light MAZDA 6 2002 Workshop Manual Suplement

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 847 of 909

T–36

AIR BAG SYSTEM

Deployment Procedure for Inside of Vehicle (Only When Vehicle Is To Be Scrapped)

1. Inspect the SST (Deployment tool).

2. Move the vehicle to an open space, away from strong winds, and close all the doors and windows.

3. Turn the ignition switch to LOCK position.

4. Disconnect the negative battery cable and wait for more than 1 minute.

5. Follow the appropriate procedure for deploying the driver-side air bag module, passenger-side air bag module,

side air bag module, curtain air bag module, or pre-tensioner seat belt.

Curtain air bag module (WGN)

1. Remove the headliner.

2. Disconnect the curtain air bag module connector.

3. Connect the SST (Adapter harness) to the curtain

air bag module.

4. Connect the SST (Deployment tool) to the SST

(Adapter harness).

5. Connect the red clip of the SST (Deployment tool)

to the positive battery terminal and the black clip

to the negative battery terminal.

6. Verify that the red light on the SST (Deployment

tool) is illuminated.

7. Make sure all persons are standing at least 6 m

{20 ft} from the vehicle.

8. Press the activation switch on the SST

(Deployment tool) to deploy the curtain air bag

module.

Deployment Procedure for Outside of Vehicle

1. Inspect the SST (Deployment tool).

2. Turn the ignition switch to LOCK position.

3. Disconnect the negative battery cable and wait for more than 1 minute.

4. Follow the appropriate procedure for deploying the driver-side air bag module, passenger-side air bag module,

side air bag module, curtain air bag module, or pre-tensioner seat belt.

49 L066 002

CURTAIN

AIR BAG MODULE

CONNECTOR

A6E81301112

49 L066 002

49 H066 002

A6E8130W151

49 H066 002

ACTIVATION

SWITCH

A6E8130W028

Page 849 of 909

T–38

AIR BAG SYSTEM

6. Tie all tires together with wire.

7. Connect the SST (Deployment tool) to the SST

(Adapter harness).

8. Connect the red clip of the SST (Deployment tool)

to the positive battery terminal and the black clip

to the negative battery terminal.

9. Verify that the red light on the SST (Deployment

tool) is illuminated.

10. Make sure all persons are standing at least 6 m

{20 ft} from the vehicle.

11. Press the activation switch on the SST

(Deployment tool) to deploy the curtain air bag

module.

End Of Sie

A6E8130W034

49 H066 002

49 L066 002

A6E8130W155

49 H066 002

ACTIVATION

SWITCH

A6E8130W028

Page 882 of 909

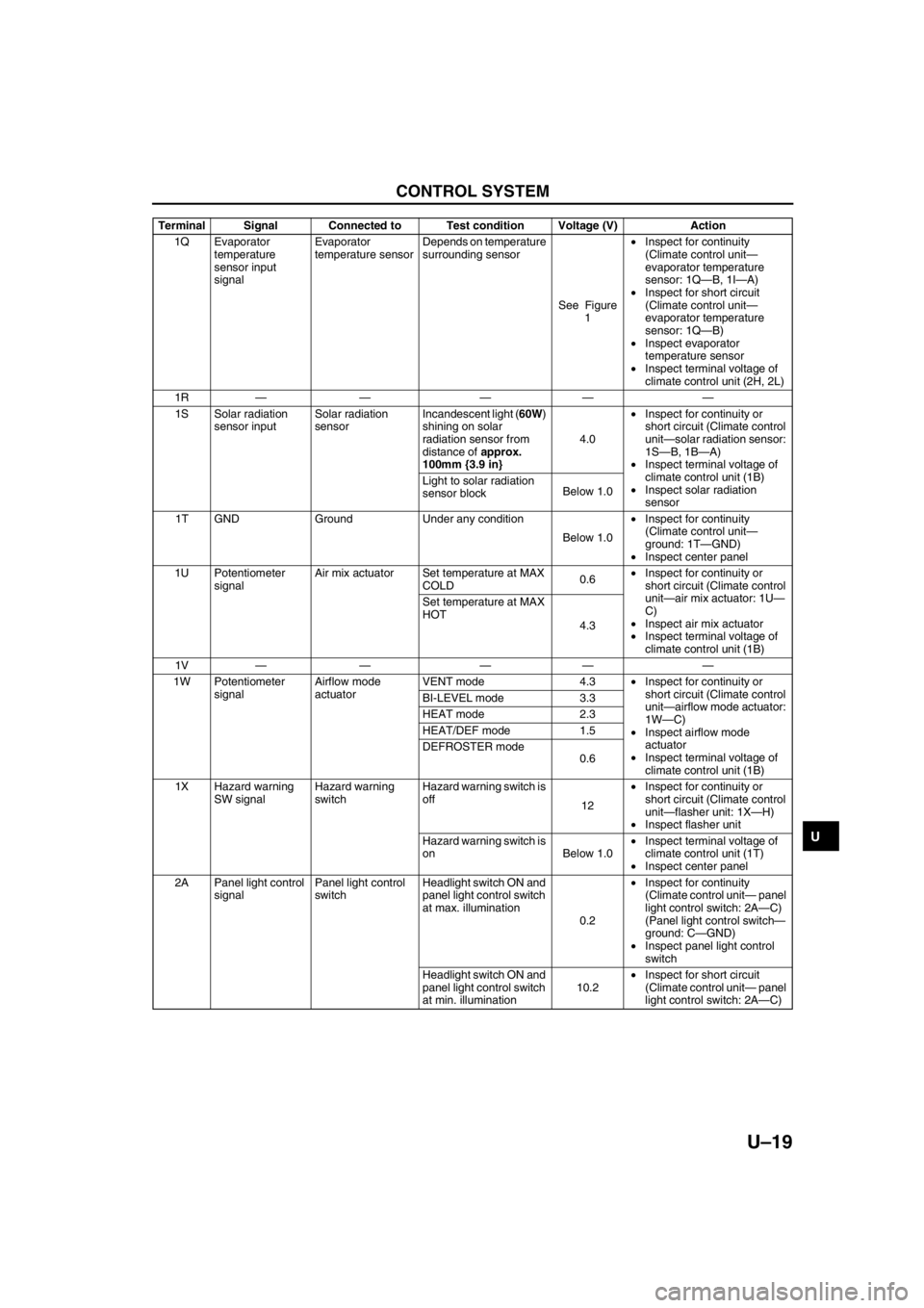

CONTROL SYSTEM

U–19

U

1Q Evaporator

temperature

sensor input

signalEvaporator

temperature sensorDepends on temperature

surrounding sensor

See Figure

1•Inspect for continuity

(Climate control unit—

evaporator temperature

sensor: 1Q—B, 1I—A)

•Inspect for short circuit

(Climate control unit—

evaporator temperature

sensor: 1Q—B)

•Inspect evaporator

temperature sensor

•Inspect terminal voltage of

climate control unit (2H, 2L)

1R—— —— —

1S Solar radiation

sensor inputSolar radiation

sensorIncandescent light (60W)

shining on solar

radiation sensor from

distance of approx.

100mm {3.9 in}4.0•Inspect for continuity or

short circuit (Climate control

unit—solar radiation sensor:

1S—B, 1B—A)

•Inspect terminal voltage of

climate control unit (1B)

•Inspect solar radiation

sensor Light to solar radiation

sensor blockBelow 1.0

1T GND Ground Under any condition

Below 1.0•Inspect for continuity

(Climate control unit—

ground: 1T—GND)

•Inspect center panel

1U Potentiometer

signalAir mix actuator Set temperature at MAX

COLD0.6•Inspect for continuity or

short circuit (Climate control

unit—air mix actuator: 1U—

C)

•Inspect air mix actuator

•Inspect terminal voltage of

climate control unit (1B) Set temperature at MAX

HOT

4.3

1V—— —— —

1W Potentiometer

signalAirflow mode

actuatorVENT mode 4.3•Inspect for continuity or

short circuit (Climate control

unit—airflow mode actuator:

1W—C)

•Inspect airflow mode

actuator

•Inspect terminal voltage of

climate control unit (1B) BI-LEVEL mode 3.3

HEAT mode 2.3

HEAT/DEF mode 1.5

DEFROSTER mode

0.6

1X Hazard warning

SW signalHazard warning

switchHazard warning switch is

off

12•Inspect for continuity or

short circuit (Climate control

unit—flasher unit: 1X—H)

•Inspect flasher unit

Hazard warning switch is

on Below 1.0•Inspect terminal voltage of

climate control unit (1T)

•Inspect center panel

2A Panel light control

signalPanel light control

switchHeadlight switch ON and

panel light control switch

at max. illumination

0.2•Inspect for continuity

(Climate control unit— panel

light control switch: 2A—C)

(Panel light control switch—

ground: C—GND)

•Inspect panel light control

switch

Headlight switch ON and

panel light control switch

at min. illumination10.2•Inspect for short circuit

(Climate control unit— panel

light control switch: 2A—C) Terminal Signal Connected to Test condition Voltage (V) Action

Page 883 of 909

U–20

CONTROL SYSTEM

2B TNS signal TNS relay Headlight switch OFF

Below 1.0•Inspect for short circuit

(Climate control unit—TNS

relay: 2B—D)

•Inspect TNS relay

•Inspect headlight switch

Headlight switch ON

12•Inspect for continuity or

short circuit (Climate control

unit—TNS relay: 2B—D)

•Inspect TNS relay

•Inspect headlight switch

2C Motor drive signal Air mix actuator Moving to COLD 12•Inspect for continuity or

short circuit (Climate control

unit—air mix actuator: 2D—

D, 2C—F)

•Inspect air mix actuator Moving to HOT

Below 1.0

2D Motor drive signal Air mix actuator Moving to HOT 12•Inspect for continuity or

short circuit (Climate control

unit—air mix actuator: 2C—

F, 2D—D)

•Inspect air mix actuator Moving to COLD

Below 1.0

2E Motor drive signal Airflow mode

actuatorMoving to DEFROSTER 12•Inspect for continuity or

short circuit (Climate control

unit—airflow mode actuator:

2E—F, 2G—D)

•Inspect airflow mode

actuator Moving to VENT

Below 1.0

2F Backup power

supply ROOM 15 A fuse Under any condition

B+•Inspect for continuity or

short circuit (Climate control

unit—fuse: 2F— ROOM 15

A fuse)

•Inspect ROOM 15 A fuse

2G Motor drive signal Airflow mode

actuatorMoving to VENT 12•Inspect for continuity or

short circuit (Climate control

unit—airflow mode actuator:

2G—D, 2E—F)

•Inspect airflow mode

actuator Moving to DEFROSTER

Below 1.0

2H IG2 A/C 15 A fuse Ignition switch at ON

position

B+•Inspect for continuity or

short circuit (Climate control

unit—fuse: 2H—A/C 15 A

fuse)

•Inspect A/C 15 A fuse

Ignition switch at LOCK

position Below 1.0•Inspect for short circuit

(Climate control unit—fuse:

2H—A/C 15 A fuse)

2I Motor drive signal Air intake actuator Moving to

RECIRCULATE12•Inspect for continuity or

short circuit (Climate control

unit—air intake actuator:

2I—F, 2K—D)

•Inspect air intake actuator Moving to FRESH

Below 1.0

2J—— —— —

2K Motor drive signal Air intake actuator Moving to FRESH 12•Inspect for continuity or

short circuit (Climate control

unit—air intake actuator:

2K—D, 2I—F)

•Inspect air intake actuator Moving to

RECIRCULATE

Below 1.0

2L GND Ground Under any condition

Below 1.0•Inspect for continuity

(Climate control unit—

ground: 2L—GND) Terminal Signal Connected to Test condition Voltage (V) Action

Page 900 of 909

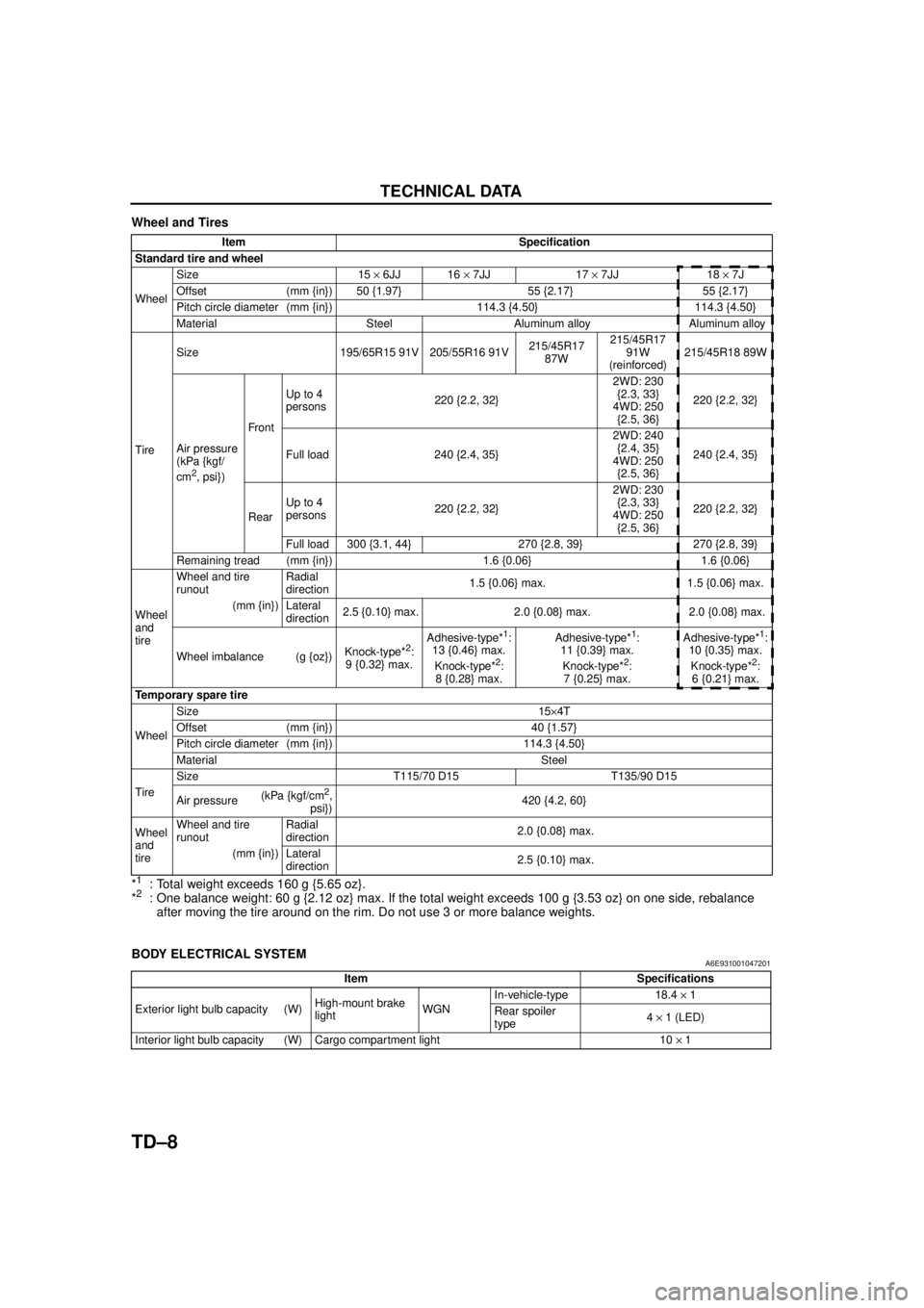

TD–8

TECHNICAL DATA

Wheel and Tires

*

1: Total weight exceeds 160 g {5.65 oz}.

*2: One balance weight: 60 g {2.12 oz} max. If the total weight exceeds 100 g {3.53 oz} on one side, rebalance after moving the tire around on the rim. Do not use 3 or more balance weights.

End Of Sie

BODY ELECTRICAL SYSTEMA6E931001047201

End Of Sie

Item Specification

Standard tire and wheel

Wheel Size 15

× 6JJ 16 × 7JJ 17 × 7JJ 18 × 7J

Offset (mm {in}) 50 {1.97} 55 {2.17} 55 {2.17}

Pitch circle diameter (mm {in}) 114.3 {4.50} 114.3 {4.50}

Material Steel Aluminum alloy Aluminum alloy

Tire Size 195/65R15 91V 205/55R16 91V

215/45R17

87W 215/45R17

91W

(reinforced) 215/45R18 89W

Air pressure

(kPa {kgf/

cm

2, psi}) Front

Up to 4

persons

220 {2.2, 32} 2WD: 230

{2.3, 33}

4WD: 250 {2.5, 36} 220 {2.2, 32}

Full load 240 {2.4, 35} 2WD: 240

{2.4, 35}

4WD: 250 {2.5, 36} 240 {2.4, 35}

Rear Up to 4

persons

220 {2.2, 32} 2WD: 230

{2.3, 33}

4WD: 250 {2.5, 36} 220 {2.2, 32}

Full load 300 {3.1, 44} 270 {2.8, 39} 270 {2.8, 39}

Remaining tread (mm {in}) 1.6 {0.06} 1.6 {0.06}

Wheel

and

tire Wheel and tire

runout

Radial

direction

1.5 {0.06} max. 1.5 {0.06} max.

(mm {in}) Lateral direction 2.5 {0.10} max. 2.0 {0.08} max. 2.0 {0.08} max.

Wheel imbalance (g {oz}) Knock-type*

2:

9 {0.32} max. Adhesive-type*

1:

13 {0.46} max.

Knock-type*

2:

8 {0.28} max. Adhesive-type*

1:

11 {0.39} max.

Knock-type*

2:

7 {0.25} max. Adhesive-type*

1:

10 {0.35} max.

Knock-type*

2:

6 {0.21} max.

Temporary spare tire

Wheel Size 15

×4T

Offset (mm {in}) 40 {1.57}

Pitch circle diameter (mm {in}) 114.3 {4.50}

Material Steel

Tire Size T115/70 D15 T135/90 D15

Air pressure

(kPa {kgf/cm

2,

psi}) 420 {4.2, 60}

Wheel

and

tire Wheel and tire

runout

Radial

direction

2.0 {0.08} max.

(mm {in}) Lateral direction 2.5 {0.10} max.

Item Specifications

Exterior light bulb capacity (W) High-mount brake

lightWGNIn-vehicle-type 18.4

× 1

Rear spoiler

type 4

× 1 (LED)

Interior light bulb capacity (W) Cargo compartment light 10 × 1