LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: steering, charging, heating, battery capacity, actuator, tow bar, Skid

Page 591 of 4500

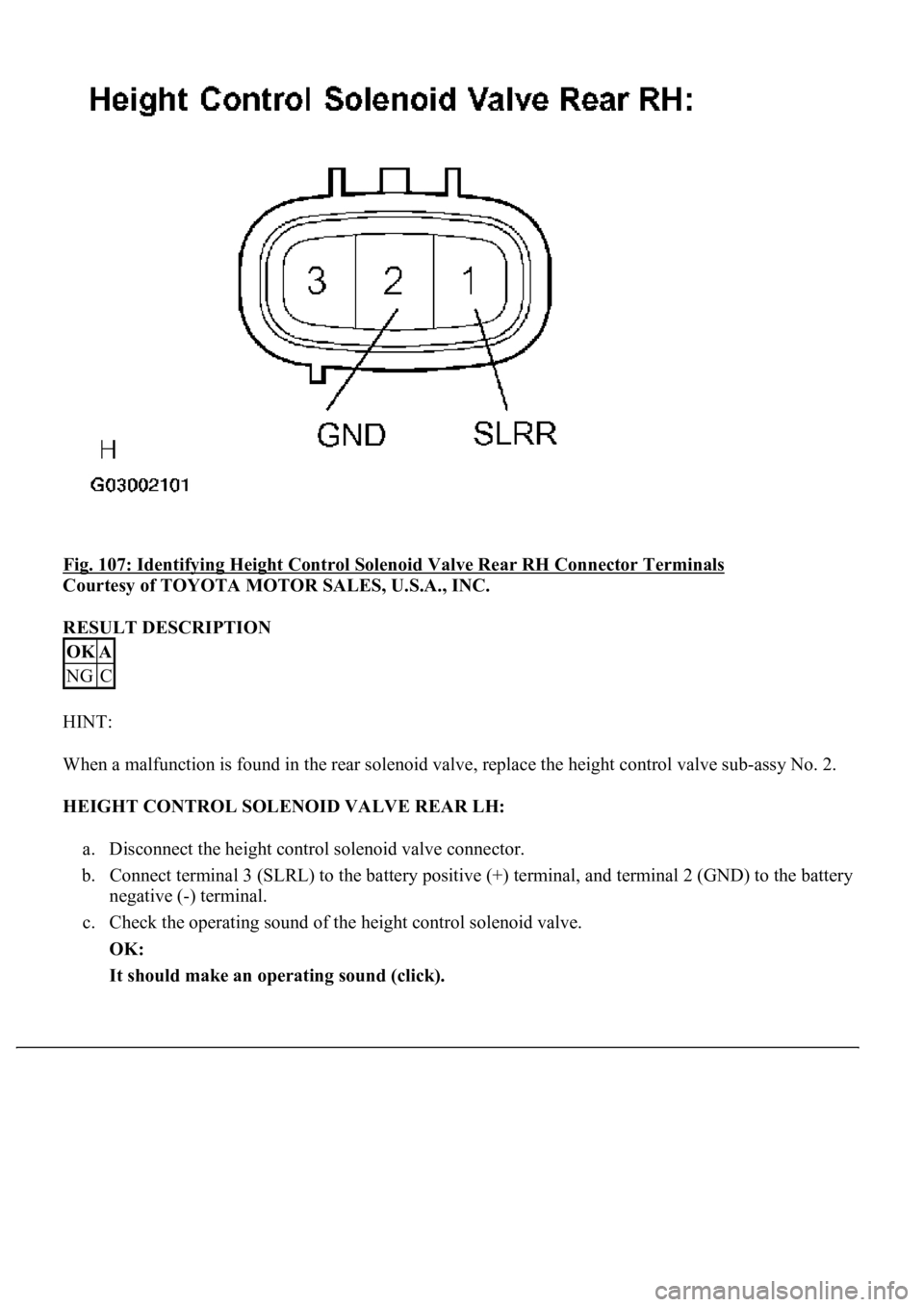

Fig. 107: Identifying Height Control Solenoid Valve Rear RH Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

RESULT DESCRIPTION

HINT:

When a malfunction is found in the rear solenoid valve, replace the height control valve sub-assy No. 2.

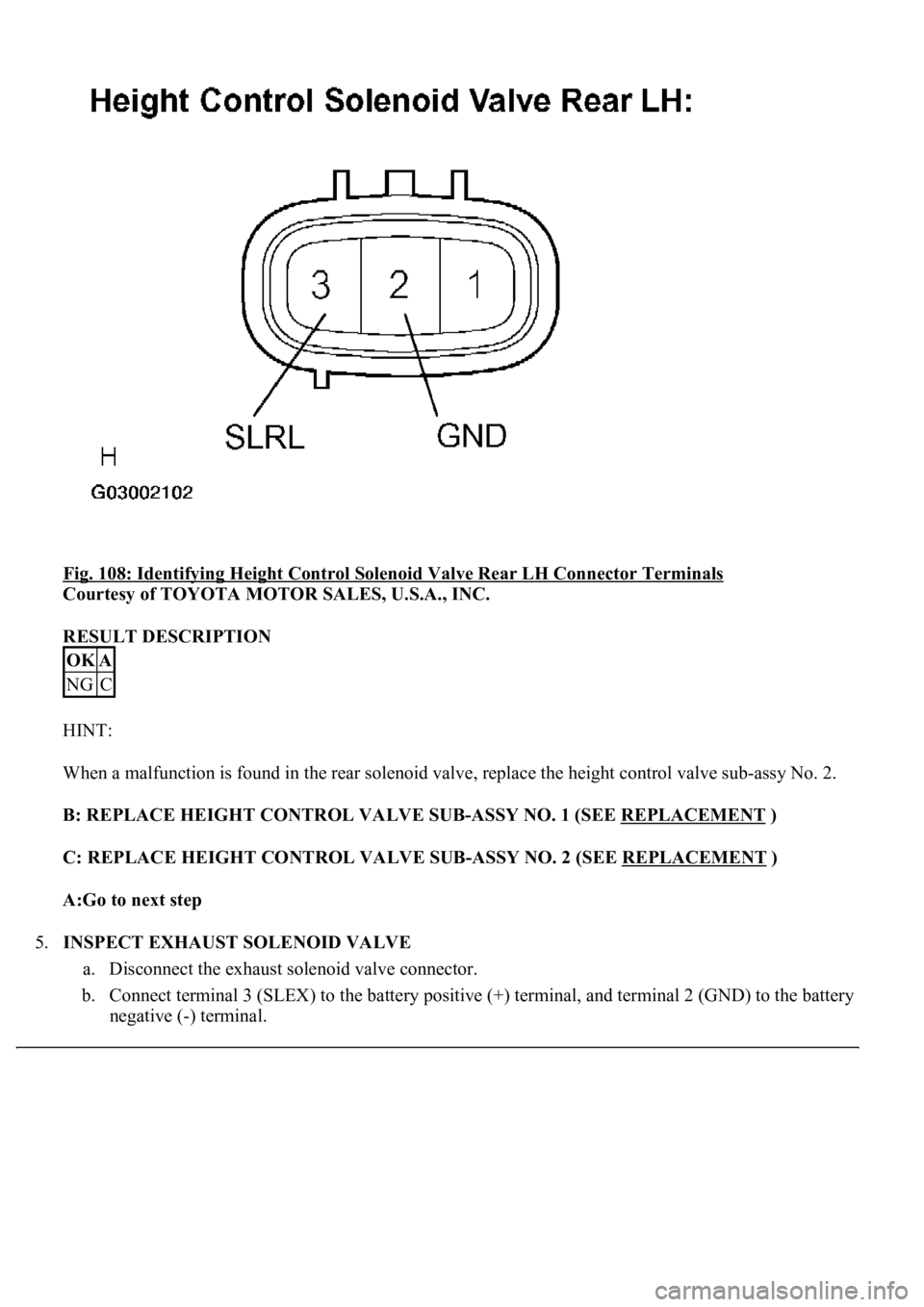

HEIGHT CONTROL SOLENOID VALVE REAR LH:

a. Disconnect the height control solenoid valve connector.

b. Connect terminal 3 (SLRL) to the battery positive (+) terminal, and terminal 2 (GND) to the battery

negative (-) terminal.

c. Check the operating sound of the height control solenoid valve.

OK:

It should make an operating sound (click).

OKA

NGC

Page 592 of 4500

Fig. 108: Identifying Height Control Solenoid Valve Rear LH Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

RESULT DESCRIPTION

HINT:

When a malfunction is found in the rear solenoid valve, replace the height control valve sub-assy No. 2.

B: REPLACE HEIGHT CONTROL VALVE SUB-ASSY NO. 1 (SEE REPLACEMENT

)

C: REPLACE HEIGHT CONTROL VALVE SUB-ASSY NO. 2 (SEE REPLACEMENT

)

A:Go to next step

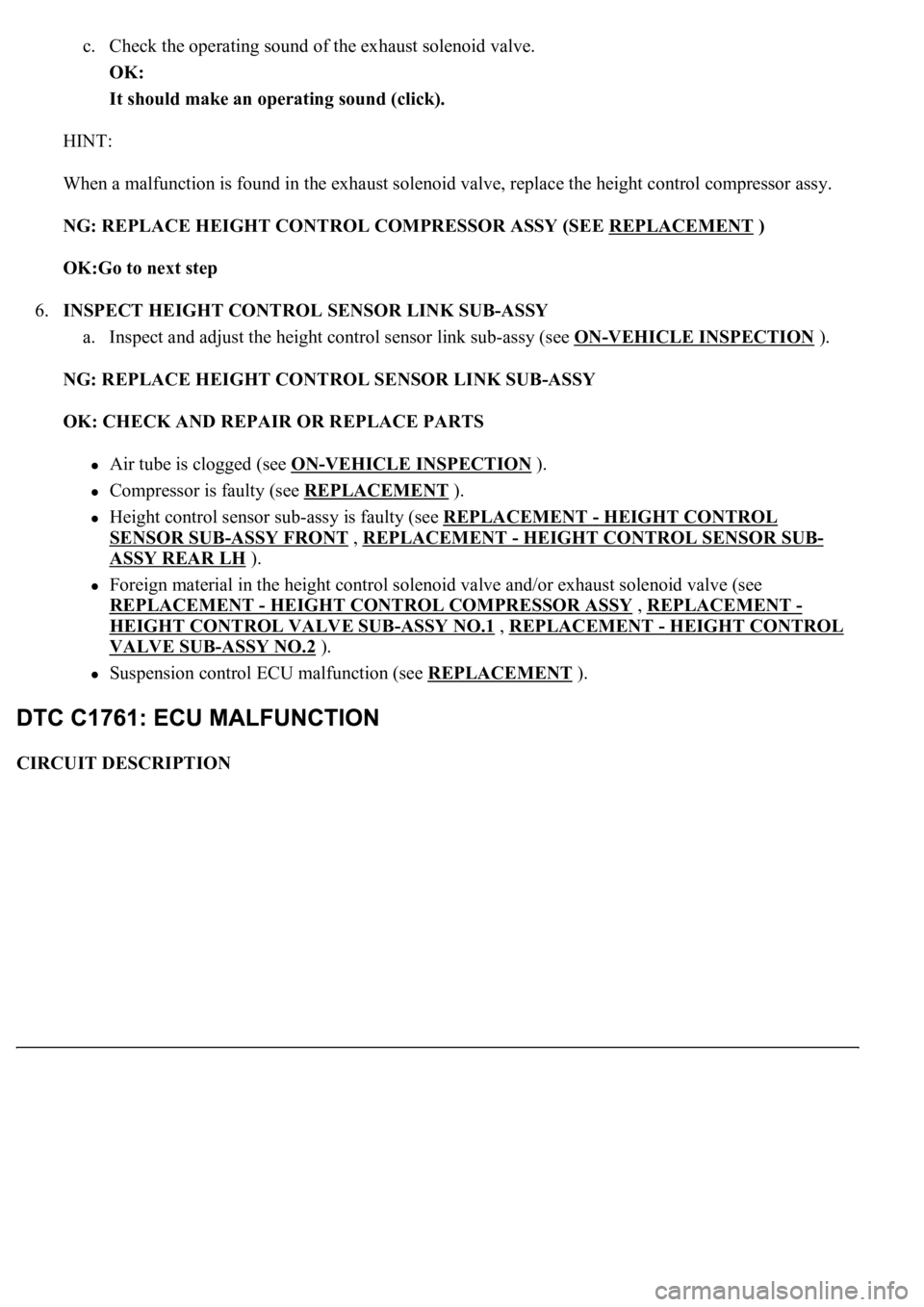

5.INSPECT EXHAUST SOLENOID VALVE

a. Disconnect the exhaust solenoid valve connector.

b. Connect terminal 3 (SLEX) to the battery positive (+) terminal, and terminal 2 (GND) to the battery

ne

gative (-) terminal.

OKA

NGC

Page 593 of 4500

c. Check the operating sound of the exhaust solenoid valve.

OK:

It should make an operating sound (click).

HINT:

When a malfunction is found in the exhaust solenoid valve, replace the height control compressor assy.

NG: REPLACE HEIGHT CONTROL COMPRESSOR ASSY (SEE REPLACEMENT

)

OK:Go to next step

6.INSPECT HEIGHT CONTROL SENSOR LINK SUB-ASSY

a. Inspect and adjust the height control sensor link sub-assy (see ON

-VEHICLE INSPECTION ).

NG: REPLACE HEIGHT CONTROL SENSOR LINK SUB-ASSY

OK: CHECK AND REPAIR OR REPLACE PARTS

Air tube is clogged (see ON-VEHICLE INSPECTION ).

Compressor is faulty (see REPLACEMENT ).

Height control sensor sub-assy is faulty (see REPLACEMENT - HEIGHT CONTROL

SENSOR SUB-ASSY FRONT , REPLACEMENT - HEIGHT CONTROL SENSOR SUB-

ASSY REAR LH ).

Foreign material in the height control solenoid valve and/or exhaust solenoid valve (see

REPLACEMENT

- HEIGHT CONTROL COMPRESSOR ASSY , REPLACEMENT -

HEIGHT CONTROL VALVE SUB

-ASSY NO.1 , REPLACEMENT - HEIGHT CONTROL

VALVE SUB-ASSY NO.2 ).

Suspension control ECU malfunction (see REPLACEMENT ).

CIRCUIT DESCRIPTION

Page 594 of 4500

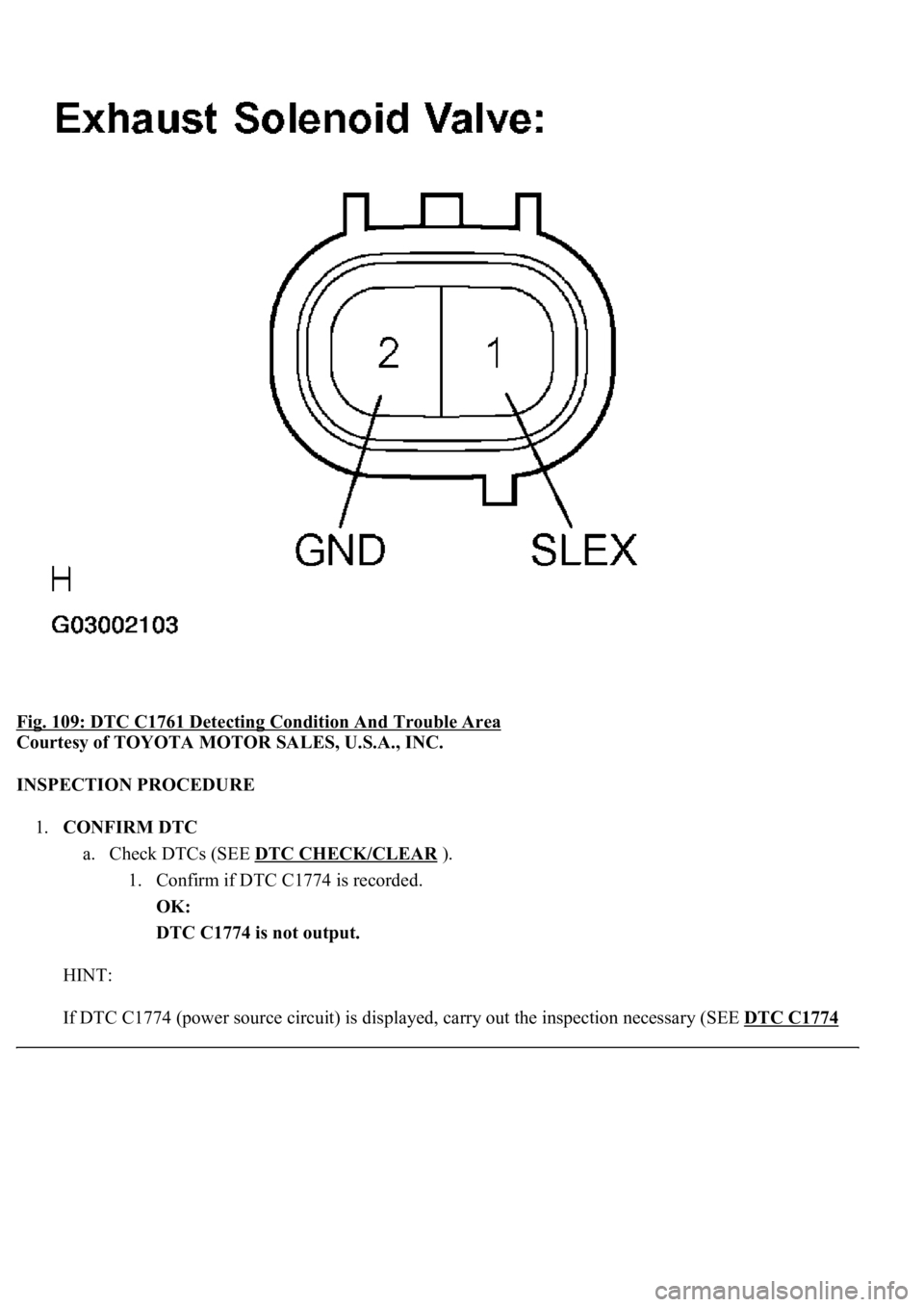

Fig. 109: DTC C1761 Detecting Condition And Trouble Area

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.CONFIRM DTC

a. Check DTCs (SEE DTC CHECK/CLEAR

).

1. Confirm if DTC C1774 is recorded.

OK:

DTC C1774 is not output.

HINT:

If DTC C1774 (power source circuit) is displa

yed, carry out the inspection necessary (SEE DTC C1774

Page 595 of 4500

POWER SOURCE CIRCUIT ).

NG: REPAIR CIRCUIT INDICATED BY OUTPUT CODE

OK:Go to next step

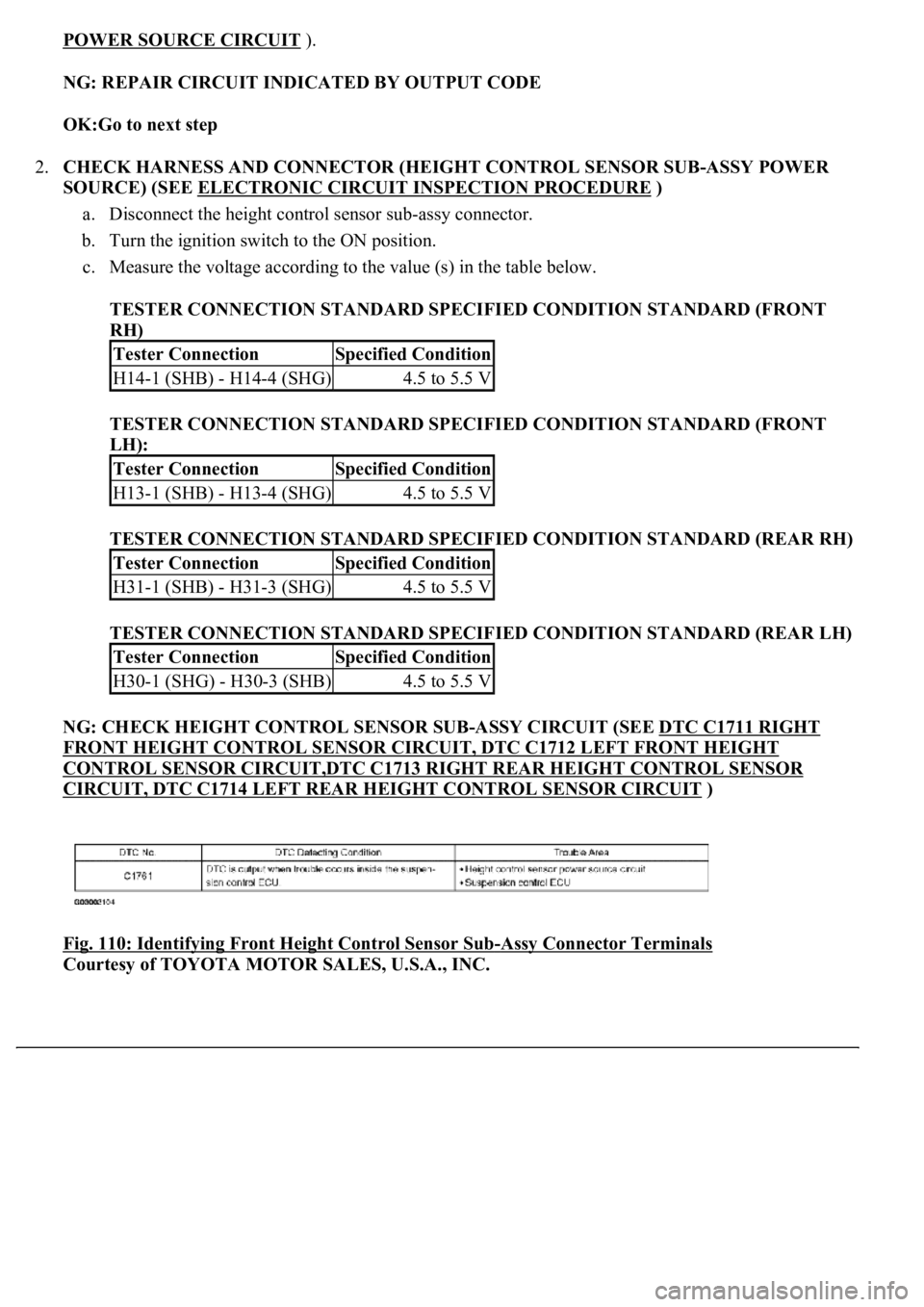

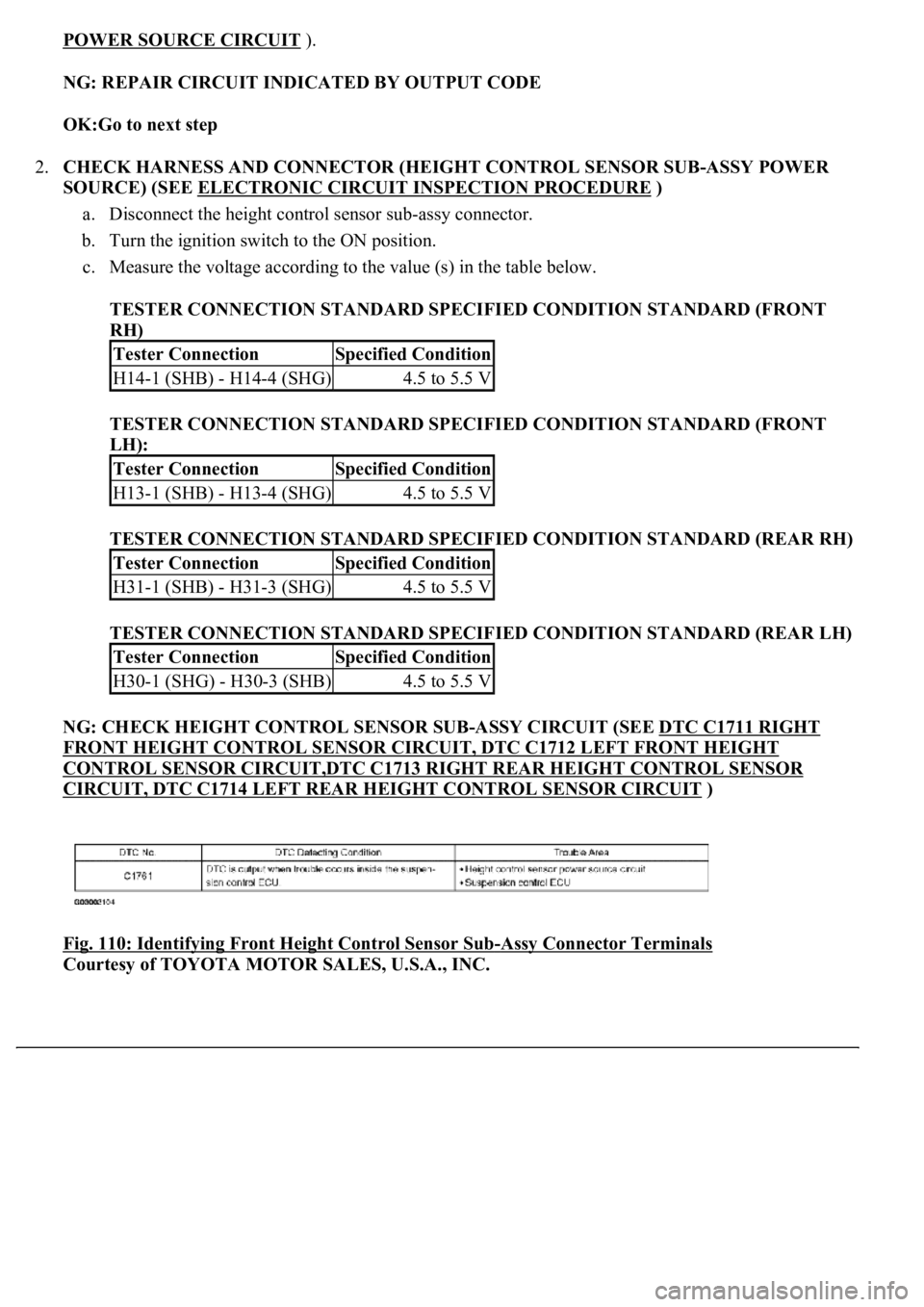

2.CHECK HARNESS AND CONNECTOR (HEIGHT CONTROL SENSOR SUB-ASSY POWER

SOURCE) (SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Disconnect the height control sensor sub-assy connector.

b. Turn the ignition switch to the ON position.

c. Measure the voltage according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION STANDARD (FRONT

RH)

TESTER CONNECTION STANDARD SPECIFIED CONDITION STANDARD (FRONT

LH):

TESTER CONNECTION STANDARD SPECIFIED CONDITION STANDARD (REAR RH)

TESTER CONNECTION STANDARD SPECIFIED CONDITION STANDARD (REAR LH)

NG: CHECK HEIGHT CONTROL SENSOR SUB-ASSY CIRCUIT (SEE DTC C1711 RIGHT

FRONT HEIGHT CONTROL SENSOR CIRCUIT, DTC C1712 LEFT FRONT HEIGHT

CONTROL SENSOR CIRCUIT,DTC C1713 RIGHT REAR HEIGHT CONTROL SENSOR

CIRCUIT, DTC C1714 LEFT REAR HEIGHT CONTROL SENSOR CIRCUIT )

Fig. 110: Identifying Front Height Control Sensor Sub

-Assy Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Tester ConnectionSpecified Condition

H14-1 (SHB) - H14-4 (SHG)4.5 to 5.5 V

Tester ConnectionSpecified Condition

H13-1 (SHB) - H13-4 (SHG)4.5 to 5.5 V

Tester ConnectionSpecified Condition

H31-1 (SHB) - H31-3 (SHG)4.5 to 5.5 V

Tester ConnectionSpecified Condition

H30-1 (SHG) - H30-3 (SHB)4.5 to 5.5 V

Page 596 of 4500

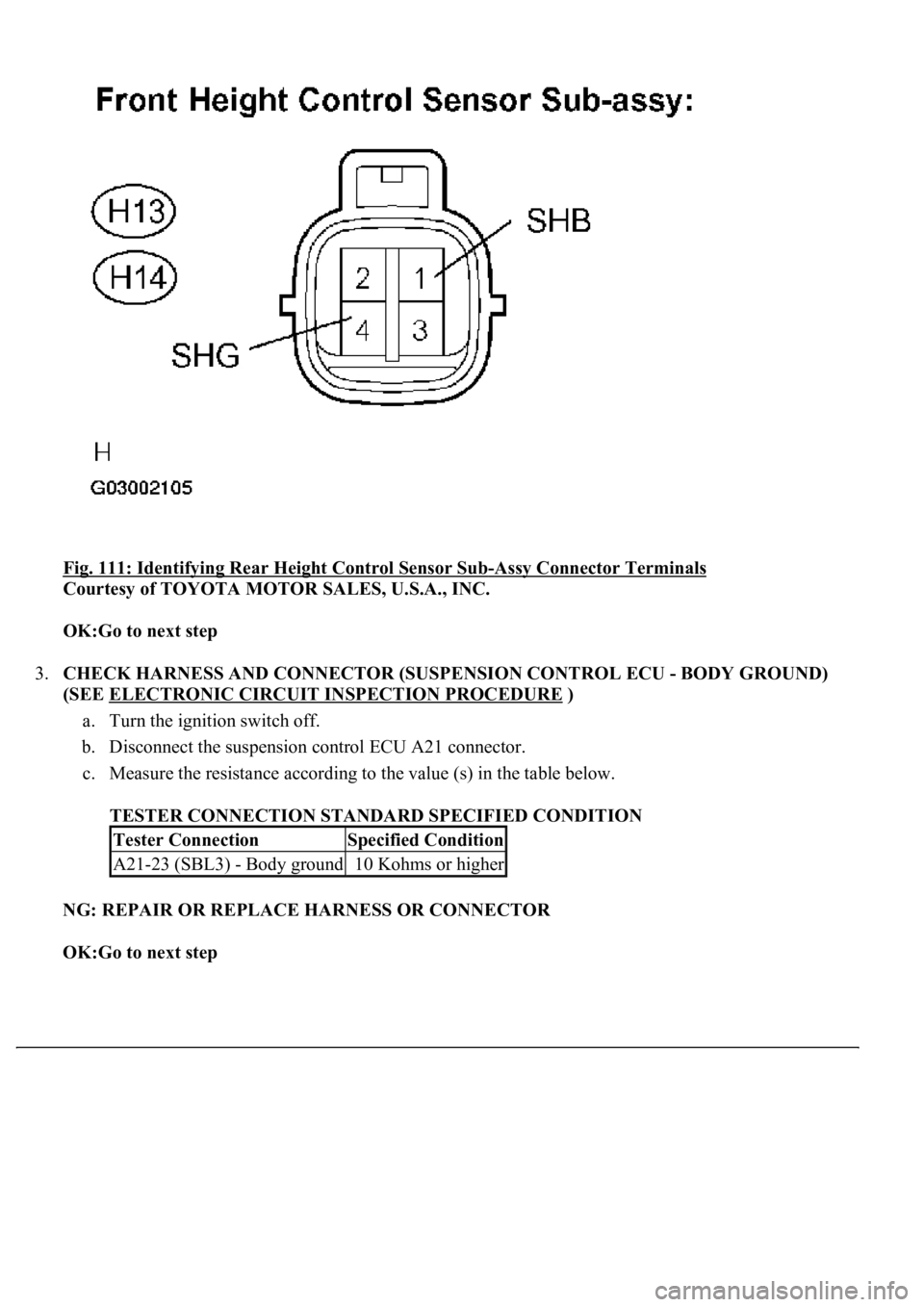

Fig. 111: Identifying Rear Height Control Sensor Sub-Assy Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OK:Go to next step

3.CHECK HARNESS AND CONNECTOR (SUSPENSION CONTROL ECU - BODY GROUND)

(SEE ELECTRONIC CIRCUIT INSPECTION PROCEDURE

)

a. Turn the ignition switch off.

b. Disconnect the suspension control ECU A21 connector.

c. Measure the resistance according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

NG: REPAIR OR REPLACE HARNESS OR CONNECTOR

OK:Go to next step

Tester ConnectionSpecified Condition

A21-23 (SBL3) - Body ground10 Kohms or higher

Page 597 of 4500

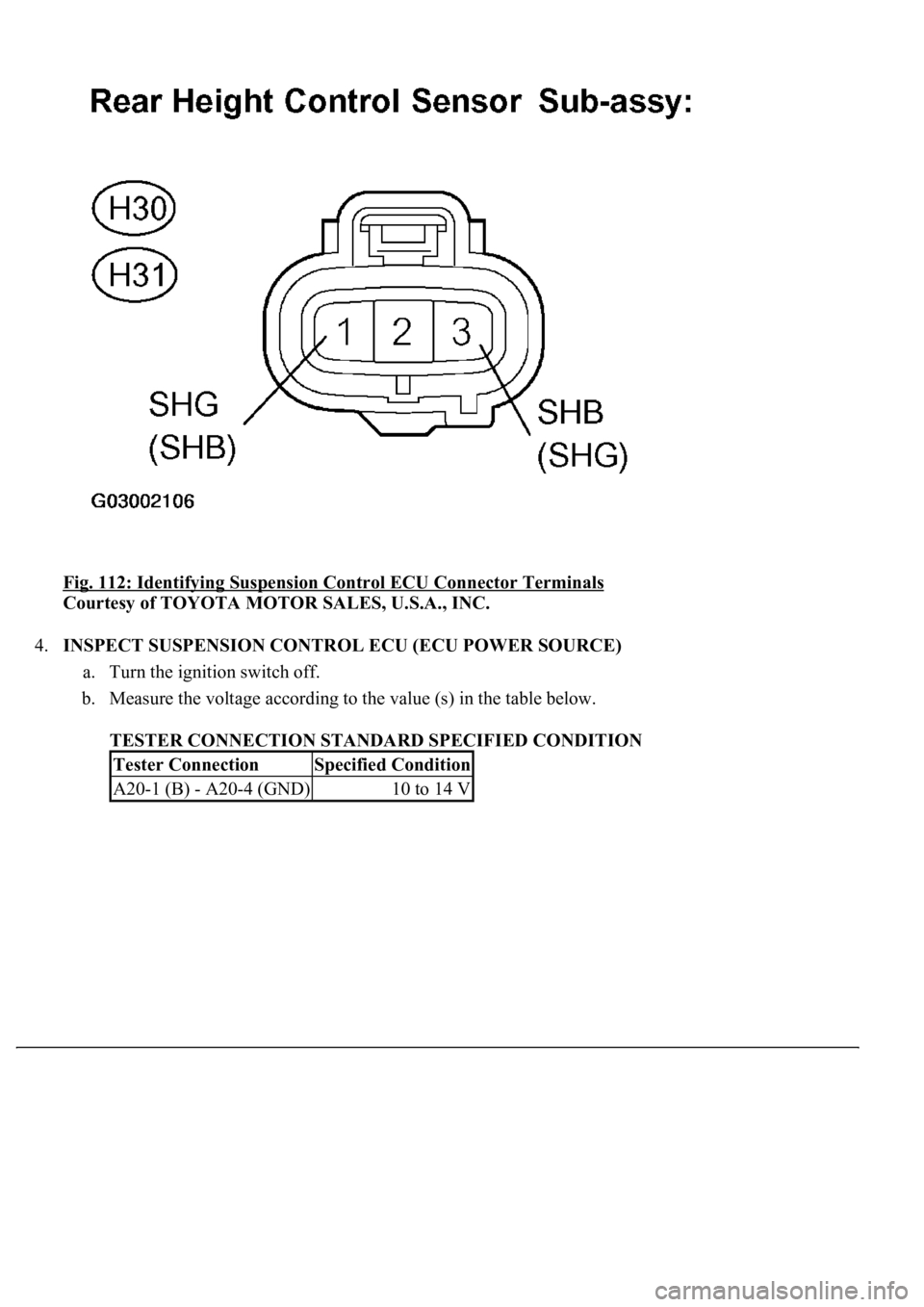

Fig. 112: Identifying Suspension Control ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

4.INSPECT SUSPENSION CONTROL ECU (ECU POWER SOURCE)

a. Turn the ignition switch off.

b. Measure the voltage according to the value (s) in the table below.

TESTER CONNECTION STANDARD SPECIFIED CONDITION

Tester ConnectionSpecified Condition

A20-1 (B) - A20-4 (GND)10 to 14 V

Page 598 of 4500

Fig. 113: Identifying Suspension Control ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

NG: CHECK POWER SOURCE CIRCUIT (SEE DTC C1774 POWER SOURCE CIRCUIT

)

OK: REPLACE SUSPENSION CONTROL ECU (SEE REPLACEMENT

)

CIRCUIT DESCRIPTION

When the ignition switch is turned to the ON position, the D-IG1 relay is activated and battery voltage is

applied to terminal B of the suspension control ECU. When the ignition switch is turned off, the D-IG1 relay is

de-energized and the power source is cut off.

This power source energizes the suspension control actuator, height control solenoid valve, D-IG1 relay, each

IC and sensor.

Page 599 of 4500

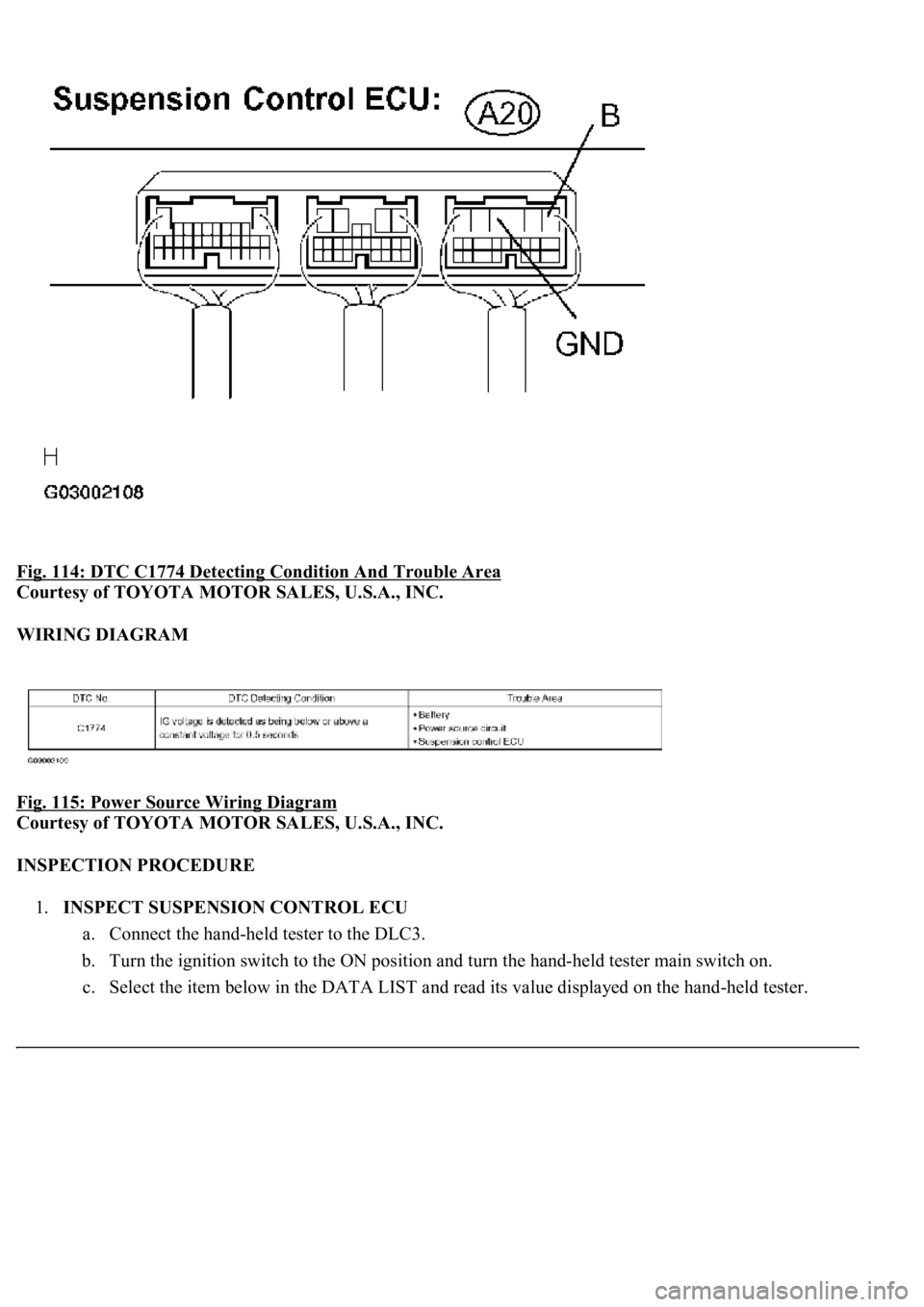

Fig. 114: DTC C1774 Detecting Condition And Trouble Area

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Fig. 115: Power Source Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.INSPECT SUSPENSION CONTROL ECU

a. Connect the hand-held tester to the DLC3.

b. Turn the ignition switch to the ON position and turn the hand-held tester main switch on.

c. Select the item below in the DATA LIST and read its value displa

yed on the hand-held tester.

Page 600 of 4500

NORMAL CONDITION AIRSUS

d. Check the voltage

Standard:

10 to 14 V

NG: Go to step 5

OK:Go to next step

2.CHECK SOURCE VOLTAGE

a. Check the battery voltage.

Standard:

11 to 14 V

NG: REPLACE BATTERY

OK:Go to next step

3.INSPECT FUSE (AM1)

a. Remove the AM1 fuse from the driver side J/B.

b. Check fuse.

1. Check continuity of the AM1 fuse.

Standard:

Continuity

ItemNormal Condition

IG VOLTAGEActual ECU power supply voltage 10 to 14 V

Trending: damper, sat nav, change wheel, radio, engine coolant, center console, wheel bolts