engine LEXUS LS430 2003 Factory Repair Manual

[x] Cancel search | Manufacturer: LEXUS, Model Year: 2003, Model line: LS430, Model: LEXUS LS430 2003Pages: 4500, PDF Size: 87.45 MB

Page 3766 of 4500

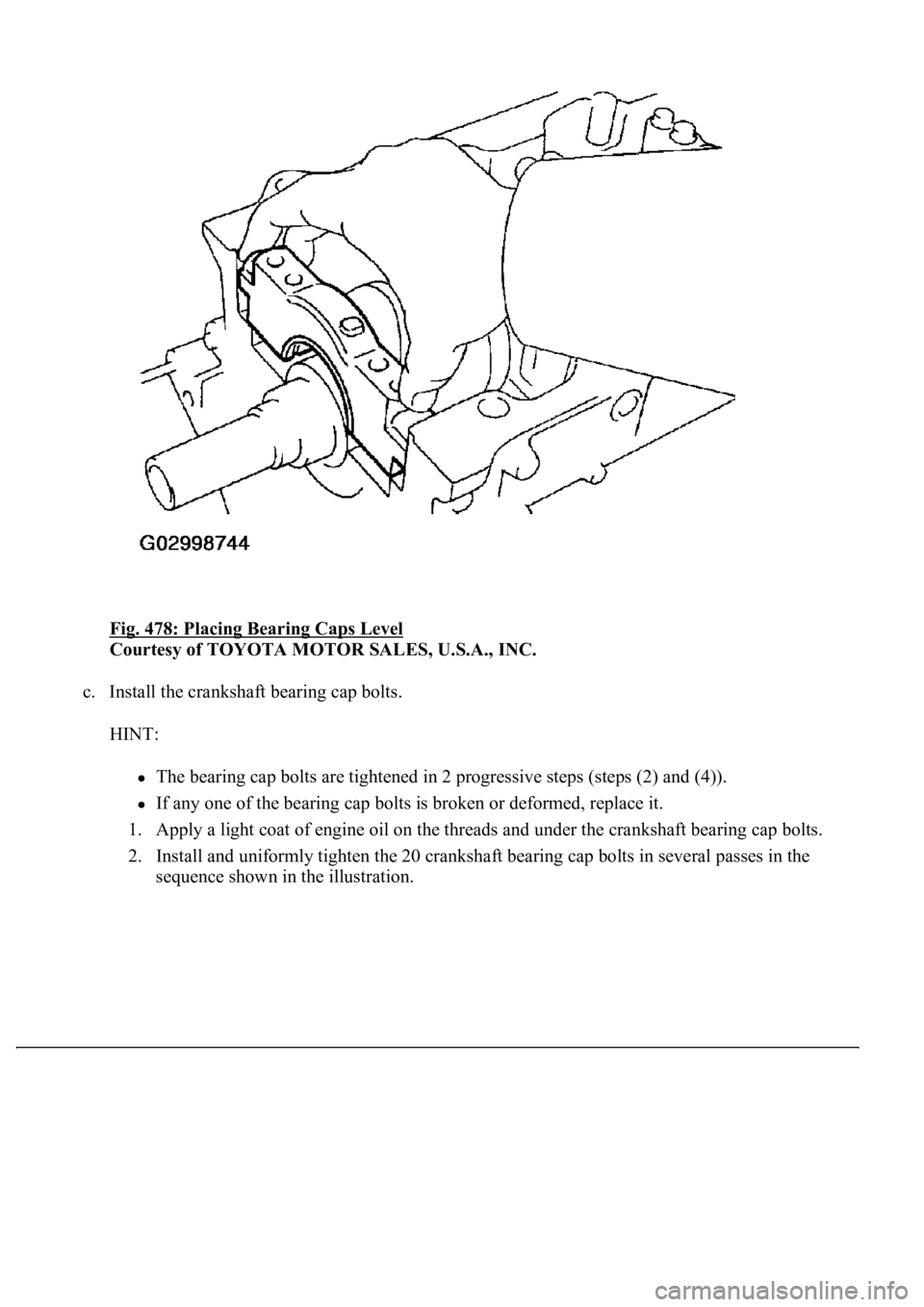

Fig. 478: Placing Bearing Caps Level

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Install the crankshaft bearing cap bolts.

HINT:

The bearing cap bolts are tightened in 2 progressive steps (steps (2) and (4)).

If any one of the bearing cap bolts is broken or deformed, replace it.

1. Apply a light coat of engine oil on the threads and under the crankshaft bearing cap bolts.

2. Install and uniformly tighten the 20 crankshaft bearing cap bolts in several passes in the

sequence shown in the illustration.

Page 3773 of 4500

Fig. 484: Identifying Outside Mark Of Connecting Rod Cap

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

c. Install the connecting rod cap bolts.

HINT:

The connecting rod cap bolts are tightened in 2 progressive steps (see steps (2) and (4)).

If any one of the connecting rod cap bolts is broken or deformed, replace it.

1. Apply a light coat of engine oil on the threads and under the heads of the connecting rod cap

bolts.

2. Install and alternately tighten the 2 connecting rod cap bolts in several passes.

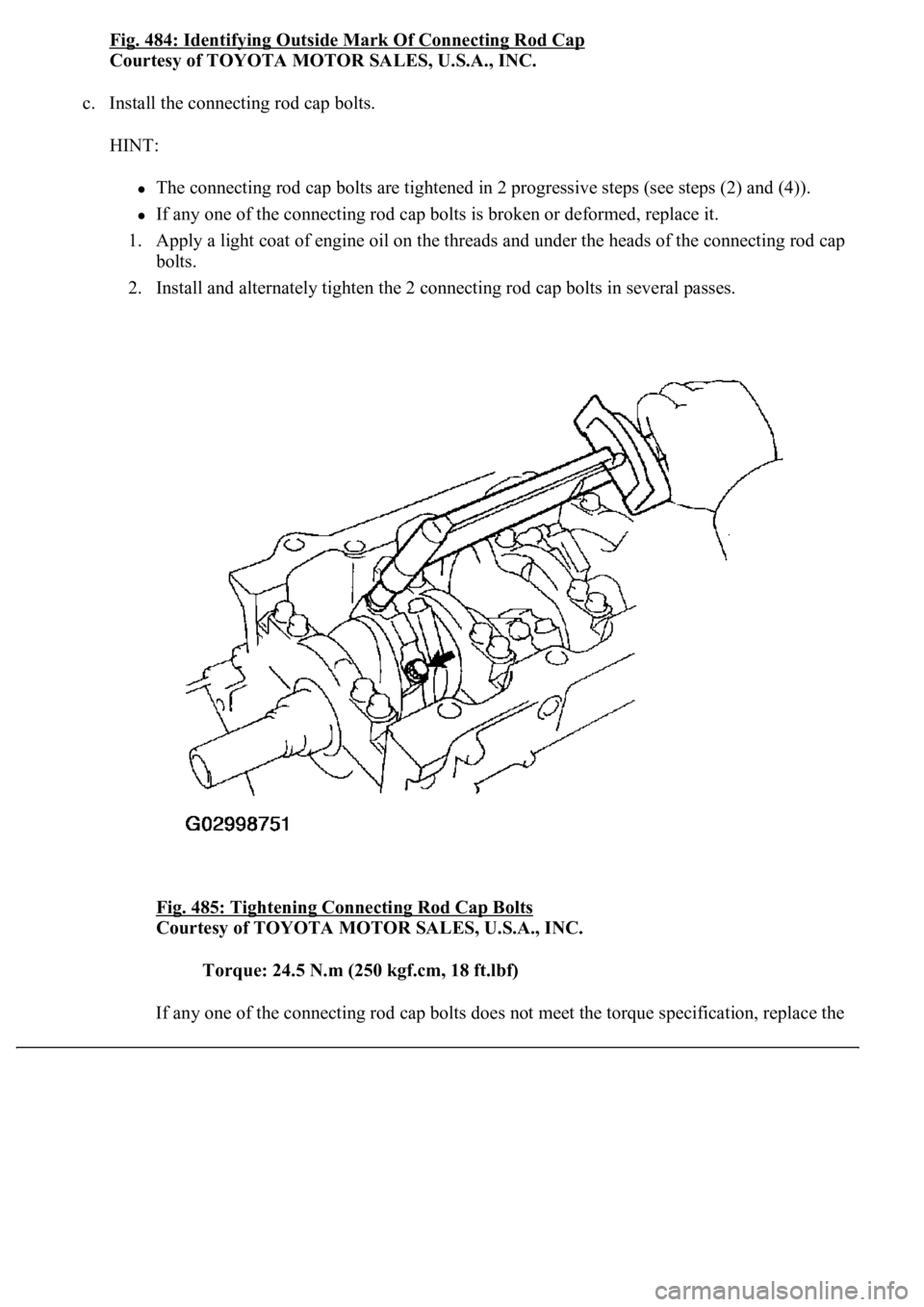

Fig. 485: Tightening Connecting Rod Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Torque: 24.5 N.m (250 kgf.cm, 18 ft.lbf)

If an

y one of the connecting rod cap bolts does not meet the torque specification, replace the

Page 3967 of 4500

OPERATION AND TILT AND TELESCOPIC POSITION OPERATION

HINT:

*1: Wireless door lock control system

*2: Smart key system

If the result is not as specified, inspect the tilt and telescopic.

4.CHECK FRONT POWER SEAT FUNCTION

a. Check the basic functions.

1. Operate the power seat switches and check to make sure each seat function works:

Sliding

Front vertical

Lifter

Reclining

Lumbar support

Cushion sliding

Headrest

OperationTilt and Telescopic Position Operation

Key is inserted to the key cylinder*1 Engine switch is

pushed*2Vertical tilt position

Key is inserted to the key cylinder*1 Engine switch is

pushed*2Telescopic flexibility (lengthening and

shortening)

Page 4021 of 4500

Fig. 29: Connecting Connector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

14.INSTALL FRONT SHOCK ABSORBER CAP LH

a. Install the front shock absorber cap LH with 3 nuts.

Torque: 58 N.m (590 kgf.cm, 43 ft.lbf)

b. Start the engine to fill the pneumatic front LH w/shock absorber cylinder assy with air.

Page 4103 of 4500

SYSTEM

3.KEEP GASOLINE AWAY FROM RUBBER AND LEATHER PARTS

4.DISCHARGE FUEL SYSTEM PRESSURE

a. Using the F/PMP relay:

1. Remove the engine room R/B cover upper.

2. Remove the F/PMP relay.

3. Start the engine.

4. After the engine has stopped, turn the ignition switch OFF.

5. Crank the engine. Check that the engine does not start.

6. Remove the fuel tank cap to discharge pressure from the fuel tank.

7. Disconnect the negative (-) battery terminal cable.

8. Reinstall the F/PMP relay.

b. Using the fuel pump connector:

1. Remove the rear seat cushion.

2. Remove the rear floor service hole cover.

3. Disconnect the fuel pump connector.

4. Start the engine.

5. After the engine has stopped, turn the ignition switch OFF.

6. Crank the engine. Check that the engine does not start.

7. Remove the fuel tank cap to discharge pressure from the fuel tank.

8. Disconnect the cable from the negative (-) battery terminal.

9. Reconnect the fuel pump connector.

10. Install the rear floor service hole cover.

11. Install the rear seat.

Page 4105 of 4500

33 N.m (340 kgf.cm, 24 ft.lbf) for use with SST

39 N.m (400 kgf.cm, 29 ft.lbf)

Fig. 6: Tightening Union Bolt To Specified Torque

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

c. Observe these precautions when removing and installing the injector.

1. Never reuse the O-ring.

2. When placing a new O-ring on the injector, take care not to damage it.

3. Coat a new O-ring with spindle oil or gasoline before installing. Never use engine, gear or

brake oil.

Page 4110 of 4500

Fig. 11: Covering Disconnected Pipe And Connector With Plastic Bag

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

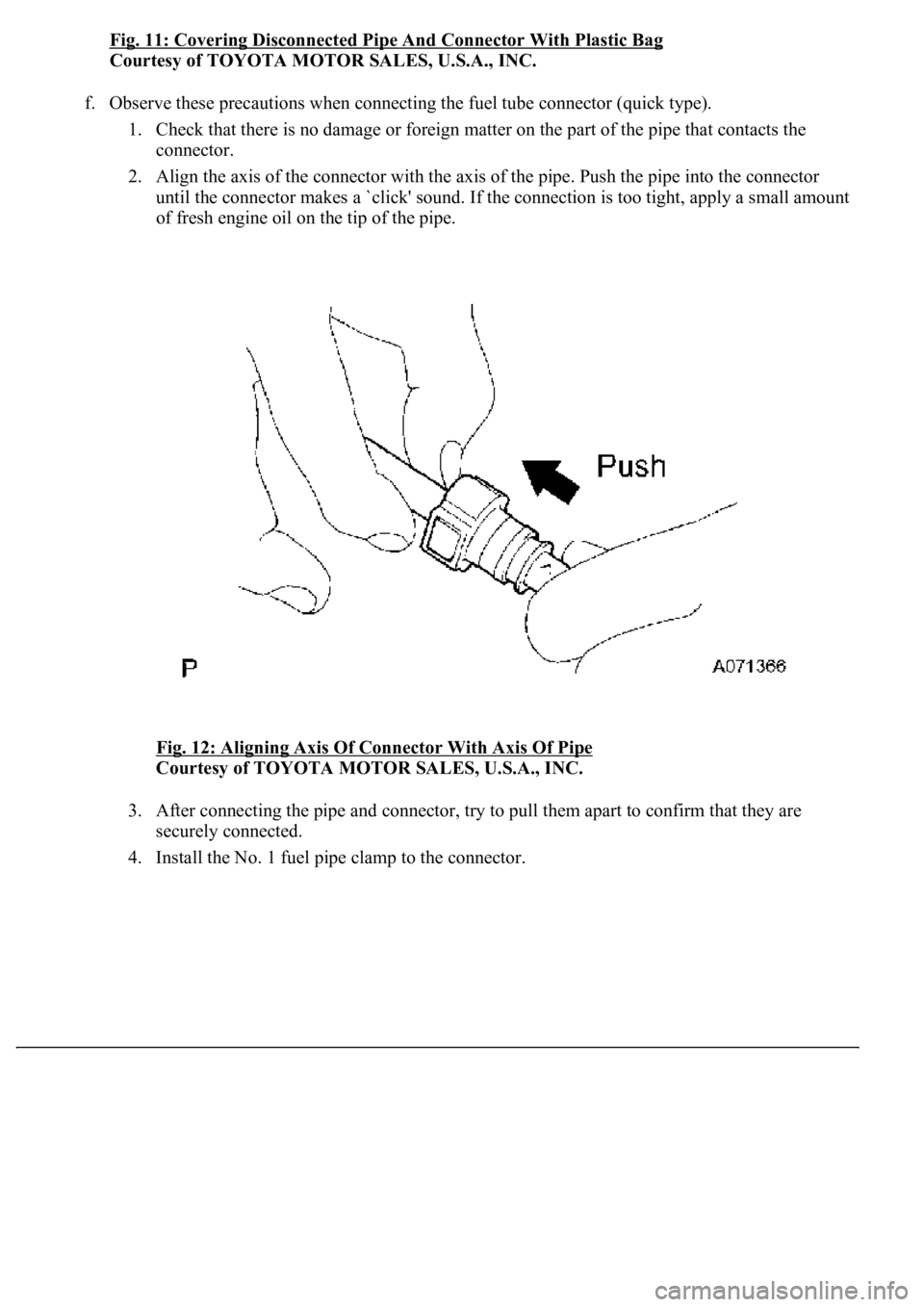

f. Observe these precautions when connecting the fuel tube connector (quick type).

1. Check that there is no damage or foreign matter on the part of the pipe that contacts the

connector.

2. Align the axis of the connector with the axis of the pipe. Push the pipe into the connector

until the connector makes a `click' sound. If the connection is too tight, apply a small amount

of fresh engine oil on the tip of the pipe.

Fig. 12: Aligning Axis Of Connector With Axis Of Pipe

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. After connecting the pipe and connector, try to pull them apart to confirm that they are

securely connected.

4. Install the No. 1 fuel pipe clamp to the connector.

Page 4112 of 4500

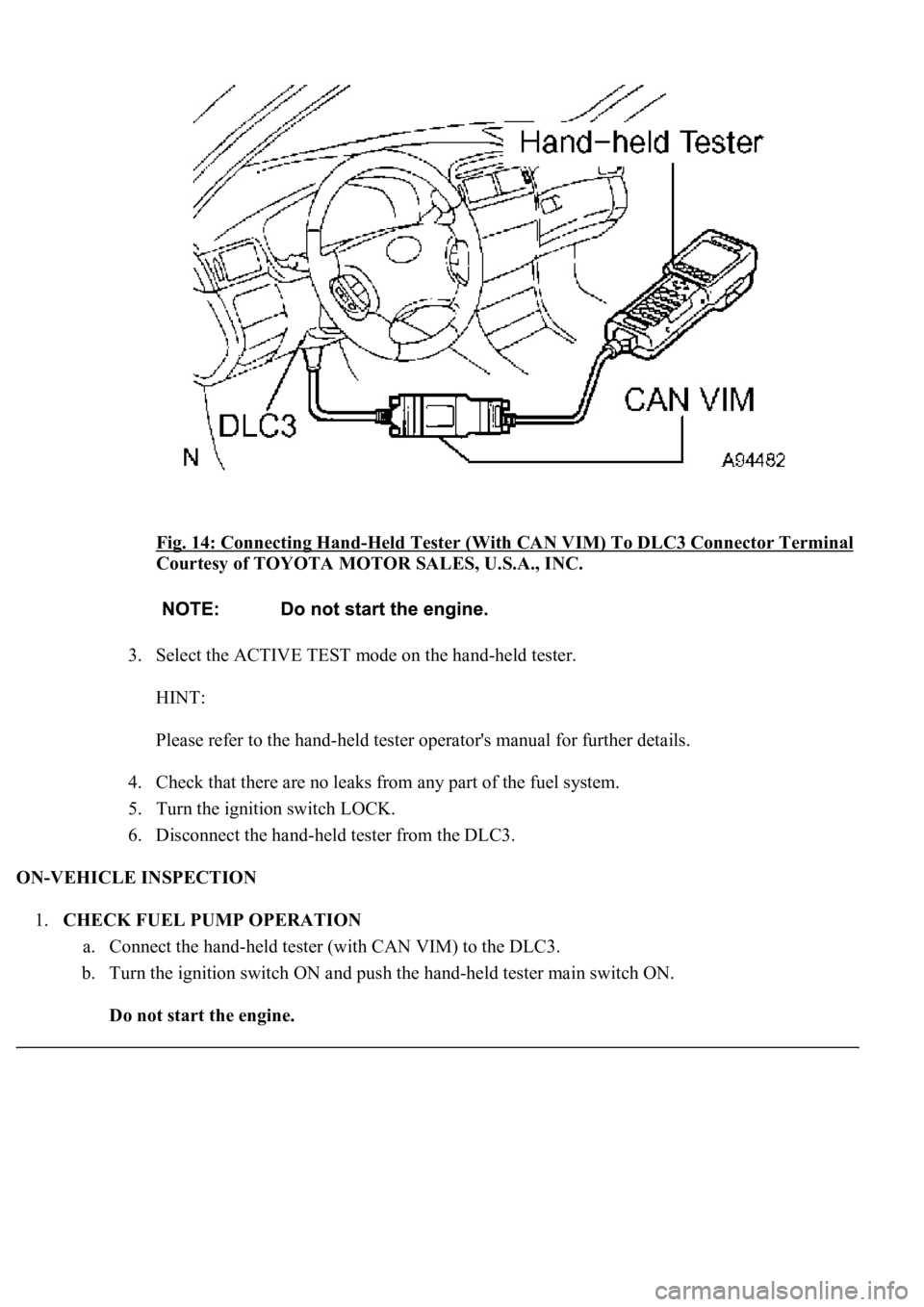

Fig. 14: Connecting Hand-Held Tester (With CAN VIM) To DLC3 Connector Terminal

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Select the ACTIVE TEST mode on the hand-held tester.

HINT:

Please refer to the hand-held tester operator's manual for further details.

4. Check that there are no leaks from any part of the fuel system.

5. Turn the ignition switch LOCK.

6. Disconnect the hand-held tester from the DLC3.

ON-VEHICLE INSPECTION

1.CHECK FUEL PUMP OPERATION

a. Connect the hand-held tester (with CAN VIM) to the DLC3.

b. Turn the ignition switch ON and push the hand-held tester main switch ON.

Do not start the engine.

Page 4115 of 4500

pressure regulator.

i. Disconnect the hand-held tester from the DLC3.

j. Start the engine.

k. Measure the fuel pressure at idle.

Fuel pressure: 304 to 343 kPa (3.1 to 3.5 kgf/cm2, 44 to 50 psi)

l. Stop the engine.

m. Check that the fuel pressure remains as specified for 5 minutes after the engine has stopped.

Fuel pressure: 147 kPa (1.5 kgf/cm2, 21 psi) or more

If pressure is not as specified, check the fuel pump, pressure regulator and/or injectors.

n. After checking fuel pressure, disconnect the negative (-) terminal cable from the battery and

carefully remove the SST to prevent gasoline from spilling.

SST 09268-45014

o. Reinstall the fuel pressure pulsation damper to the RH delivery pipe (see REPLACEMENT

).

p. Reconnect the negative (-) terminal cable to the battery.

q. Check for fuel leaks.

3.INSPECT FUEL PUMP

Page 4129 of 4500

REPLACEMENT

1.WORK FOR PREVENTING GASOLINE FROM SPILLING OUT (See PRECAUTION

)

2.DISCONNECT BATTERY NEGATIVE TERMINAL

3.REMOVE V-BANK COVER

a. Remove the 2 nuts and V-bank cover.

4.REMOVE AIR CLEANER INLET NO.1

5.REMOVE INTAKE AIR CONNECTOR PIPE

a. Disconnect the air hose and ventilation hose No. 1.

b. Loosen the hose clamp.

c. Remove the bolt and intake air connector pipe.

6.REMOVE V-BANK COVER BRACKET NO.1

7.REMOVE V-BANK COVER BRACKET NO.2

8.REMOVE V-BANK COVER BRACKET NO.3

9.REMOVE V-VANK COVER BRACKET NO.4

10.REMOVE VACUUM SWITCHING VALVE ASSY

11.DISCONNECT ENGINE WIRE