4WD MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 696 of 909

M–66

ELECTRONIC 4WD CONTROL SYSTEM

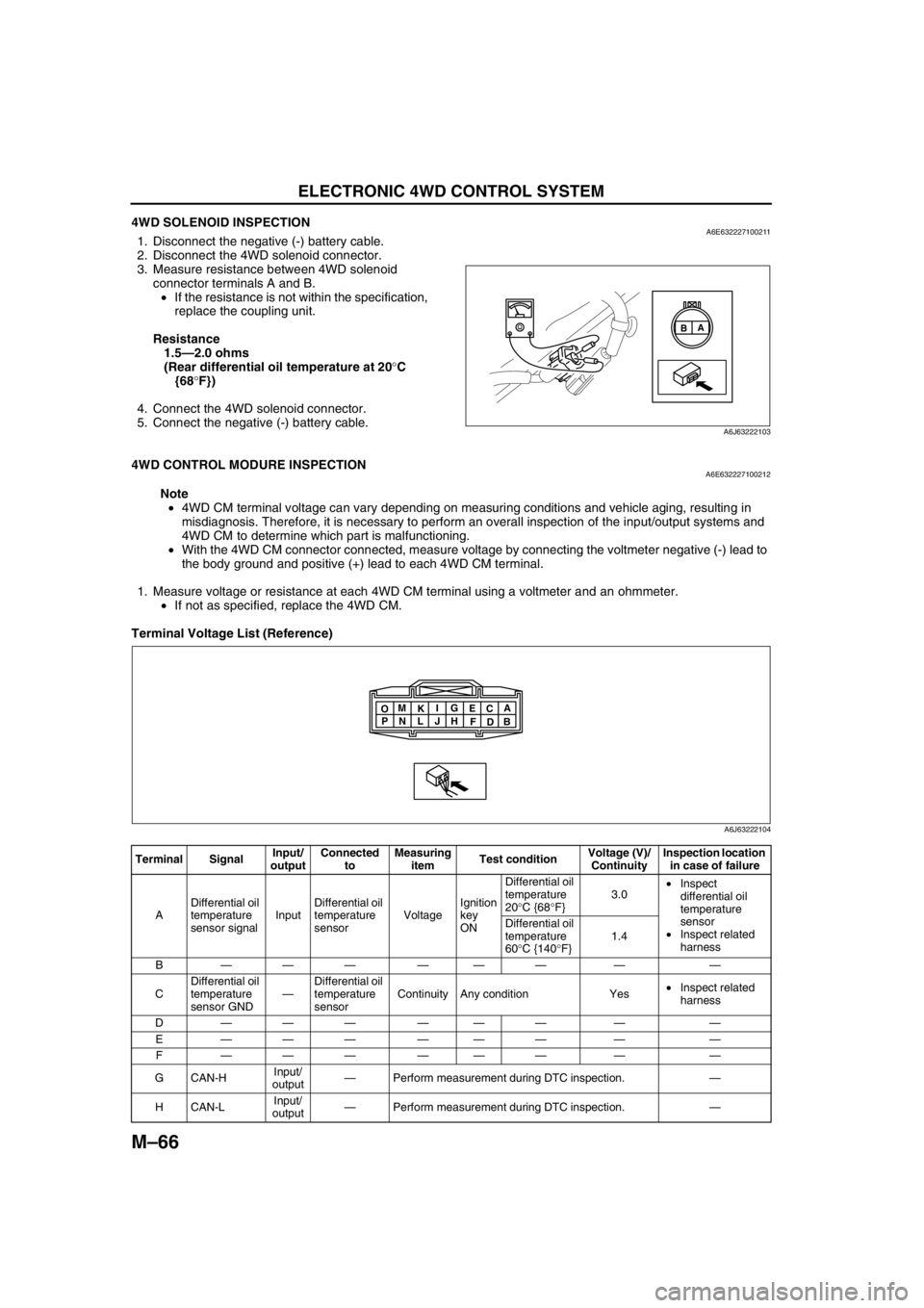

4WD SOLENOID INSPECTIONA6E6322271002111. Disconnect the negative (-) battery cable.

2. Disconnect the 4WD solenoid connector.

3. Measure resistance between 4WD solenoid

connector terminals A and B.

•If the resistance is not within the specification,

replace the coupling unit.

Resistance

1.5—2.0 ohms

(Rear differential oil temperature at 20°C

{68°F})

4. Connect the 4WD solenoid connector.

5. Connect the negative (-) battery cable.

End Of Sie

4WD CONTROL MODURE INSPECTIONA6E632227100212

Note

•4WD CM terminal voltage can vary depending on measuring conditions and vehicle aging, resulting in

misdiagnosis. Therefore, it is necessary to perform an overall inspection of the input/output systems and

4WD CM to determine which part is malfunctioning.

•With the 4WD CM connector connected, measure voltage by connecting the voltmeter negative (-) lead to

the body ground and positive (+) lead to each 4WD CM terminal.

1. Measure voltage or resistance at each 4WD CM terminal using a voltmeter and an ohmmeter.

•If not as specified, replace the 4WD CM.

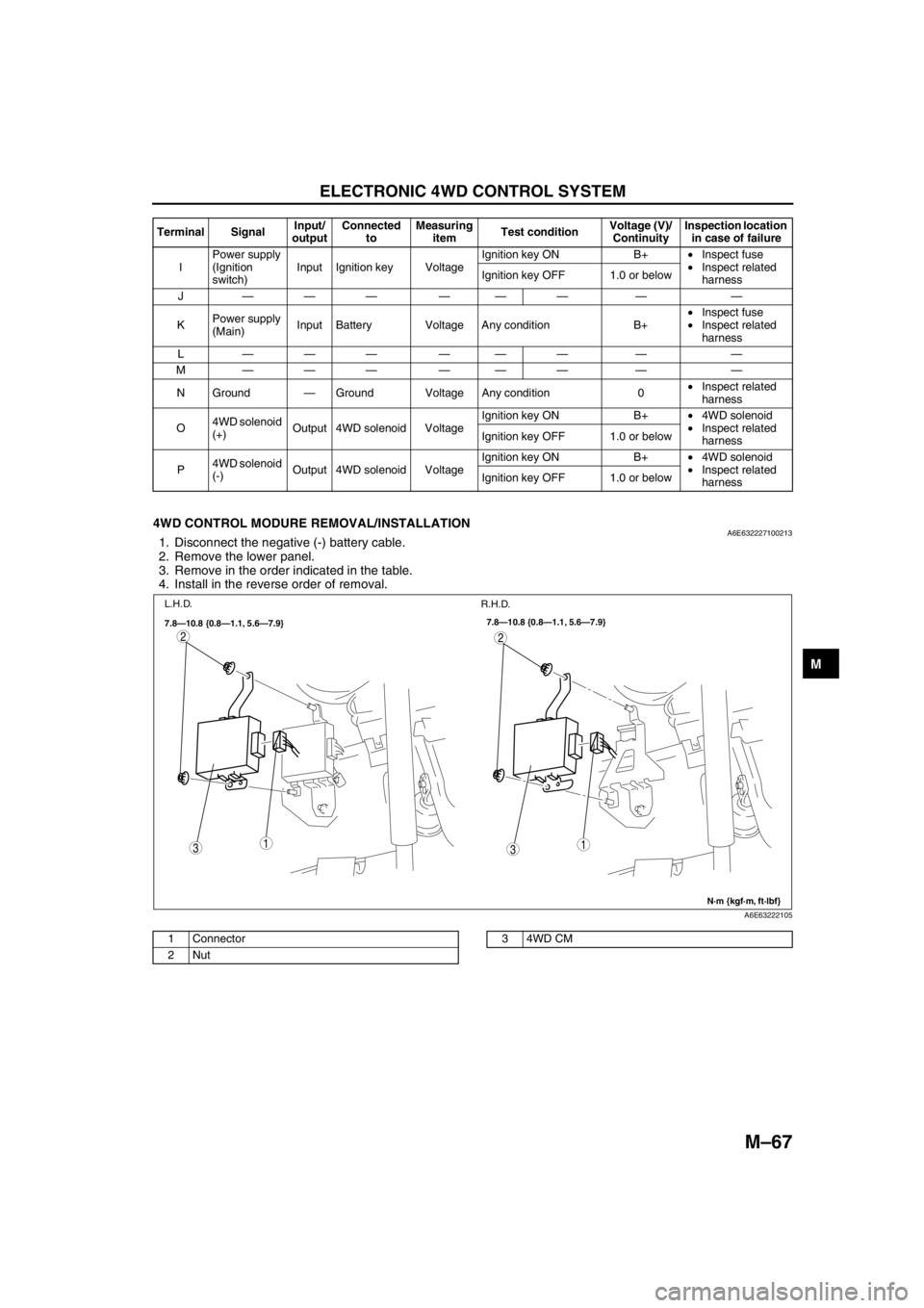

Terminal Voltage List (Reference)

A

B

A6J63222103

Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

ADifferential oil

temperature

sensor signalInputDifferential oil

temperature

sensorVoltageIgnition

key

ONDifferential oil

temperature

20°C {68°F}3.0•Inspect

differential oil

temperature

sensor

•Inspect related

harness Differential oil

temperature

60°C {140°F}1.4

B——— ——— — —

CDifferential oil

temperature

sensor GND—Differential oil

temperature

sensorContinuity Any condition Yes•Inspect related

harness

D——— ——— — —

E——— ——— — —

F——— ——— — —

GCAN-HInput/

output—Perform measurement during DTC inspection.—

HCAN-LInput/

output—Perform measurement during DTC inspection.—

A

B C

D E

F G

H I

J K

L M

N O

P

A6J63222104

Page 697 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–67

M

End Of Sie

4WD CONTROL MODURE REMOVAL/INSTALLATIONA6E6322271002131. Disconnect the negative (-) battery cable.

2. Remove the lower panel.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

.

End Of Sie

IPower supply

(Ignition

switch)Input Ignition key VoltageIgnition key ON B+•Inspect fuse

•Inspect related

harness Ignition key OFF 1.0 or below

J——— ——— — —

KPower supply

(Main)Input Battery Voltage Any condition B+•Inspect fuse

•Inspect related

harness

L——— ——— — —

M——— ——— — —

N Ground—Ground Voltage Any condition 0•Inspect related

harness

O4WD solenoid

(+)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below

P4WD solenoid

(-)Output 4WD solenoid VoltageIgnition key ON B+•4WD solenoid

•Inspect related

harness Ignition key OFF 1.0 or below Terminal SignalInput/

outputConnected

toMeasuring

itemTest conditionVoltage (V)/

ContinuityInspection location

in case of failure

31

2

31

2

7.8—10.8 {0.8—1.1, 5.6—7.9}

N·m {kgf·m, ft·lbf} 7.8—10.8 {0.8—1.1, 5.6—7.9}

L.H.D.

R.H.D.

A6E63222105

1 Connector

2Nut34WD CM

Page 698 of 909

M–68

ELECTRONIC 4WD CONTROL SYSTEM

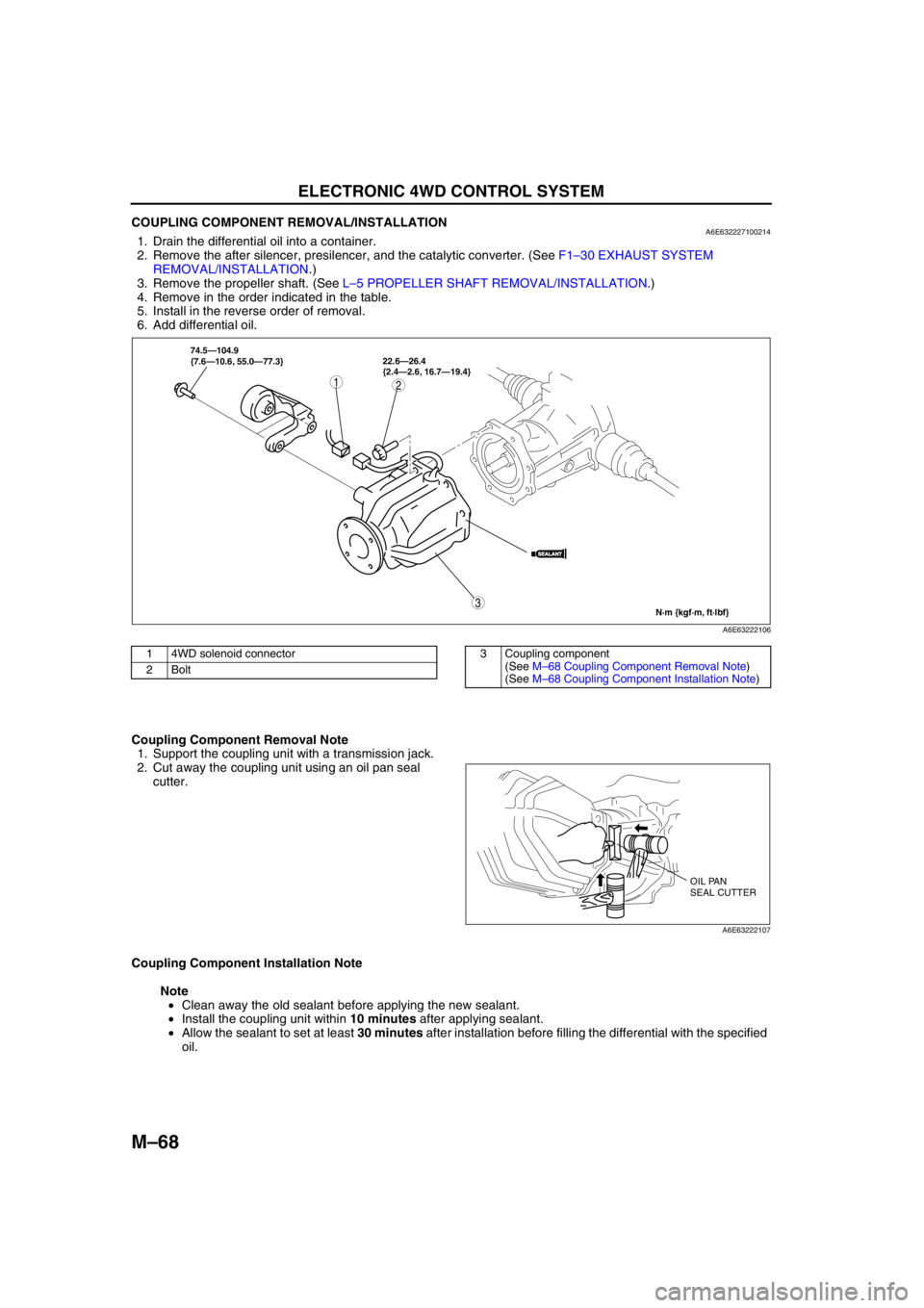

COUPLING COMPONENT REMOVAL/INSTALLATIONA6E6322271002141. Drain the differential oil into a container.

2. Remove the after silencer, presilencer, and the catalytic converter. (See F1–30 EXHAUST SYSTEM

REMOVAL/INSTALLATION.)

3. Remove the propeller shaft. (See L–5 PROPELLER SHAFT REMOVAL/INSTALLATION.)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Add differential oil.

.

Coupling Component Removal Note

1. Support the coupling unit with a transmission jack.

2. Cut away the coupling unit using an oil pan seal

cutter.

Coupling Component Installation Note

Note

•Clean away the old sealant before applying the new sealant.

•Install the coupling unit within 10 minutes after applying sealant.

•Allow the sealant to set at least 30 minutes after installation before filling the differential with the specified

oil.

3

12

SEALANTSEALANT

74.5—104.9

{7.6—10.6, 55.0—77.3}22.6—26.4

{2.4—2.6, 16.7—19.4}

N·m {kgf·m, ft·lbf}

A6E63222106

1 4WD solenoid connector

2Bolt3 Coupling component

(See M–68 Coupling Component Removal Note)

(See M–68 Coupling Component Installation Note)

OIL PAN

SEAL CUTTER

A6E63222107

Page 699 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–69

M

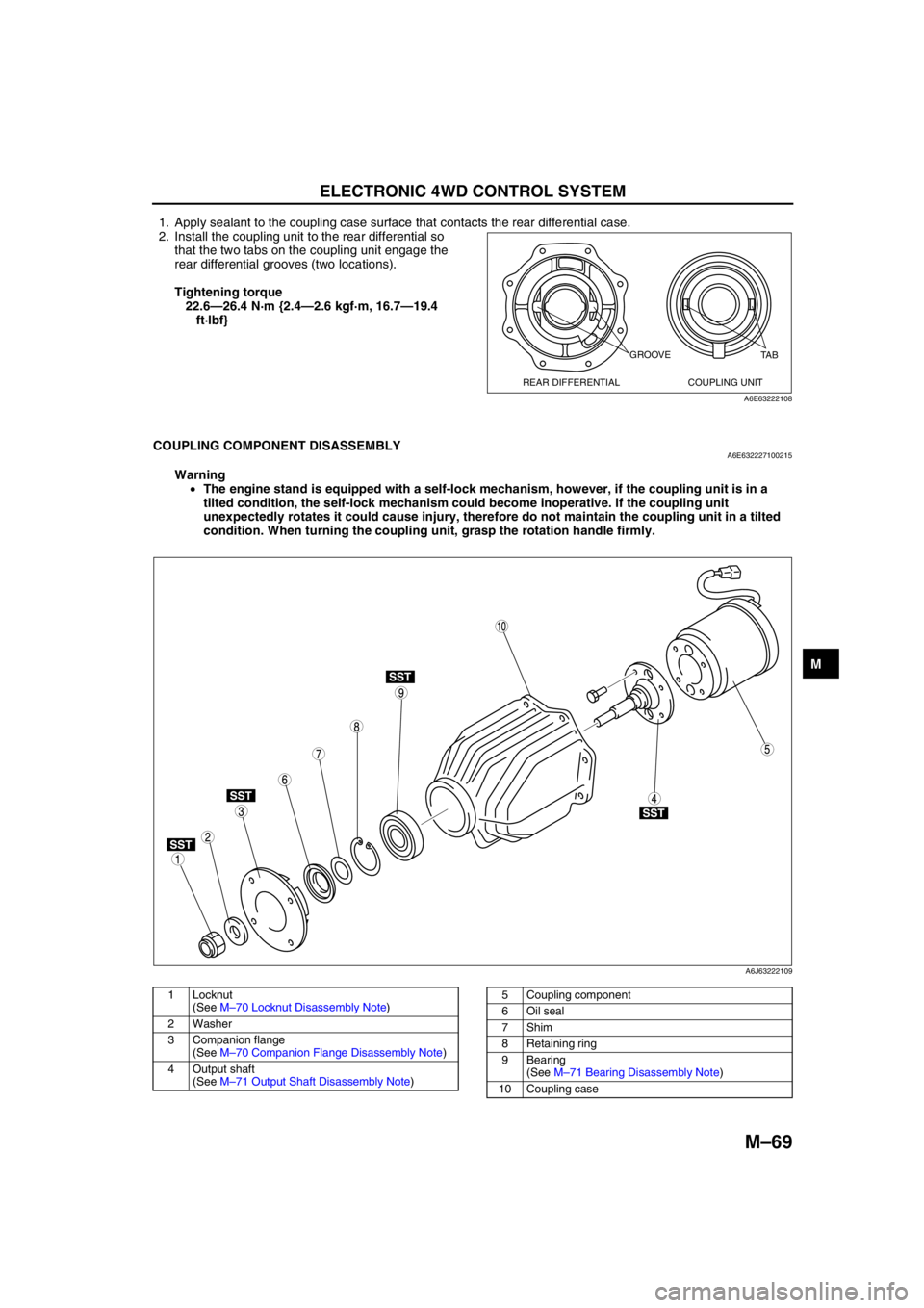

1. Apply sealant to the coupling case surface that contacts the rear differential case.

2. Install the coupling unit to the rear differential so

that the two tabs on the coupling unit engage the

rear differential grooves (two locations).

Tightening torque

22.6—26.4 N·m {2.4—2.6 kgf·m, 16.7—19.4

ft·lbf}

End Of Sie

COUPLING COMPONENT DISASSEMBLYA6E632227100215

Warning

•The engine stand is equipped with a self-lock mechanism, however, if the coupling unit is in a

tilted condition, the self-lock mechanism could become inoperative. If the coupling unit

unexpectedly rotates it could cause injury, therefore do not maintain the coupling unit in a tilted

condition. When turning the coupling unit, grasp the rotation handle firmly.

.

GROOVE

REAR DIFFERENTIAL COUPLING UNITTA B

A6E63222108

SST

SST

SST

SST

9

8

75

4

3

1

2

10

6

A6J63222109

1 Locknut

(See M–70 Locknut Disassembly Note)

2Washer

3 Companion flange

(See M–70 Companion Flange Disassembly Note)

4 Output shaft

(See M–71 Output Shaft Disassembly Note)5 Coupling component

6Oil seal

7Shim

8 Retaining ring

9 Bearing

(See M–71 Bearing Disassembly Note)

10 Coupling case

Page 700 of 909

M–70

ELECTRONIC 4WD CONTROL SYSTEM

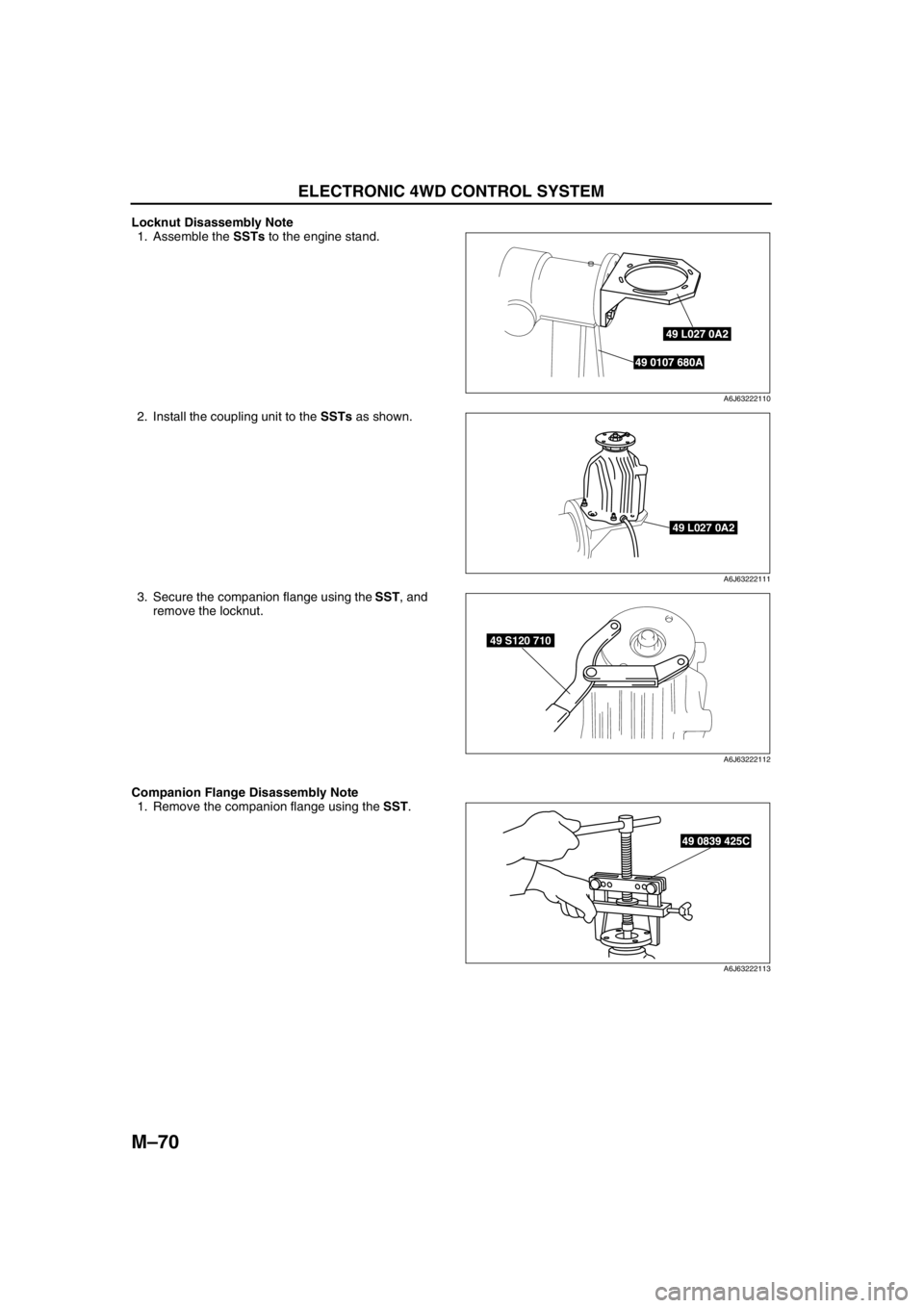

Locknut Disassembly Note

1. Assemble the SSTs to the engine stand.

2. Install the coupling unit to the SSTs as shown.

3. Secure the companion flange using the SST, and

remove the locknut.

Companion Flange Disassembly Note

1. Remove the companion flange using the SST.

49 L027 0A2

49 0107 680A

A6J63222110

49 L027 0A2

A6J63222111

49 S120 710

A6J63222112

49 0839 425C

A6J63222113

Page 701 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–71

M

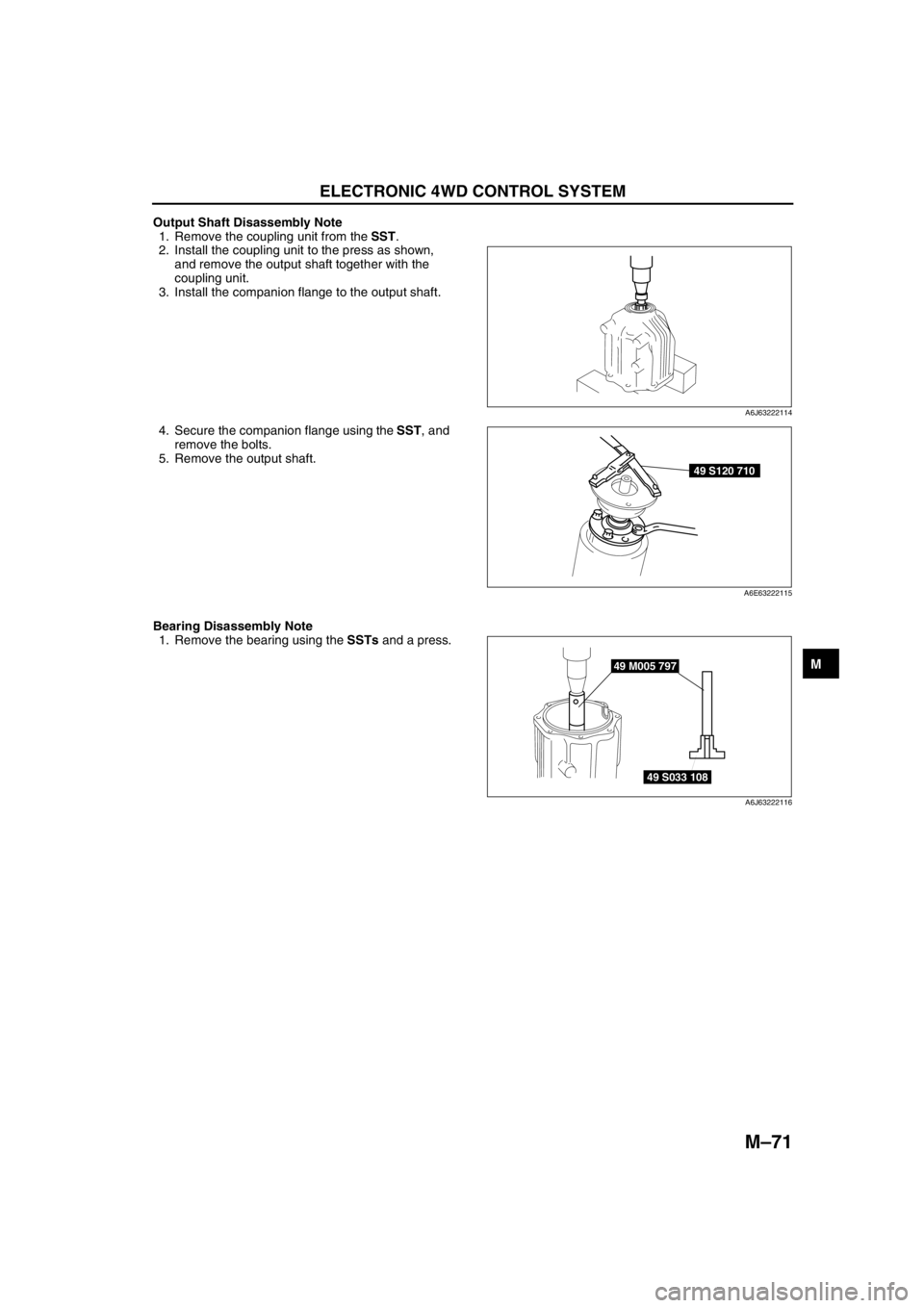

Output Shaft Disassembly Note

1. Remove the coupling unit from the SST.

2. Install the coupling unit to the press as shown,

and remove the output shaft together with the

coupling unit.

3. Install the companion flange to the output shaft.

4. Secure the companion flange using the SST, and

remove the bolts.

5. Remove the output shaft.

Bearing Disassembly Note

1. Remove the bearing using the SSTs and a press.

End Of Sie

A6J63222114

49 S120 710

A6E63222115

49 M005 797

49 S033 108

A6J63222116

Page 702 of 909

M–72

ELECTRONIC 4WD CONTROL SYSTEM

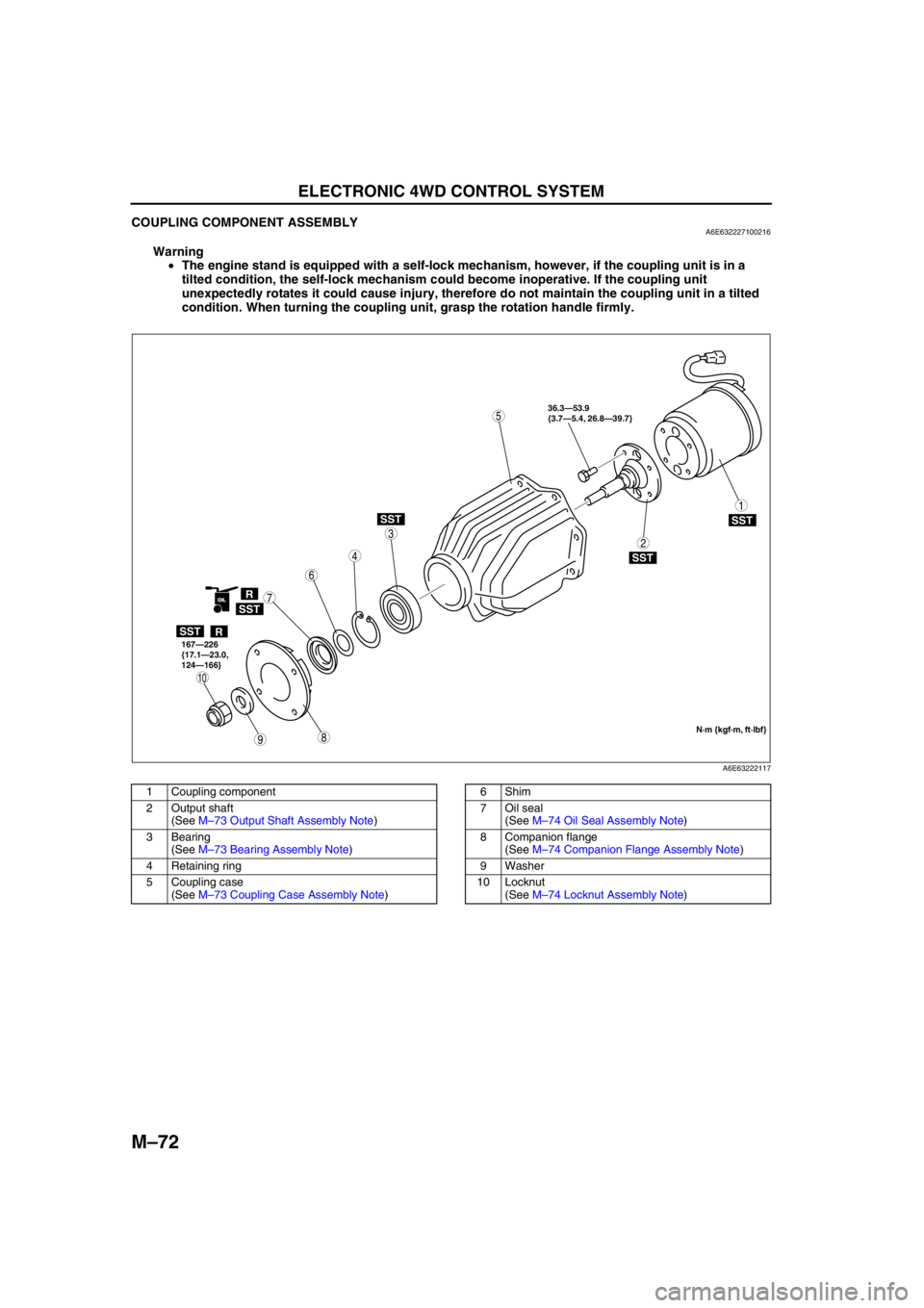

COUPLING COMPONENT ASSEMBLYA6E632227100216

Warning

•The engine stand is equipped with a self-lock mechanism, however, if the coupling unit is in a

tilted condition, the self-lock mechanism could become inoperative. If the coupling unit

unexpectedly rotates it could cause injury, therefore do not maintain the coupling unit in a tilted

condition. When turning the coupling unit, grasp the rotation handle firmly.

.

98

7

5

4

3

1

2

10

6

SST

SST

R

SST

SST

SST

R

OIL

36.3—53.9

{3.7—5.4, 26.8—39.7}

167—226

{17.1—23.0,

124—166}

N·m {kgf·m, ft·lbf}

A6E63222117

1 Coupling component

2 Output shaft

(See M–73 Output Shaft Assembly Note)

3 Bearing

(See M–73 Bearing Assembly Note)

4 Retaining ring

5 Coupling case

(See M–73 Coupling Case Assembly Note)6Shim

7 Oil seal

(See M–74 Oil Seal Assembly Note)

8 Companion flange

(See M–74 Companion Flange Assembly Note)

9Washer

10 Locknut

(See M–74 Locknut Assembly Note)

Page 703 of 909

ELECTRONIC 4WD CONTROL SYSTEM

M–73

M

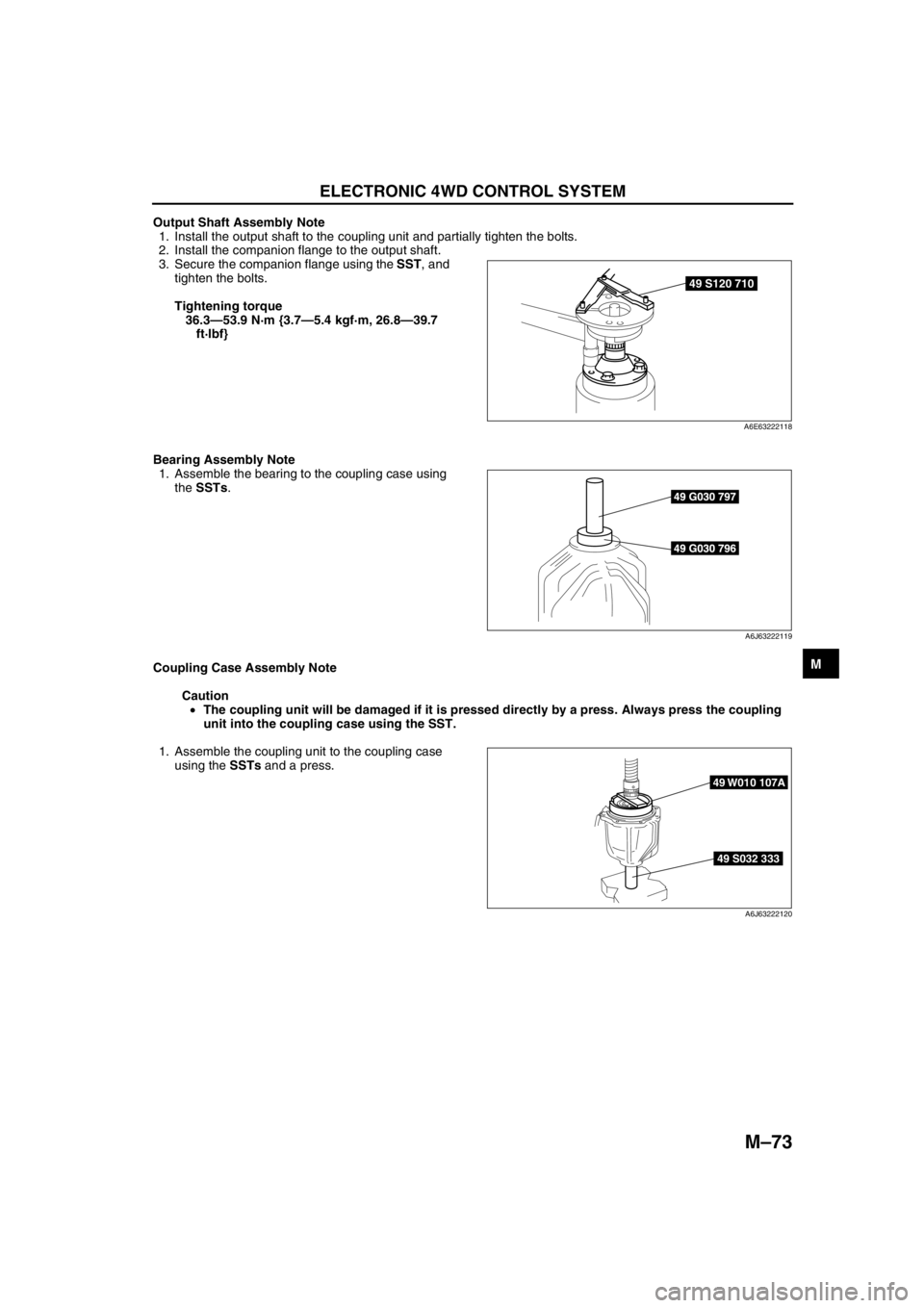

Output Shaft Assembly Note

1. Install the output shaft to the coupling unit and partially tighten the bolts.

2. Install the companion flange to the output shaft.

3. Secure the companion flange using the SST, and

tighten the bolts.

Tightening torque

36.3—53.9 N·m {3.7—5.4 kgf·m, 26.8—39.7

ft·lbf}

Bearing Assembly Note

1. Assemble the bearing to the coupling case using

the SSTs.

Coupling Case Assembly Note

Caution

•The coupling unit will be damaged if it is pressed directly by a press. Always press the coupling

unit into the coupling case using the SST.

1. Assemble the coupling unit to the coupling case

using the SSTs and a press.

49 S120 710

A6E63222118

49 G030 797

49 G030 796

A6J63222119

49 S032 333

49 W010 107A

A6J63222120

Page 704 of 909

M–74

ELECTRONIC 4WD CONTROL SYSTEM

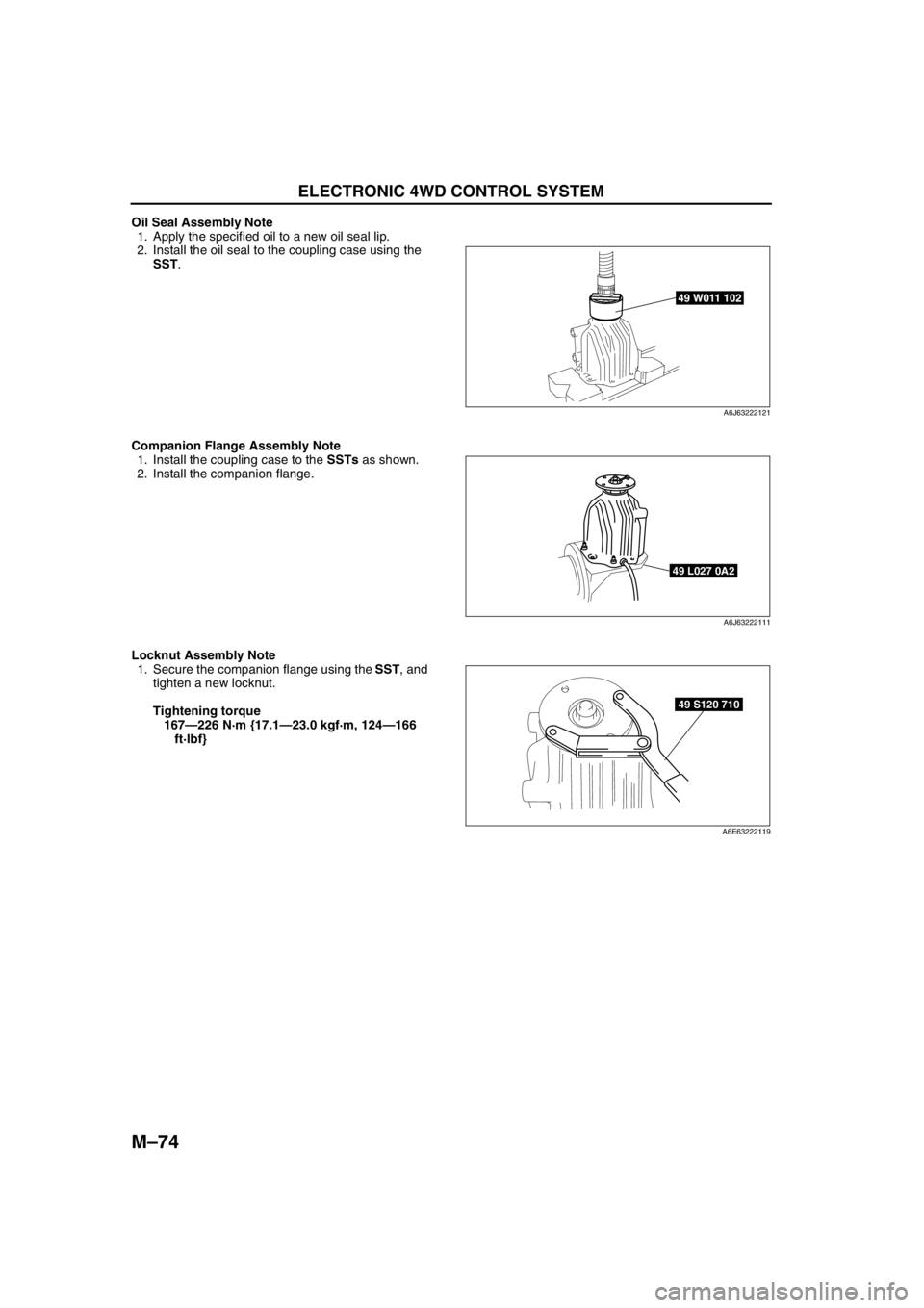

Oil Seal Assembly Note

1. Apply the specified oil to a new oil seal lip.

2. Install the oil seal to the coupling case using the

SST.

Companion Flange Assembly Note

1. Install the coupling case to the SSTs as shown.

2. Install the companion flange.

Locknut Assembly Note

1. Secure the companion flange using the SST, and

tighten a new locknut.

Tightening torque

167—226 N·m {17.1—23.0 kgf·m, 124—166

ft·lbf}

End Of Sie

49 W011 102

A6J63222121

49 L027 0A2

A6J63222111

49 S120 710

A6E63222119

Page 705 of 909

ON-BOARD DIAGNOSTIC

M–75

M

WIRING DIAGRAMA6E637027100201

End Of Sie

ON-BOARD DIAGNOSTIC

IGNITION SWITCH

BATTERY

DIFFERENTIAL OIL

TEMPERATURE

SENSOR4WD CM4WD SOLENOID ELECTRONIC CONTROL

COUPLING

CAN DRIVERINSTRUMENT CLUSTER

CAN-H

CAN-LPCM DSC HU/CM KO

P I

A

C

NH G

TCM

A6E63702002