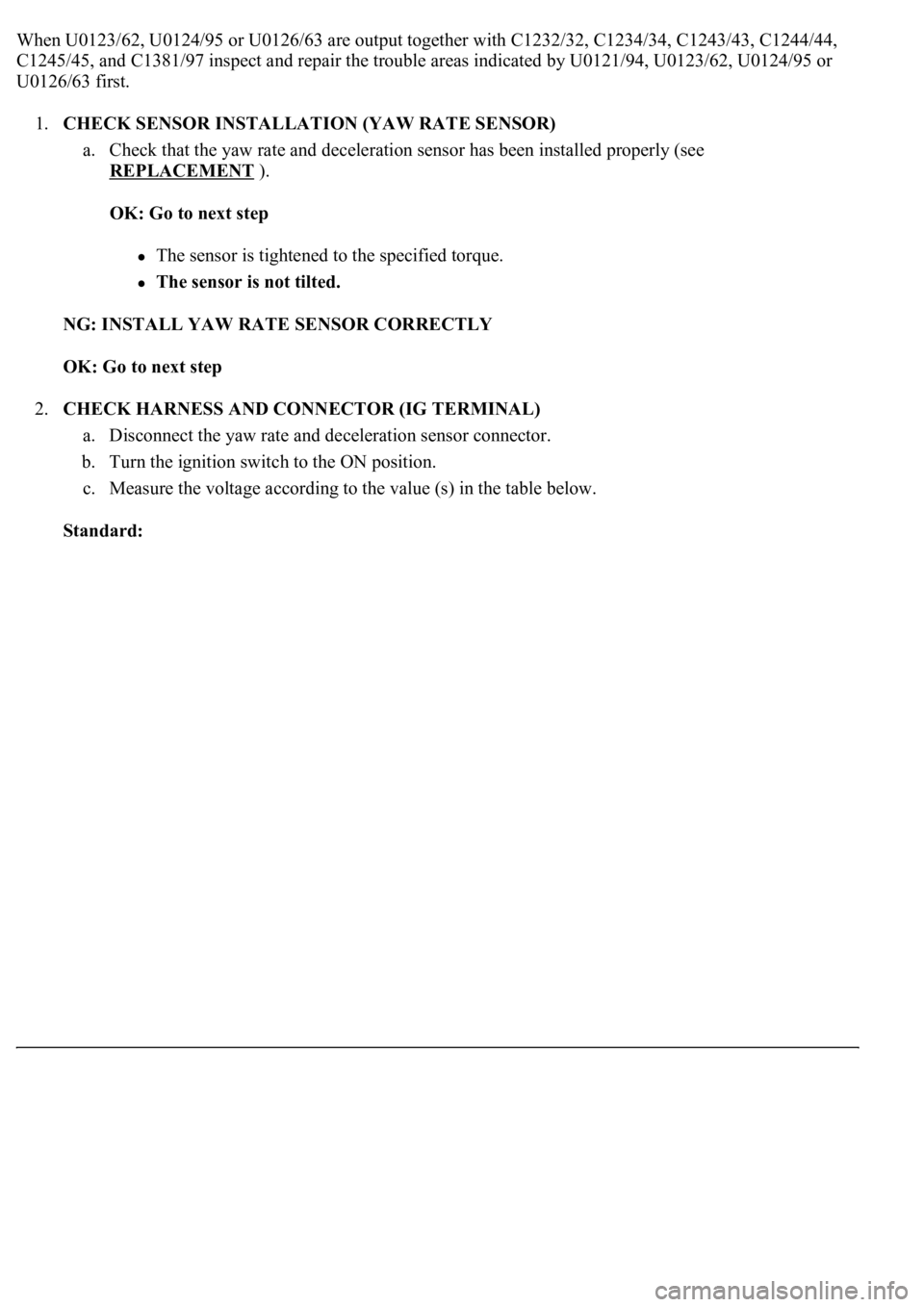

2.CHECK HARNESS AND CONNECTOR (IG TERMINAL)

a. Disconnect the yaw rate and deceleration sensor connector.

b. Turn the ignition switch to the ON position.

c. Measure the voltage according to the value (s) in the table below.

Standard:

Page 114 of 4500

Fig. 81: Identifying Yaw Rate And Deceleration Sensor Connector Terminals (1 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

TESTER CONNECTION SPECIFIED CONDITION

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: Go to next step

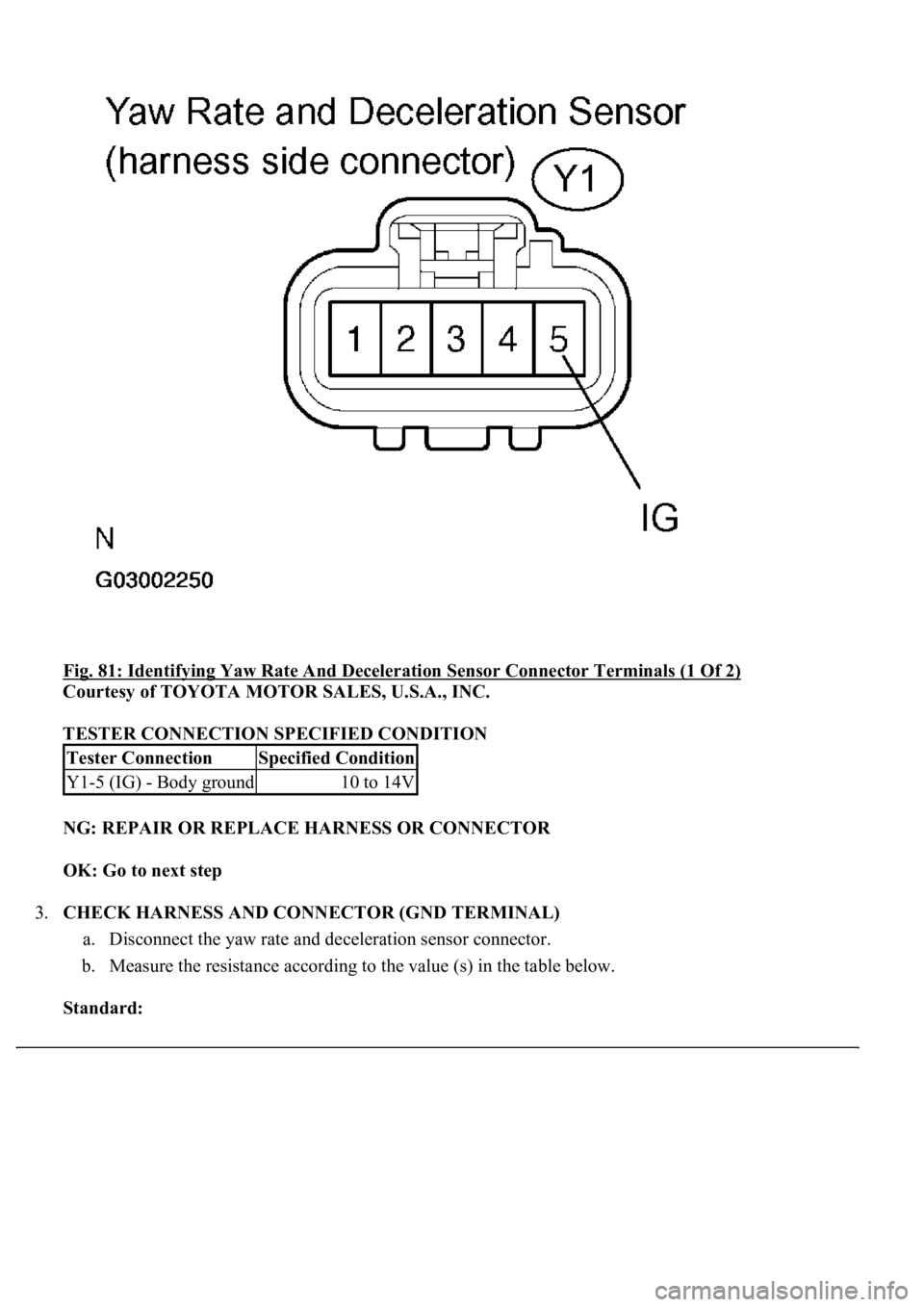

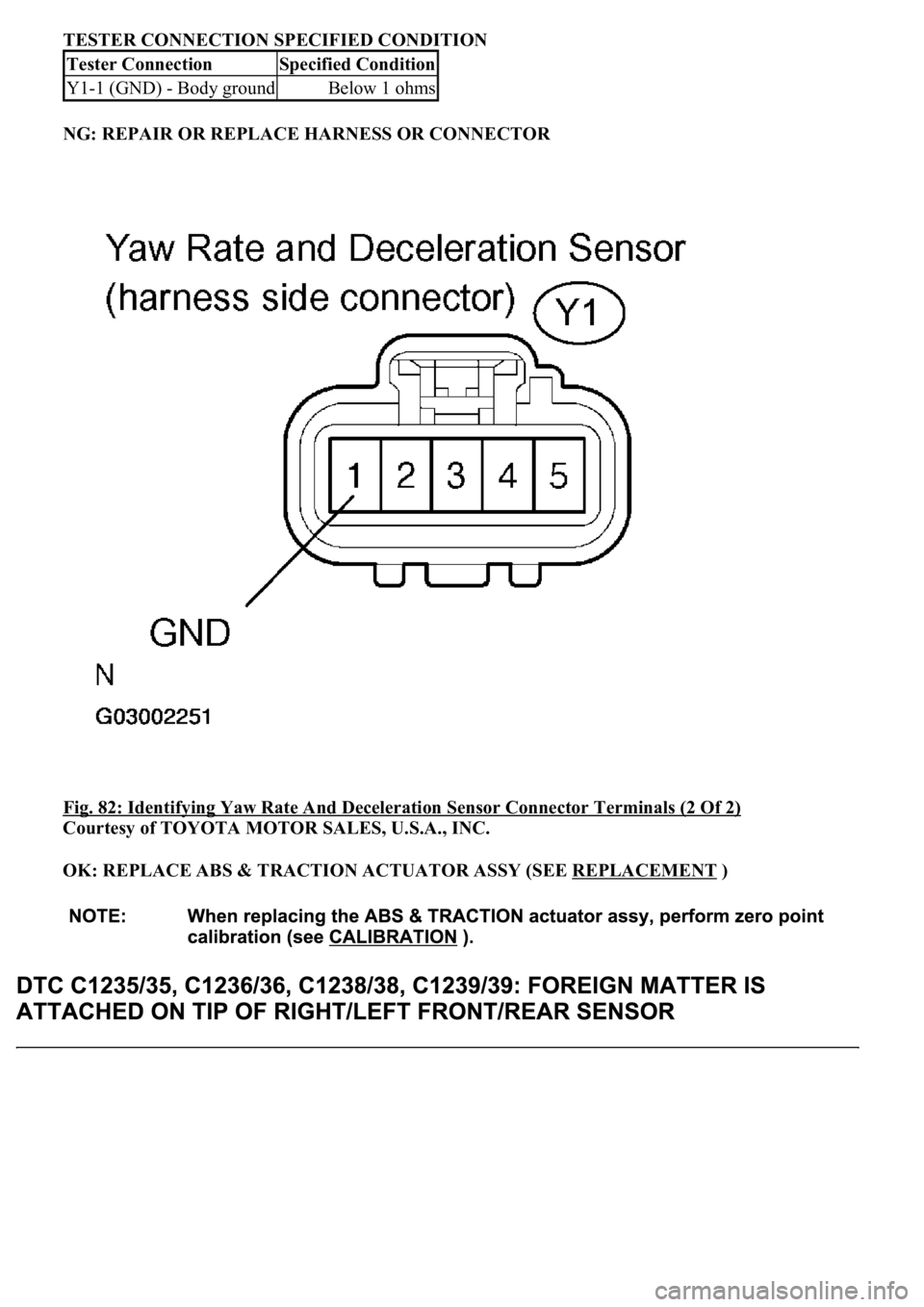

3.CHECK HARNESS AND CONNECTOR (GND TERMINAL)

a. Disconnect the yaw rate and deceleration sensor connector.

b. Measure the resistance according to the value (s) in the table below.

Standard:

Tester ConnectionSpecified Condition

Y1-5 (IG) - Body ground10 to 14V

Page 115 of 4500

TESTER CONNECTION SPECIFIED CONDITION

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Fig. 82: Identifying Yaw Rate And Deceleration Sensor Connector Terminals (2 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK: REPLACE ABS & TRACTION ACTUATOR ASSY (SEE REPLACEMENT

)

Tester ConnectionSpecified Condition

Y1-1 (GND) - Body groundBelow 1 ohms

Page 116 of 4500

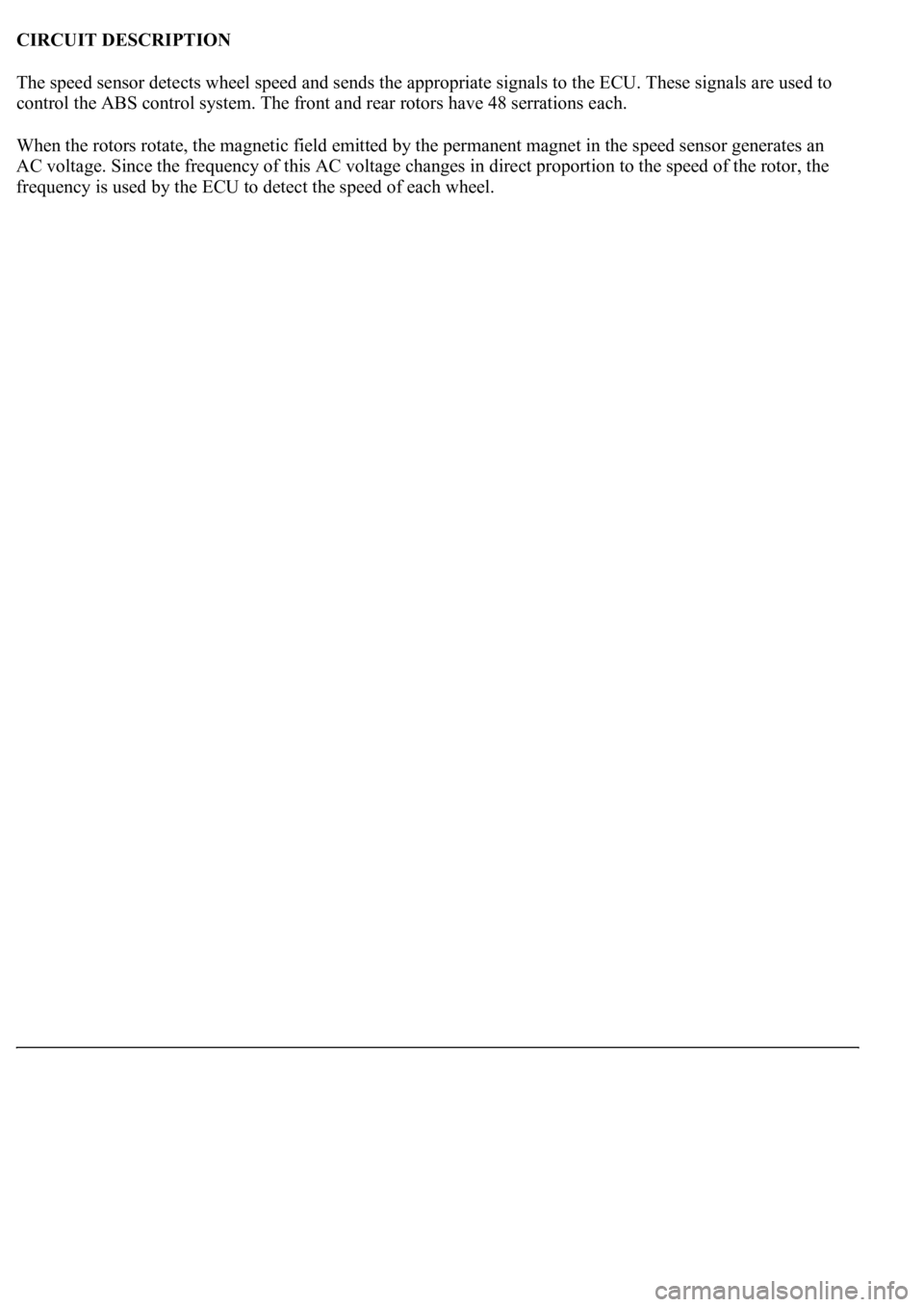

CIRCUIT DESCRIPTION

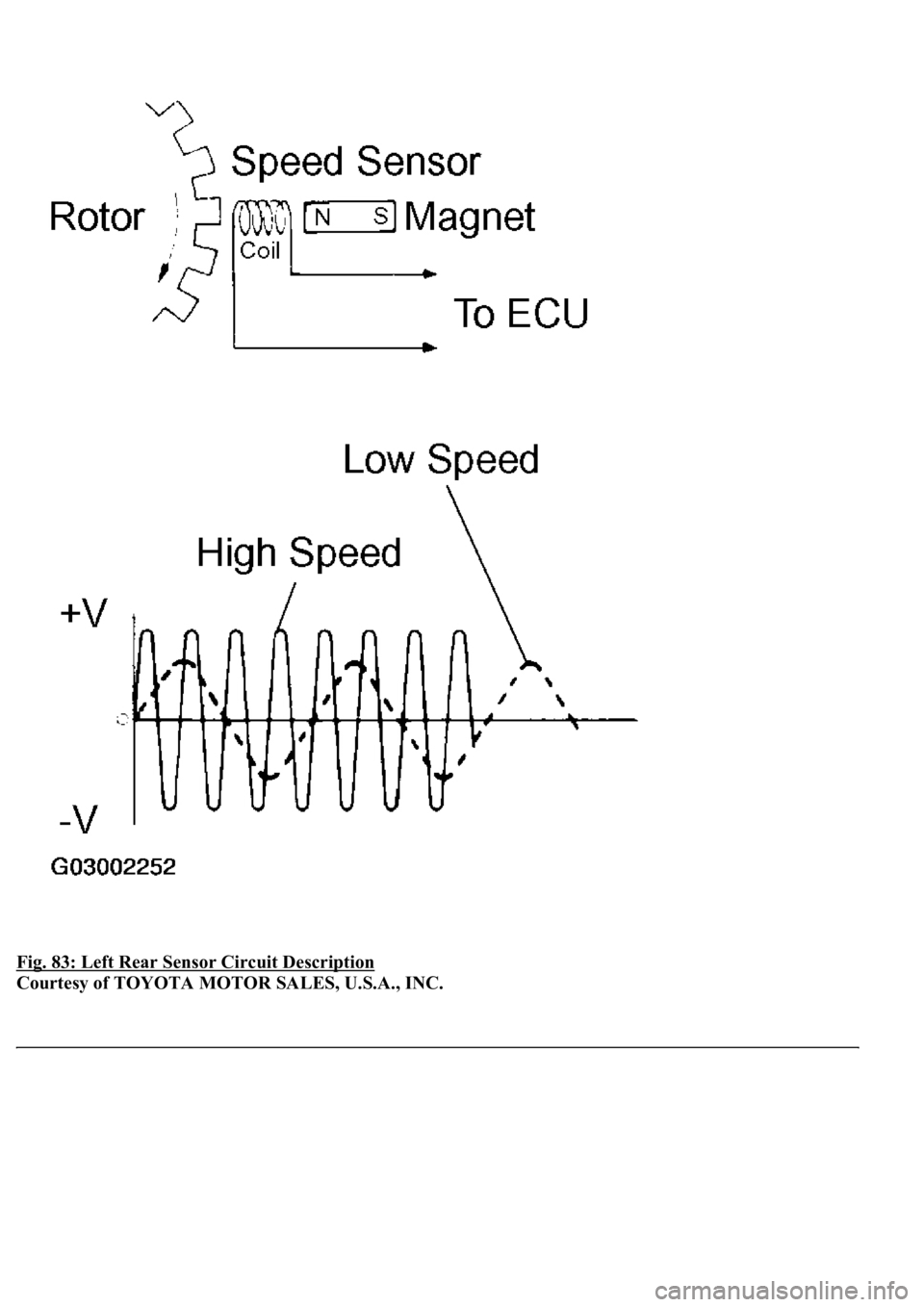

The speed sensor detects wheel speed and sends the appropriate signals to the ECU. These signals are used to

control the ABS control system. The front and rear rotors have 48 serrations each.

When the rotors rotate, the magnetic field emitted by the permanent magnet in the speed sensor generates an

AC voltage. Since the frequency of this AC voltage changes in direct proportion to the speed of the rotor, the

frequenc

y is used by the ECU to detect the speed of each wheel.

Page 117 of 4500

Fig. 83: Left Rear Sensor Circuit Description

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 118 of 4500

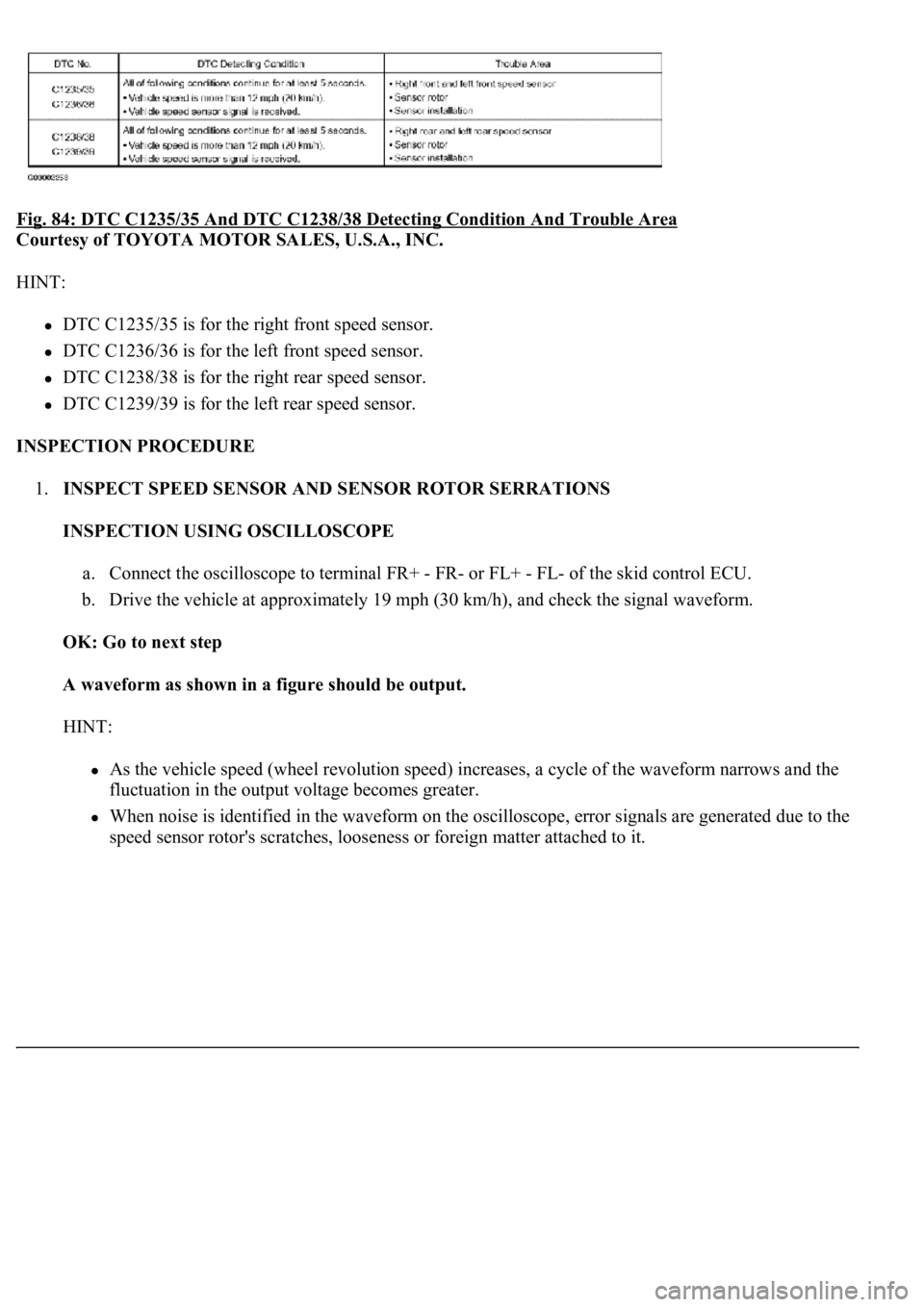

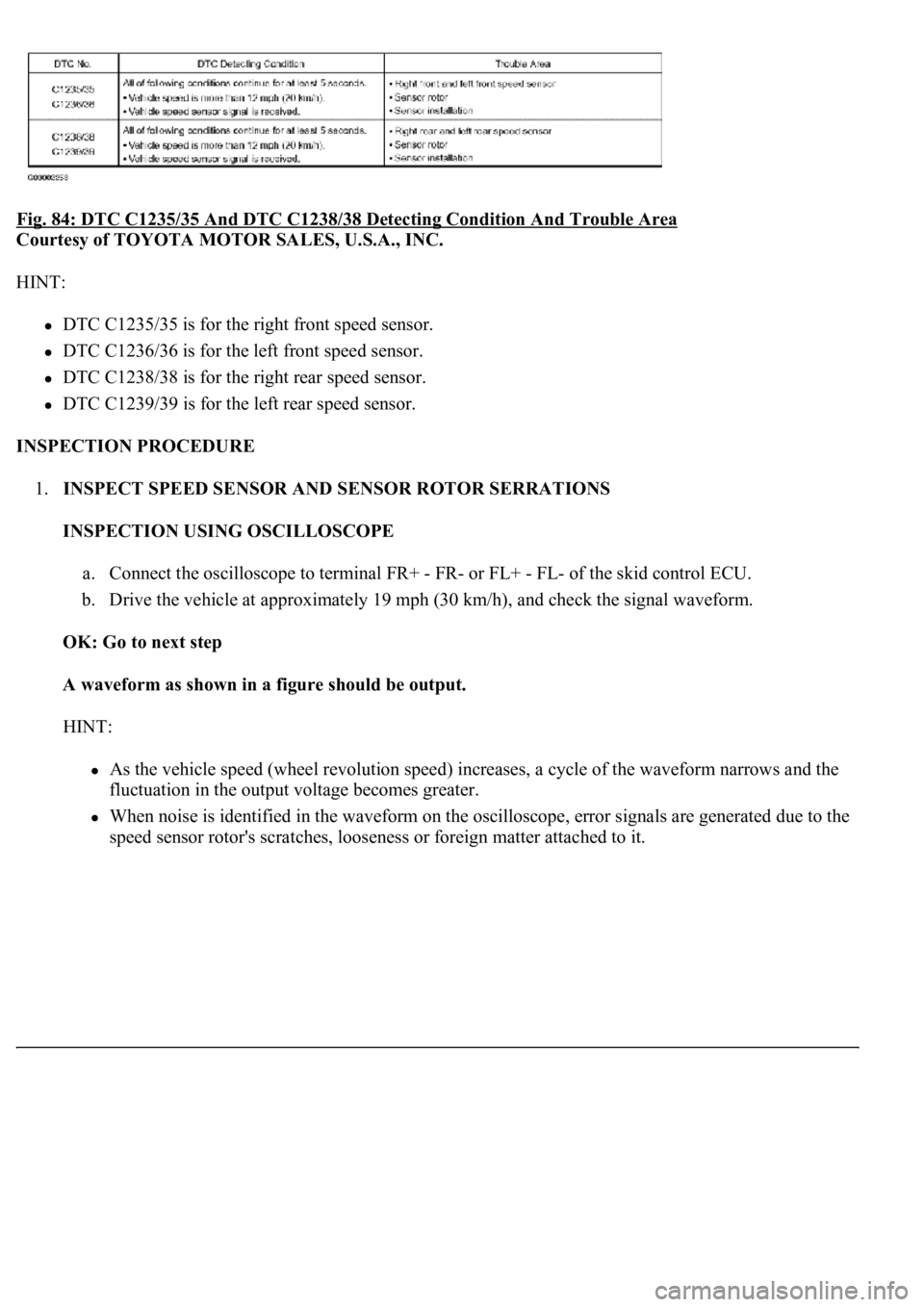

Fig. 84: DTC C1235/35 And DTC C1238/38 Detecting Condition And Trouble Area

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

DTC C1235/35 is for the right front speed sensor.

DTC C1236/36 is for the left front speed sensor.

DTC C1238/38 is for the right rear speed sensor.

DTC C1239/39 is for the left rear speed sensor.

INSPECTION PROCEDURE

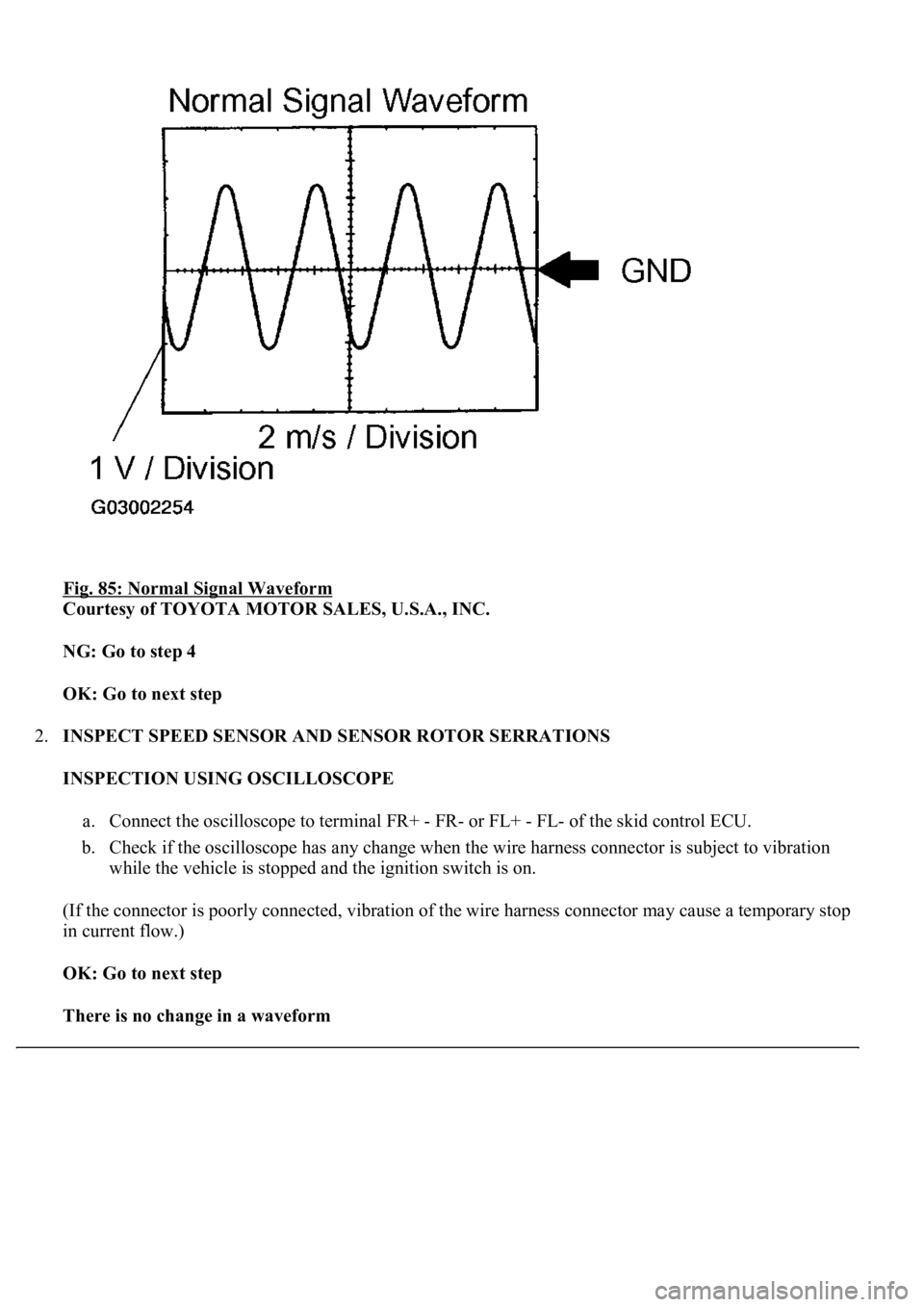

1.INSPECT SPEED SENSOR AND SENSOR ROTOR SERRATIONS

INSPECTION USING OSCILLOSCOPE

a. Connect the oscilloscope to terminal FR+ - FR- or FL+ - FL- of the skid control ECU.

b. Drive the vehicle at approximately 19 mph (30 km/h), and check the signal waveform.

OK: Go to next step

A waveform as shown in a figure should be output.

HINT:

As the vehicle speed (wheel revolution speed) increases, a cycle of the waveform narrows and the

fluctuation in the output voltage becomes greater.

When noise is identified in the waveform on the oscilloscope, error signals are generated due to the

speed sensor rotor's scratches, looseness or forei

gn matter attached to it.

Page 119 of 4500

Fig. 85: Normal Signal Waveform

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: Go to step 4

OK: Go to next step

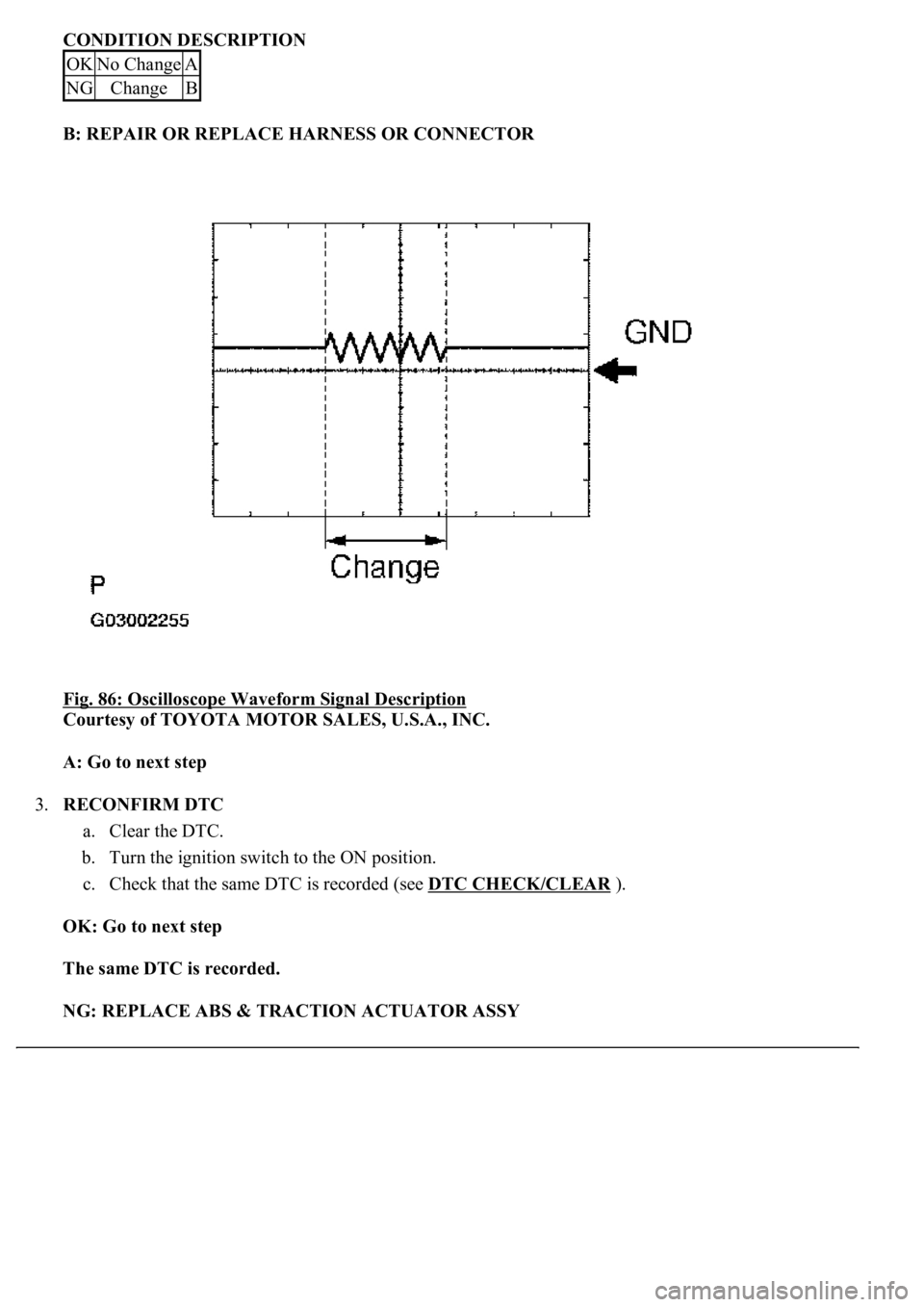

2.INSPECT SPEED SENSOR AND SENSOR ROTOR SERRATIONS

INSPECTION USING OSCILLOSCOPE

a. Connect the oscilloscope to terminal FR+ - FR- or FL+ - FL- of the skid control ECU.

b. Check if the oscilloscope has any change when the wire harness connector is subject to vibration

while the vehicle is stopped and the ignition switch is on.

(If the connector is poorly connected, vibration of the wire harness connector may cause a temporary stop

in current flow.)

OK: Go to next step

There is no change in a waveform

Page 120 of 4500

CONDITION DESCRIPTION

B: REPAIR OR REPLACE HARNESS OR CONNECTOR

Fig. 86: Oscilloscope Waveform Signal Description

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

A: Go to next step

3.RECONFIRM DTC

a. Clear the DTC.

b. Turn the ignition switch to the ON position.

c. Check that the same DTC is recorded (see DTC CHECK/CLEAR

).

OK: Go to next step

The same DTC is recorded.

NG: REPLACE ABS & TRACTION ACTUATOR ASSY

OKNo ChangeA

NGChangeB

Trending: ignition, airbag, display, evap, high beam, reset, diagnostic menu