LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Page 3356 of 4500

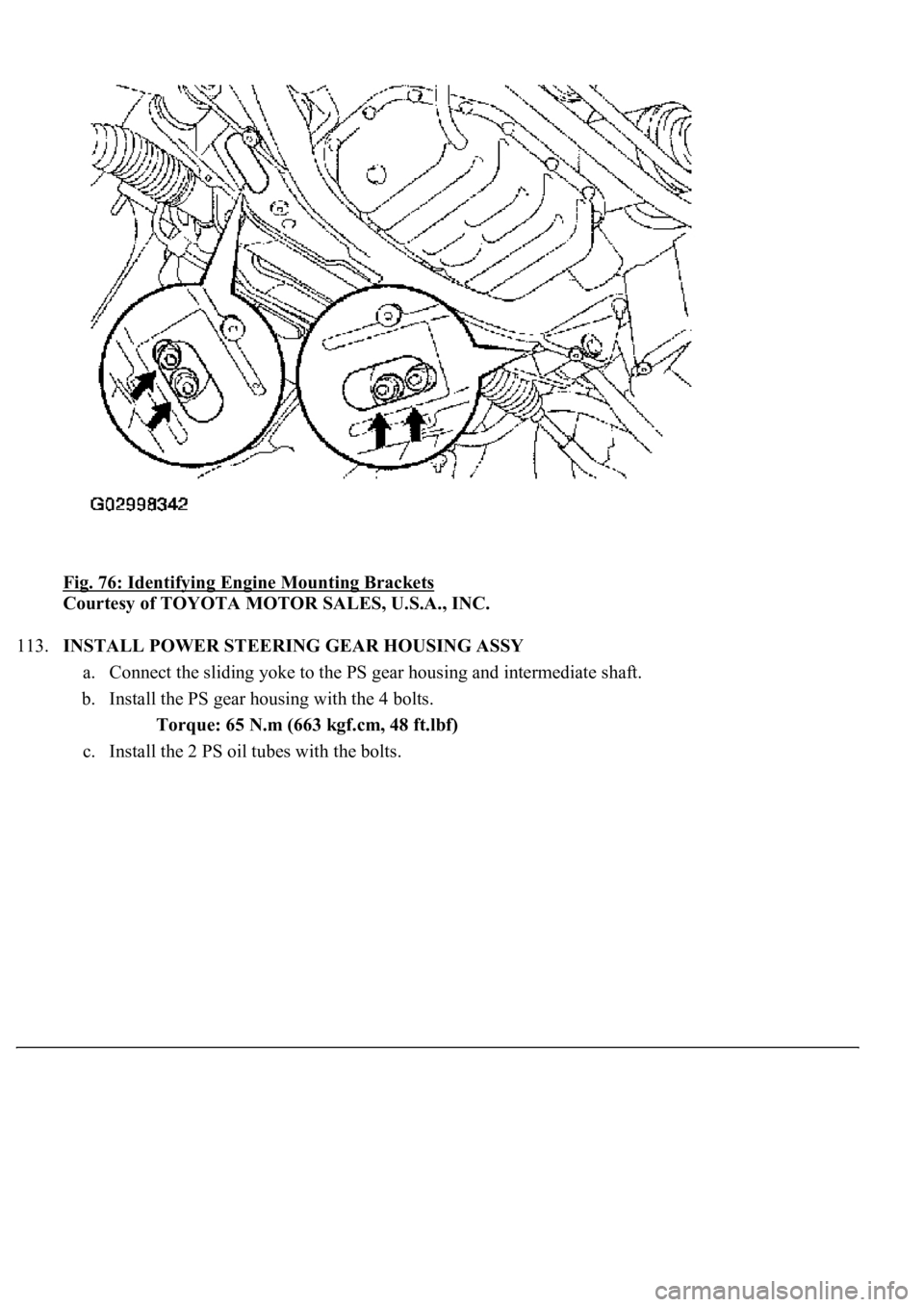

Fig. 76: Identifying Engine Mounting Brackets

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

113.INSTALL POWER STEERING GEAR HOUSING ASSY

a. Connect the sliding yoke to the PS gear housing and intermediate shaft.

b. Install the PS gear housing with the 4 bolts.

Torque: 65 N.m (663 kgf.cm, 48 ft.lbf)

c. Install the 2 PS oil tubes with the bolts.

Page 3359 of 4500

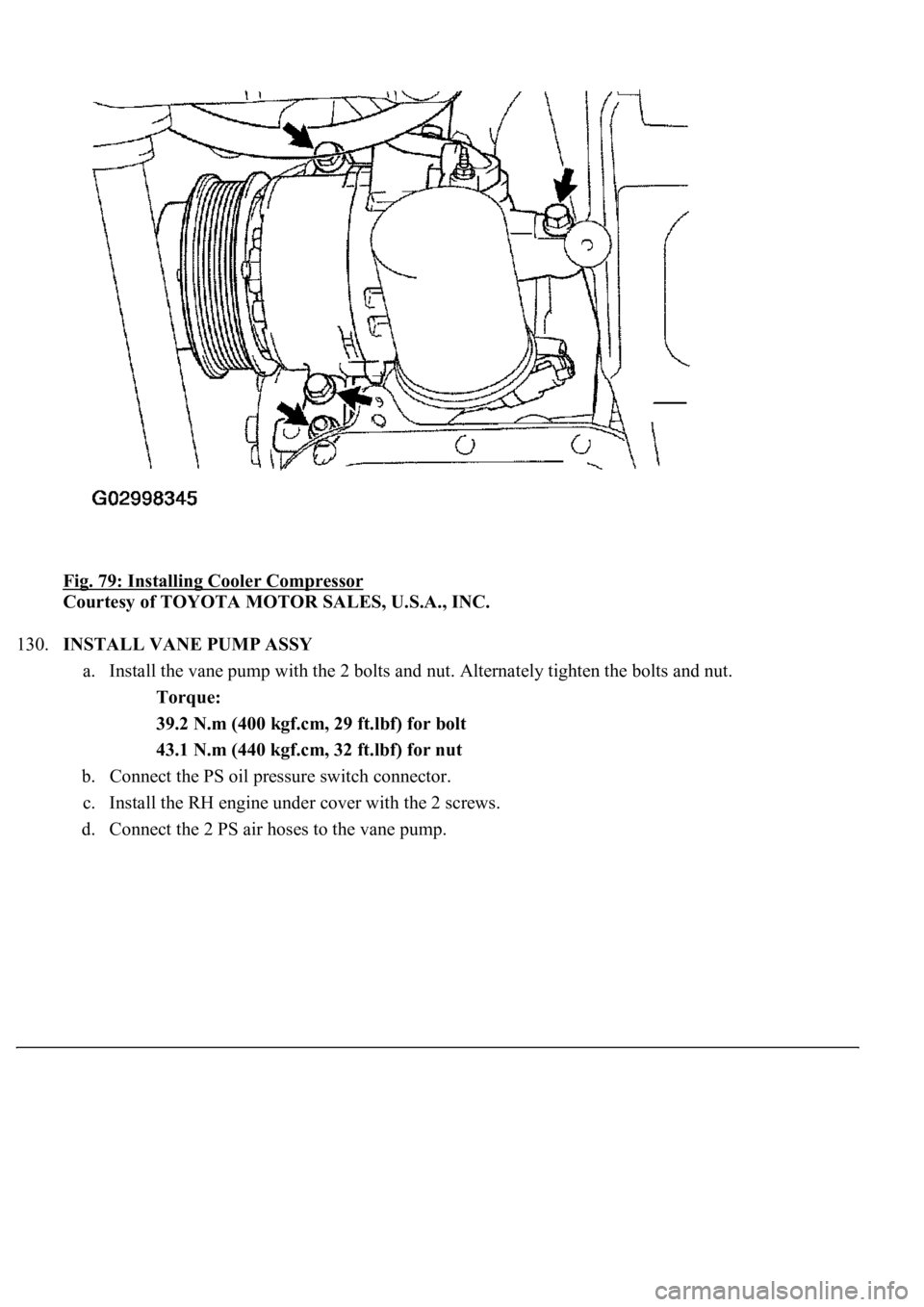

Fig. 79: Installing Cooler Compressor

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

130.INSTALL VANE PUMP ASSY

a. Install the vane pump with the 2 bolts and nut. Alternately tighten the bolts and nut.

Torque:

39.2 N.m (400 kgf.cm, 29 ft.lbf) for bolt

43.1 N.m (440 kgf.cm, 32 ft.lbf) for nut

b. Connect the PS oil pressure switch connector.

c. Install the RH engine under cover with the 2 screws.

d. Connect the 2 PS air hoses to the vane pump.

Page 3360 of 4500

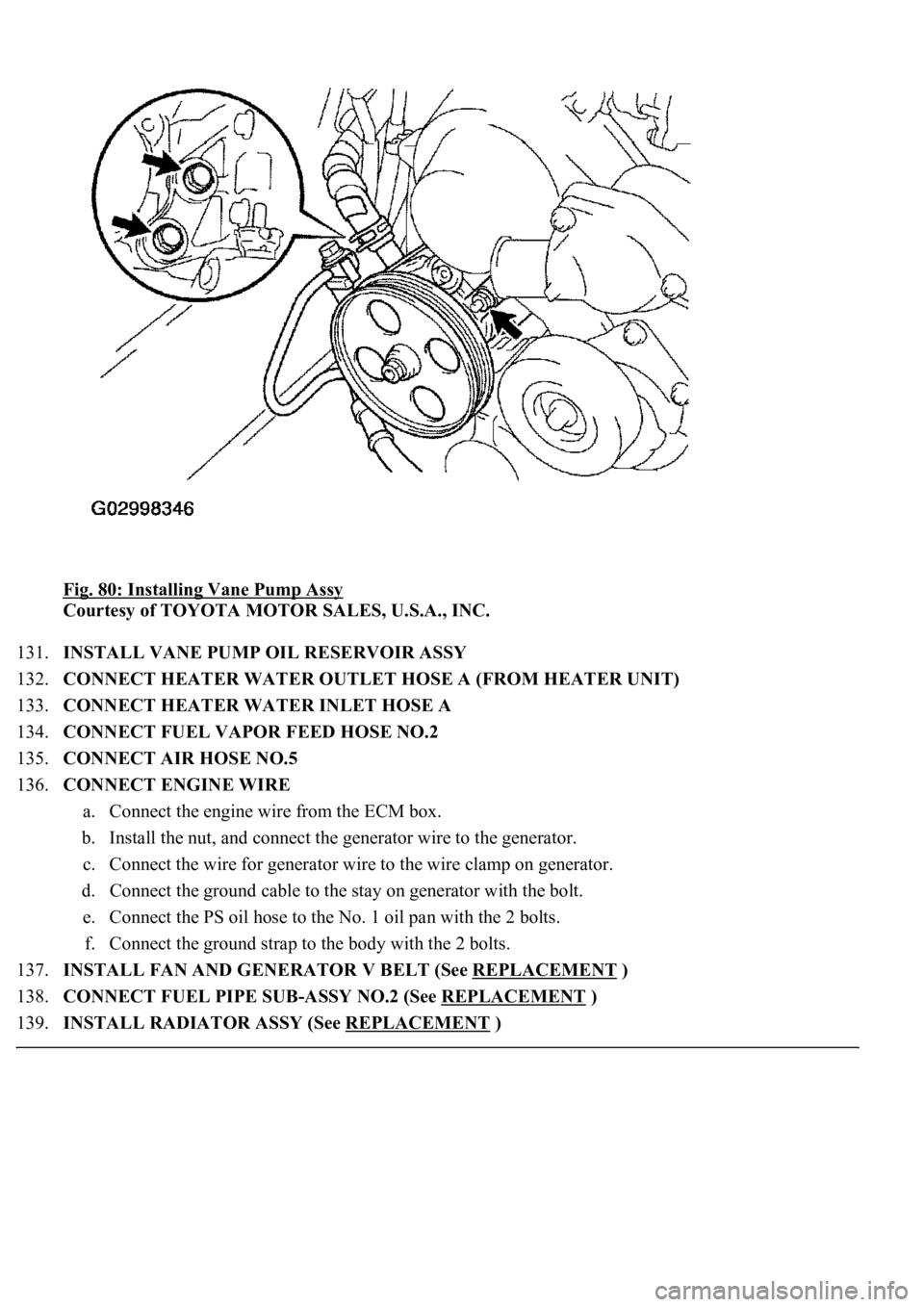

Fig. 80: Installing Vane Pump Assy

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

131.INSTALL VANE PUMP OIL RESERVOIR ASSY

132.CONNECT HEATER WATER OUTLET HOSE A (FROM HEATER UNIT)

133.CONNECT HEATER WATER INLET HOSE A

134.CONNECT FUEL VAPOR FEED HOSE NO.2

135.CONNECT AIR HOSE NO.5

136.CONNECT ENGINE WIRE

a. Connect the engine wire from the ECM box.

b. Install the nut, and connect the generator wire to the generator.

c. Connect the wire for generator wire to the wire clamp on generator.

d. Connect the ground cable to the stay on generator with the bolt.

e. Connect the PS oil hose to the No. 1 oil pan with the 2 bolts.

f. Connect the ground strap to the body with the 2 bolts.

137.INSTALL FAN AND GENERATOR V BELT (See REPLACEMENT

)

138.CONNECT FUEL PIPE SUB-ASSY NO.2 (See REPLACEMENT

)

139.INSTALL RADIATOR ASSY (See REPLACEMENT

)

Page 3361 of 4500

140.INSTALL ENGINE UNDER COVER NO.2

141.INSTALL ENGINE UNDER COVER NO.1

142.INSTALL FRONT WHEEL

143.INSTALL AIR CLEANER ASSY

144.INSTALL INTAKE AIR CONNECTOR PIPE

145.INSTALL AIR CLEANER INLET NO.1

146.INSTALL V-BANK COVER

147.INSTALL HOOD SUB-ASSY (See ADJUSTMENT

and OVERHAUL )

148.CONNECT BATTERY NEGATIVE TERMINAL

149.ADD AUTOMATIC TRANSMISSION FLUID

150.ADD ENGINE COOLANT (See REPLACEMENT

)

151.ADD ENGINE OIL (See ON

-VEHICLE INSPECTION )

152.ADD POWER STEERING FLUID

153.BLEED POWER STEERING FLUID

154.INSPECT AUTOMATIC TRANSMISSION FLUID (See ADJUSTMENT

)

155.INSPECT ENGINE OIL LEAKS

156.CHECK FOR ENGINE COOLANT LEAKS

157.INSPECT FOR FUEL LEAKS

158.CHECK FOR EXHAUST GAS LEAKS

159.INSPECT AND ADJUST FRONT WHEEL ALIGNMENT

160.INSPECT IGNITION TIMING

161.INSPECT ENGINE IDLE SPEED

162.INSPECT CO/HC

163.ADJUST ENGINE (See INSPECTION

)

164.CHECK ABS SPEED SENSOR SIGNAL (See TEST MODE PROCEDURE

)

OVERHAUL

1.REMOVE SPARK PLUG

2.REMOVE OIL FILLER CAP SUB-ASSY

3.REMOVE CYLINDER HEAD COVER SUB-ASSY LH

a. Remove the 9 bolts, 9 seal washers, cylinder head cover and gasket.

4.REMOVE CYLINDER HEAD COVER SUB-ASSY

a. Remove the 9 bolts, 9 seal washers, c

ylinder head cover and gasket.

Page 3363 of 4500

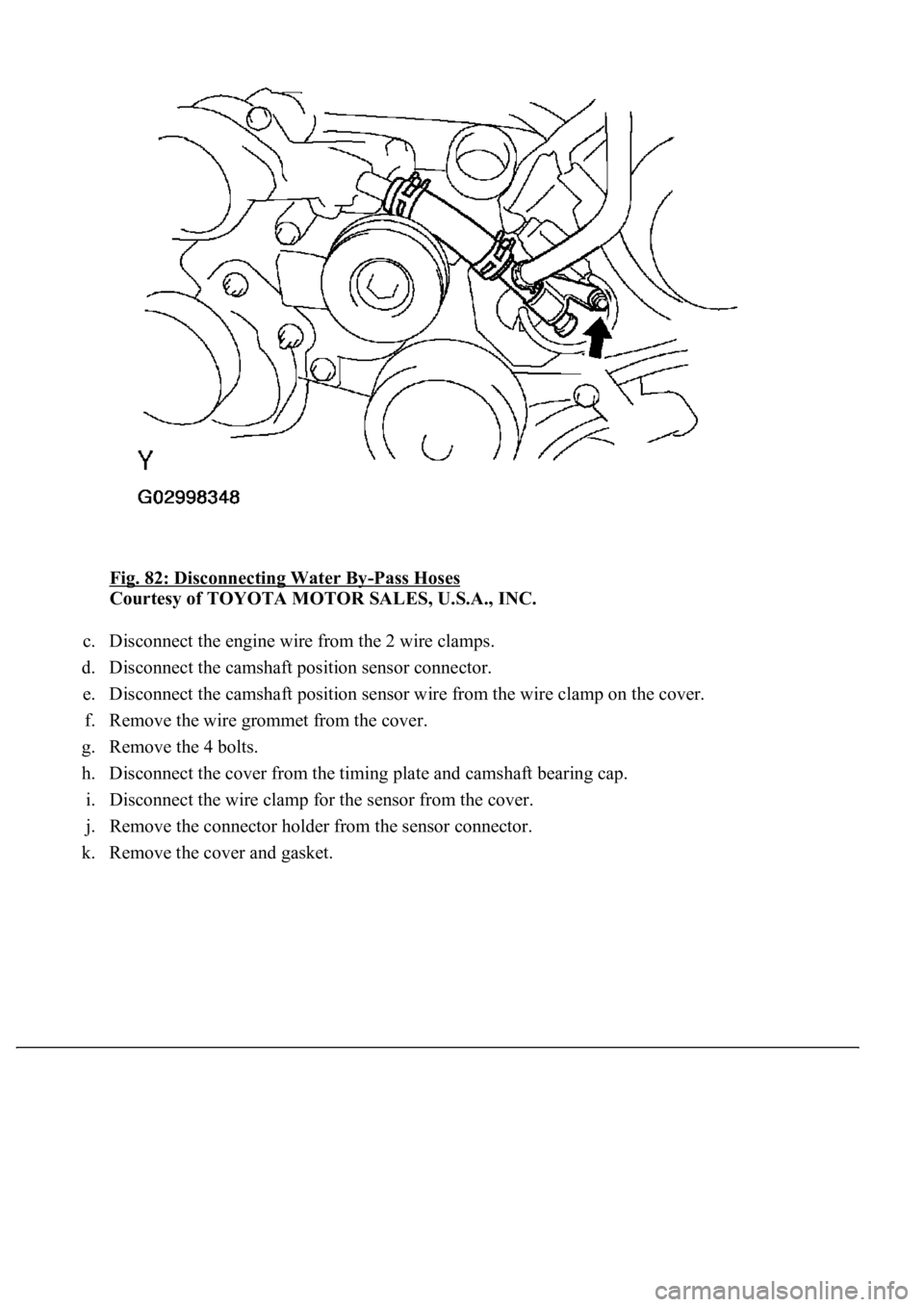

Fig. 82: Disconnecting Water By-Pass Hoses

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Disconnect the engine wire from the 2 wire clamps.

d. Disconnect the camshaft position sensor connector.

e. Disconnect the camshaft position sensor wire from the wire clamp on the cover.

f. Remove the wire grommet from the cover.

g. Remove the 4 bolts.

h. Disconnect the cover from the timing plate and camshaft bearing cap.

i. Disconnect the wire clamp for the sensor from the cover.

j. Remove the connector holder from the sensor connector.

k. Remove the cover and

gasket.

Page 3391 of 4500

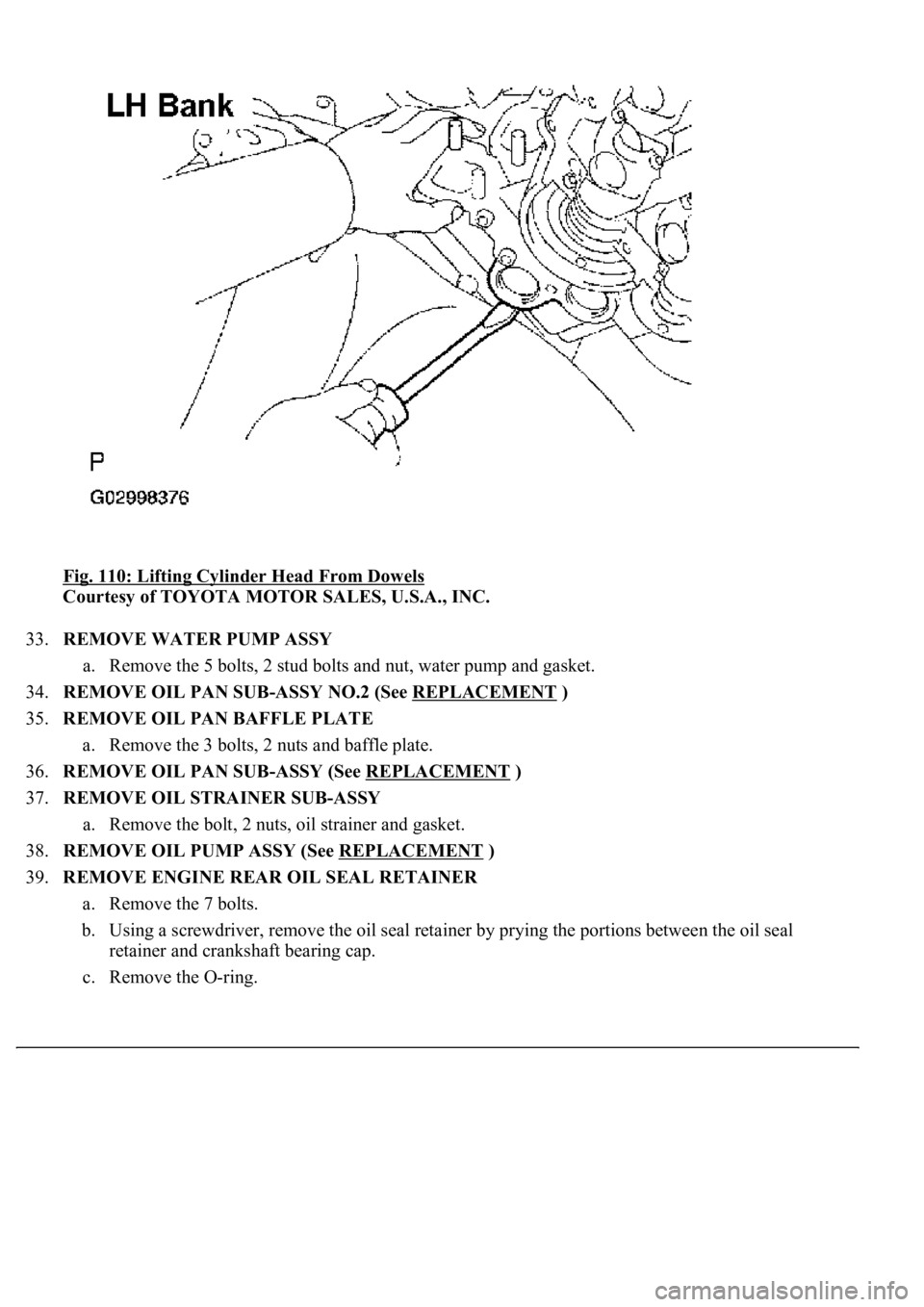

Fig. 110: Lifting Cylinder Head From Dowels

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

33.REMOVE WATER PUMP ASSY

a. Remove the 5 bolts, 2 stud bolts and nut, water pump and gasket.

34.REMOVE OIL PAN SUB-ASSY NO.2 (See REPLACEMENT

)

35.REMOVE OIL PAN BAFFLE PLATE

a. Remove the 3 bolts, 2 nuts and baffle plate.

36.REMOVE OIL PAN SUB-ASSY (See REPLACEMENT

)

37.REMOVE OIL STRAINER SUB-ASSY

a. Remove the bolt, 2 nuts, oil strainer and gasket.

38.REMOVE OIL PUMP ASSY (See REPLACEMENT

)

39.REMOVE ENGINE REAR OIL SEAL RETAINER

a. Remove the 7 bolts.

b. Using a screwdriver, remove the oil seal retainer by prying the portions between the oil seal

retainer and crankshaft bearing cap.

c. Remove the O-ring.

Page 3392 of 4500

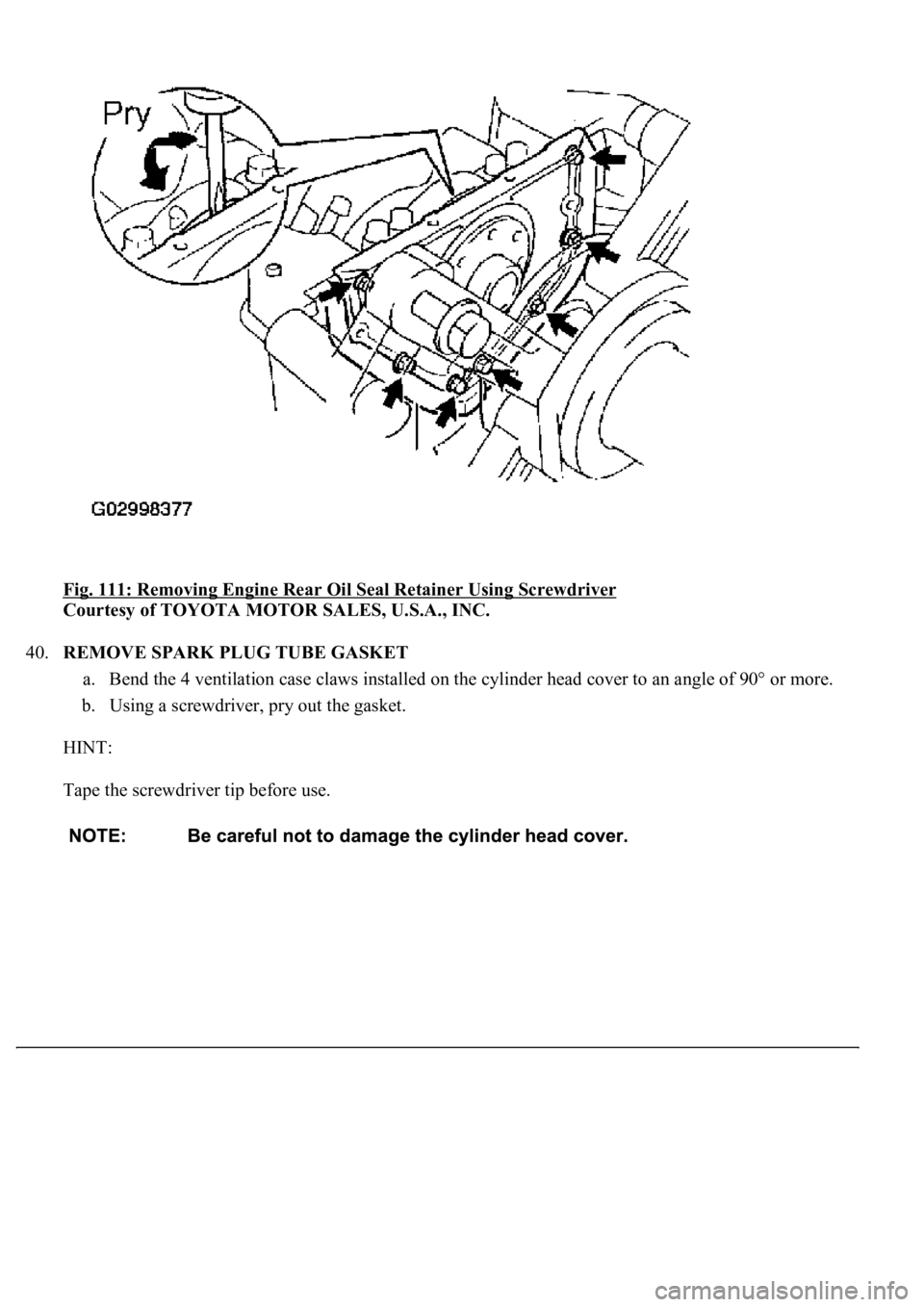

Fig. 111: Removing Engine Rear Oil Seal Retainer Using Screwdriver

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

40.REMOVE SPARK PLUG TUBE GASKET

a. Bend the 4 ventilation case claws installed on the cylinder head cover to an angle of 90° or more.

b. Using a screwdriver, pry out the gasket.

HINT:

Tape the screwdriver tip before use.

Page 3411 of 4500

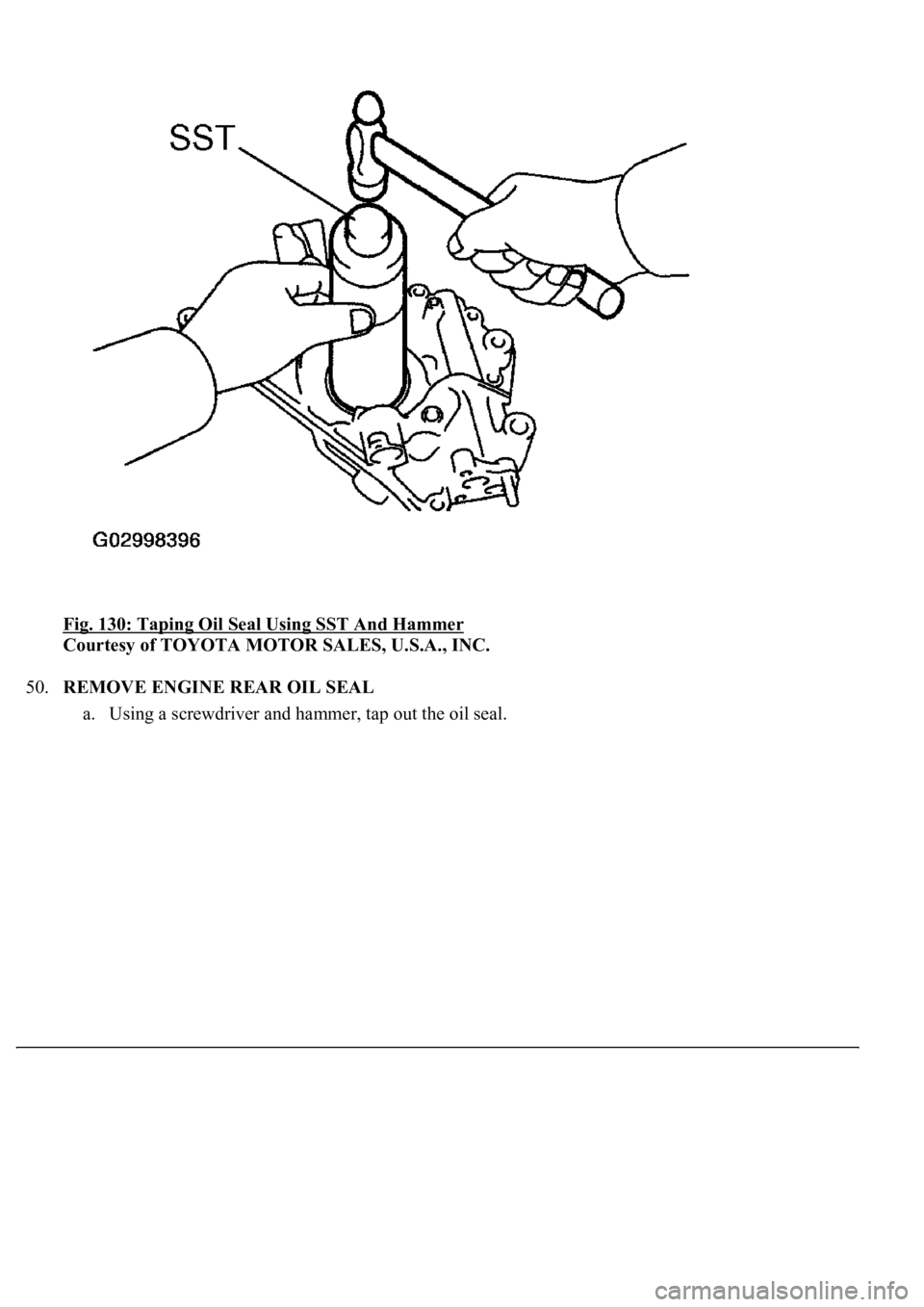

Fig. 130: Taping Oil Seal Using SST And Hammer

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

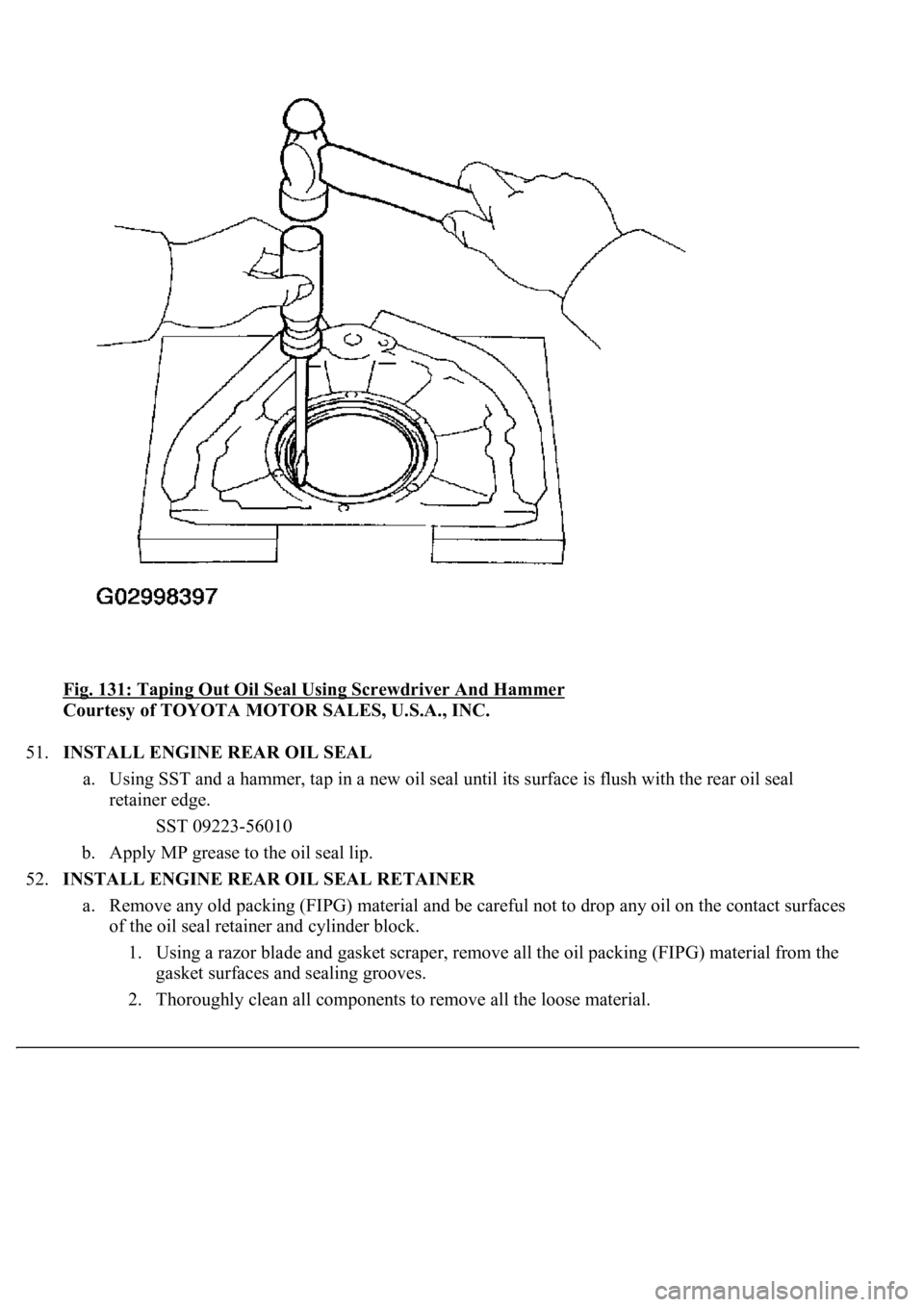

50.REMOVE ENGINE REAR OIL SEAL

a. Using a screwdriver and hammer, tap out the oil seal.

Page 3412 of 4500

Fig. 131: Taping Out Oil Seal Using Screwdriver And Hammer

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

51.INSTALL ENGINE REAR OIL SEAL

a. Using SST and a hammer, tap in a new oil seal until its surface is flush with the rear oil seal

retainer edge.

SST 09223-56010

b. Apply MP grease to the oil seal lip.

52.INSTALL ENGINE REAR OIL SEAL RETAINER

a. Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces

of the oil seal retainer and cylinder block.

1. Using a razor blade and gasket scraper, remove all the oil packing (FIPG) material from the

gasket surfaces and sealing grooves.

2. Thoroughly clean all components to remove all the loose material.

Page 3418 of 4500

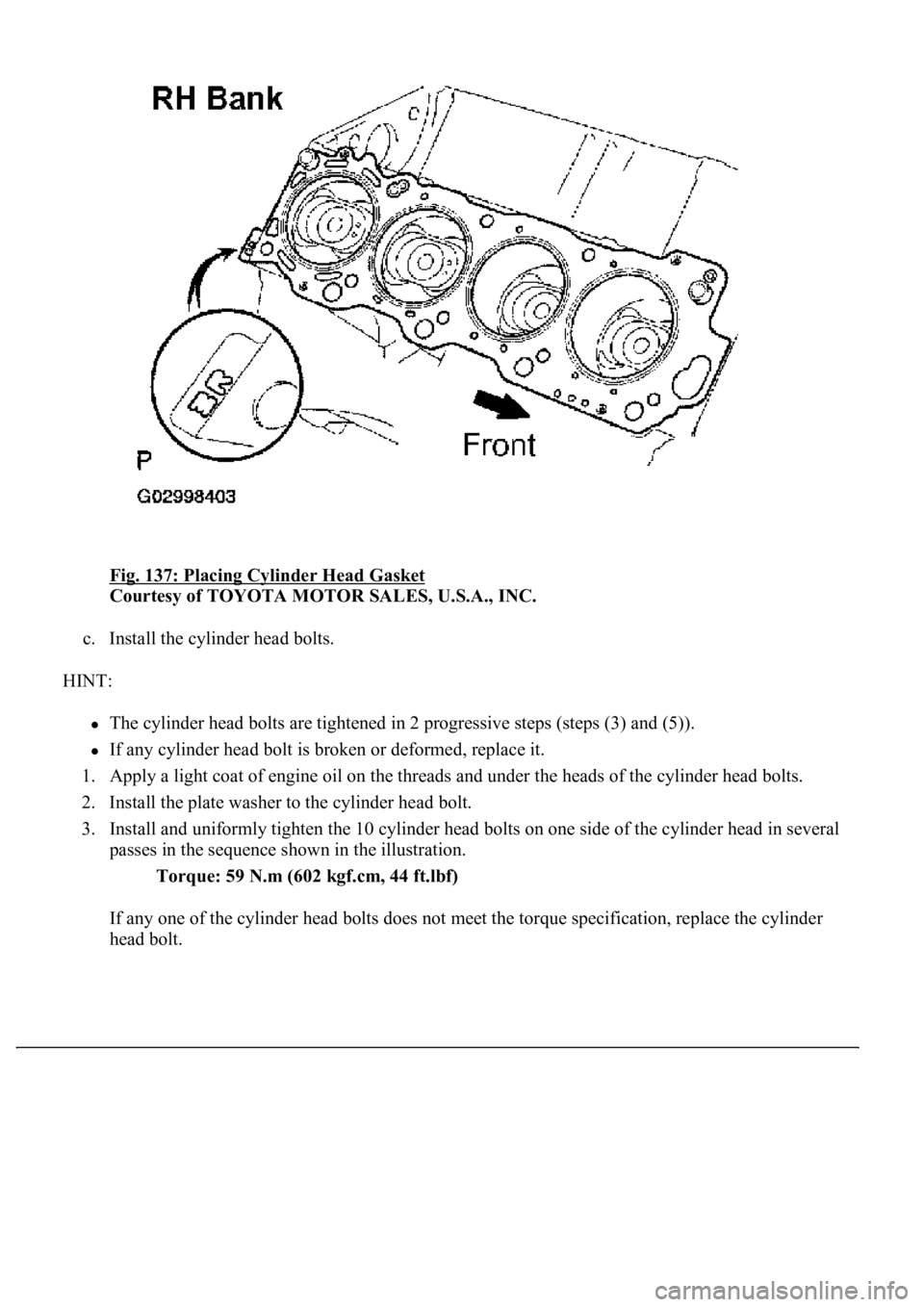

Fig. 137: Placing Cylinder Head Gasket

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Install the cylinder head bolts.

HINT:

The cylinder head bolts are tightened in 2 progressive steps (steps (3) and (5)).

If any cylinder head bolt is broken or deformed, replace it.

1. Apply a light coat of engine oil on the threads and under the heads of the cylinder head bolts.

2. Install the plate washer to the cylinder head bolt.

3. Install and uniformly tighten the 10 cylinder head bolts on one side of the cylinder head in several

passes in the sequence shown in the illustration.

Torque: 59 N.m (602 kgf.cm, 44 ft.lbf)

If any one of the cylinder head bolts does not meet the torque specification, replace the cylinder

head bolt.