4WD MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 121 of 909

CONTROL SYSTEM

F1–33

F1

PCM INSPECTION (4WD)A6E394018880207Using SST (WDS or equivalent)

Note

•PIDs for the following parts are not available on this model. Go to the appropriate part inspection page.

—CMP sensor

—Main relay

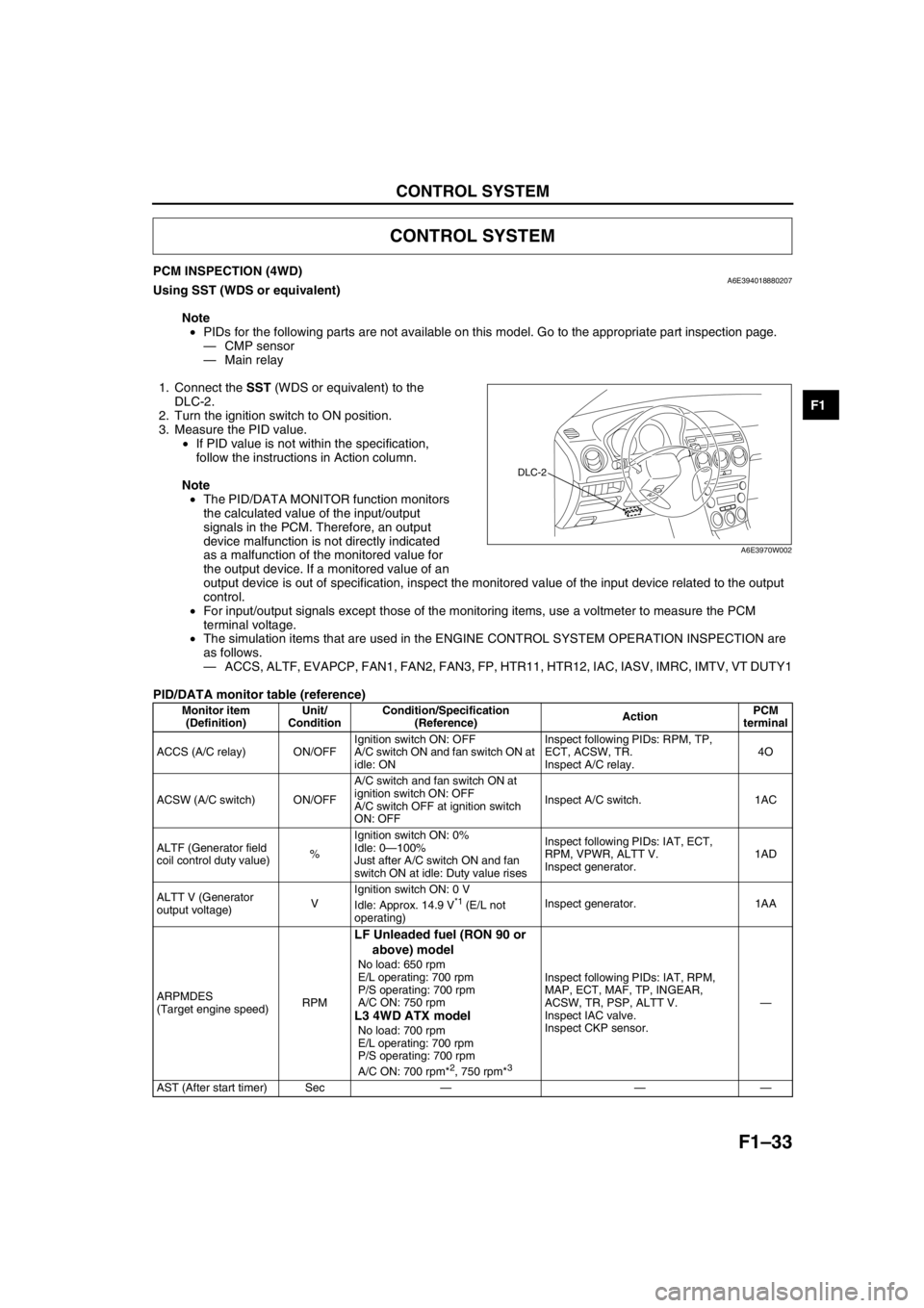

1. Connect the SST (WDS or equivalent) to the

DLC-2.

2. Turn the ignition switch to ON position.

3. Measure the PID value.

•If PID value is not within the specification,

follow the instructions in Action column.

Note

•The PID/DATA MONITOR function monitors

the calculated value of the input/output

signals in the PCM. Therefore, an output

device malfunction is not directly indicated

as a malfunction of the monitored value for

the output device. If a monitored value of an

output device is out of specification, inspect the monitored value of the input device related to the output

control.

•For input/output signals except those of the monitoring items, use a voltmeter to measure the PCM

terminal voltage.

•The simulation items that are used in the ENGINE CONTROL SYSTEM OPERATION INSPECTION are

as follows.

—ACCS, ALTF, EVAPCP, FAN1, FAN2, FAN3, FP, HTR11, HTR12, IAC, IASV, IMRC, IMTV, VT DUTY1

PID/DATA monitor table (reference)

CONTROL SYSTEM

DLC-2

A6E3970W002

Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

ACCS (A/C relay) ON/OFFIgnition switch ON: OFF

A/C switch ON and fan switch ON at

idle: ONInspect following PIDs: RPM, TP,

ECT, ACSW, TR.

Inspect A/C relay.4O

ACSW (A/C switch) ON/OFFA/C switch and fan switch ON at

ignition switch ON: OFF

A/C switch OFF at ignition switch

ON: OFFInspect A/C switch. 1AC

ALTF (Generator field

coil control duty value)%Ignition switch ON: 0%

Idle: 0—100%

Just after A/C switch ON and fan

switch ON at idle: Duty value risesInspect following PIDs: IAT, ECT,

RPM, VPWR, ALTT V.

Inspect generator.1AD

ALTT V (Generator

output voltage)VIgnition switch ON: 0 V

Idle: Approx. 14.9 V

*1 (E/L not

operating)Inspect generator. 1AA

ARPMDES

(Target engine speed)RPM

LF Unleaded fuel (RON 90 or

above) model

No load: 650 rpm

E/L operating: 700 rpm

P/S operating: 700 rpm

A/C ON: 750 rpm

L3 4WD ATX model

No load: 700 rpm

E/L operating: 700 rpm

P/S operating: 700 rpm

A/C ON: 700 rpm*

2, 750 rpm*3

Inspect following PIDs: IAT, RPM,

MAP, ECT, MAF, TP, INGEAR,

ACSW, TR, PSP, ALTT V.

Inspect IAC valve.

Inspect CKP sensor.—

AST (After start timer) Sec———

Page 124 of 909

F1–36

CONTROL SYSTEM

*1: Calculated value; differs from terminal voltage

*2: Refrigerant pressure switch (middle) turns on when the refrigerant pressure is 1.69—1.84 MPa {17.3—18.7

kgf/cm2, 247—265 psi}

*3: Refrigerant pressure switch (middle) turns off when the refrigerant pressure is 1.26—1.49 MPa {12.9—15.1

kgf/cm2, 184—214 psi}

*4: L3 and L8, LF (Intensely hot area) engine models

*5: Immobilizer system equipped model

*6: Immobilizer system not equipped

*7: L3 engine model only

*8: MTX model only

•Following PIDs are for the ATX models. If inspects for following PIDs, see K2–180 PID/DATA MONITOR

INSPECTION.

PIDs for the ATX models

—GEAR, LINEDES, LPS, OP_SW_B, SSA/SS1, SSB/SS2, SSC/SS3, TCS, TFT, TFTV, THOP, TR,

TR_SENS, TSS

RO2FT1 (Rear oxygen

sensor fuel trim)—Idle (after warm up): approx. –

0.03—0.03Perform applicable DTC

troubleshooting.—

RPM (Engine speed) rpm

LF Unleaded fuel (RON 90 or

above) model

No load: 600—700 rpm

E/L operating: 650—750 rpm

P/S operating: 650—750 rpm

A/C ON: 700—800 rpm

L3 4WD ATX model

No load: 650—750 rpm

E/L operating: 650—750 rpm

P/S operating: 650—750 rpm

A/C ON: 650—750 rpm*

2, 700—

800 rpm*3

Inspect CKP sensor. 2D, 2G

SEGRP (EGR valve

(stepping motor)

position)StepIgnition switch ON: 0 step

Idle: 0 step

Cranking: 0—60 stepsInspect following PIDs: MAF, TP,

ECT, RPM, VSS.

Inspect EGR valve.4E, 4H,

4K, 4N

SHRTFT1 (Short term

fuel trim)%Idle (after warm up): approx.–30—

25%Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

SPARKADV (Ignition

timing)°Ignition switch ON: BTDC 0°

Idle: BTDC approx. 10°Inspect following PIDs: MAF, TP,

ECT, RPM, INGEAR, TR, PSP,

ACSW, VPWR.

Inspect ignition timing.2J, 2M

TEST (Test mode) ON/OFF———

TP (TP)%CTP: 13—23%

WOT: 86—96%

Inspect TP sensor. 2A

VCTP: 0.65—1.15 V

WOT: 4.3—4.8 V

TPCT

(TP sensor voltage at

CTP )V0.65—1.15 V Inspect TP sensor. 2A

VPWR (Battery positive

voltage)V Ignition switch ON: B+Inspect main relay.

Inspect battery.2Y, 2Z

VSS (Vehicle speed) kph, mphVehicle speed 20 kph {12 mph}:

20 kph {12 mph}

Vehicle speed 40 kph {25 mph}:

20 kph {12 mph}Perform applicable DTC

troubleshooting.

(See F1–54 DTC TABLE)—

VT DUTY1*

7% Idle: 0%Inspect following PIDs: TP, ECT,

RPM.

Inspect OCV.2I, 2L Monitor item

(Definition)Unit/

ConditionCondition/Specification

(Reference)ActionPCM

terminal

Page 132 of 909

F1–44

CONTROL SYSTEM

*6: Unleaded fuel (RON 90 or above) models

*7: Exclude L3 engine models

*8: MTX, without ABS models

*9: Immobilizer system equipped

*10: Immobilizer system not equipped

*11: 2WD ATX models

*12: 4WD ATX models

*13: Exclude MTX models without ABS

*14: Exclude 2WD ATX models

Inspection Using An Oscilloscope (Reference)

IGT1, IGT2 control signals

PCM terminals

•IGT1(No.1 and No.4): 1A(+)—1D(–)

•IGT2(No.2 and No.3): 1B(+)—1C(–)

Oscilloscope setting

•4 V/DIV (Y), 0.01 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

Generator output voltage signal

PCM terminals

•1AA(+)—2AC(–)

Oscilloscope setting

•2 V/DIV (Y), 2 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX] or 700 rpm [ATX], no load, P/S off, A/C

off)

HO2S (front) signal

PCM terminals

•1AB(+)—2H(–)

Oscilloscope setting

•0.1 V/DIV (Y), 400 ms/DIV (X), DC range

Vehicle condition

•Idle after warm up (engine speed approx. 650

rpm [MTX], 700 rpm [ATX], no load, P/S off, A/C

off)

0 V

A6A3940W003

0 V

A6A3940W004

0 V

A6A3940W005

Page 138 of 909

F1–50

ON-BOARD DIAGNOSTIC

OUTLINEA6E397018881201•The construction and operation of the on-board diagnostic system is essentially carried over from that of the

current Mazda6 (GG), except for the following. (See Mazda6 Training Manual 3359-1*-02C.)

4WD ATX model

—DTCs, PID monitoring items, and simulation items have been deleted to match the vehicle characteristics.

Unleaded fuel (RON 90 or above) model

—DTCs and PID monitoring items which relevant to BARO sensor have been deleted to match the vehicle

characteristics.

End Of Sie

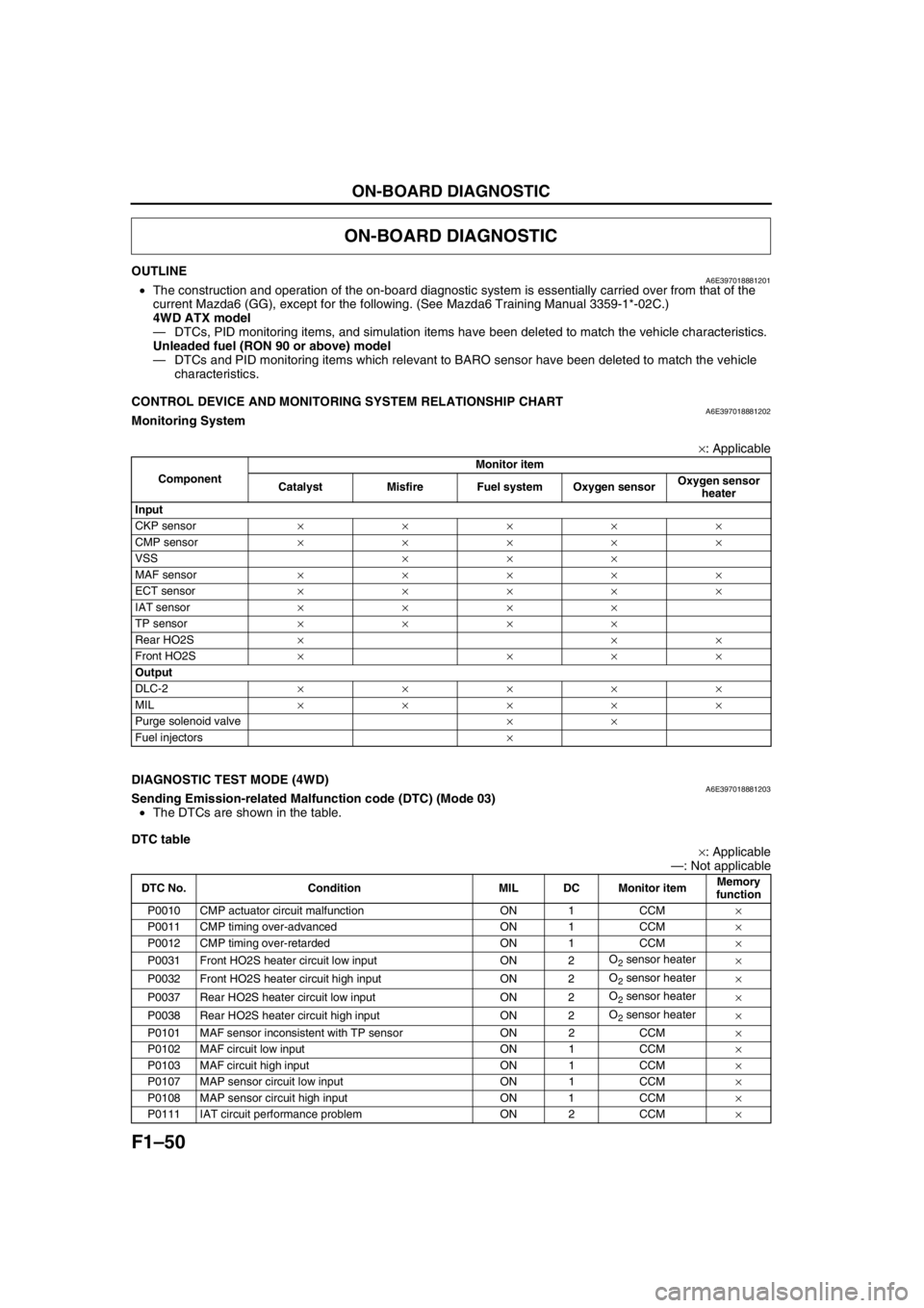

CONTROL DEVICE AND MONITORING SYSTEM RELATIONSHIP CHARTA6E397018881202Monitoring System

×: Applicable

End Of Sie

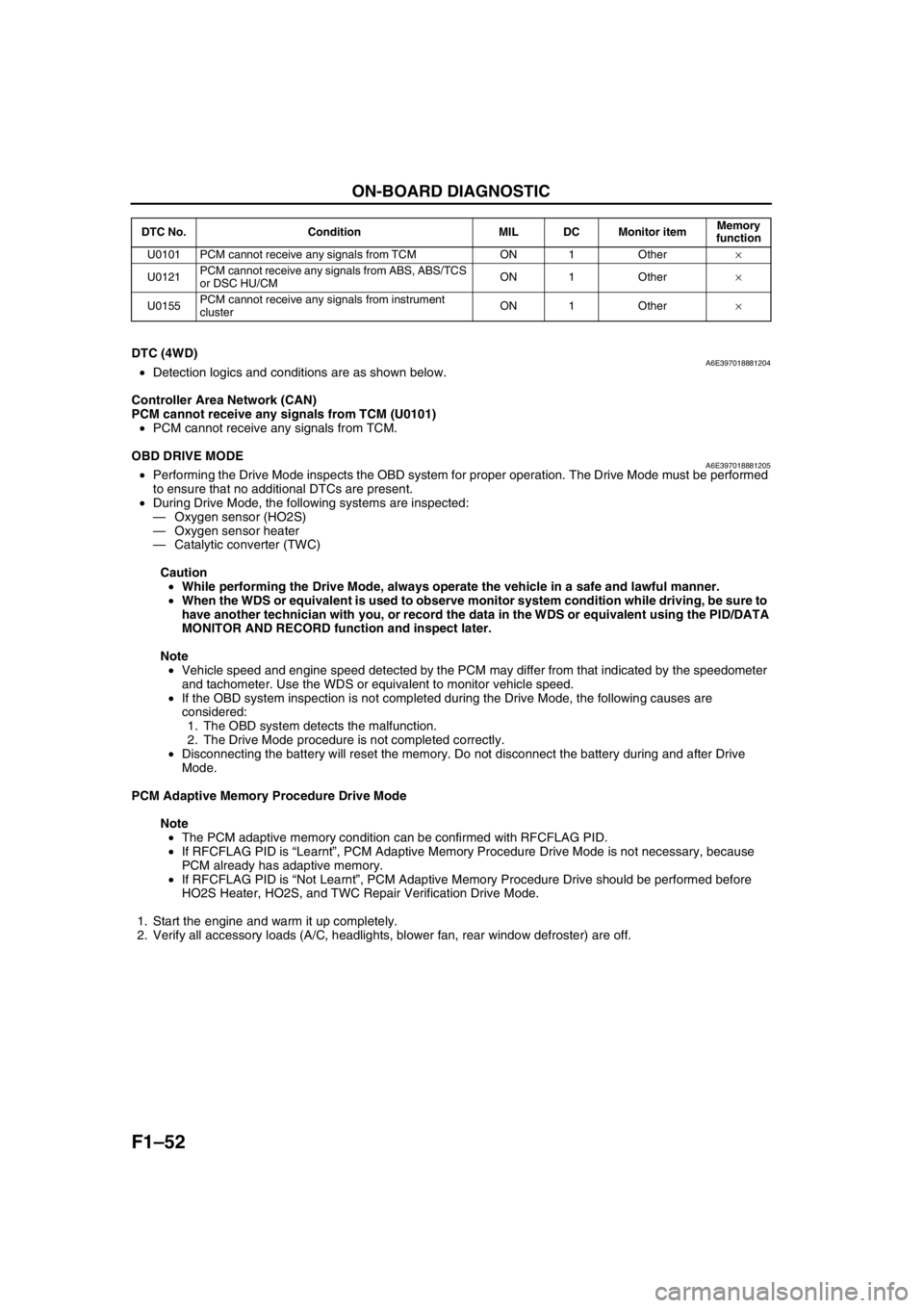

DIAGNOSTIC TEST MODE (4WD)A6E397018881203Sending Emission-related Malfunction code (DTC) (Mode 03)

•The DTCs are shown in the table.

DTC table

×: Applicable

—: Not applicable

ON-BOARD DIAGNOSTIC

ComponentMonitor item

Catalyst Misfire Fuel system Oxygen sensor Oxygen sensor

heater

Input

CKP sensor×××××

CMP sensor×××××

VSS×××

MAF sensor×××××

ECT sensor×××××

IAT sensor××××

TP sensor××××

Rear HO2S×××

Front HO2S××××

Output

DLC-2×××××

MIL×××××

Purge solenoid valve××

Fuel injectors×

DTC No. Condition MIL DC Monitor itemMemory

function

P0010 CMP actuator circuit malfunction ON 1 CCM×

P0011 CMP timing over-advanced ON 1 CCM×

P0012 CMP timing over-retarded ON 1 CCM×

P0031 Front HO2S heater circuit low input ON 2O

2 sensor heater

×

P0032 Front HO2S heater circuit high input ON 2O

2 sensor heater

×

P0037 Rear HO2S heater circuit low input ON 2O

2 sensor heater

×

P0038 Rear HO2S heater circuit high input ON 2O

2 sensor heater

×

P0101 MAF sensor inconsistent with TP sensor ON 2 CCM×

P0102 MAF circuit low input ON 1 CCM×

P0103 MAF circuit high input ON 1 CCM×

P0107 MAP sensor circuit low input ON 1 CCM×

P0108 MAP sensor circuit high input ON 1 CCM×

P0111 IAT circuit performance problem ON 2 CCM×

Page 140 of 909

F1–52

ON-BOARD DIAGNOSTIC

End Of Sie

DTC (4WD)A6E397018881204•Detection logics and conditions are as shown below.

Controller Area Network (CAN)

PCM cannot receive any signals from TCM (U0101)

•PCM cannot receive any signals from TCM.

End Of Sie

OBD DRIVE MODEA6E397018881205•Performing the Drive Mode inspects the OBD system for proper operation. The Drive Mode must be performed

to ensure that no additional DTCs are present.

•During Drive Mode, the following systems are inspected:

—Oxygen sensor (HO2S)

—Oxygen sensor heater

—Catalytic converter (TWC)

Caution

•While performing the Drive Mode, always operate the vehicle in a safe and lawful manner.

•When the WDS or equivalent is used to observe monitor system condition while driving, be sure to

have another technician with you, or record the data in the WDS or equivalent using the PID/DATA

MONITOR AND RECORD function and inspect later.

Note

•Vehicle speed and engine speed detected by the PCM may differ from that indicated by the speedometer

and tachometer. Use the WDS or equivalent to monitor vehicle speed.

•If the OBD system inspection is not completed during the Drive Mode, the following causes are

considered:

1. The OBD system detects the malfunction.

2. The Drive Mode procedure is not completed correctly.

•Disconnecting the battery will reset the memory. Do not disconnect the battery during and after Drive

Mode.

PCM Adaptive Memory Procedure Drive Mode

Note

•The PCM adaptive memory condition can be confirmed with RFCFLAG PID.

•If RFCFLAG PID is “Learnt”, PCM Adaptive Memory Procedure Drive Mode is not necessary, because

PCM already has adaptive memory.

•If RFCFLAG PID is “Not Learnt”, PCM Adaptive Memory Procedure Drive should be performed before

HO2S Heater, HO2S, and TWC Repair Verification Drive Mode.

1. Start the engine and warm it up completely.

2. Verify all accessory loads (A/C, headlights, blower fan, rear window defroster) are off.

U0101 PCM cannot receive any signals from TCM ON 1 Other×

U0121PCM cannot receive any signals from ABS, ABS/TCS

or DSC HU/CMON 1 Other×

U0155PCM cannot receive any signals from instrument

clusterON 1 Other× DTC No. Condition MIL DC Monitor itemMemory

function

Page 148 of 909

F1–60

TROUBLESHOOTING

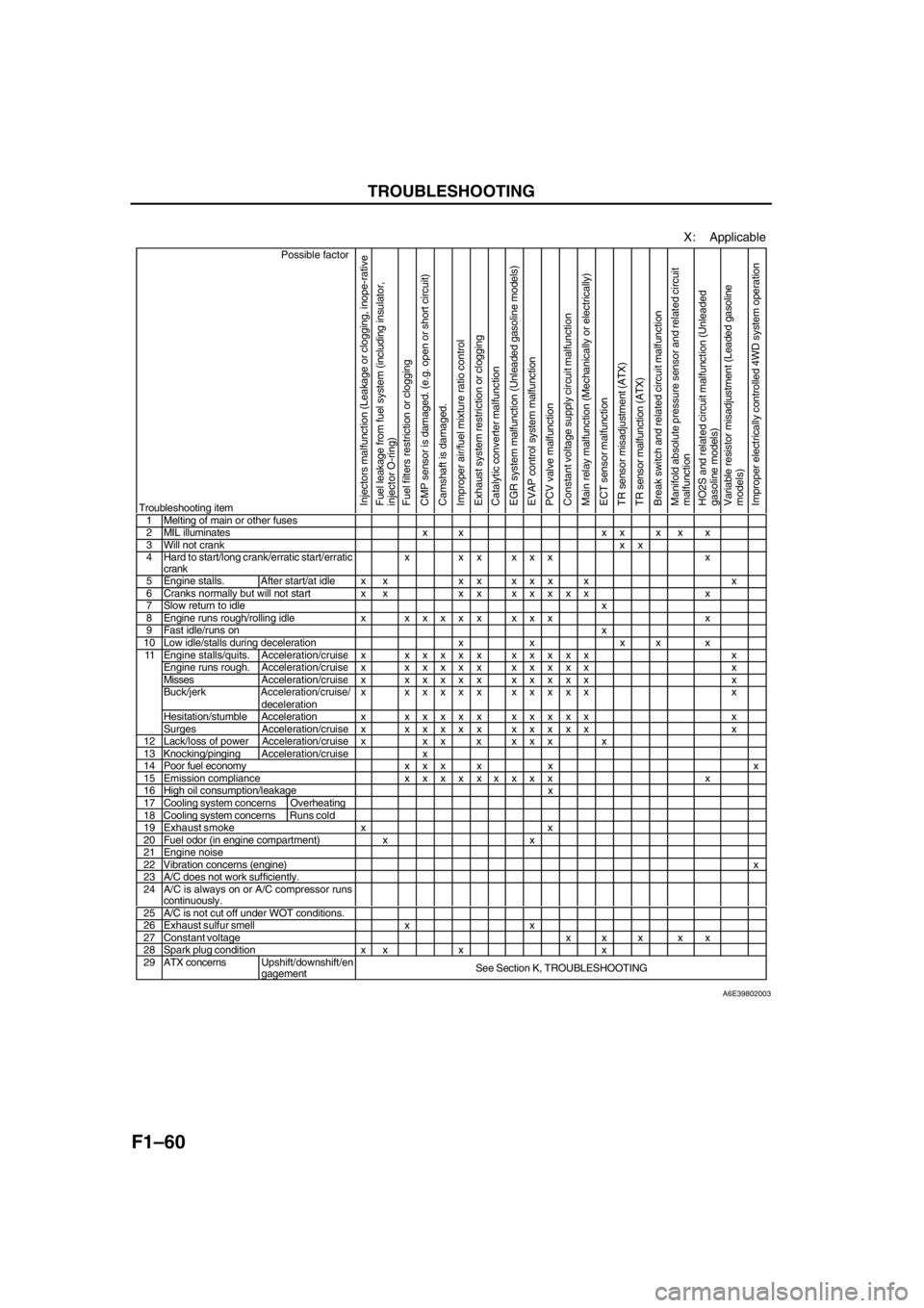

X: Applicable

Possible factor

Troubleshooting item

Injectors malfunction (Leakage or clogging, inope-rative

Fuel leakage from fuel system (including insulator,

injector O-ring)

Fuel filters restriction or clogging

CMP sensor is damaged. (e.g. open or short circuit)

Camshaft is damaged.

Improper air/fuel mixture ratio control

Exhaust system restriction or clogging

Catalytic converter malfunction

EGR system malfunction (Unleaded gasoline models)

EVAP control system malfunction

PCV valve malfunction

Constant voltage supply circuit malfunction

Main relay malfunction (Mechanically or electrically)

ECT sensor malfunction

TR sensor misadjustment (ATX)

TR sensor malfunction (ATX)

Break switch and related circuit malfunction

Manifold absolute pressure sensor and related circuit

malfunction

HO2S and related circuit malfunction (Unleaded

gasoline models)

Variable resistor misadjustment (Leaded gasoline

models)

Improper electrically controlled 4WD system operation

1 Melting of main or other fuses2 MIL illuminates x x x x x x x3 Will not crankxx4 Hard to start/long crank/erratic start/erratic

crankx xx xxx x

5 Engine stalls. After start/at idle x x x x x x x x x6 Cranks normally but will not start x x x xxxxxx x7 Slow return to idlex8 Engine runs rough/rolling idle xxxxxx xxx x9 Fast idle/runs onx10 Low idle/stalls during deceleration x x x x xEngine stalls/quits.Acceleration/cruisex xxxxx xxxxx xEngine runs rough. Acceleration/cruisex xxxxx xxxxx xMissesAcceleration/cruisex xxxxx xxxxx xBuck/jerk Acceleration/cruise/

decelerationx xxxxx xxxxx x

Hesitation/stumble Acceleration xxxxxx xxxxx x

11

Surges Acceleration/cruise xxxxxx xxxxx x

12 Lack/loss of power Acceleration/cruise x x x x x x x x13 Knocking/pingingAcceleration/cruise x14 Poor fuel economy x x x x x x15 Emission compliancexxxxxxxxx x16 High oil consumption/leakage x17 Cooling system concerns Overheating18 Cooling system concernsRuns cold19 Exhaust smoke x x20 Fuel odor (in engine compartment) x x21 Engine noise22 Vibration concerns (engine)x23 A/C does not work sufficiently.24 A/C is always on or A/C compressor runs

continuously.

25 A/C is not cut off under WOT conditions.26 Exhaust sulfur smell x x27 Constant voltage x x x x x28 Spark plug condition x x x x29 ATX concernsUpshift/downshift/en

gagementSee Section K, TROUBLESHOOTING

A6E39802003

Page 150 of 909

F1–62

TROUBLESHOOTING

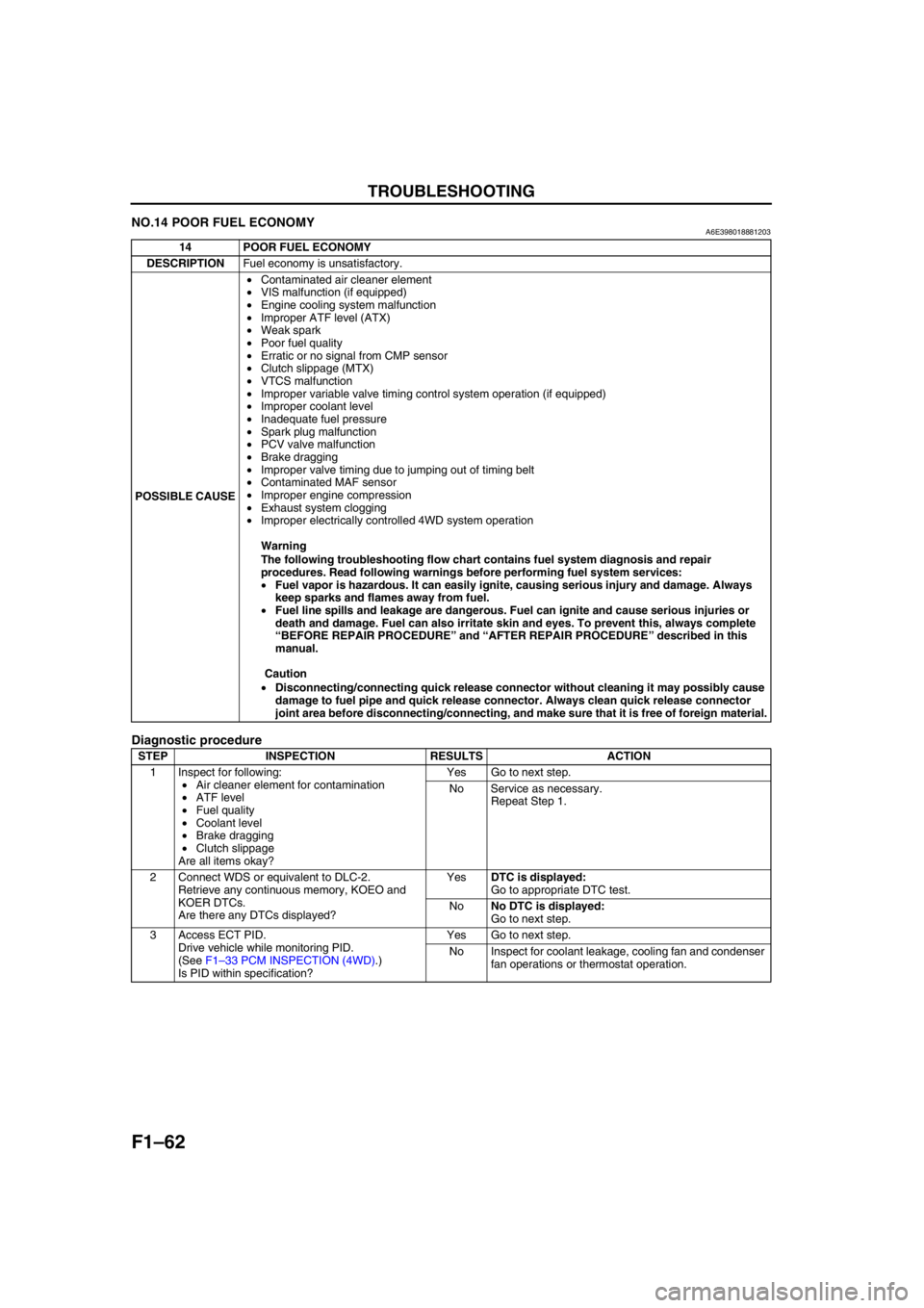

NO.14 POOR FUEL ECONOMYA6E398018881203

Diagnostic procedure

14 POOR FUEL ECONOMY

DESCRIPTIONFuel economy is unsatisfactory.

POSSIBLE CAUSE•Contaminated air cleaner element

•VIS malfunction (if equipped)

•Engine cooling system malfunction

•Improper ATF level (ATX)

•Weak spark

•Poor fuel quality

•Erratic or no signal from CMP sensor

•Clutch slippage (MTX)

•VTCS malfunction

•Improper variable valve timing control system operation (if equipped)

•Improper coolant level

•Inadequate fuel pressure

•Spark plug malfunction

•PCV valve malfunction

•Brake dragging

•Improper valve timing due to jumping out of timing belt

•Contaminated MAF sensor

•Improper engine compression

•Exhaust system clogging

•Improper electrically controlled 4WD system operation

Warning

The following troubleshooting flow chart contains fuel system diagnosis and repair

procedures. Read following warnings before performing fuel system services:

•Fuel vapor is hazardous. It can easily ignite, causing serious injury and damage. Always

keep sparks and flames away from fuel.

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or

death and damage. Fuel can also irritate skin and eyes. To prevent this, always complete

“BEFORE REPAIR PROCEDURE” and “AFTER REPAIR PROCEDURE” described in this

manual.

Caution

•Disconnecting/connecting quick release connector without cleaning it may possibly cause

damage to fuel pipe and quick release connector. Always clean quick release connector

joint area before disconnecting/connecting, and make sure that it is free of foreign material.

STEP INSPECTION RESULTS ACTION

1 Inspect for following:

•Air cleaner element for contamination

•ATF level

•Fuel quality

•Coolant level

•Brake dragging

•Clutch slippage

Are all items okay?Yes Go to next step.

No Service as necessary.

Repeat Step 1.

2 Connect WDS or equivalent to DLC-2.

Retrieve any continuous memory, KOEO and

KOER DTCs.

Are there any DTCs displayed?YesDTC is displayed:

Go to appropriate DTC test.

NoNo DTC is displayed:

Go to next step.

3 Access ECT PID.

Drive vehicle while monitoring PID.

(See F1–33 PCM INSPECTION (4WD).)

Is PID within specification?Yes Go to next step.

No Inspect for coolant leakage, cooling fan and condenser

fan operations or thermostat operation.

Page 151 of 909

TROUBLESHOOTING

F1–63

F1

End Of Sie

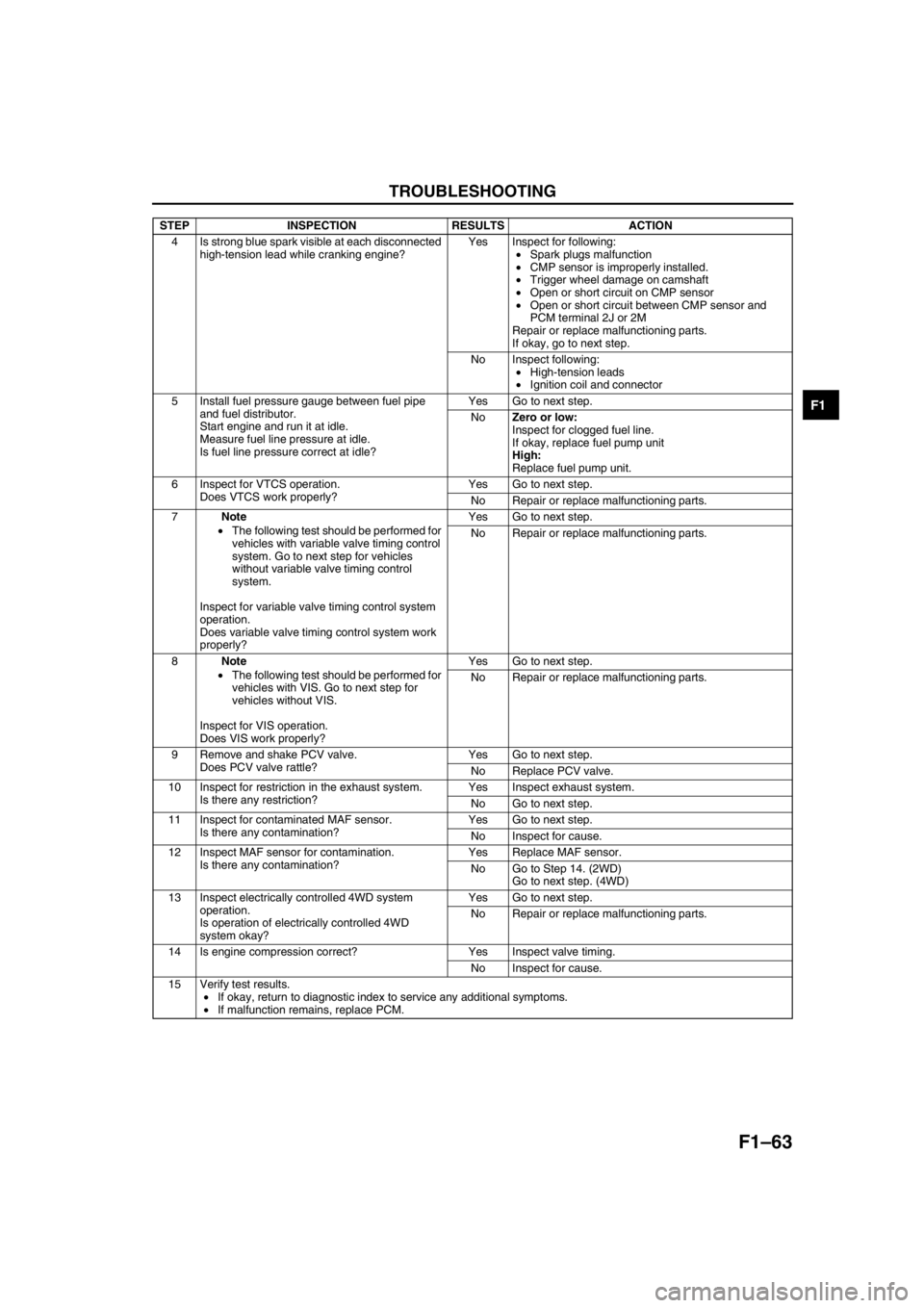

4 Is strong blue spark visible at each disconnected

high-tension lead while cranking engine?Yes Inspect for following:

•Spark plugs malfunction

•CMP sensor is improperly installed.

•Trigger wheel damage on camshaft

•Open or short circuit on CMP sensor

•Open or short circuit between CMP sensor and

PCM terminal 2J or 2M

Repair or replace malfunctioning parts.

If okay, go to next step.

No Inspect following:

•High-tension leads

•Ignition coil and connector

5 Install fuel pressure gauge between fuel pipe

and fuel distributor.

Start engine and run it at idle.

Measure fuel line pressure at idle.

Is fuel line pressure correct at idle?Yes Go to next step.

NoZero or low:

Inspect for clogged fuel line.

If okay, replace fuel pump unit

High:

Replace fuel pump unit.

6 Inspect for VTCS operation.

Does VTCS work properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

7Note

•The following test should be performed for

vehicles with variable valve timing control

system. Go to next step for vehicles

without variable valve timing control

system.

Inspect for variable valve timing control system

operation.

Does variable valve timing control system work

properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

8Note

•The following test should be performed for

vehicles with VIS. Go to next step for

vehicles without VIS.

Inspect for VIS operation.

Does VIS work properly?Yes Go to next step.

No Repair or replace malfunctioning parts.

9 Remove and shake PCV valve.

Does PCV valve rattle?Yes Go to next step.

No Replace PCV valve.

10 Inspect for restriction in the exhaust system.

Is there any restriction?Yes Inspect exhaust system.

No Go to next step.

11 Inspect for contaminated MAF sensor.

Is there any contamination?Yes Go to next step.

No Inspect for cause.

12 Inspect MAF sensor for contamination.

Is there any contamination?Yes Replace MAF sensor.

No Go to Step 14. (2WD)

Go to next step. (4WD)

13 Inspect electrically controlled 4WD system

operation.

Is operation of electrically controlled 4WD

system okay?Yes Go to next step.

No Repair or replace malfunctioning parts.

14 Is engine compression correct? Yes Inspect valve timing.

No Inspect for cause.

15 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM. STEP INSPECTION RESULTS ACTION

Page 152 of 909

F1–64

TROUBLESHOOTING

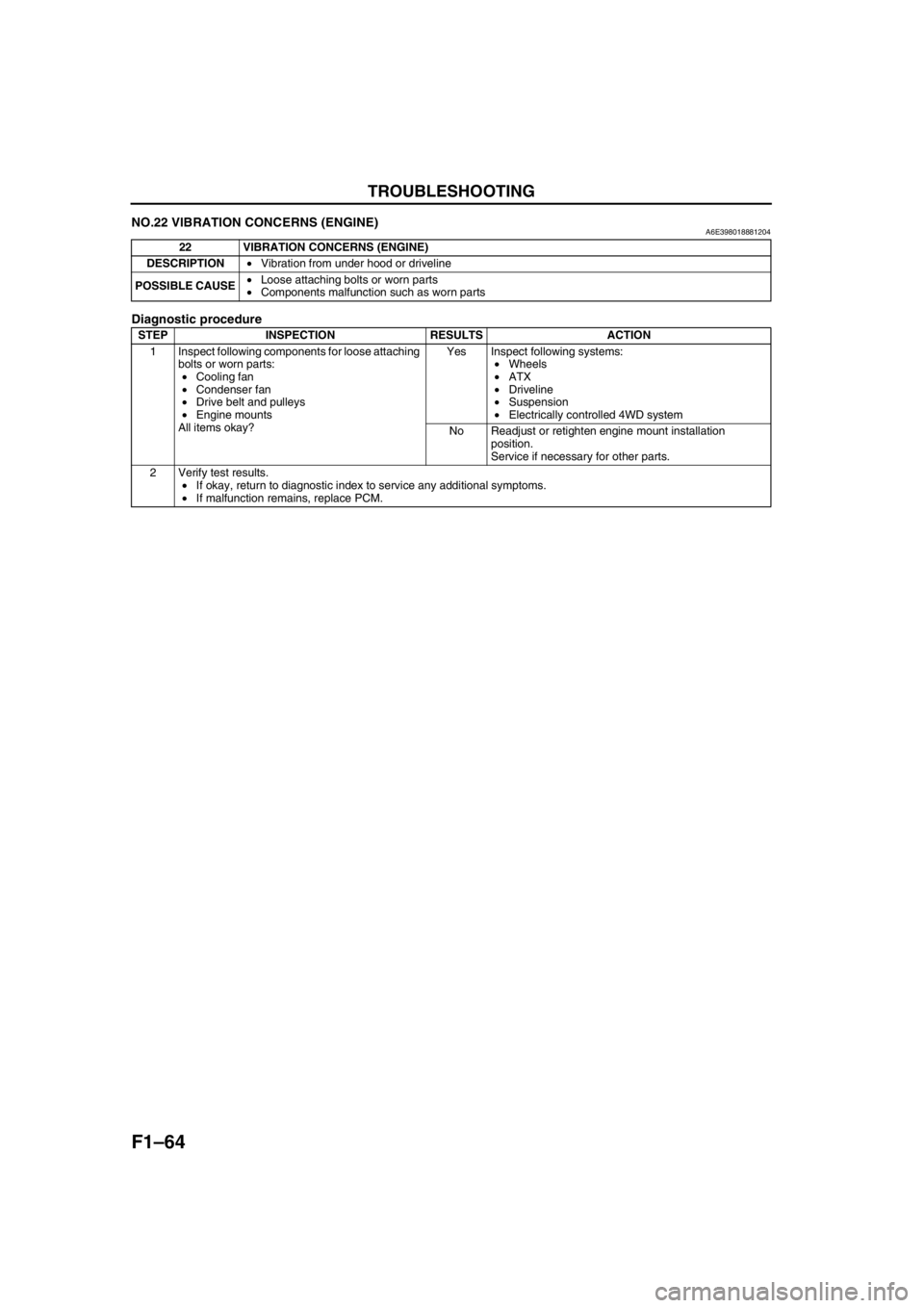

NO.22 VIBRATION CONCERNS (ENGINE)A6E398018881204

Diagnostic procedure

End Of Sie

22 VIBRATION CONCERNS (ENGINE)

DESCRIPTION•Vibration from under hood or driveline

POSSIBLE CAUSE•Loose attaching bolts or worn parts

•Components malfunction such as worn parts

STEP INSPECTION RESULTS ACTION

1 Inspect following components for loose attaching

bolts or worn parts:

•Cooling fan

•Condenser fan

•Drive belt and pulleys

•Engine mounts

All items okay?Yes Inspect following systems:

•Wheels

•ATX

•Driveline

•Suspension

•Electrically controlled 4WD system

No Readjust or retighten engine mount installation

position.

Service if necessary for other parts.

2 Verify test results.

•If okay, return to diagnostic index to service any additional symptoms.

•If malfunction remains, replace PCM.

Page 392 of 909

STARTING SYSTEM

G–9

G

STARTER REMOVAL/INSTALLATIONA6E471418400202

Warning

•When the battery cables are connected, touching the vehicle body with starter terminal B will

generate sparks. This can cause personal injury, fire, and damage to the electrical components.

Always disconnect the battery negative cables before performing the following operation.

1. Disconnect the negative battery cable.

2. Remove the plug hole plate. (L8, LF, and L3 engine models)

3. Remove the engine cover. (MZR-CD (RF Turbo) engine model) (See B2–9 TIMING BELT REMOVAL/

INSTALLATION.)

4. Remove the air cleaner assembly. (L8, LF, and L3 engine models).

5. Remove the under cover.

6. Remove the oil filter and oil cooler component with the cooling hose connected. Position the oil filter and oil

cooler component so that it is out of the way. (L3 engine model (4WD))

7. Remove the solenoid valve assembly with the vacuum hose and the connector connected. Position the

solenoid valve assembly so that it is out of the way. (MZR-CD (RF Turbo) engine model)

8. Remove the release cylinder with the oil pipe connected. Position the release cylinder so that it is out of the

way. (MTX)

9. Remove in the order indicated in the table.

10. Install in the reverse order of removal.

STARTING SYSTEM