LEXUS SC400 1991 Service Repair Manual

Manufacturer: LEXUS, Model Year: 1991,

Model line: SC400,

Model: LEXUS SC400 1991

Pages: 4087, PDF Size: 75.75 MB

LEXUS SC400 1991 Service Repair Manual

SC400 1991

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57051/w960_57051-0.png

LEXUS SC400 1991 Service Repair Manual

Trending: engine coolant, wire diagram, brake light, transmission, coolant level, dimensions, evap

Page 1591 of 4087

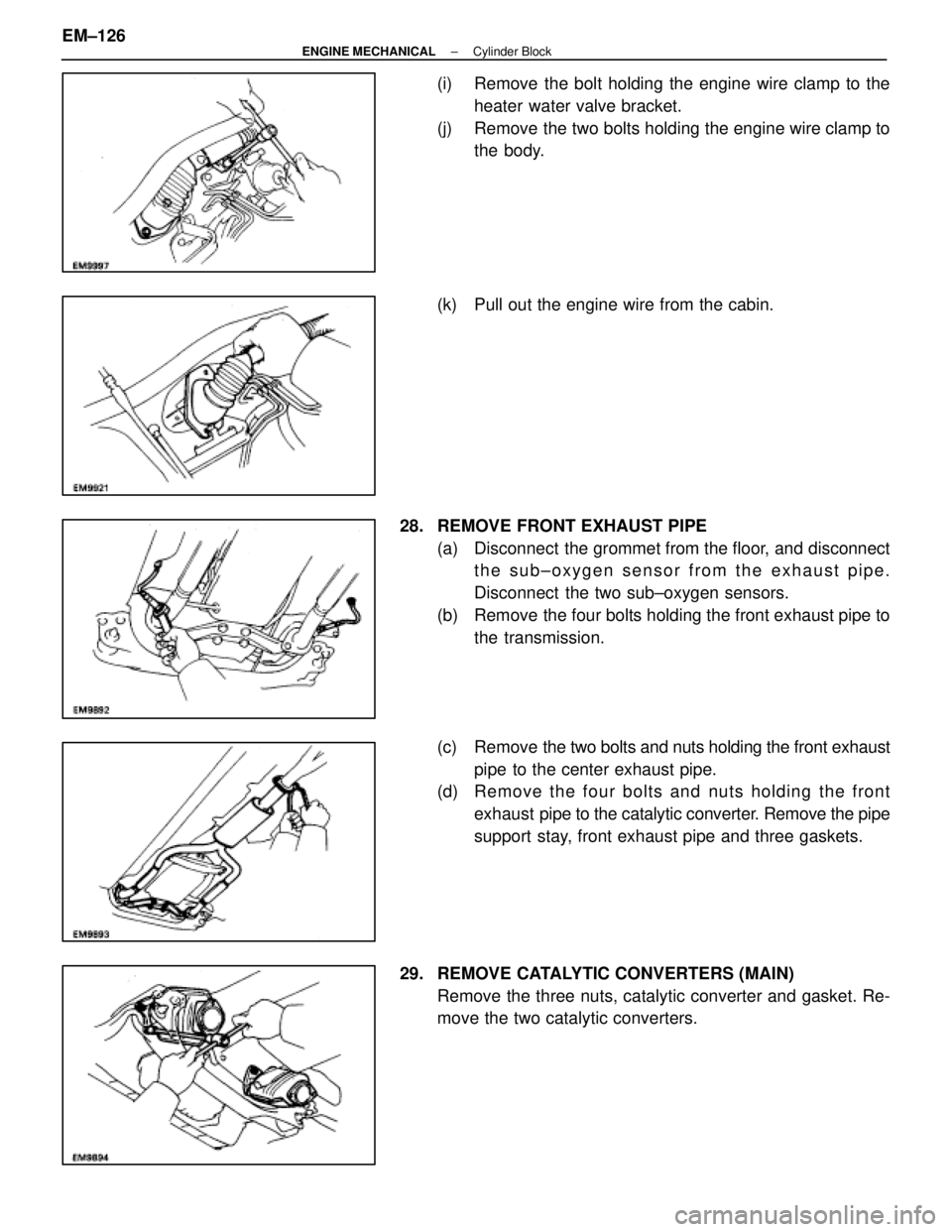

(i) Remove the bolt holding the engine wire clamp to theheater water valve bracket.

(j) Remove the two bolts holding the engine wire clamp to the body.

(k) Pull out the engine wire from the cabin.

28. REMOVE FRONT EXHAUST PIPE (a) Disconnect the grommet from the floor, and disconnectthe sub±oxygen sensor from the exhaust pipe.

Disconnect the two sub±oxygen sensors.

(b) Remove the four bolts holding the front exhaust pipe to the transmission.

(c) Remove the two bolts and nuts holding the front exhaust

pipe to the center exhaust pipe.

(d) Re mo ve th e fo u r bo lts an d nu ts ho ld in g th e fro n t

exhaust pipe to the catalytic converter. Remove the pipe

support stay, front exhaust pipe and three gaskets.

29. REMOVE CATALYTIC CONVERTERS (MAIN) Remove the three nuts, catalytic converter and gasket. Re-

move the two catalytic converters.

EM±126

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1592 of 4087

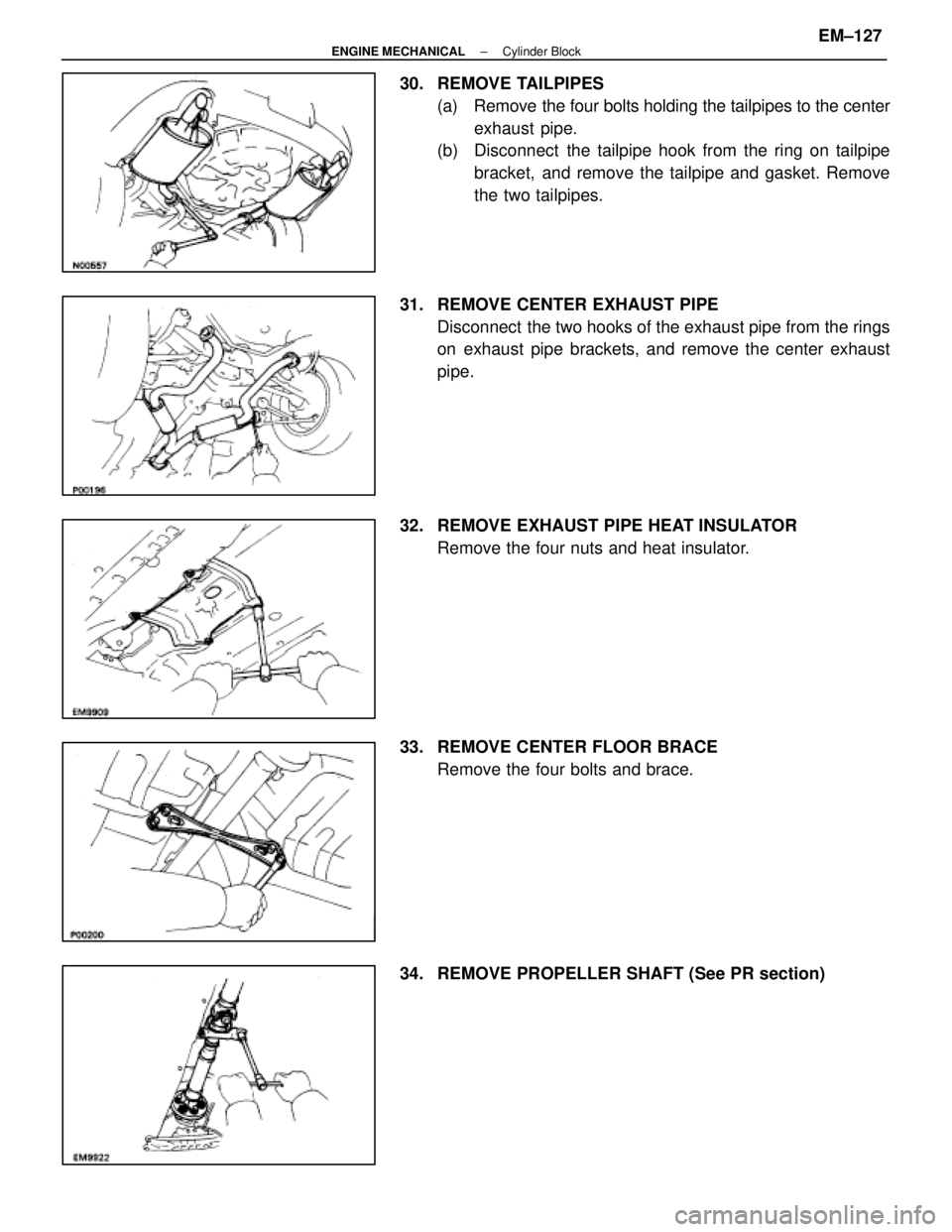

30. REMOVE TAILPIPES(a) Remove the four bolts holding the tailpipes to the centerexhaust pipe.

(b) Disconnect the tailpipe hook from the ring on tailpipe

bracket, and remove the tailpipe and gasket. Remove

the two tailpipes.

31. REMOVE CENTER EXHAUST PIPE Disconnect the two hooks of the exhaust pipe from the rings

on exhaust pipe brackets, and remove the center exhaust

pipe.

32. REMOVE EXHAUST PIPE HEAT INSULATOR Remove the four nuts and heat insulator.

33. REMOVE CENTER FLOOR BRACE Remove the four bolts and brace.

34. REMOVE PROPELLER SHAFT (See PR section)

±

ENGINE MECHANICAL Cylinder BlockEM±127

WhereEverybodyKnowsYourName

Page 1593 of 4087

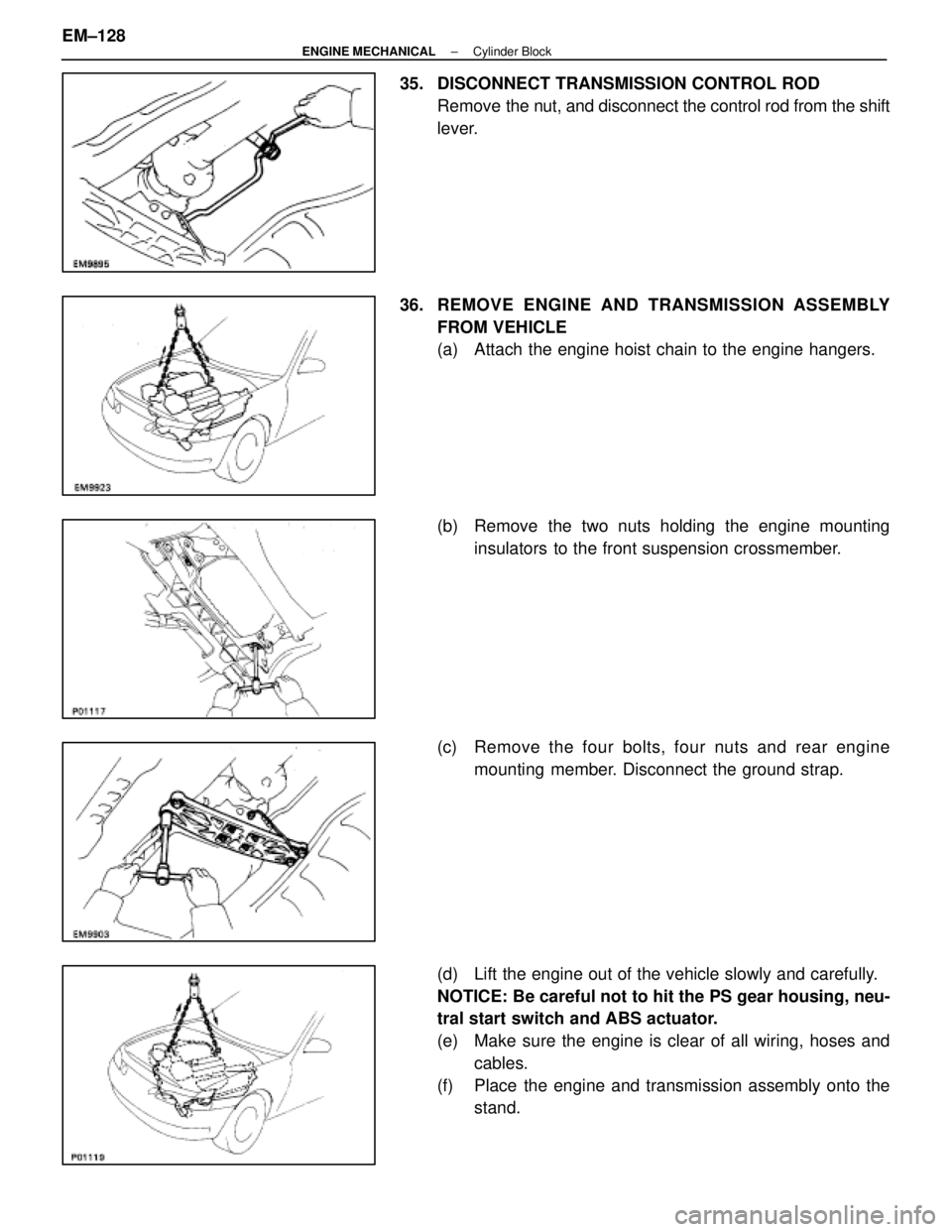

35. DISCONNECT TRANSMISSION CONTROL RODRemove the nut, and disconnect the control rod from the shift

lever.

36. REMOVE ENGINE AND TRANSMISSION A SSEMBLY

FROM VEHICLE

(a) Attach the engine hoist chain to the engine hangers.

(b) Remove the two nuts holding the engine mounting insulators to the front suspension crossmember.

(c) Remove the four bolts, four nuts and rear engine mounting member. Disconnect the ground strap.

(d) Lift the engine out of the vehicle slowly and carefully.

NOTICE: Be careful not to hit the PS gear housing, neu-

tral start switch and ABS actuator.

(e) Make sure the engine is clear of all wiring, hoses and cables.

(f) Place the engine and transmission assembly onto the stand.

EM±128

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1594 of 4087

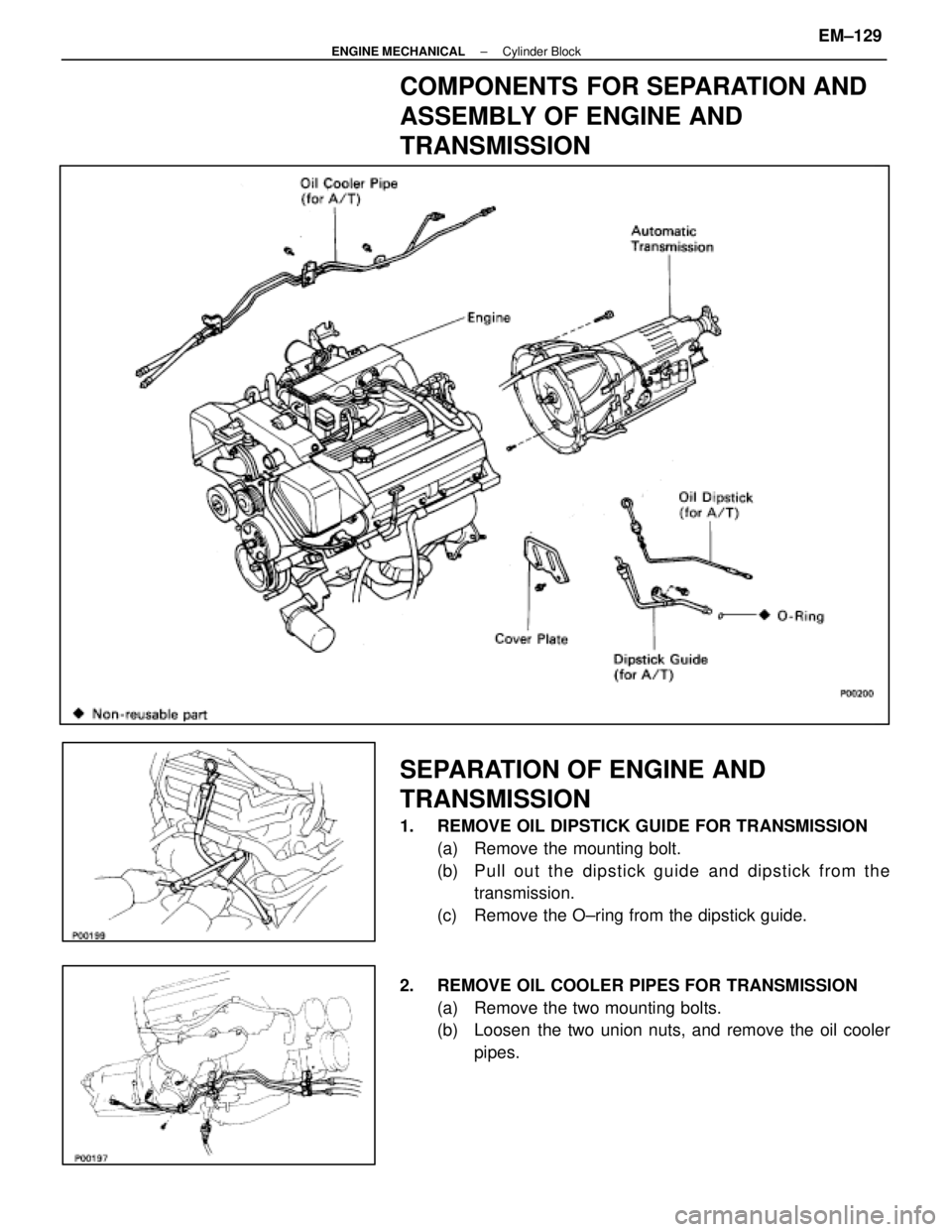

COMPONENTS FOR SEPARATION AND

ASSEMBLY OF ENGINE AND

TRANSMISSION

SEPARATION OF ENGINE AND

TRANSMISSION

1. REMOVE OIL DIPSTICK GUIDE FOR TRANSMISSION(a) Remove the mounting bolt.

(b) P u ll ou t th e dip stick gu id e an d dip stick fro m th etransmission.

(c) Remove the O±ring from the dipstick guide.

2. REMOVE OIL COOLER PIPES FOR TRANSMISSION (a) Remove the two mounting bolts.

(b) Loosen the two union nuts, and remove the oil coolerpipes.

±

ENGINE MECHANICAL Cylinder BlockEM±129

WhereEverybodyKnowsYourName

Page 1595 of 4087

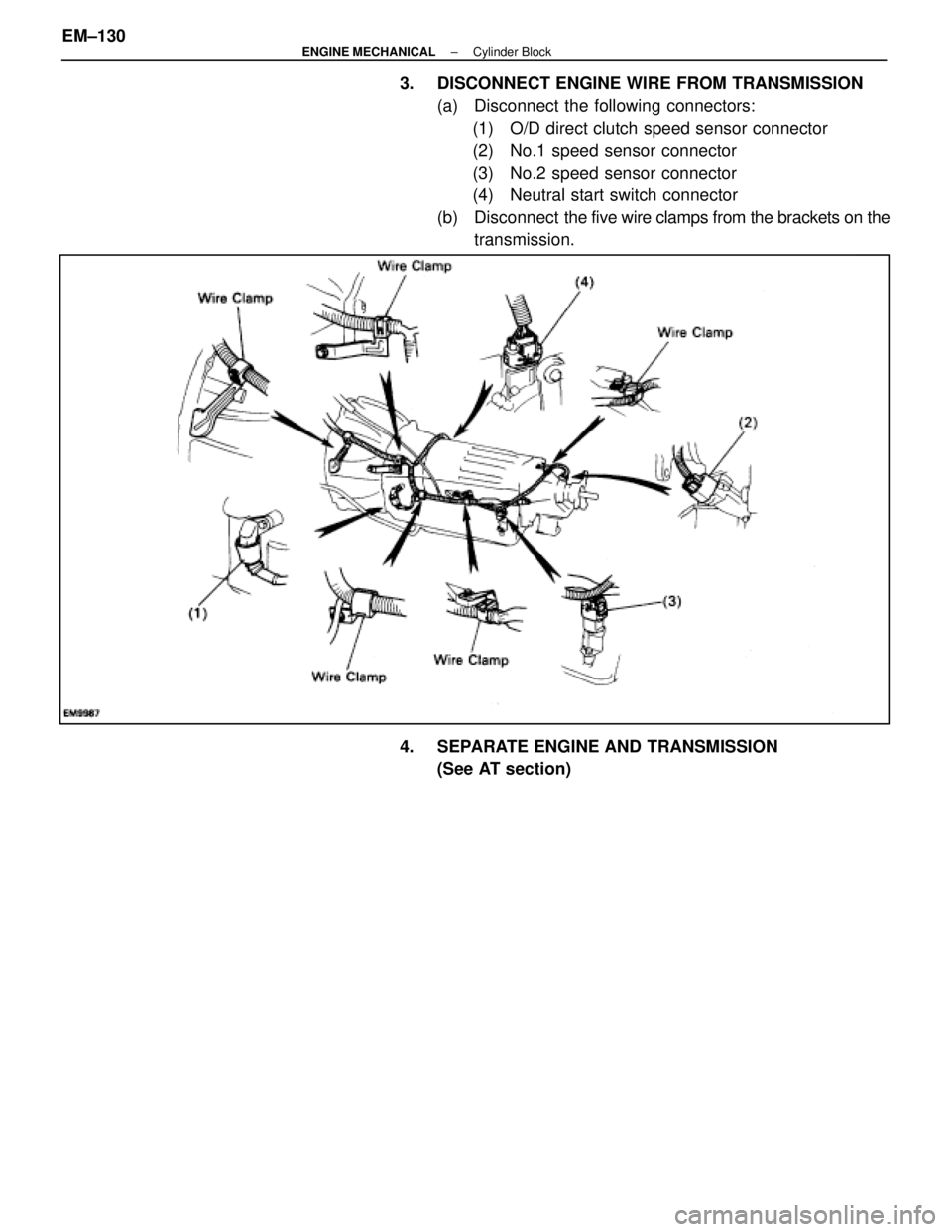

3. DISCONNECT ENGINE WIRE FROM TRANSMISSION(a) Disconnect the following connectors:(1) O/D direct clutch speed sensor connector

(2) No.1 speed sensor connector

(3) No.2 speed sensor connector

(4) Neutral start switch connector

(b) Disconnect the five wire clamps from the brackets on the

transmission.

4. SEPARATE ENGINE AND TRANSMISSION (See AT section)

EM±130

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1596 of 4087

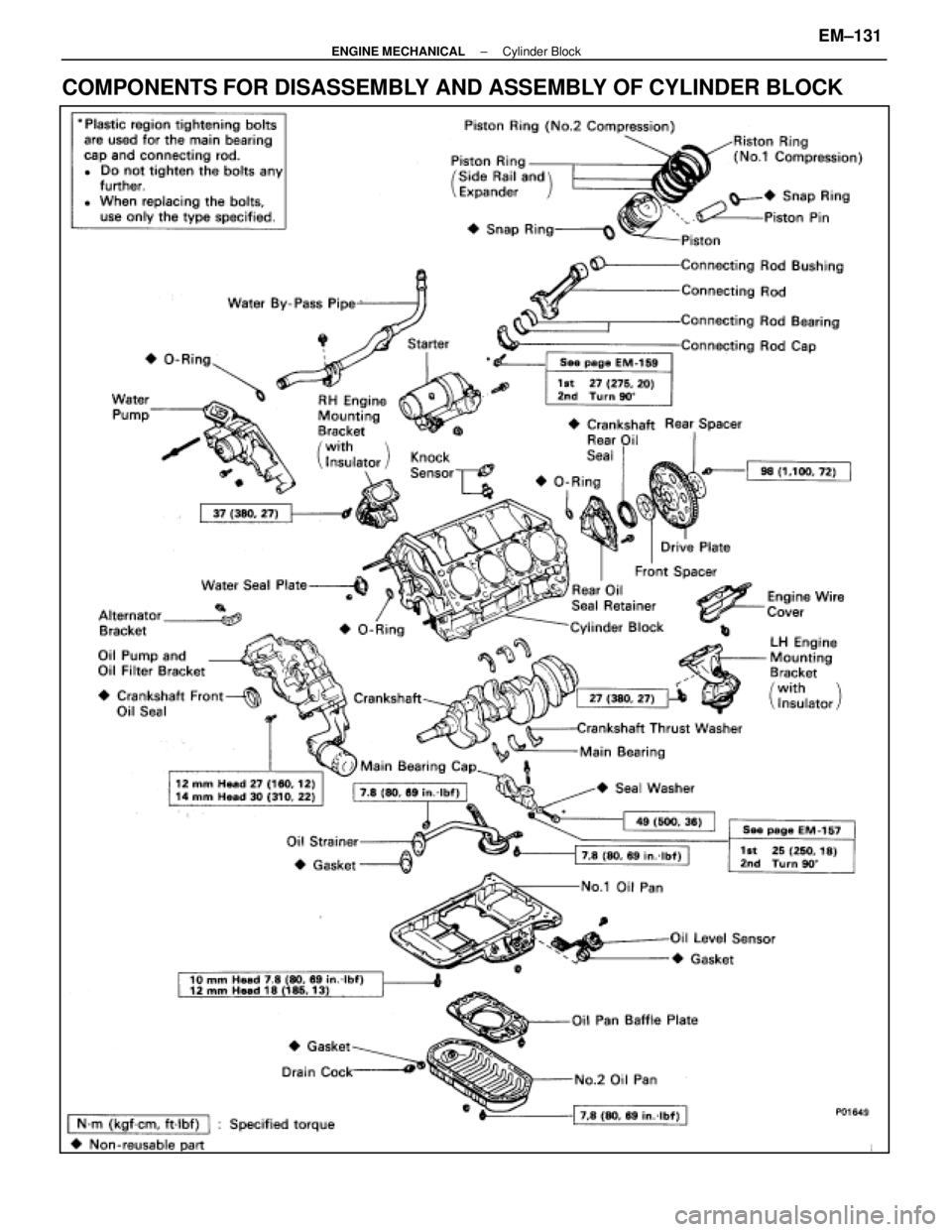

COMPONENTS FOR DISASSEMBLY AND ASSEMBLY OF CYLINDER BLOCK

±

ENGINE MECHANICAL Cylinder BlockEM±131

WhereEverybodyKnowsYourName

Page 1597 of 4087

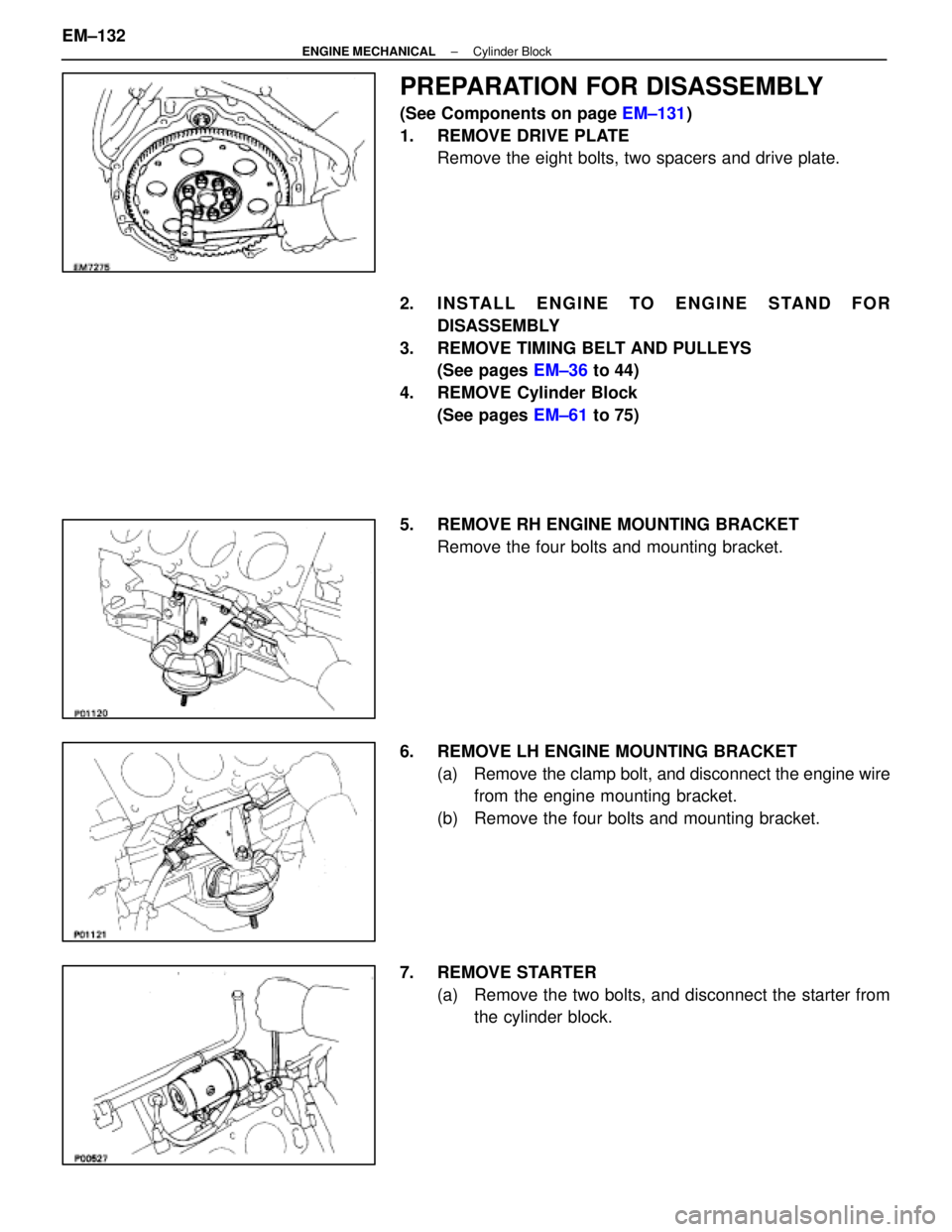

PREPARATION FOR DISASSEMBLY

(See Components on page EM±131)

1. REMOVE DRIVE PLATE Remove the eight bolts, two spacers and drive plate.

2. INSTALL ENGINE TO ENGINE STAND FOR DISASSEMBLY

3. REMOVE TIMING BELT AND PULLEYS (See pages EM±36 to 44)

4. REMOVE Cylinder Block (See pages EM±61 to 75)

5. REMOVE RH ENGINE MOUNTING BRACKET Remove the four bolts and mounting bracket.

6. REMOVE LH ENGINE MOUNTING BRACKET (a) Remove the clamp bolt, and disconnect the engine wirefrom the engine mounting bracket.

(b) Remove the four bolts and mounting bracket.

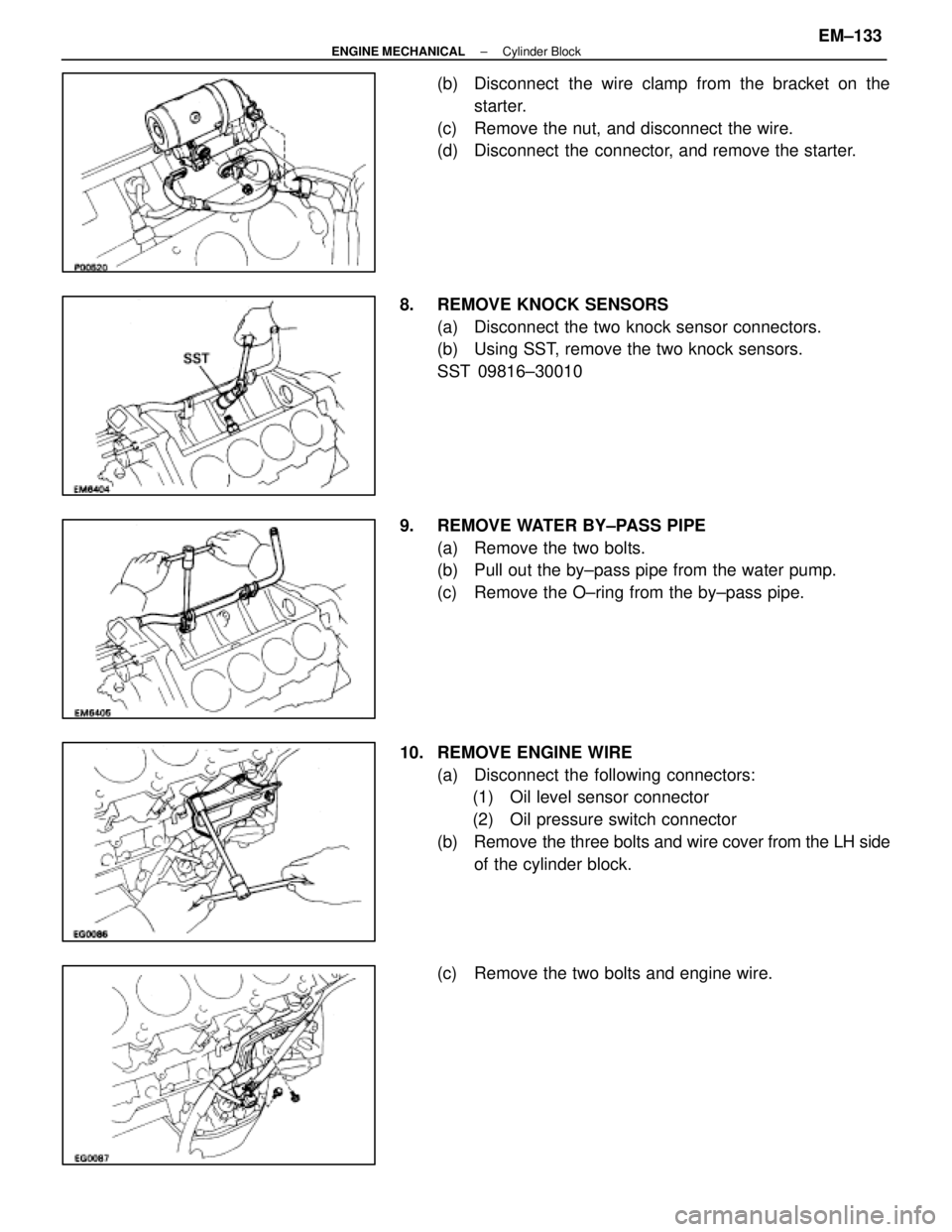

7. REMOVE STARTER (a) Remove the two bolts, and disconnect the starter fromthe cylinder block.

EM±132

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1598 of 4087

(b) Disconnect the wire clamp from the bracket on thestarter.

(c) Remove the nut, and disconnect the wire.

(d) Disconnect the connector, and remove the starter.

8. REMOVE KNOCK SENSORS (a) Disconnect the two knock sensor connectors.

(b) Using SST, remove the two knock sensors.

SST 09816±30010

9. REMOVE WATER BY±PASS PIPE (a) Remove the two bolts.

(b) Pull out the by±pass pipe from the water pump.

(c) Remove the O±ring from the by±pass pipe.

10. REMOVE ENGINE WIRE (a) Disconnect the following connectors:(1) Oil level sensor connector

(2) Oil pressure switch connector

(b) Remove the three bolts and wire cover from the LH side

of the cylinder block.

(c) Remove the two bolts and engine wire.

±

ENGINE MECHANICAL Cylinder BlockEM±133

WhereEverybodyKnowsYourName

Page 1599 of 4087

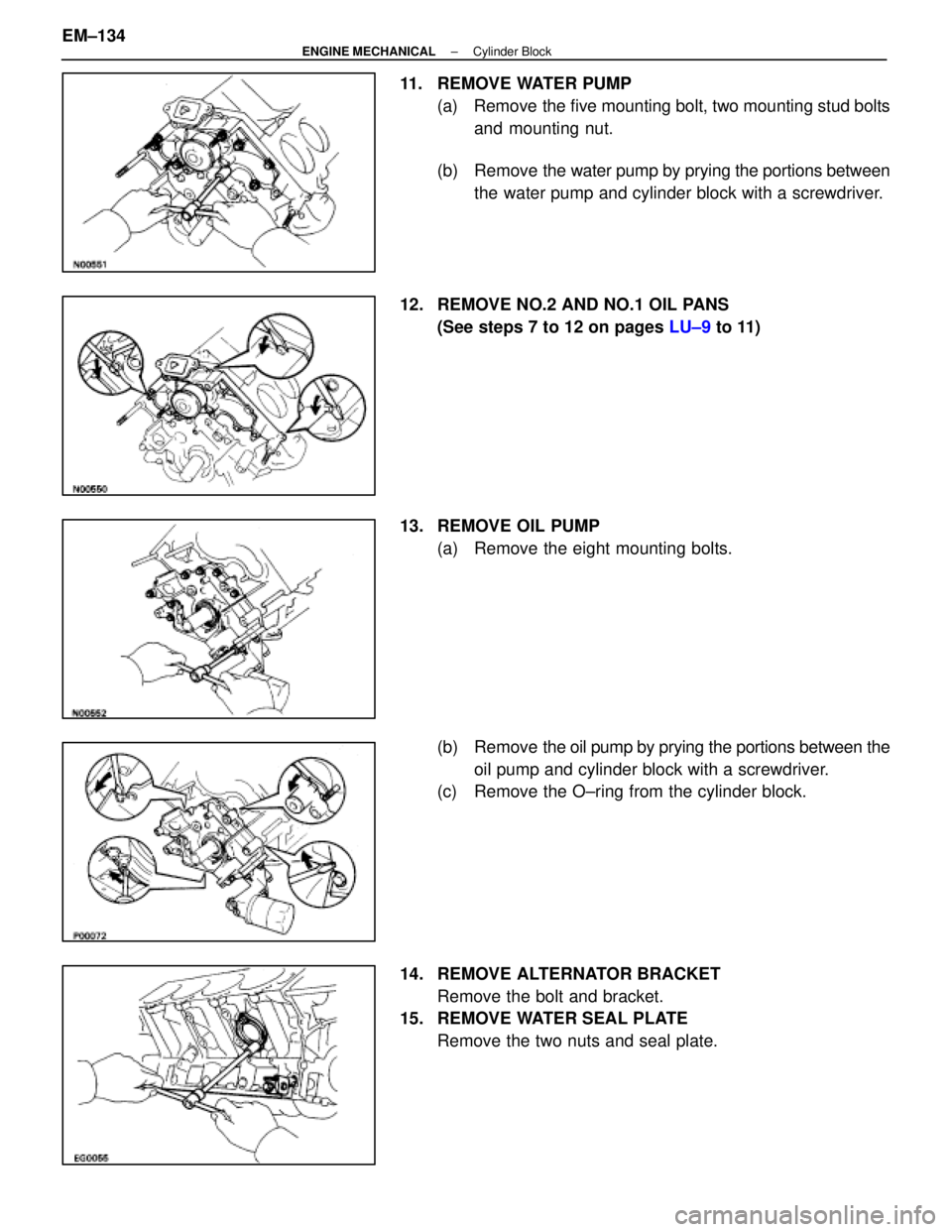

11. REMOVE WATER PUMP(a) Remove the five mounting bolt, two mounting stud boltsand mounting nut.

(b) Remove the water pump by prying the portions between

the water pump and cylinder block with a screwdriver.

12. REMOVE NO.2 AND NO.1 OIL PANS (See steps 7 to 12 on pages LU±9 to 11)

13. REMOVE OIL PUMP (a) Remove the eight mounting bolts.

(b) Remove the oil pump by prying the portions between the

oil pump and cylinder block with a screwdriver.

(c) Remove the O±ring from the cylinder block.

14. REMOVE ALTERNATOR BRACKET Remove the bolt and bracket.

15. REMOVE WATER SEAL PLATE

Remove the two nuts and seal plate.

EM±134

±

ENGINE MECHANICAL Cylinder Block

WhereEverybodyKnowsYourName

Page 1600 of 4087

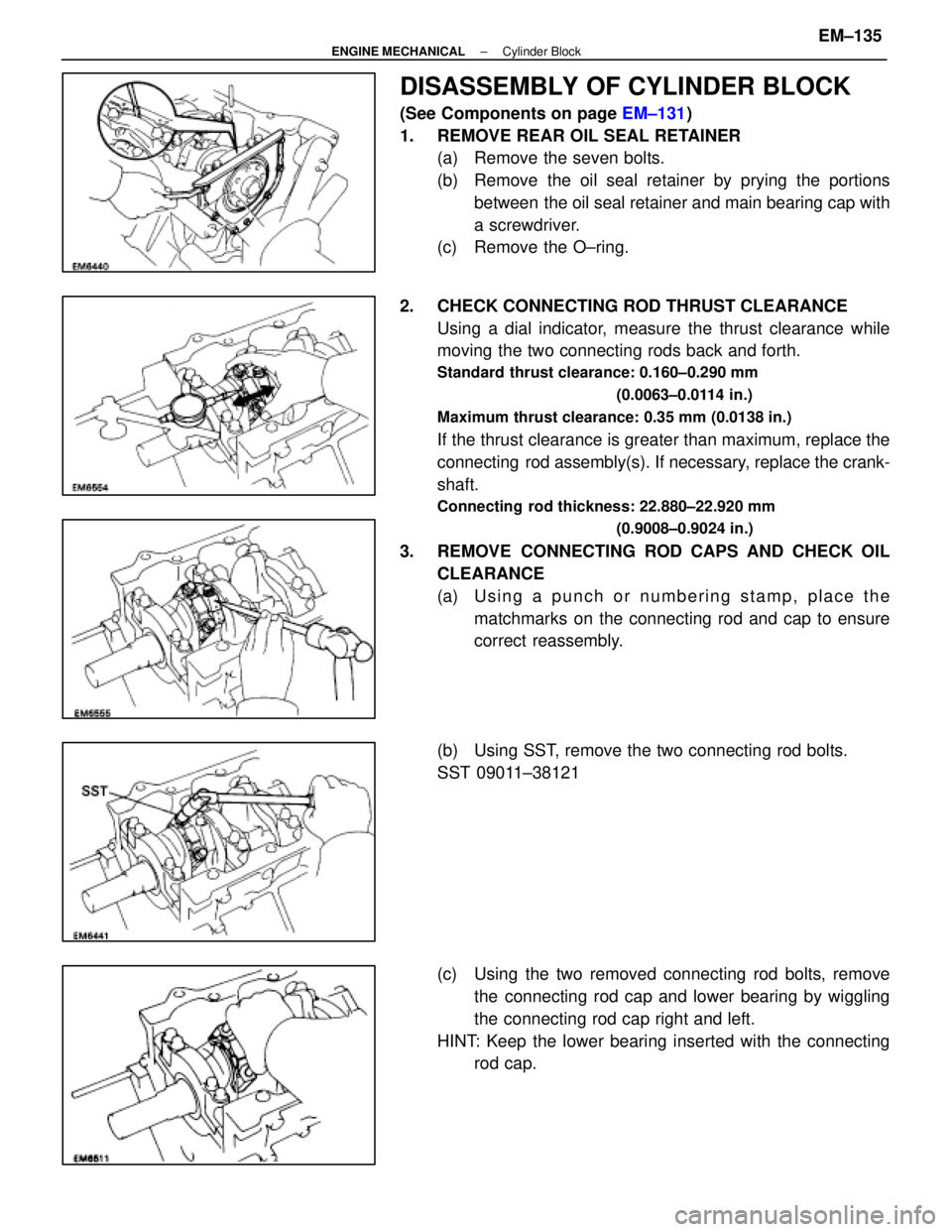

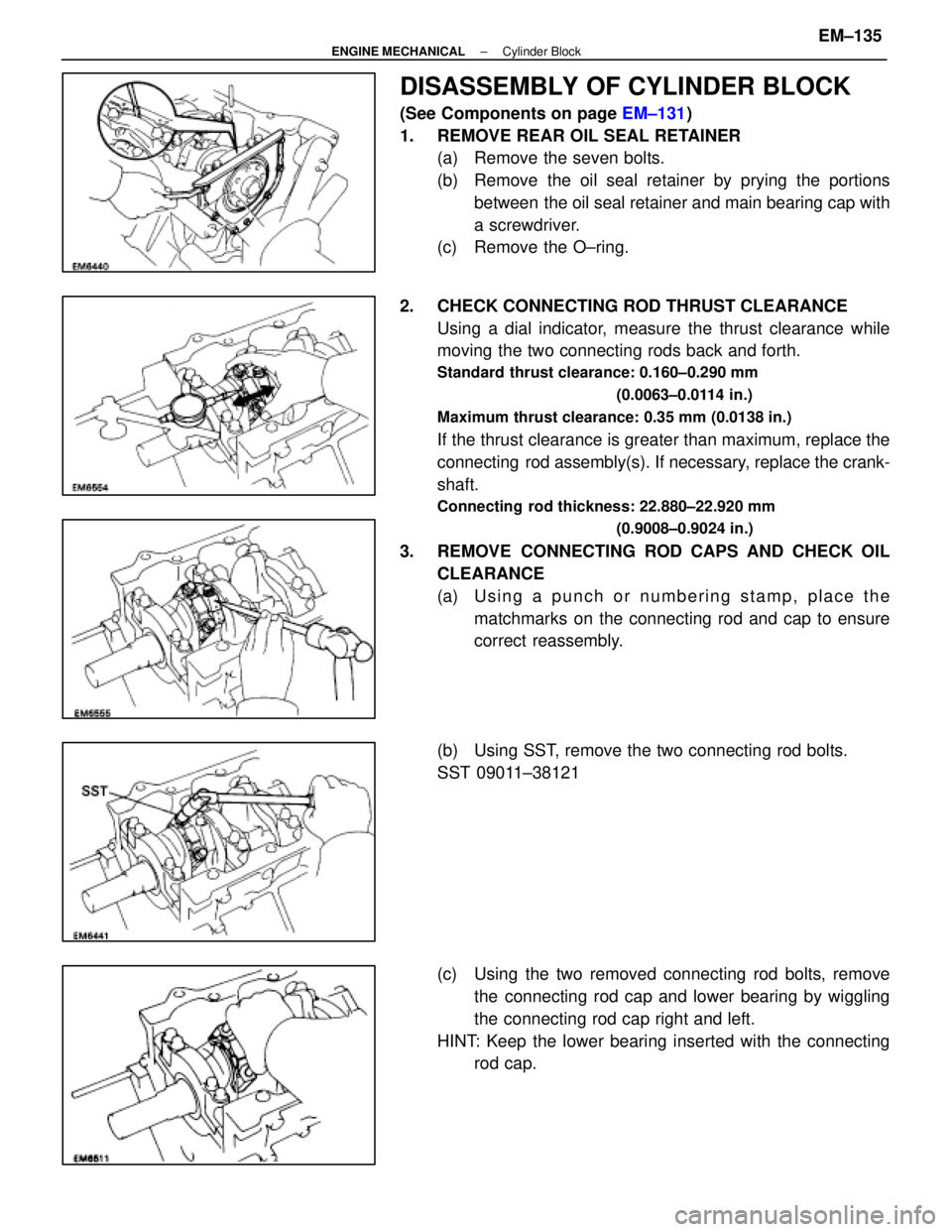

DISASSEMBLY OF CYLINDER BLOCK

(See Components on page EM±131)

1. REMOVE REAR OIL SEAL RETAINER (a) Remove the seven bolts.

(b) Remove the oil seal retainer by prying the portions

between the oil seal retainer and main bearing cap with

a screwdriver.

(c) Remove the O±ring.

2. CHECK CONNECTING ROD THRUST CLEARANCE Using a dial indicator, measure the thrust clearance while

moving the two connecting rods back and forth.

Standard thrust clearance: 0.160±0.290 mm

(0.0063±0.0114 in.)

Maximum thrust clearance: 0.35 mm (0.0138 in.)

If the thrust clearance is greater than maximum, replace the

connecting rod assembly(s). If necessary, replace the crank-

shaft.

Connecting rod thickness: 22.880±22.920 mm (0.9008±0.9024 in.)

3. REMOVE CONNECTING ROD CAPS AND CHECK OILCLEARANCE

(a) Using a punch or numbering stamp, place thematchmarks on the connecting rod and cap to ensure

correct reassembly.

(b) Using SST, remove the two connecting rod bolts.

SST 09011±38121

(c) Using the two removed connecting rod bolts, remove the connecting rod cap and lower bearing by wiggling

the connecting rod cap right and left.

HINT: Keep the lower bearing inserted with the connecting rod cap.

±

ENGINE MECHANICAL Cylinder BlockEM±135

WhereEverybodyKnowsYourName

Trending: headlight bulb, Parking Brake Boot, ignition buzzer, fold seats, spare tire, air bleeding, bolt pattern