light MAZDA 6 2002 Suplement Service Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 409 of 909

MANUAL TRANSAXLE

J2–7

J2

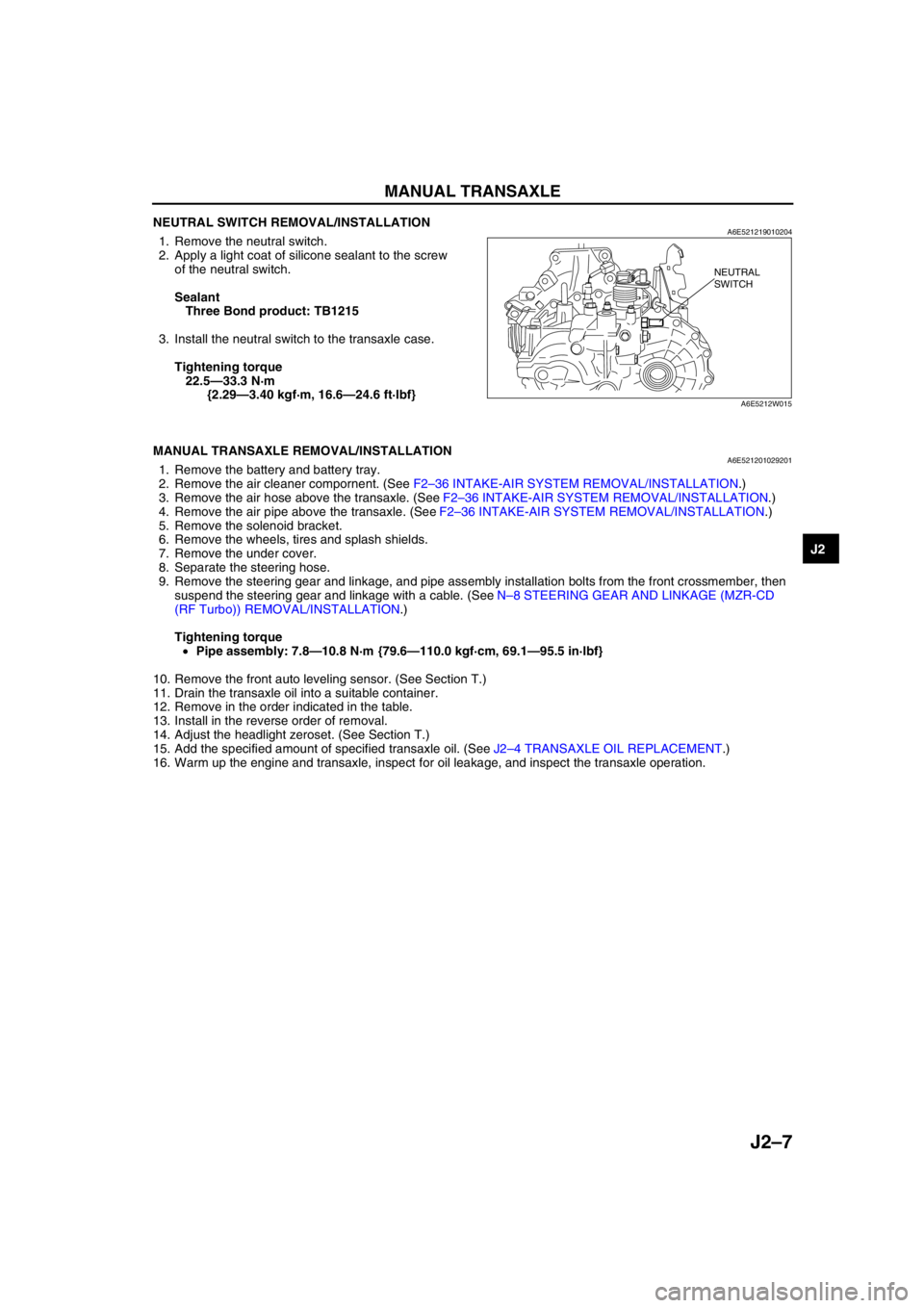

NEUTRAL SWITCH REMOVAL/INSTALLATIONA6E5212190102041. Remove the neutral switch.

2. Apply a light coat of silicone sealant to the screw

of the neutral switch.

Sealant

Three Bond product: TB1215

3. Install the neutral switch to the transaxle case.

Tightening torque

22.5—33.3 N·m

{2.29—3.40 kgf·m, 16.6—24.6 ft·lbf}

End Of Sie

MANUAL TRANSAXLE REMOVAL/INSTALLATIONA6E5212010292011. Remove the battery and battery tray.

2. Remove the air cleaner compornent. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

3. Remove the air hose above the transaxle. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

4. Remove the air pipe above the transaxle. (See F2–36 INTAKE-AIR SYSTEM REMOVAL/INSTALLATION.)

5. Remove the solenoid bracket.

6. Remove the wheels, tires and splash shields.

7. Remove the under cover.

8. Separate the steering hose.

9. Remove the steering gear and linkage, and pipe assembly installation bolts from the front crossmember, then

suspend the steering gear and linkage with a cable. (See N–8 STEERING GEAR AND LINKAGE (MZR-CD

(RF Turbo)) REMOVAL/INSTALLATION.)

Tightening torque

•Pipe assembly: 7.8—10.8 N·m {79.6—110.0 kgf·cm, 69.1—95.5 in·lbf}

10. Remove the front auto leveling sensor. (See Section T.)

11. Drain the transaxle oil into a suitable container.

12. Remove in the order indicated in the table.

13. Install in the reverse order of removal.

14. Adjust the headlight zeroset. (See Section T.)

15. Add the specified amount of specified transaxle oil. (See J2–4 TRANSAXLE OIL REPLACEMENT.)

16. Warm up the engine and transaxle, inspect for oil leakage, and inspect the transaxle operation.

NEUTRAL

SWITCH

A6E5212W015

Page 412 of 909

J2–10

MANUAL TRANSAXLE

Manual Transaxle Installation Note

1. Set the transaxle on a jack and lift into place.

2. Install the transaxle mounting bolts.

3. Install the stud of the No.4 engine mount.

Tightening torque

27.4—40.2 N·m

{2.80—4.09 kgf·m, 20.2—29.6 ft·lbf}

4. Tighten the SST (49 E017 5A0)so that the engine

is located at the specified position.

No.4 Engine Mount Installation Note

1. Verify that the No.4 engine mount rubber is installed as shown.

2. Lightly tighten the bolt A and B.

3. Align the contacted area to front frame of the bolt C to the front frame.

4. Tighten the bolt A, then bolt B.

5. Tighten the bolt C, then bolt D.

Tightening torque

A,B,C,D: 58.8—80.4 N·m

{6.00—8.19 kgf·m, 43.4—59.2 ft·lbf}

6. Verify that the No.4 engine mount bracket is

installed as shown.

7. Lightly tighten the bolt E.

8. Set the transaxle on a garage jack and lift it.

9. Align the hole of the No.4 engine mount bracket

with the stud bolts of transaxle.

10. Lightly tighten the nut F, G and bolt H.

11. Tighten the nut F, G in order of F→G, then bolt H.

A6E5212W022

STUD

A6E5212W020

D

H

C

FB

A

GE

A6E5212W024

TRANSAXLE

GARAGE JACK

A6E5212W023

Page 413 of 909

MANUAL TRANSAXLE

J2–11

J2

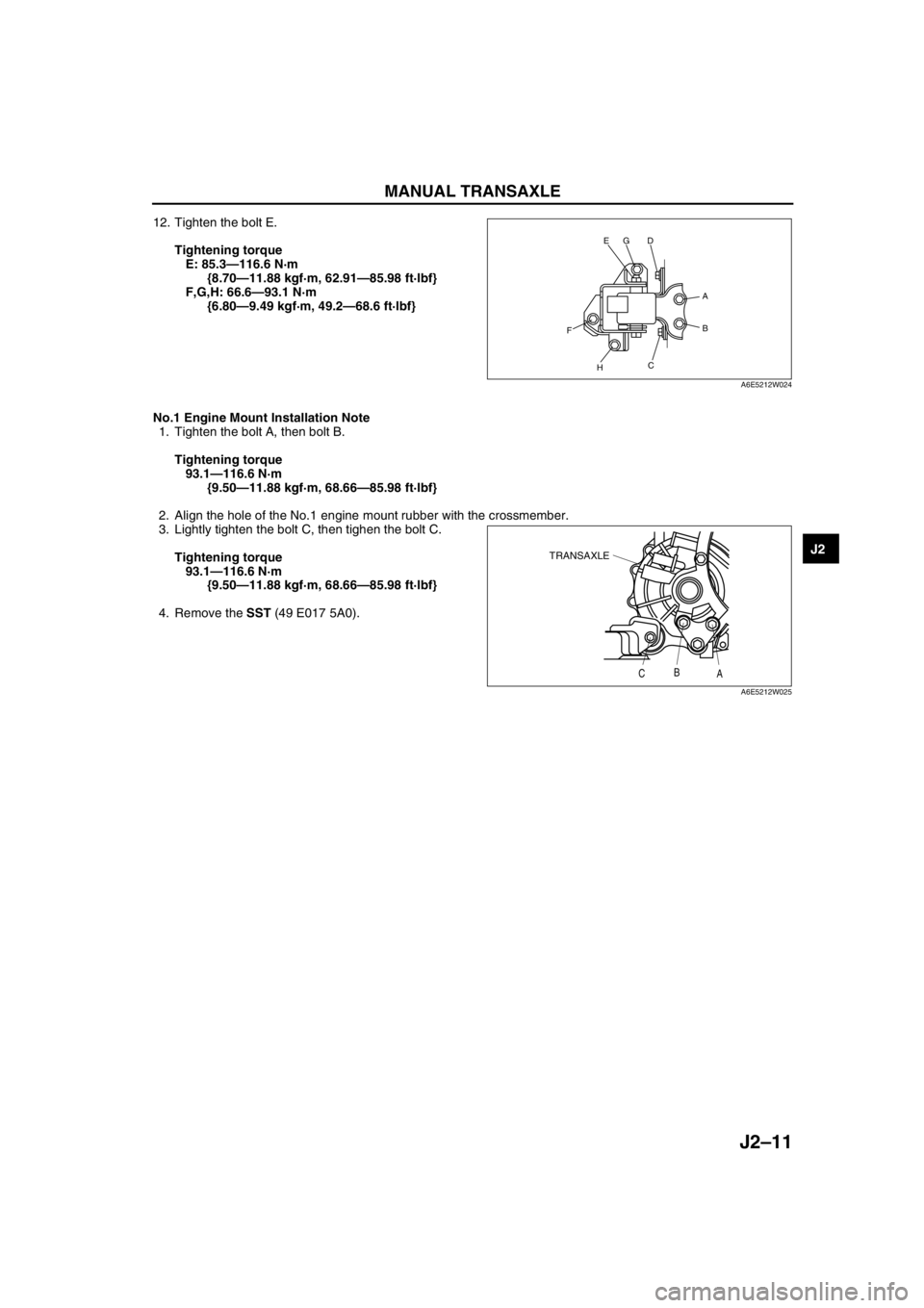

12. Tighten the bolt E.

Tightening torque

E: 85.3—116.6 N·m

{8.70—11.88 kgf·m, 62.91—85.98 ft·lbf}

F,G,H: 66.6—93.1 N·m

{6.80—9.49 kgf·m, 49.2—68.6 ft·lbf}

No.1 Engine Mount Installation Note

1. Tighten the bolt A, then bolt B.

Tightening torque

93.1—116.6 N·m

{9.50—11.88 kgf·m, 68.66—85.98 ft·lbf}

2. Align the hole of the No.1 engine mount rubber with the crossmember.

3. Lightly tighten the bolt C, then tighen the bolt C.

Tightening torque

93.1—116.6 N·m

{9.50—11.88 kgf·m, 68.66—85.98 ft·lbf}

4. Remove the SST (49 E017 5A0).

End Of Sie

D

H

C

FB

A

GE

A6E5212W024

TRANSAXLE

CB

A

A6E5212W025

Page 417 of 909

K2–2

AUTOMATIC TRANSAXLE ON-BOARD

DIAGNOSTIC FUNCTION .......................... K2-123

AFTER REPAIR PROCEDURE ..................... K2-124

DTC TABLE ................................................... K2-126

DTC P0705 .................................................... K2-127

DTC P0706 .................................................... K2-129

DTC P0711 .................................................... K2-132

DTC P0712 .................................................... K2-133

DTC P0713 .................................................... K2-135

DTC P0715 .................................................... K2-137

DTC P0720 .................................................... K2-139

DTC P0740 .................................................... K2-142

DTC P0743 .................................................... K2-144

DTC P0748 .................................................... K2-146

DTC P0751 .................................................... K2-149

DTC P0752 .................................................... K2-150

DTC P0753 .................................................... K2-151

DTC P0756 .................................................... K2-153

DTC P0757 .................................................... K2-154

DTC P0758 .................................................... K2-155

DTC P0761 .................................................... K2-158

DTC P0762 .................................................... K2-159

DTC P0763 .................................................... K2-160

DTC P0768 .................................................... K2-163

DTC P0773 .................................................... K2-166

DTC P0778 .................................................... K2-169

DTC P0791 .................................................... K2-172

DTC P0798 .................................................... K2-175

DTC P1710 .................................................... K2-178

PID/DATA MONITOR INSPECTION.............. K2-180

TROUBLESHOOTING...................................... K2-182

FOREWORD .................................................. K2-182

AUTOMATIC TRANSAXLE BASIC

INSPECTION .............................................. K2-182

AUTOMATIC TRANSAXLE SYMPTOM

TROUBLESHOOTING ................................ K2-183

NO.1 VEHICLE DOES NOT MOVE IN

D RANGE, OR IN R POSITION .................. K2-188

NO.2 VEHICLE MOVES IN N POSITION ...... K2-188

NO.3 VEHICLE MOVES IN P POSITION,

OR PARKING GEAR DOES NOT

DISENGAGE WHEN P IS DISENGAGED .. K2-189

NO.4 EXCESSIVE CREEP ............................ K2-189

NO.5 NO CREEP AT ALL .............................. K2-189

NO.6 LOW MAXIMUM SPEED AND

POOR ACCELERATION............................. K2-190

NO.7 NO SHIFTING....................................... K2-191

NO.8 DOES NOT SHIFT TO FIFTH

GEAR (5GR) ............................................... K2-192

NO.9 ABNORMAL SHIFTING ........................ K2-193

NO.10 FREQUENT SHIFTING ...................... K2-193

NO.11 SHIFT POINT IS HIGH OR LOW ....... K2-194

NO.12 TORQUE CONVERTER

CLUTCH (TCC) NON-OPERATION ........... K2-194

NO.13 NO KICKDOWN.................................. K2-195

NO.14 ENGINE FLARES UP OR

SLIPS WHEN UPSHIFTING OR

DOWNSHIFTING ........................................ K2-195

NO.15 ENGINE FLARES UP OR

SLIPS WHEN ACCELERATING VEHICLE. K2-196

NO.16 JUDDER UPON TORQUE

CONVERTER CLUTCH (TCC)

OPERATION ............................................... K2-196NO.17 EXCESSIVE SHIFT SHOCK

FROM N TO D OR N TO R

POSITION/RANGE ..................................... K2-196

NO.18 EXCESSIVE SHIFT SHOCK IS

GIVEN WHEN UPSHIFTING AND

DOWNSHIFTING ........................................ K2-197

NO.19 EXCESSIVE SHIFT SHOCK

ON TORQUE CONVERTER CLUTCH

(TCC) .......................................................... K2-197

NO.20 NOISE OCCURS AT IDLE WHEN

VEHICLE IS STOPPED IN ALL

POSITIONS/RANGES ................................ K2-198

NO.21 NOISE OCCURS AT IDLE

WHEN VEHICLE IS STOPPED IN

D RANGE, OR IN R POSITION .................. K2-198

NO.22 NO ENGINE BRAKING IN 1GR

POSITION OF M RANGE ........................... K2-198

NO.23 TRANSAXLE OVERHEATS ............... K2-199

NO.24 ENGINE STALLS WHEN SHIFTED

TO D RANGE, OR IN R POSITION ............ K2-199

NO.25 ENGINE STALLS WHEN DRIVING

AT SLOW SPEED OR STOPPING ............. K2-200

NO.26 STARTER DOES NOT WORK ........... K2-200

NO.27 GEAR POSITION INDICATOR

LIGHT DOES NOT ILLUMINATE IN

M RANGE ................................................... K2-200

NO.28 GEAR POSITION INDICATOR

LIGHT ILLUMINATES IN D RANGE

OR IN P, N, R POSITIONS ......................... K2-201

NO.29 DOES NOT SHIFT UP IN M RANGE . K2-201

NO.30 DOES NOT SHIFT DOWN IN

M RANGE ................................................... K2-201

Page 418 of 909

OUTLINE

K2–3

K2

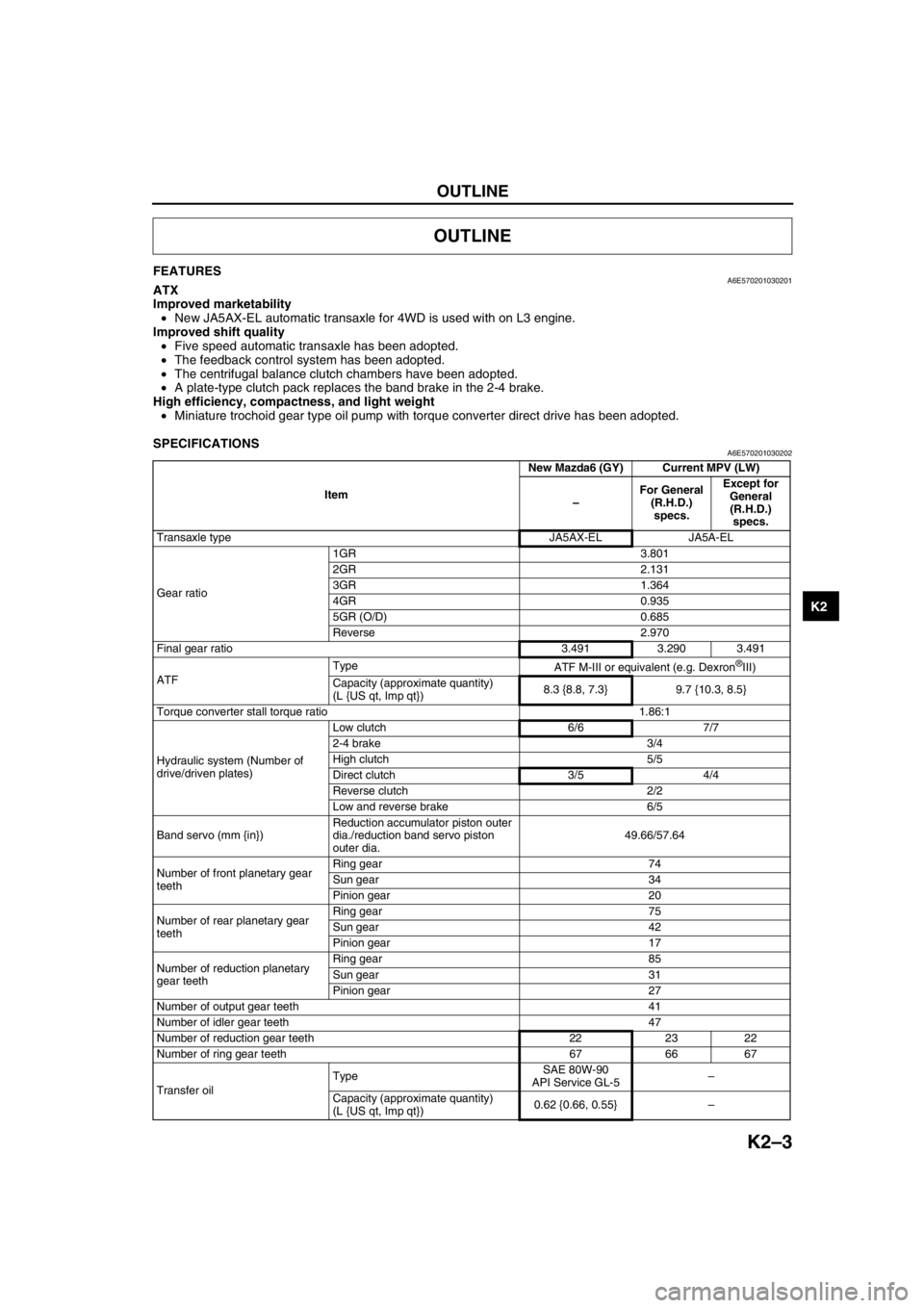

FEATURESA6E570201030201ATX

Improved marketability

•New JA5AX-EL automatic transaxle for 4WD is used with on L3 engine.

Improved shift quality

•Five speed automatic transaxle has been adopted.

•The feedback control system has been adopted.

•The centrifugal balance clutch chambers have been adopted.

•A plate-type clutch pack replaces the band brake in the 2-4 brake.

High efficiency, compactness, and light weight

•Miniature trochoid gear type oil pump with torque converter direct drive has been adopted.

End Of Sie

SPECIFICATIONSA6E570201030202

OUTLINE

ItemNew Mazda6 (GY) Current MPV (LW)

–For General

(R.H.D.)

specs.Except for

General

(R.H.D.)

specs.

Transaxle type JA5AX-EL JA5A-EL

Gear ratio1GR 3.801

2GR 2.131

3GR 1.364

4GR 0.935

5GR (O/D) 0.685

Reverse 2.970

Final gear ratio 3.491 3.290 3.491

ATFType

ATF M-III or equivalent (e.g. Dexron

®III)

Capacity (approximate quantity)

(L {US qt, Imp qt})8.3 {8.8, 7.3} 9.7 {10.3, 8.5}

Torque converter stall torque ratio 1.86:1

Hydraulic system (Number of

drive/driven plates)Low clutch 6/6 7/7

2-4 brake 3/4

High clutch 5/5

Direct clutch 3/5 4/4

Reverse clutch 2/2

Low and reverse brake 6/5

Band servo (mm {in})Reduction accumulator piston outer

dia./reduction band servo piston

outer dia.49.66/57.64

Number of front planetary gear

teethRing gear 74

Sun gear 34

Pinion gear 20

Number of rear planetary gear

teethRing gear 75

Sun gear 42

Pinion gear 17

Number of reduction planetary

gear teethRing gear 85

Sun gear 31

Pinion gear 27

Number of output gear teeth 41

Number of idler gear teeth 47

Number of reduction gear teeth 22 23 22

Number of ring gear teeth 67 66 67

Transfer oilTypeSAE 80W-90

API Service GL-5–

Capacity (approximate quantity)

(L {US qt, Imp qt})0.62 {0.66, 0.55}–

Page 423 of 909

K2–8

AUTOMATIC TRANSAXLE

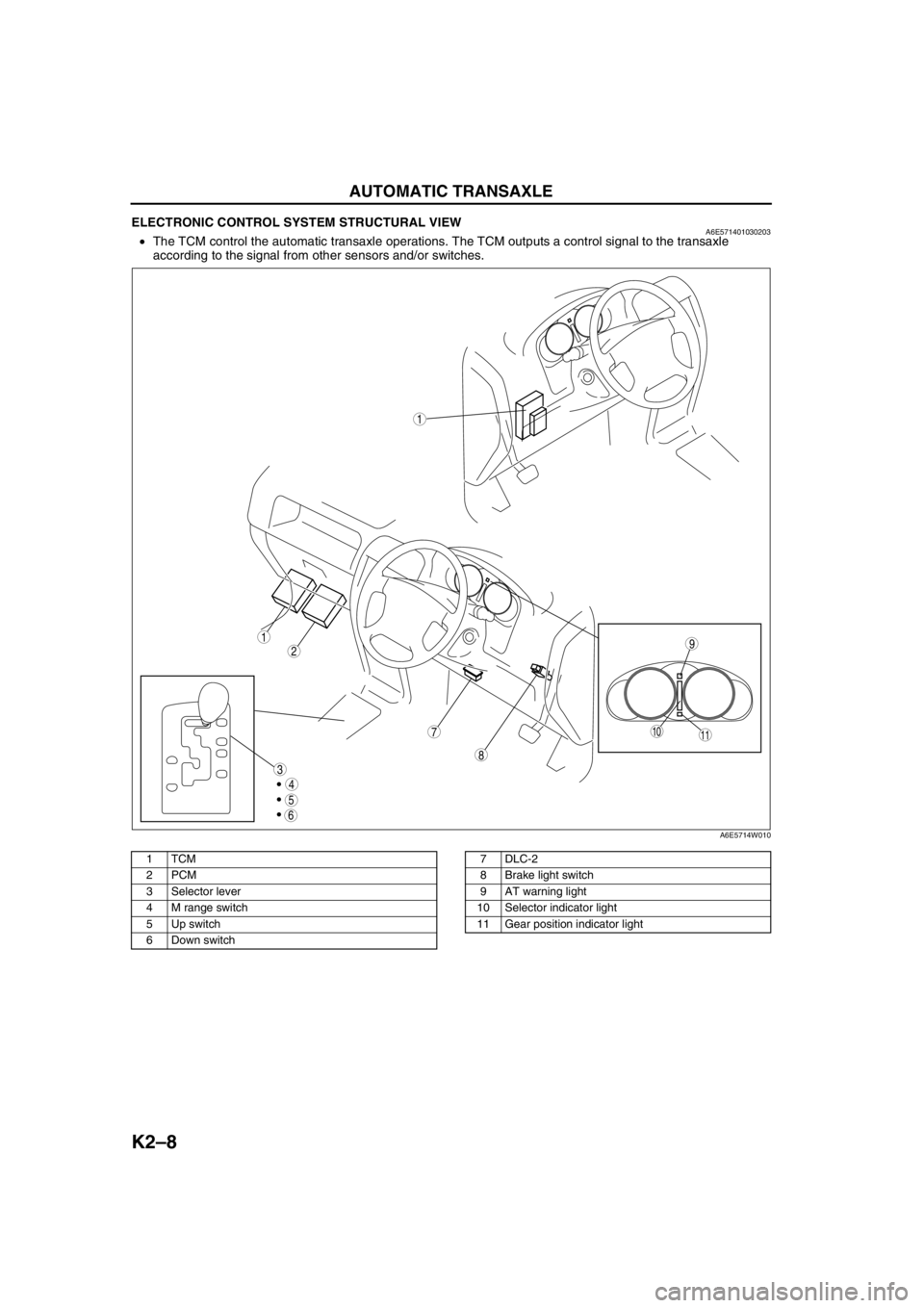

ELECTRONIC CONTROL SYSTEM STRUCTURAL VIEWA6E571401030203•The TCM control the automatic transaxle operations. The TCM outputs a control signal to the transaxle

according to the signal from other sensors and/or switches.

.

9

8

7

5

4

3

1

2

1011

6

1

A6E5714W010

1TCM

2PCM

3Selector lever

4 M range switch

5 Up switch

6 Down switch7DLC-2

8 Brake light switch

9 AT warning light

10 Selector indicator light

11 Gear position indicator light

Page 426 of 909

AUTOMATIC TRANSAXLE

K2–11

K2

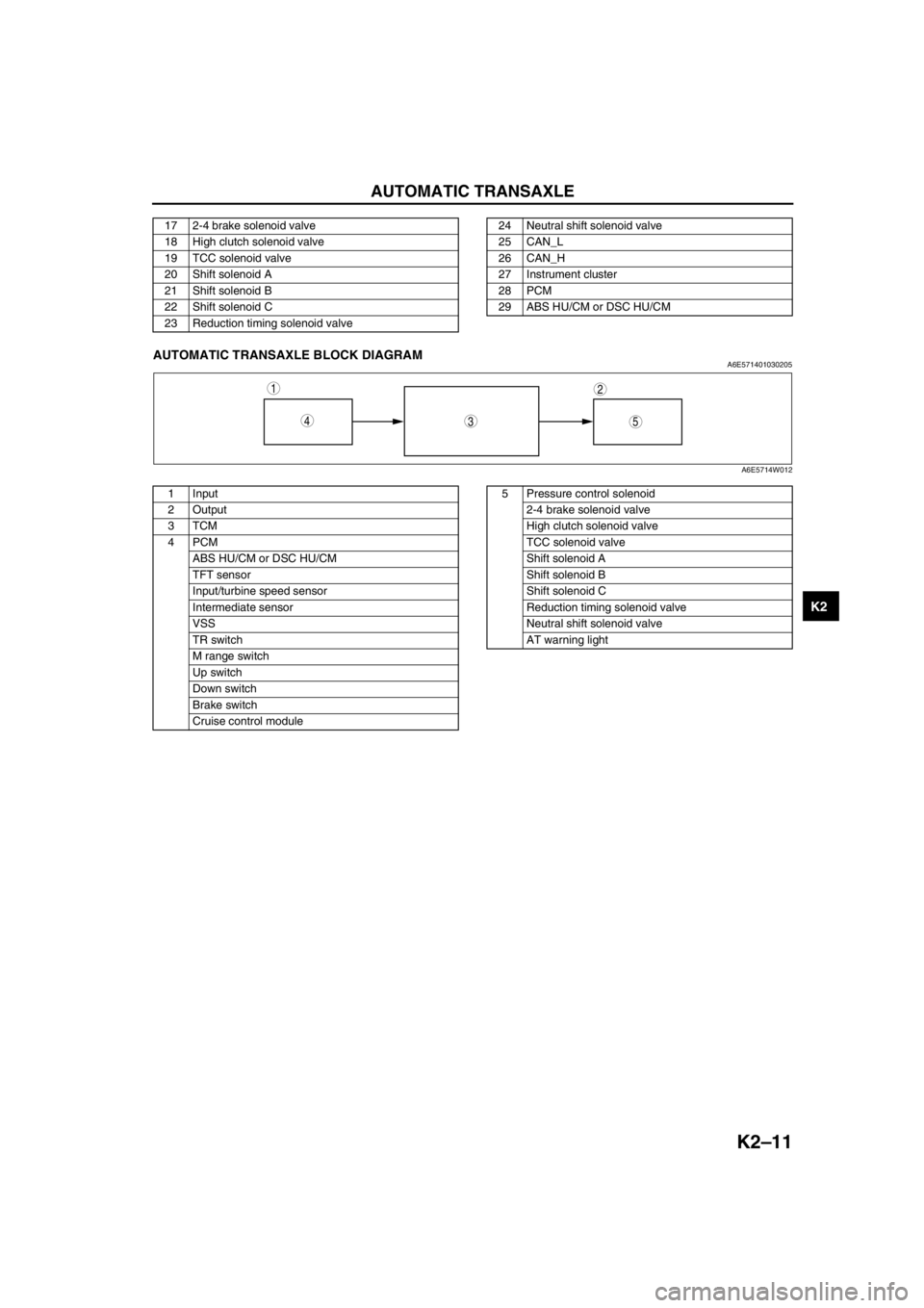

End Of SieAUTOMATIC TRANSAXLE BLOCK DIAGRAMA6E571401030205

.

17 2-4 brake solenoid valve

18 High clutch solenoid valve

19 TCC solenoid valve

20 Shift solenoid A

21 Shift solenoid B

22 Shift solenoid C

23 Reduction timing solenoid valve24 Neutral shift solenoid valve

25 CAN_L

26 CAN_H

27 Instrument cluster

28 PCM

29 ABS HU/CM or DSC HU/CM

543

12

A6E5714W012

1 Input

2Output

3TCM

4PCM

ABS HU/CM or DSC HU/CM

TFT sensor

Input/turbine speed sensor

Intermediate sensor

VSS

TR switch

M range switch

Up switch

Down switch

Brake switch

Cruise control module5 Pressure control solenoid

2-4 brake solenoid valve

High clutch solenoid valve

TCC solenoid valve

Shift solenoid A

Shift solenoid B

Shift solenoid C

Reduction timing solenoid valve

Neutral shift solenoid valve

AT warning light

Page 428 of 909

AUTOMATIC TRANSAXLE

K2–13

K2

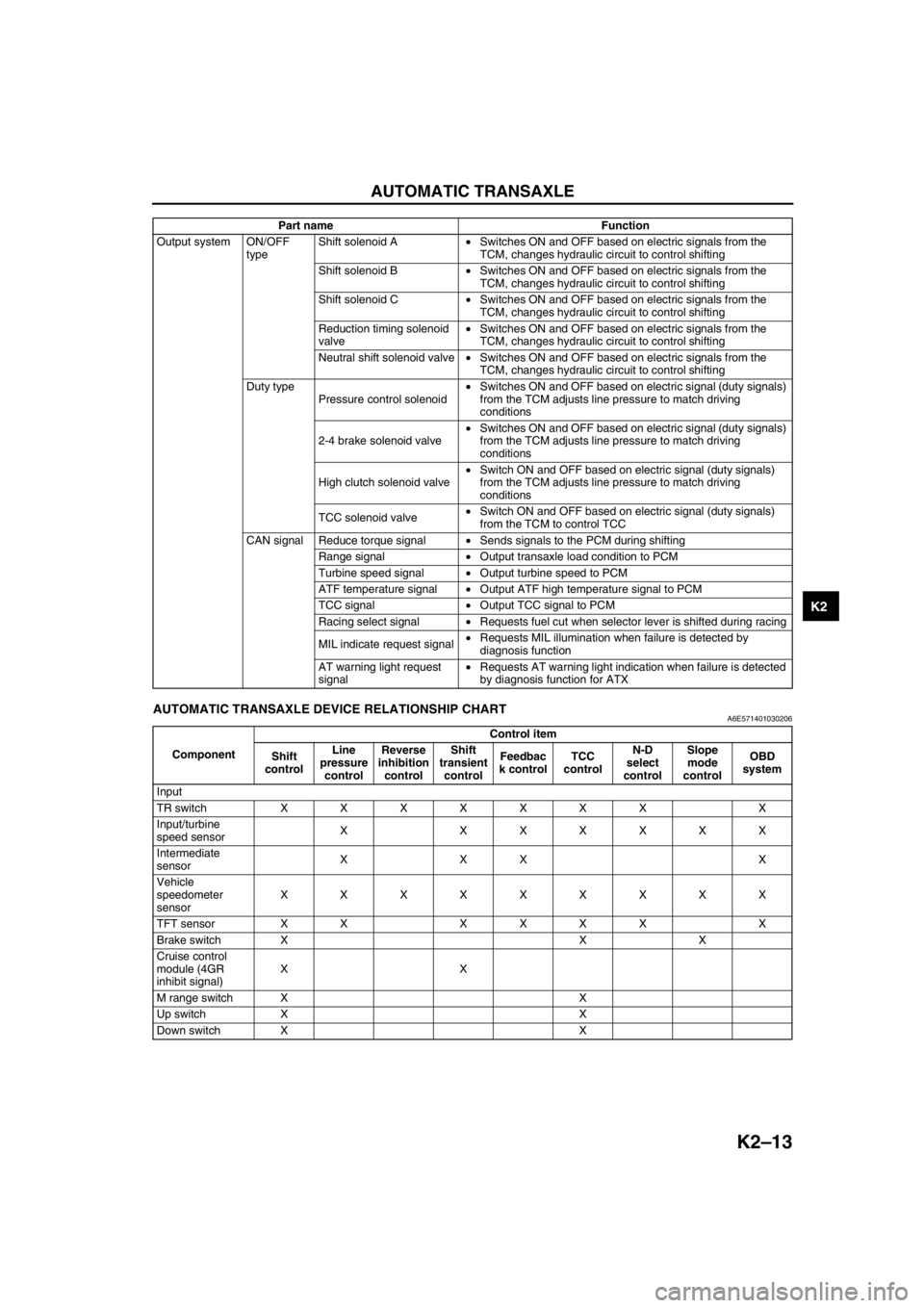

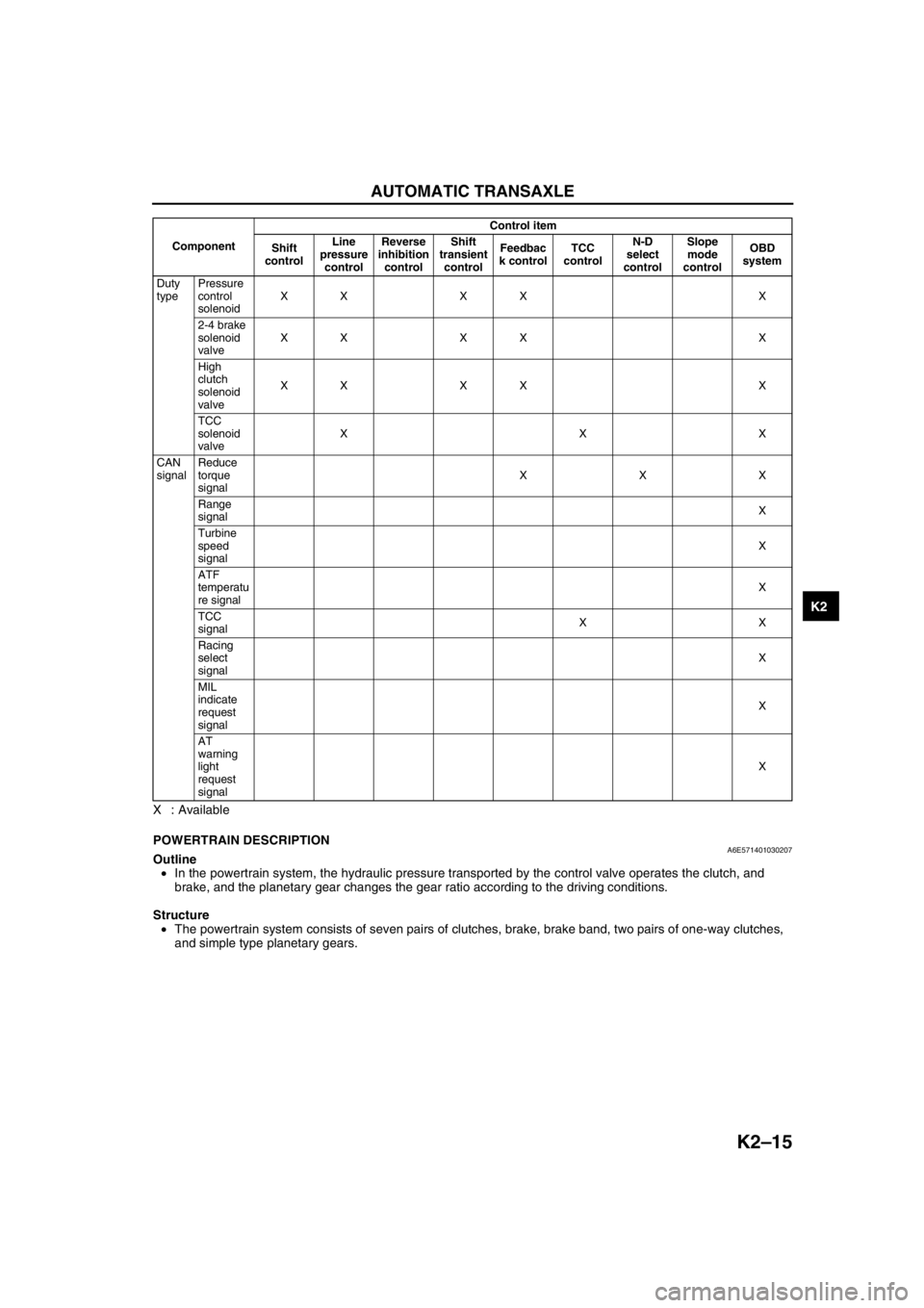

End Of SieAUTOMATIC TRANSAXLE DEVICE RELATIONSHIP CHARTA6E571401030206

Output system ON/OFF

typeShift solenoid A•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Shift solenoid B•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Shift solenoid C•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Reduction timing solenoid

valve•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Neutral shift solenoid valve•Switches ON and OFF based on electric signals from the

TCM, changes hydraulic circuit to control shifting

Duty type

Pressure control solenoid•Switches ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

2-4 brake solenoid valve•Switches ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

High clutch solenoid valve•Switch ON and OFF based on electric signal (duty signals)

from the TCM adjusts line pressure to match driving

conditions

TCC solenoid valve•Switch ON and OFF based on electric signal (duty signals)

from the TCM to control TCC

CAN signal Reduce torque signal•Sends signals to the PCM during shifting

Range signal•Output transaxle load condition to PCM

Turbine speed signal•Output turbine speed to PCM

ATF temperature signal•Output ATF high temperature signal to PCM

TCC signal•Output TCC signal to PCM

Racing select signal•Requests fuel cut when selector lever is shifted during racing

MIL indicate request signal•Requests MIL illumination when failure is detected by

diagnosis function

AT warning light request

signal•Requests AT warning light indication when failure is detected

by diagnosis function for ATX Part name Function

ComponentControl item

Shift

controlLine

pressure

controlReverse

inhibition

controlShift

transient

controlFeedbac

k controlTCC

controlN-D

select

controlSlope

mode

controlOBD

system

Input

TR switch XXXXXXX X

Input/turbine

speed sensorX XXXXXX

Intermediate

sensorXXX X

Vehicle

speedometer

sensorXXXXXXXXX

TFT sensor XX XXXX X

Brake switch X X X

Cruise control

module (4GR

inhibit signal)XX

M range switch X X

Up switch X X

Down switch X X

Page 430 of 909

AUTOMATIC TRANSAXLE

K2–15

K2

X : Available

End Of SiePOWERTRAIN DESCRIPTIONA6E571401030207Outline

•In the powertrain system, the hydraulic pressure transported by the control valve operates the clutch, and

brake, and the planetary gear changes the gear ratio according to the driving conditions.

Structure

•The powertrain system consists of seven pairs of clutches, brake, brake band, two pairs of one-way clutches,

and simple type planetary gears.

Duty

typePressure

control

solenoidXX XX X

2-4 brake

solenoid

valveXX XX X

High

clutch

solenoid

valveXX XX X

TCC

solenoid

valveXXX

CAN

signalReduce

torque

signalXXX

Range

signalX

Turbine

speed

signalX

ATF

temperatu

re signalX

TCC

signalXX

Racing

select

signalX

MIL

indicate

request

signalX

AT

warning

light

request

signalX ComponentControl item

Shift

controlLine

pressure

controlReverse

inhibition

controlShift

transient

controlFeedbac

k controlTCC

controlN-D

select

controlSlope

mode

controlOBD

system

Page 456 of 909

AUTOMATIC TRANSAXLE

K2–41

K2

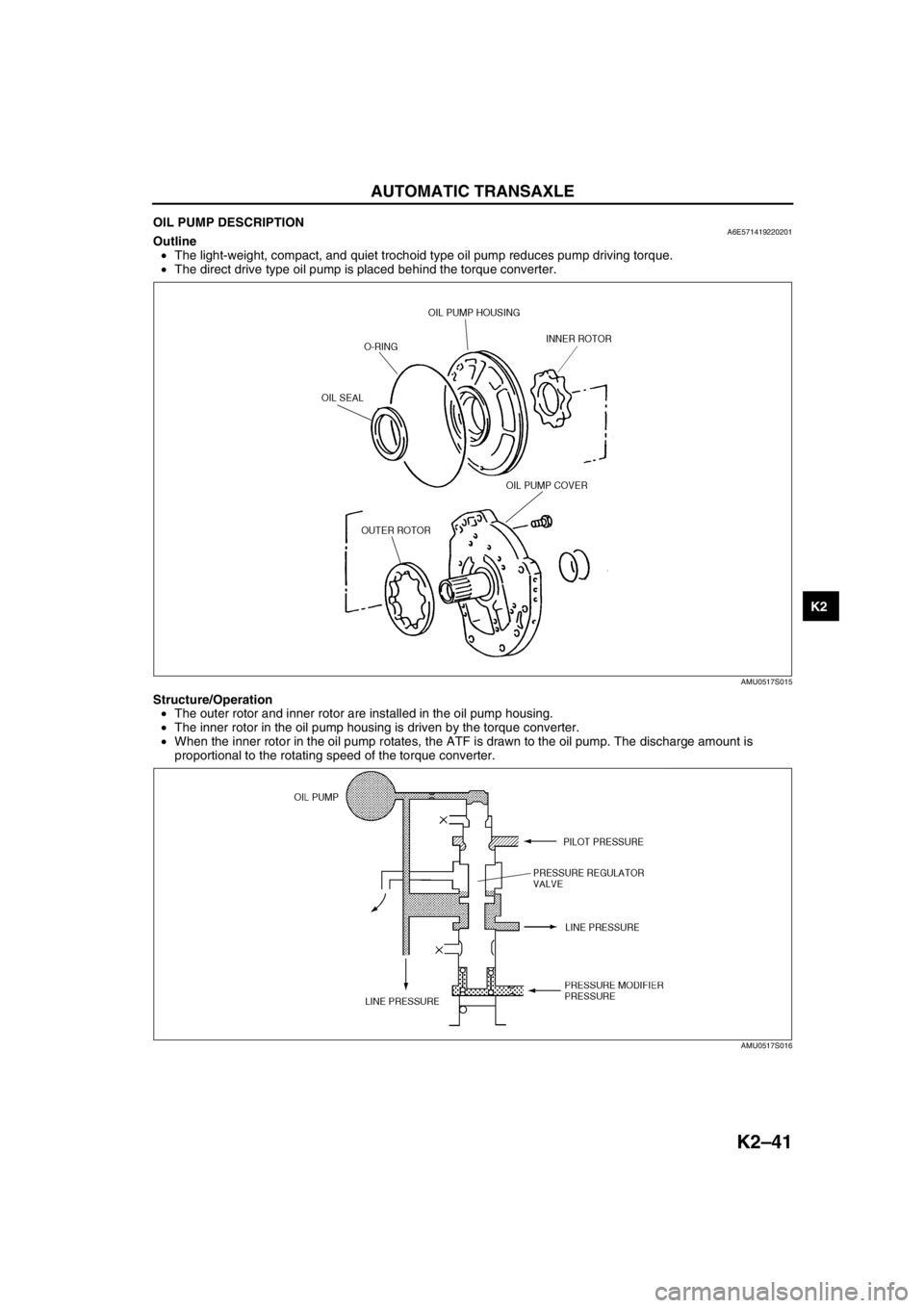

OIL PUMP DESCRIPTIONA6E571419220201Outline

•The light-weight, compact, and quiet trochoid type oil pump reduces pump driving torque.

•The direct drive type oil pump is placed behind the torque converter.

Structure/Operation

•The outer rotor and inner rotor are installed in the oil pump housing.

•The inner rotor in the oil pump housing is driven by the torque converter.

•When the inner rotor in the oil pump rotates, the ATF is drawn to the oil pump. The discharge amount is

proportional to the rotating speed of the torque converter.

End Of Sie

AMU0517S015

AMU0517S016