engine MAZDA 6 2002 Suplement Owner's Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 27 of 909

ENGINE

B1–5

B1

6

5

4

3

1

2

74.5—104.9

{7.6—10.6, 55.0—76.6}

N·m {kgf·m, ft·lbf} 85.3—116.6

{8.7—11.8, 62.9—85.9}58.8—80.4

{6.0—8.1, 43.3—58.5} 74.5—104.9

{7.6—10.6,

55.0—76.6}66.6—93.1

{6.8—9.4, 49.2—67.9}

66.6—93.1

{6.8—9.4,

49.2—67.9}58.8—80.4

{6.0—8.1, 43.3—58.5}

8.0—11.5 N·m

{81.6—117.2 kgf·cm,

70.9—101.7 in·lbf}

A6E2213W001

1 No.1 Engine mount rubber

(See B1–6 No.1 Engine Mount Rubber Removal

Note)

(See B1–9 No.1 Engine Mount Rubber Installation

Note)

2 No.1 Engine mount bracket

(See B1–9 No.1 Engine Mount Bracket Installation

Note)

3 No.4 Engine mount bracket and No.4 Engine mount

rubber

(See B1–6 No.4 Engine Mount Bracket and No.4

Engine Mount Rubber Removal Note)

(See B1–8 No.4 Engine Mount Bracket and No.4

Engine Mount Rubber Installation Note)4 Engine ground

5 No.3 Engine joint bracket

(See B1–8 No.3 Engine Joint Bracket Installation

Note)

6 Engine, transaxle

Page 28 of 909

B1–6

ENGINE

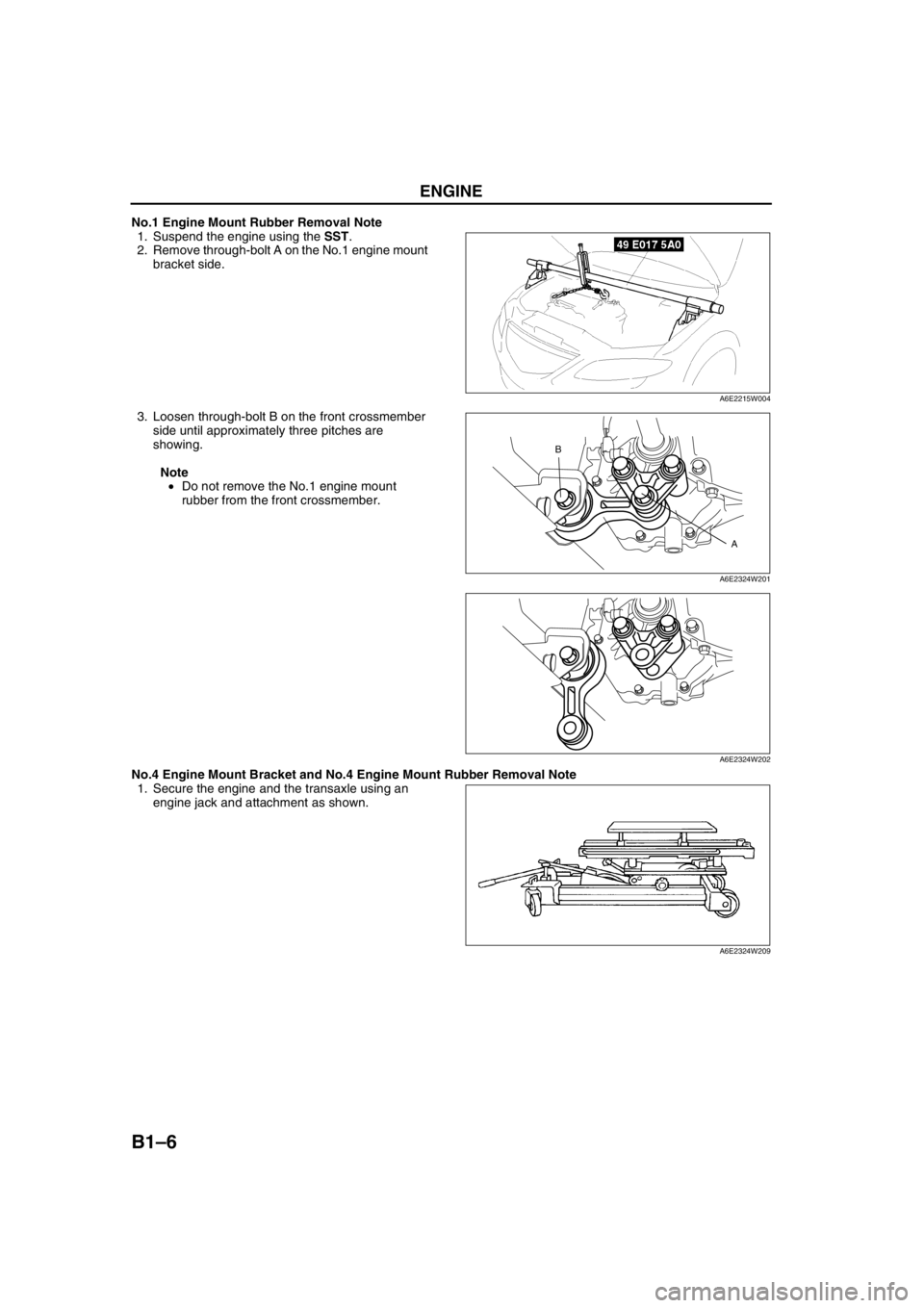

No.1 Engine Mount Rubber Removal Note

1. Suspend the engine using the SST.

2. Remove through-bolt A on the No.1 engine mount

bracket side.

3. Loosen through-bolt B on the front crossmember

side until approximately three pitches are

showing.

Note

•Do not remove the No.1 engine mount

rubber from the front crossmember.

No.4 Engine Mount Bracket and No.4 Engine Mount Rubber Removal Note

1. Secure the engine and the transaxle using an

engine jack and attachment as shown.

A6E2215W004

A B

A6E2324W201

A6E2324W202

A6E2324W209

Page 29 of 909

ENGINE

B1–7

B1

2. Remove the SST.

3. Secure the engine and the transaxle using a

hoist.

4. Remove the No.4 engine mount bracket and

engine mount rubber together as a unit.

A6E2215W004

A6E2324W203

A6E2324W204

Page 30 of 909

B1–8

ENGINE

No.3 Engine Joint Bracket Installation Note

1. Tighten the No.3 engine mount bracket stud bolt.

Tightening torque

7.0—13 N·m {71.4—132.5 kgf·cm, 62.0—115.0

in·lbf}

2. Tighten the No.3 engine joint bracket bolt and nut

in the order as shown.

Tightening torque

74.5—104.9 N·m {7.6—10.6 kgf·m, 55.0—76.6

ft·lbf}

No.4 Engine Mount Bracket and No.4 Engine Mount Rubber Installation Note

1. Tighten the No.4 engine mount bracket and No.4

engine mount rubber bolt and nut in the order as

shown.

2. Secure the engine and the transaxle using an

engine jack and attachment as shown.

No.3

ENGINE

MOUNT

BRACKET

STUD

BOLT

A6E2215W011

12

A6E2316W111

Bolt or nut No.Tightening torque

(N·m {kgf·m, ft·lbf})

1, 2, 358.8—80.4 {6.0—8.1, 43.3—58.5}

4, 5, 666.6—93.1 {6.8—9.4, 49.2—67.9}

5431

2

6

A6E2324W206

A6E2324W209

Page 31 of 909

ENGINE

B1–9

B1

3. Remove the hoist and secure the engine and

transaxle using SST.

No.1 Engine Mount Bracket Installation Note

1. Tighten No.1 engine mount bracket bolt A.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m, 68.7—85.9

ft·lbf}

2. Tighten No.1 engine mount bracket bolt B.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m, 68.7—85.9

ft·lbf}

No.1 Engine Mount Rubber Installation Note

1. Tighten through-bolt A on the No.1 engine mount

bracket.

Tightening torque

85.3—116.6 N·m {8.7—11.8 kgf·m, 62.9—85.9

ft·lbf}

2. Tighten through-bolt B on the front crossmember

side.

Tightening torque

93.1—116.6 N·m {9.5—11.8 kgf·m, 68.7—85.9

ft·lbf}

End Of Sie

A6E2215W004

A

B

A6E2324W207

A B

A6E2324W201

Page 32 of 909

![MAZDA 6 2002 Suplement Owners Manual B2–1

B2

B2ENGINE [MZR-CD (RF Turbo)]

OUTLINE.............................................................. B2-2

OUTLINE OF CONSTRUCTION........................ B2-2

FEATURES ........................ MAZDA 6 2002 Suplement Owners Manual B2–1

B2

B2ENGINE [MZR-CD (RF Turbo)]

OUTLINE.............................................................. B2-2

OUTLINE OF CONSTRUCTION........................ B2-2

FEATURES ........................](/img/28/57057/w960_57057-31.png)

B2–1

B2

B2ENGINE [MZR-CD (RF Turbo)]

OUTLINE.............................................................. B2-2

OUTLINE OF CONSTRUCTION........................ B2-2

FEATURES ........................................................ B2-2

SPECIFICATIONS ............................................. B2-2

LOCATION INDEX............................................... B2-3

LOCATION INDEX ............................................. B2-3

DRIVE BELT......................................................... B2-4

DRIVE BELT INSPECTION ............................... B2-4

DRIVE BELT REPLACEMENT .......................... B2-4

DRIVE BELT AUTO TENSIONER

INSPECTION .................................................. B2-5

VALVE CLEARANCE........................................... B2-5

VALVE CLEARANCE INSPECTION.................. B2-5

VALVE CLEARANCE ADJUSTMENT ............... B2-6

COMPRESSION PRESSURE.............................. B2-8

COMPRESSION INSPECTION ......................... B2-8

TIMING BELT....................................................... B2-9

TIMING BELT REMOVAL/INSTALLATION ....... B2-9

CYLINDER HEAD GASKET............................... B2-15

CYLINDER HEAD GASKET REPLACEMENT B2-15

FRONT OIL SEAL.............................................. B2-24

FRONT OIL SEAL REPLACEMENT ................ B2-24

REAR OIL SEAL................................................ B2-26

REAR OIL SEAL REPLACEMENT .................. B2-26

ENGINE.............................................................. B2-27

ENGINE REMOVAL/INSTALLATION .............. B2-27

ENGINE DISASSEMBLY/ASSEMBLY............. B2-32 FEATURES

SERVICE

Page 33 of 909

B2–2

OUTLINE

OUTLINE OF CONSTRUCTIONA6E230202000201•MZR-CD (RF Turbo) engine is newly adopted as Mazda6 (GG, GY).

•The construction of MZR-CD (RF Turbo) engine and operation which were newly adopted for the Mazda6 (GG,

GY) are the same as the current Mazda MPV(LW) MZR-CD (RF Turbo) engine model and current Mazda 323

(BJ) RF Turbo engine model except for the following components. (See Mazda MPV Workshop Manual

Supplement 1737-1*-02C.), (See Mazda 323 Workshop Manual Supplement 1633-10-98G.)

—Engine mount

•The construction and the operation of the engine mount for the new Mazda6 (GG, GY) MZR-CD (RF Turbo)

engine model is the same as the current Mazda6 (GG). (See Mazda6 Training Manual 3359-1*-02C)

End Of Sie

FEATURESA6E230202000202Improved engine performance

•Coated pistons have been adopted.

Reduced engine noise and vibration

•An aluminium alloy oil pan upper block has been adopted.

•An eight counter weight crankshaft has been adopted.

•A crankshaft pulley cover has been adopted.

•An engine cover with insulator has been adopted.

•A pendulum type engine mount has been adopted.

Improved serviceability

•A serpentine type drive belt has been adopted.

•An auto tensioner that automatically adjusts the drive belt tension has been adopted.

Improved design

•An engine cover has been adopted.

End Of Sie

SPECIFICATIONSA6E230202000203

End Of Sie

OUTLINE

ItemSpecifications

New Mazda6 (GG, GY) Current Mazda MPV (LW)

MZR-CD (RF Turbo) MZR-CD (RF Turbo)

TypeDiesel, 4-cycle

Cylinder arrangement and number In-line, 4-cylinder

Combustion chamber Direct injection

Valve system SOHC, belt-driven, 16-valve

Displacement (ml {cc, cu in}) 1,998 {1.998, 122.9}

Bore × stroke (mm {in}) 86.0 × 86.0 {3.39 × 3.39}

Compression ratio 18.4

Compression pressure

(kPa {kgf/cm

2, psi} [rpm])3,500 {35.7, 507.7} [250]

Valve timingINOpen BTDC (°)6

Close ABDC (°)30

EXOpen BBDC (°)41

Close ATDC (°)8

Valve clearance

[engine cold]IN (mm {in}) 0.12 —0.18 {0.005—0.007} (0.15±0.03 {0.006±0.0011})

EX (mm {in}) 0.32—0.38 {0.013—0.014} (0.35±0.03 {0.014±0.0011})

Page 34 of 909

LOCATION INDEX

B2–3

B2

LOCATION INDEXA6E230001002201

.

LOCATION INDEX

7

5

4

3

1

2

6

A6E2500W100

1Drive belt

(See B2–4 DRIVE BELT INSPECTION)

(See B2–4 DRIVE BELT REPLACEMENT)

(See B2–4 DRIVE BELT AUTO TENSIONER

INSPECTION)

2 Rocker arm

(See B2–5 VALVE CLEARANCE INSPECTION)

(See B2–6 VALVE CLEARANCE ADJUSTMENT)

3 Engine

(See B2–8 COMPRESSION INSPECTION)

(See B2–27 ENGINE REMOVAL/INSTALLATION)

(See B2–32 ENGINE DISASSEMBLY/ASSEMBLY)

4 Timing Belt

(See B2–9 TIMING BELT REMOVAL/

INSTALLATION)

5 Cylinder head gasket

(See B2–15 CYLINDER HEAD GASKET

REPLACEMENT)

6 Front oil seal

(See B2–24 FRONT OIL SEAL REPLACEMENT)

7 Rear oil seal

(See B2–26 REAR OIL SEAL REPLACEMENT)

Page 36 of 909

DRIVE BELT, VALVE CLEARANCE

B2–5

B2

3. Turn the drive belt auto tensioner pulley by hand

and verify that it rotates smoothly.

•Replace the drive belt auto tensioner if

necessary.

4. Install the drive belt.

End Of Sie

VALVE CLEARANCE INSPECTIONA6E2312121112011. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove the timing belt cover bolt as shown.

3. Remove the cylinder head cover. (See B2–15

CYLINDER HEAD GASKET REPLACEMENT.)

4. Turn the crankshaft and align the timing mark so

that the piston of the No.1 or No.4 cylinder is at

TDC of compression.

5. Measure valve clearances A with the No.1

cylinder at TDC of compression, and those of B

with the No.4 cylinder at TDC of compression.

•If the valve clearance is not within the

specification, adjust the valves. (See B2–6

VALVE CLEARANCE ADJUSTMENT.)

Standard valve clearance [Engine cold]

IN: 0.12—0.18 mm {0.005—0.007 in}

(0.15±0.03 mm {0.006±0.0011 in})

EX: 0.32—0.38 mm {0.013—0.014 in}

(0.35±0.03 mm {0.014±0.0011 in})

6. Turn the crankshaft one full turn and measure the

remaining valve clearances.

•Adjust if necessary. (See B2–6 VALVE

CLEARANCE ADJUSTMENT.)

7. Install the cylinder head cover. (See B2–21 Cylinder Head Cover Installation Note.)

A6E2310W103

VALVE CLEARANCE

TIMING BELT

COVER BOLT

UPPER TIMING BELT COVER

A6E2312W200

A

A B

B

A6E2312W201

MEASURING

POINT

A6E2312W101

Page 37 of 909

B2–6

VALVE CLEARANCE

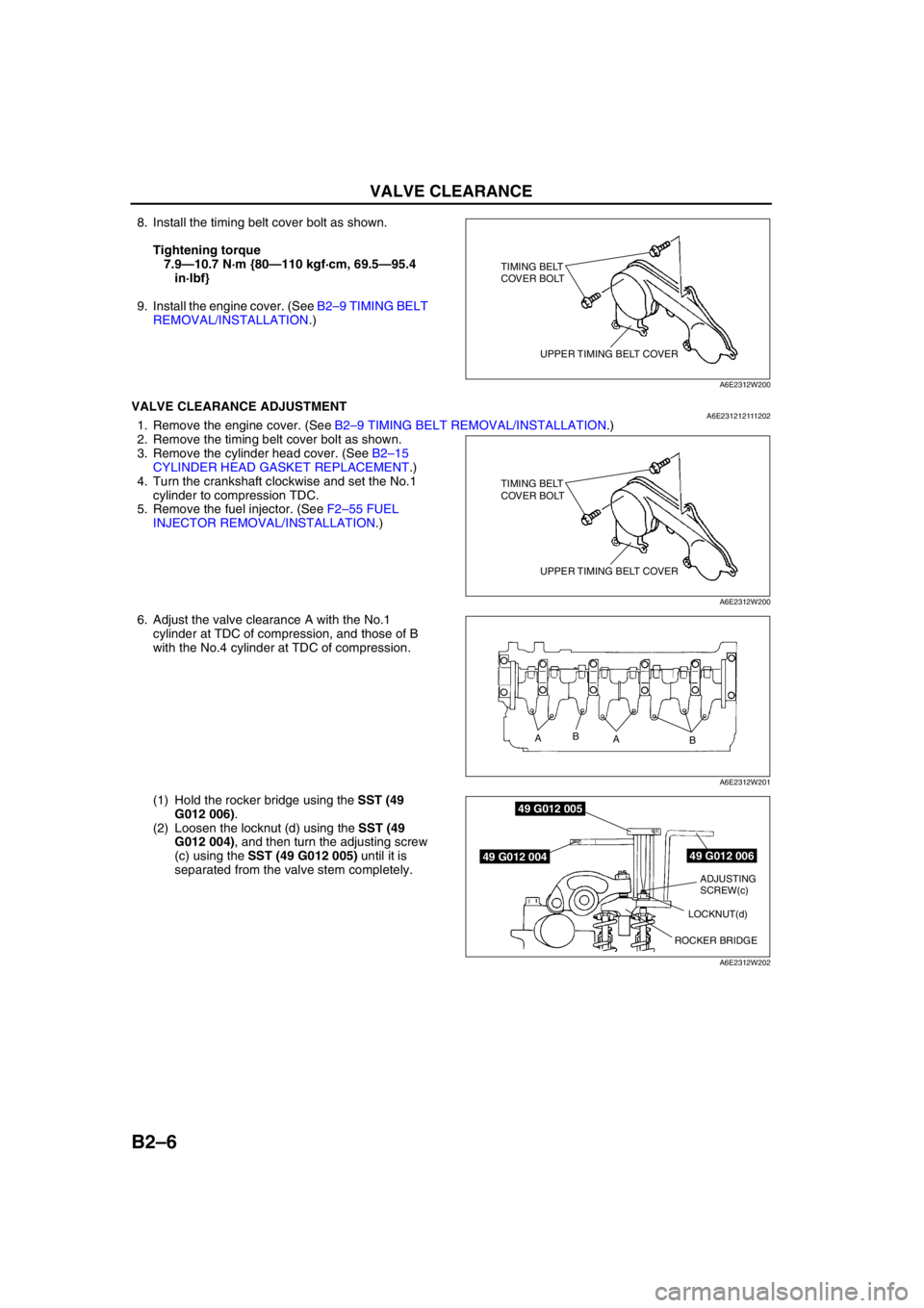

8. Install the timing belt cover bolt as shown.

Tightening torque

7.9—10.7 N·m {80—110 kgf·cm, 69.5—95.4

in·lbf}

9. Install the engine cover. (See B2–9 TIMING BELT

REMOVAL/INSTALLATION.)

End Of SieVALVE CLEARANCE ADJUSTMENTA6E2312121112021. Remove the engine cover. (See B2–9 TIMING BELT REMOVAL/INSTALLATION.)

2. Remove the timing belt cover bolt as shown.

3. Remove the cylinder head cover. (See B2–15

CYLINDER HEAD GASKET REPLACEMENT.)

4. Turn the crankshaft clockwise and set the No.1

cylinder to compression TDC.

5. Remove the fuel injector. (See F2–55 FUEL

INJECTOR REMOVAL/INSTALLATION.)

6. Adjust the valve clearance A with the No.1

cylinder at TDC of compression, and those of B

with the No.4 cylinder at TDC of compression.

(1) Hold the rocker bridge using the SST (49

G012 006).

(2) Loosen the locknut (d) using the SST (49

G012 004), and then turn the adjusting screw

(c) using the SST (49 G012 005) until it is

separated from the valve stem completely.

TIMING BELT

COVER BOLT

UPPER TIMING BELT COVER

A6E2312W200

TIMING BELT

COVER BOLT

UPPER TIMING BELT COVER

A6E2312W200

A

A B

B

A6E2312W201

49 G012 006

49 G012 005

49 G012 004

ADJUSTING

SCREW(c)

ROCKER BRIDGELOCKNUT(d)

NORMAL

A6E2312W202