LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: boot, inter lock cable, snow chains, seat adjustment, air suspension, differential, maintenance reset

Page 571 of 4500

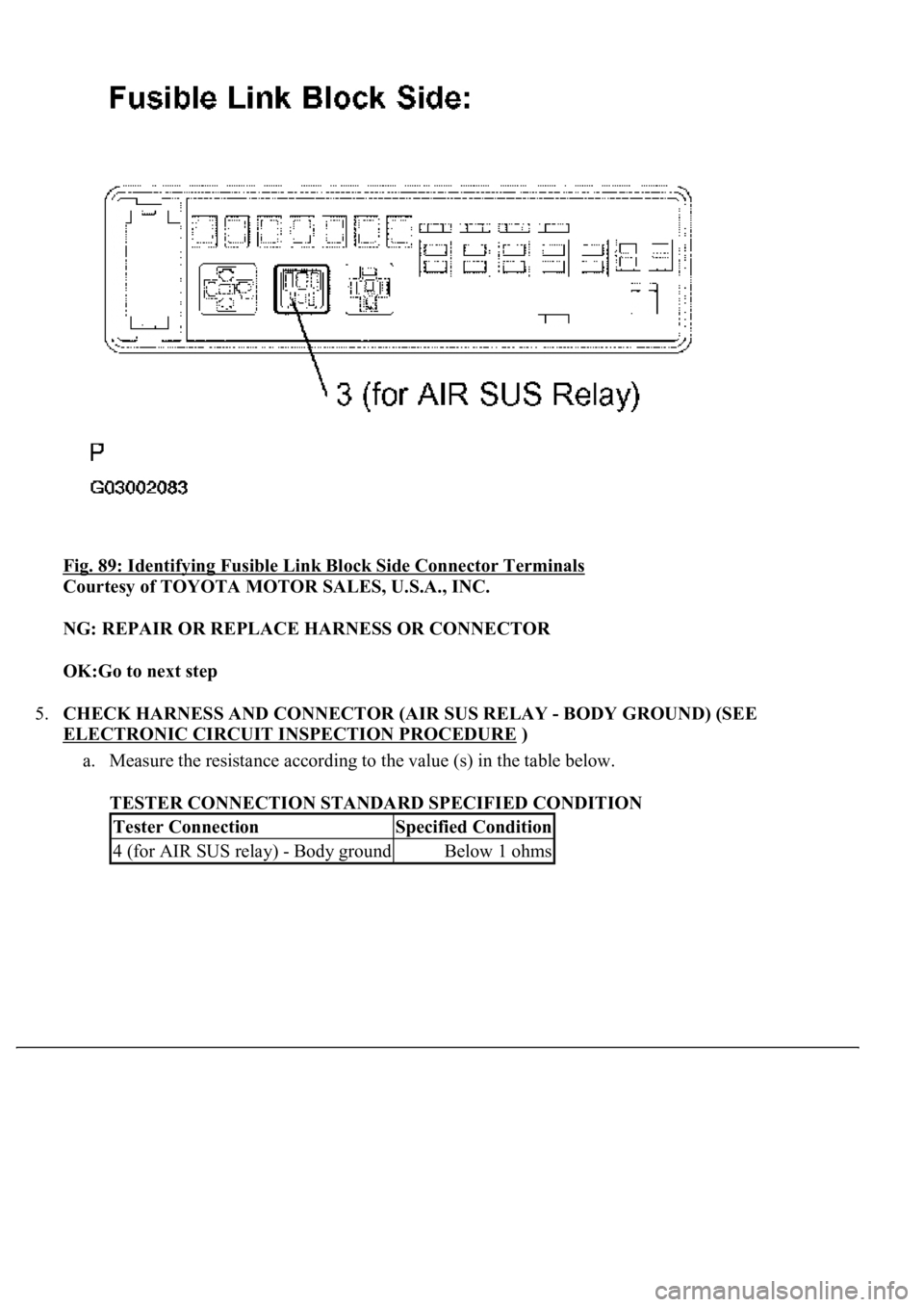

Fig. 89: Identifying Fusible Link Block Side Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK:Go to next step

5.CHECK HARNESS AND CONNECTOR (AIR SUS RELAY - BODY GROUND) (SEE

ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

Tester ConnectionSpecified Condition

4 (for AIR SUS relay) - Body groundBelow 1 ohms

Page 572 of 4500

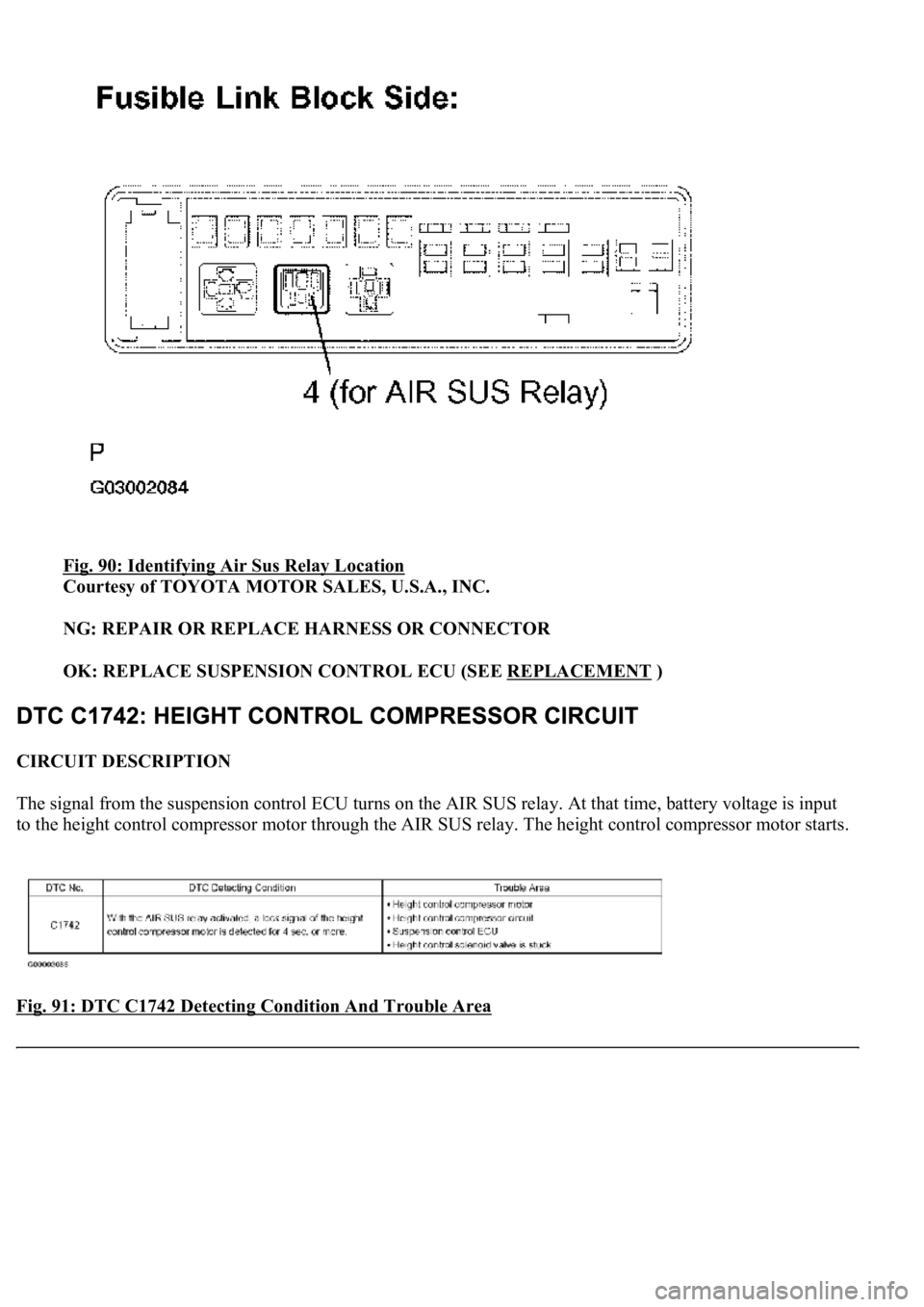

Fig. 90: Identifying Air Sus Relay Location

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK: REPLACE SUSPENSION CONTROL ECU (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

The signal from the suspension control ECU turns on the AIR SUS relay. At that time, battery voltage is input

to the height control compressor motor through the AIR SUS relay. The height control compressor motor starts.

<0029004c004a00110003001c0014001d0003002700370026000300260014001a001700150003002700480057004800460057004c0051004a00030026005200510047004c0057004c005200510003002400510047000300370055005200580045004f004800

030024005500480044[

Page 573 of 4500

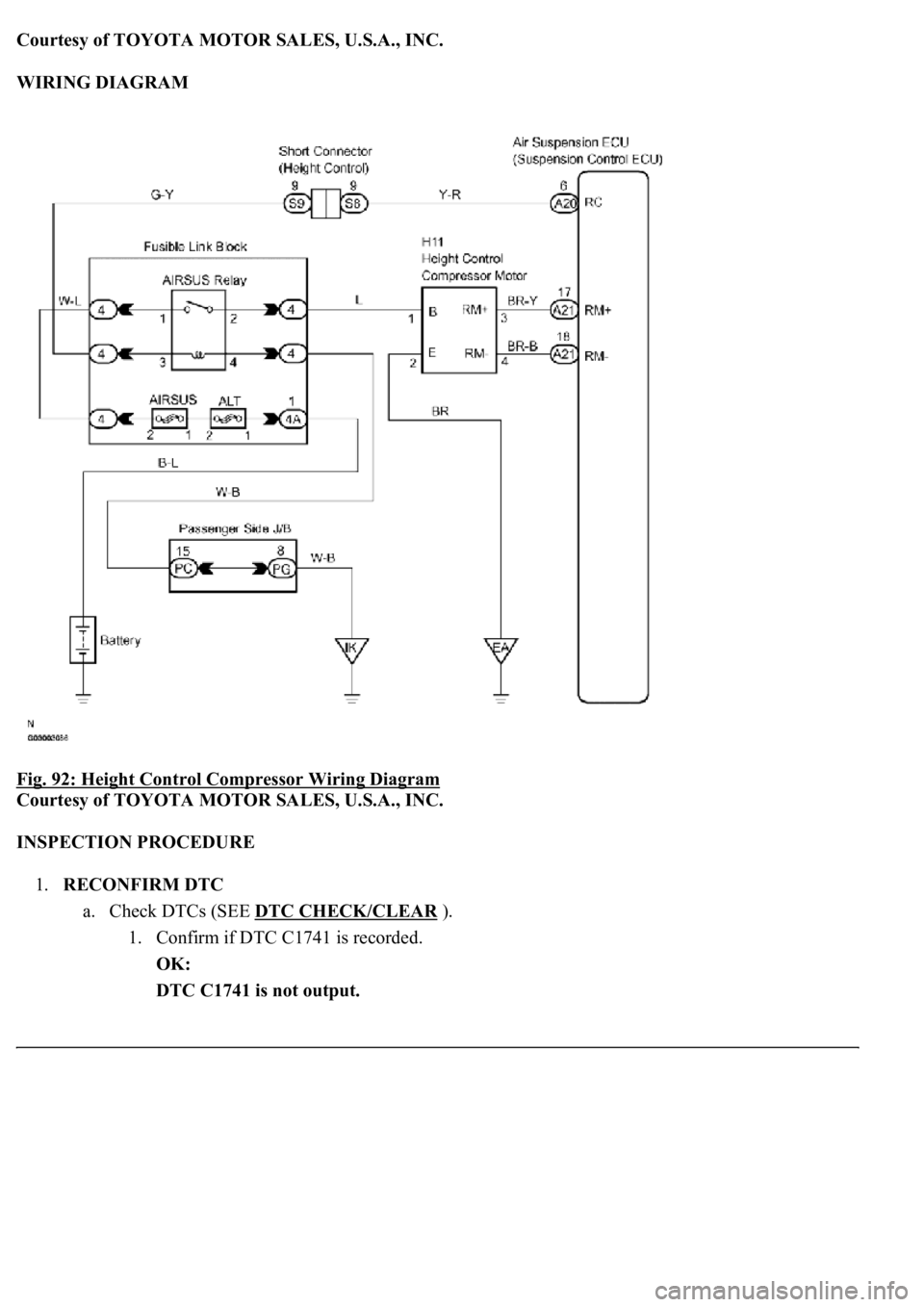

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Fig. 92: Height Control Compressor Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.RECONFIRM DTC

a. Check DTCs (SEE DTC CHECK/CLEAR

).

1. Confirm if DTC C1741 is recorded.

OK:

DTC C1741 is not output.

Page 574 of 4500

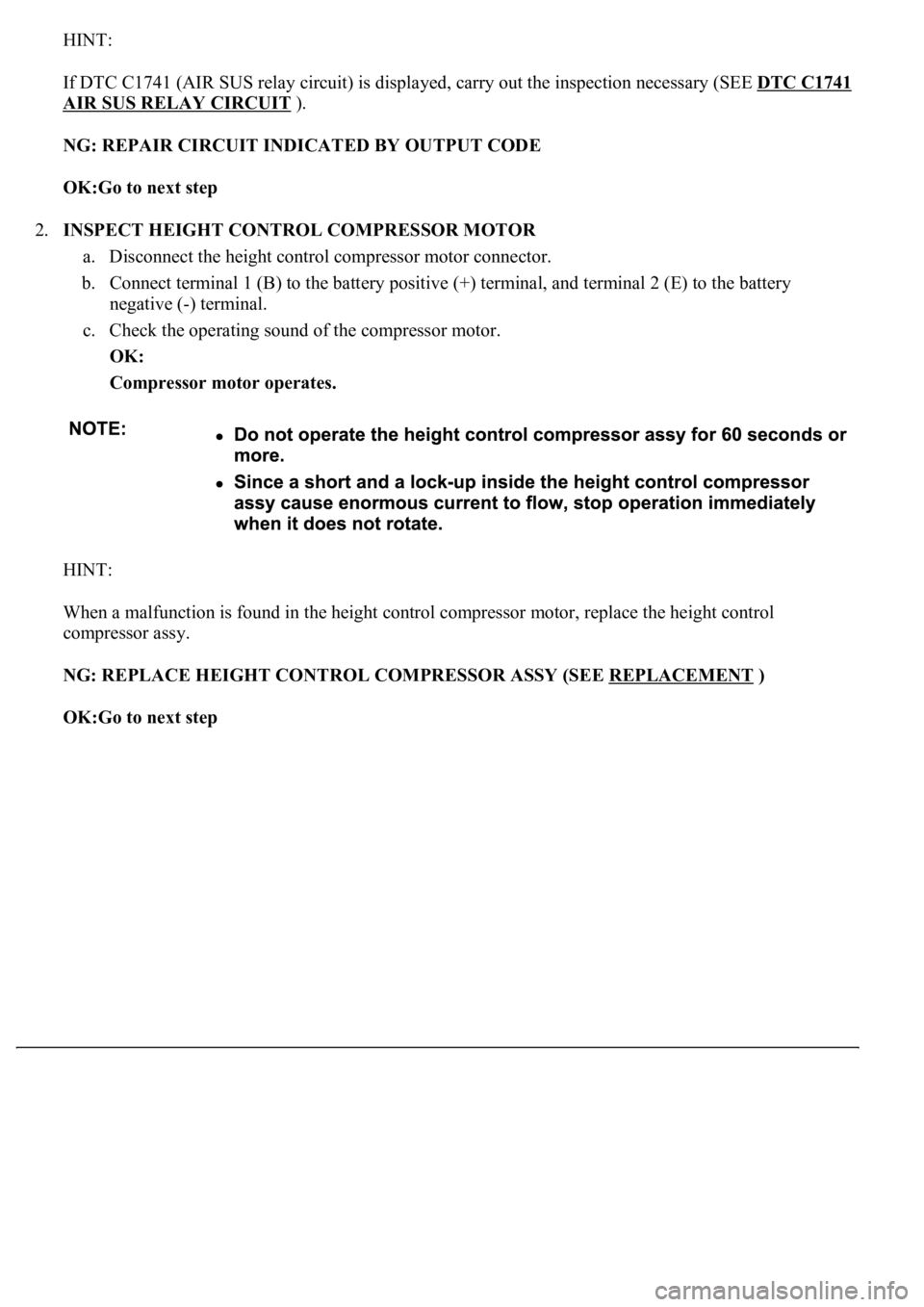

HINT:

If DTC C1741 (AIR SUS relay circuit) is displayed, carry out the inspection necessary (SEE DTC C1741

AIR SUS RELAY CIRCUIT ).

NG: REPAIR CIRCUIT INDICATED BY OUTPUT CODE

OK:Go to next step

2.INSPECT HEIGHT CONTROL COMPRESSOR MOTOR

a. Disconnect the height control compressor motor connector.

b. Connect terminal 1 (B) to the battery positive (+) terminal, and terminal 2 (E) to the battery

negative (-) terminal.

c. Check the operating sound of the compressor motor.

OK:

Compressor motor operates.

HINT:

When a malfunction is found in the height control compressor motor, replace the height control

compressor assy.

NG: REPLACE HEIGHT CONTROL COMPRESSOR ASSY (SEE REPLACEMENT

)

OK:Go to next step

Page 575 of 4500

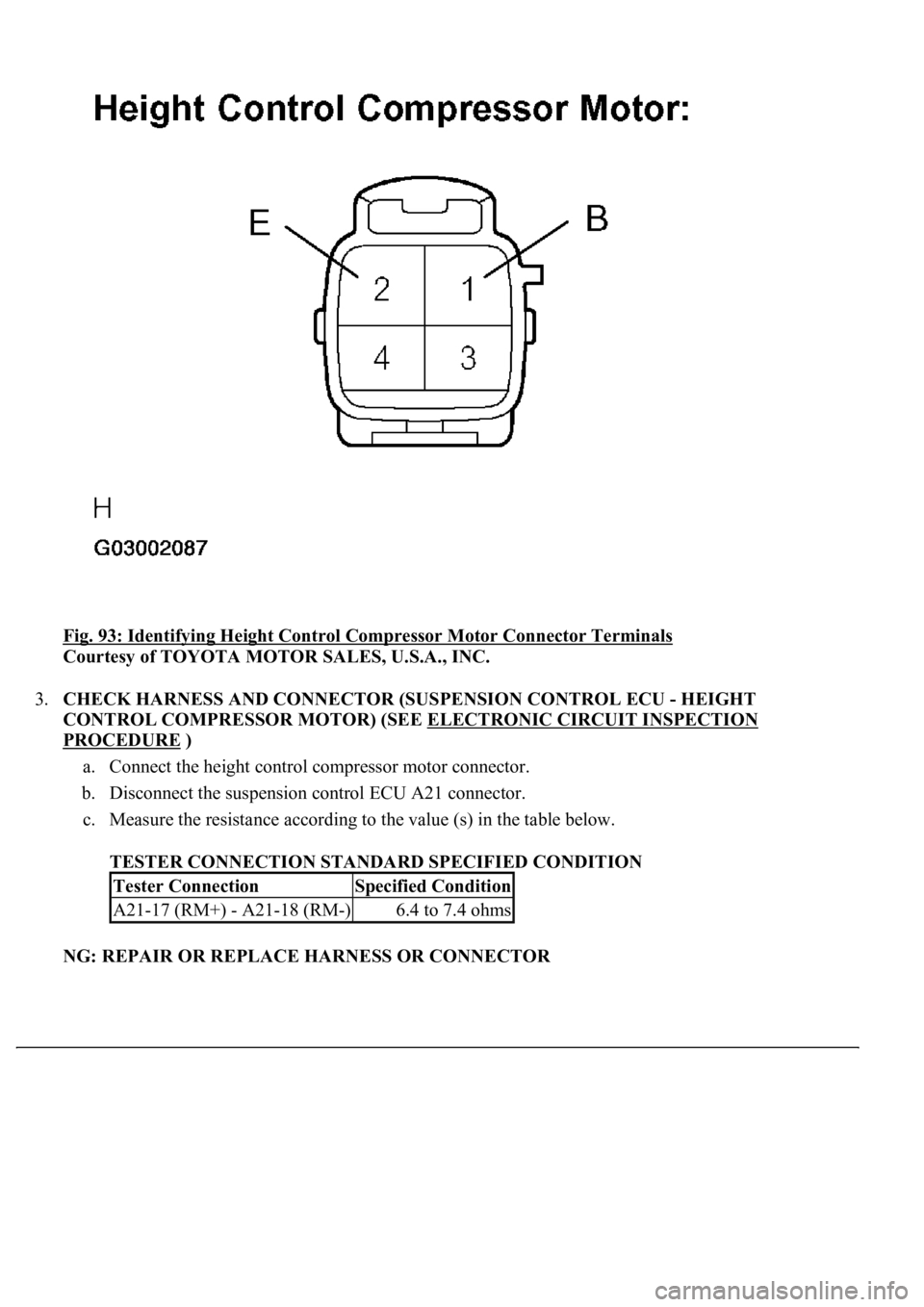

Fig. 93: Identifying Height Control Compressor Motor Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3.CHECK HARNESS AND CONNECTOR (SUSPENSION CONTROL ECU - HEIGHT

CONTROL COMPRESSOR MOTOR) (SEE ELECTRONIC CIRCUIT INSPECTION

PROCEDURE )

a. Connect the height control compressor motor connector.

b. Disconnect the suspension control ECU A21 connector.

c. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

Tester ConnectionSpecified Condition

A21-17 (RM+) - A21-18 (RM-)6.4 to 7.4 ohms

Page 576 of 4500

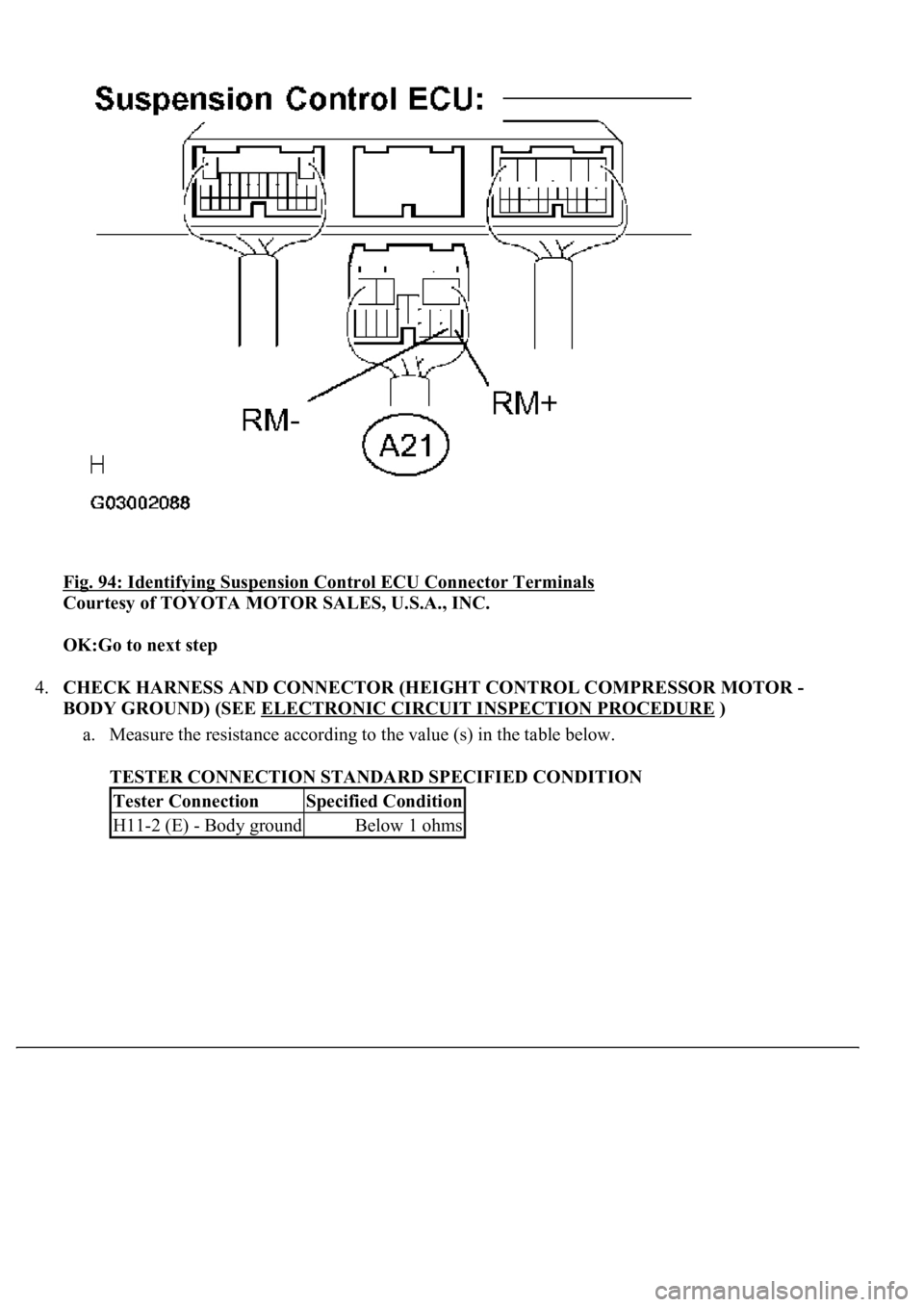

Fig. 94: Identifying Suspension Control ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK:Go to next step

4.CHECK HARNESS AND CONNECTOR (HEIGHT CONTROL COMPRESSOR MOTOR -

BODY GROUND) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

Tester ConnectionSpecified Condition

H11-2 (E) - Body groundBelow 1 ohms

Page 577 of 4500

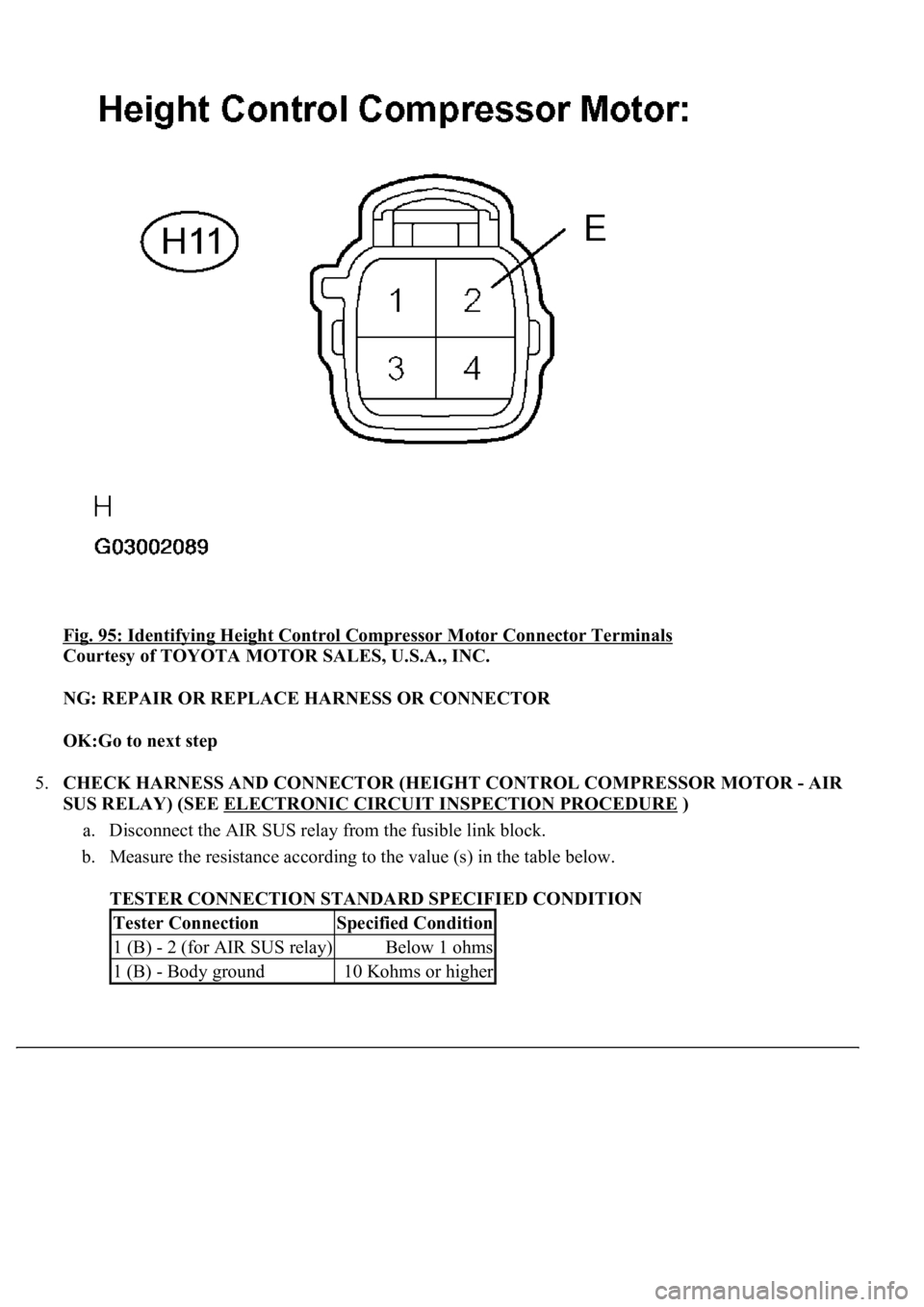

Fig. 95: Identifying Height Control Compressor Motor Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK:Go to next step

5.CHECK HARNESS AND CONNECTOR (HEIGHT CONTROL COMPRESSOR MOTOR - AIR

SUS RELAY) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Disconnect the AIR SUS relay from the fusible link block.

b. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

Tester ConnectionSpecified Condition

1 (B) - 2 (for AIR SUS relay)Below 1 ohms

1 (B) - Body ground10 Kohms or higher

Page 578 of 4500

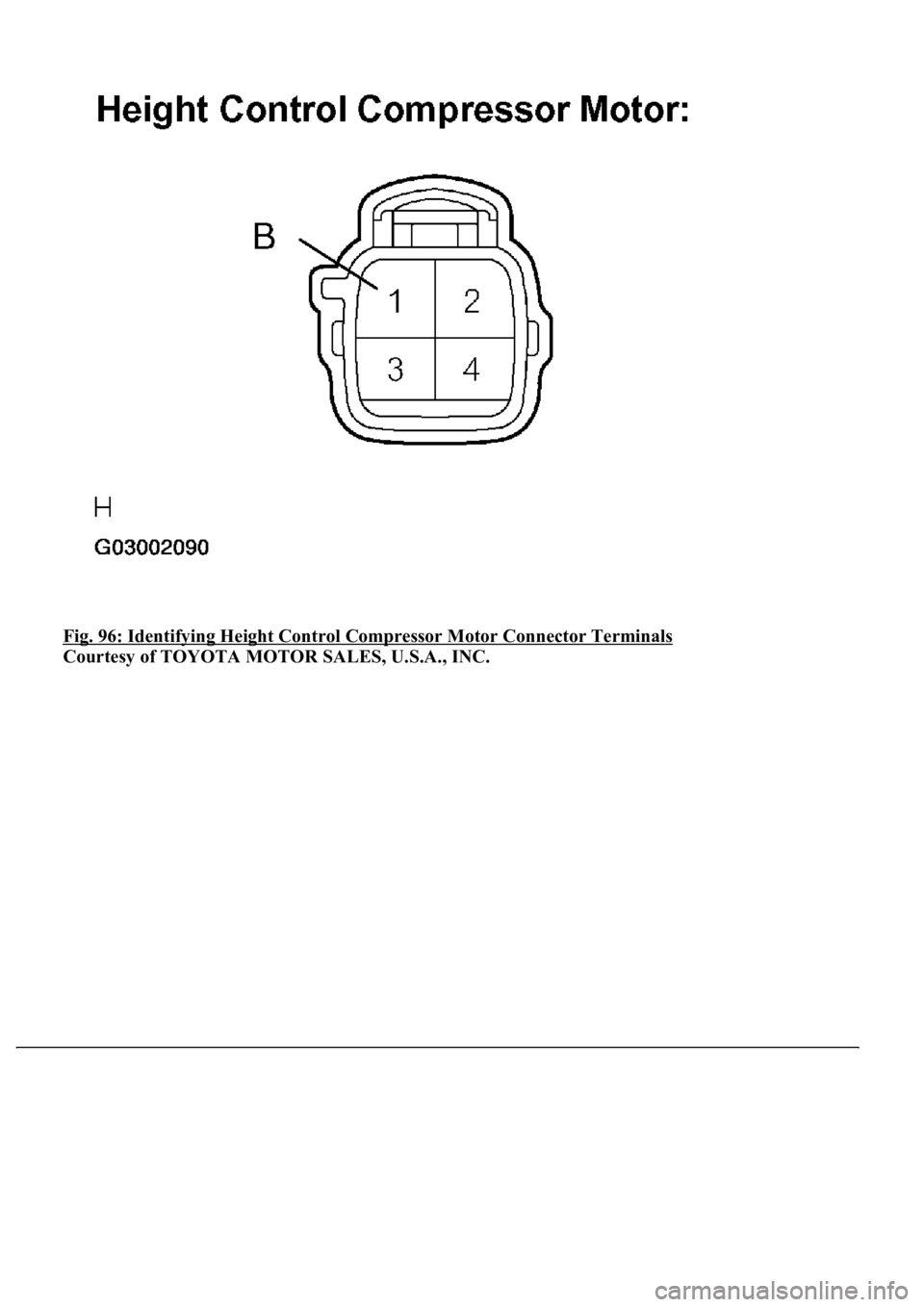

Fig. 96: Identifying Height Control Compressor Motor Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 579 of 4500

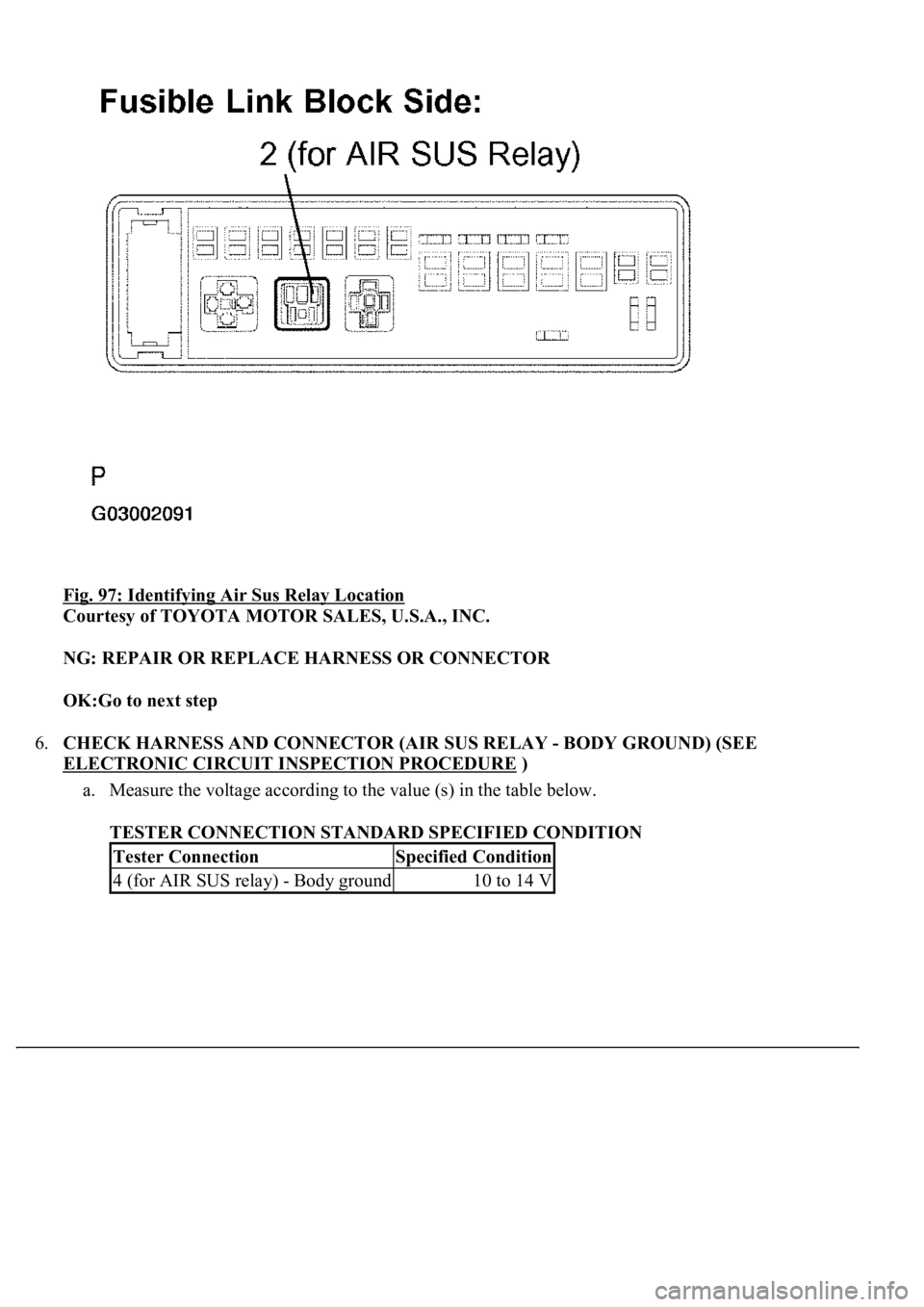

Fig. 97: Identifying Air Sus Relay Location

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK:Go to next step

6.CHECK HARNESS AND CONNECTOR (AIR SUS RELAY - BODY GROUND) (SEE

ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Measure the voltage according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

Tester ConnectionSpecified Condition

4 (for AIR SUS relay) - Body ground10 to 14 V

Page 580 of 4500

Fig. 98: Identifying Air Sus Relay Location

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK:Go to next step

7.INSPECT HEIGHT CONTROL SOLENOID VALVE

a. Connect the hand-held tester to the DLC3.

b. Turn the ignition switch to the ON position and turn the hand-held tester main switch on.

c. Select the item below in the ACTIVE TEST and operate it with the hand-held tester.

VEHICLE CONDITION / TEST DETAILS AIRSUS

ItemVehicle Condition / Test DetailsDiagnostic Note

FR SOLTurn OFF right front solenoid valve one second

after turning it ONOperation of solenoid (clicking sound)

can be heard

FL SOLTurn OFF left front solenoid valve one second

after turning it ONOperation of solenoid (clicking sound)

can be heard

RR SOLTurn OFF right rear solenoid valve one second

after turning it ONOperation of solenoid (clicking sound)

can be heard

RL SOLTurn OFF left rear solenoid valve one second Operation of solenoid (clicking sound)

Trending: oil filter, automatic transmission, spark plugs, tire type, Door lock actuator, warning lights, Skid