ECU MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 732 of 909

N–18

ENGINE SPEED SENSING POWER STEERING

Power Steering Oil Pump Component Disassembly Note

1. Secure the power pressure oil pump using the SST.

Caution

•Use the SST to prevent damage to the

pump when securing it in a vise.

Clip Disassembly Note

1. Lift up the clip tab using a flathead screwdriver.

2. Remove the clip by pushing it with a flathead

screwdriver and a hammer as shown in the figure.

Vane Assembly Note

1. Place the vanes in the rotor with the rounded

edges contacting the cam.

10 Rear pump body

(See N–19 Rear Pump Body Assembly Note)

11 Gasket

12 Cam ring

(See N–19 Cam Ring Assembly Note)13 Rotor

14 Vane

(See N–18 Vane Assembly Note)

15 Side plate

16 Power steering oil pump

49 F032 301

A6E66142010

CLIP

R

A6E66142008

A6E6316W013

Page 733 of 909

ENGINE SPEED SENSING POWER STEERING

N–19

N

Cam Ring Assembly Note

1. Install the cam ring in the front pump body with

the mark facing upward.

Rear Pump Body Assembly Note

1. After installing the rear body, manually turn the shaft to verify that it rotates smoothly.

Clip Assembly Note

1. Push the clip slowly in the direction shown in the

figure.

2. Confirm that the clip tab is securely fastened.

End Of Sie

A6E6316W014

CLIP

R

A6E66142009

Page 778 of 909

R–16

REAR SUSPENSION

Bolt (Trailing Link Front Side) Removal Note

1. Support the trailing link with a jack.

Caution

•Removing the trailing link is dangerous.

The trailing link could fall and cause

serious injury or death. Verify that the

jack securely supports the trailing link.

2. Remove the bolts (trailing link front side).

Bolt (Lateral Link Outer Side) Removal Note

1. Loosen the bolt (lateral link inner side).

2. Remove the bolt (lateral link outer side).

Bolt (Lateral Link Outer Side) Installation Note

1. Tighten the bolt (lateral link outer side).

2. Tighten the bolt (lateral link inner side).

Tightening torque

86.2—116.6 N·m {8.80—11.88 kgf·m, 63.58—85.99 ft·lbf}

Bolt (Trailing Link Front Side) Installation Note

1. Support the trailing link with a jack.

2. Tighten the bolts (trailing link front side).

End Of SieREAR CROSSMEMBER REMOVAL/INSTALLATION (4WD)A6E741628400201

Caution

•Performing the following procedures without first removing the ABS wheel-speed sensor may

possibly cause an open circuit in the harness if it is pulled by mistake. Before performing the

following procedures, remove the ABS wheel-speed sensor (axle side) and fix it to an appropriate

place where the sensor will not be pulled by mistake while servicing the vehicle.

1. Remove the rear auto leveling sensor and harness.

(See T–20 REAR AUTO LEVELING SENSOR REMOVAL/INSTALLATION.)

2. Remove the middle pipe.

(See F1–30 EXHAUST SYSTEM REMOVAL/INSTALLATION.)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

5. Adjust the headlight zeroset.

6. Inspect the rear wheel alignment.

(See R–9 REAR WHEEL ALIGNMENT (WGN).)

JACK

A6E74162010

JACK

A6E74162010

Page 780 of 909

R–18

REAR SUSPENSION

Crossmember component, Differential And Drive Shaft Removal Note

1. Support the differential with a jack, and remove

the nut.

Warning

•Removing the crossmember component,

differential and drive shaft is dangerous.

The crossmember component,

differential and drive shaft could fall and

cause serious injury or death. Verify that

the jack securely supports the differential

lower side.

2. Remove the crossmember component,

differential and drive shaft.

Rear Crossmember Bushing Removal Note

1. Remove the bushing using a screw driver (-),

being careful not to damage the rear

crossmember.

Rear Crossmember Bushing Installation Note

1. Set the bushings as shown in the figure.

JACK

A6E74162012

A6E7416W001

A

B

D

C

A

B

C,D

FRONT

UPPER SIDELOWER SIDE

OVAL

HOLECROSS-

SECTIONAL

VIEW

A6E74162014

Page 793 of 909

S–12

MOLDING

ROOF MOLDING REMOVALA6E773050620201With Roof Rail

1. Remove the roof rail.

2. Detach the clips which secure A section of roof

moldings, using a screwdriver or equivalent tool.

3. Remove the roof molding No.2 and No.3.

4. While pulling the roof molding No.1 up, detach the

fit for the T stud of the B section and the roof

molding No.1 and then remove the roof molding

No.1.

End Of Sie

ROOF MOLDING INSTALLATIONA6E773050620202With Roof Rail

1. Attach the roof molding No.1 to the T stud at the A

section.

2. Hook the roof molding No.1 to clip B at the B

section, press it in, and attach the roof molding

No.1 to clip B.

MOLDING

FRONTb

ba

a B

TOP VIEW

SEC. a—a CLIP

SEC. b—b T STUD

ROOF

MOLDING No.3RROOF

MOLDING No.1R

ROOF

MOLDING No.2R

AAA

AA A

A6A7730W102

FRONTb

b a

aB

A

TOP VIEW

SEC. a—a T STUD

ROOF MOLDING No.1

SEC. b—b CLIP B

A6A7730W104

Page 813 of 909

T–2

OUTLINE, POWER SYSTEM

OUTLINE OF CONSTRUCTIONA6E810201088201•The construction and operation of the body electrical system is essentially carried over from that of the current

Mazda6 (GG) model, except for the following features. (See Mazda6 Training Manual 3359-1*-02C)

End Of Sie

FEATURESA6E810201088202Improved Safety

•There are two types of high-mount brake lights. (WGN)

Improved Marketability

•A cargo compartment light has been adopted. (WGN)

•The installation positions of the rear wiper and washer components have been changed. (WGN)

•A fuel gauge sender sub-unit has been adopted. (4WD)

•A 4WD indicator light, glow indicator light and sedimentor warning light have been adopted.

•The installation positions of the condenser and the noise filter have been changed. (WGN)

•An antenna feeder has been adopted. (WGN)

•A rear auto leveling sensor especially for the 4WD has been adopted. (4WD)

Improved Security

•A rear intruder sensor has been adopted. (WGN)

End Of Sie

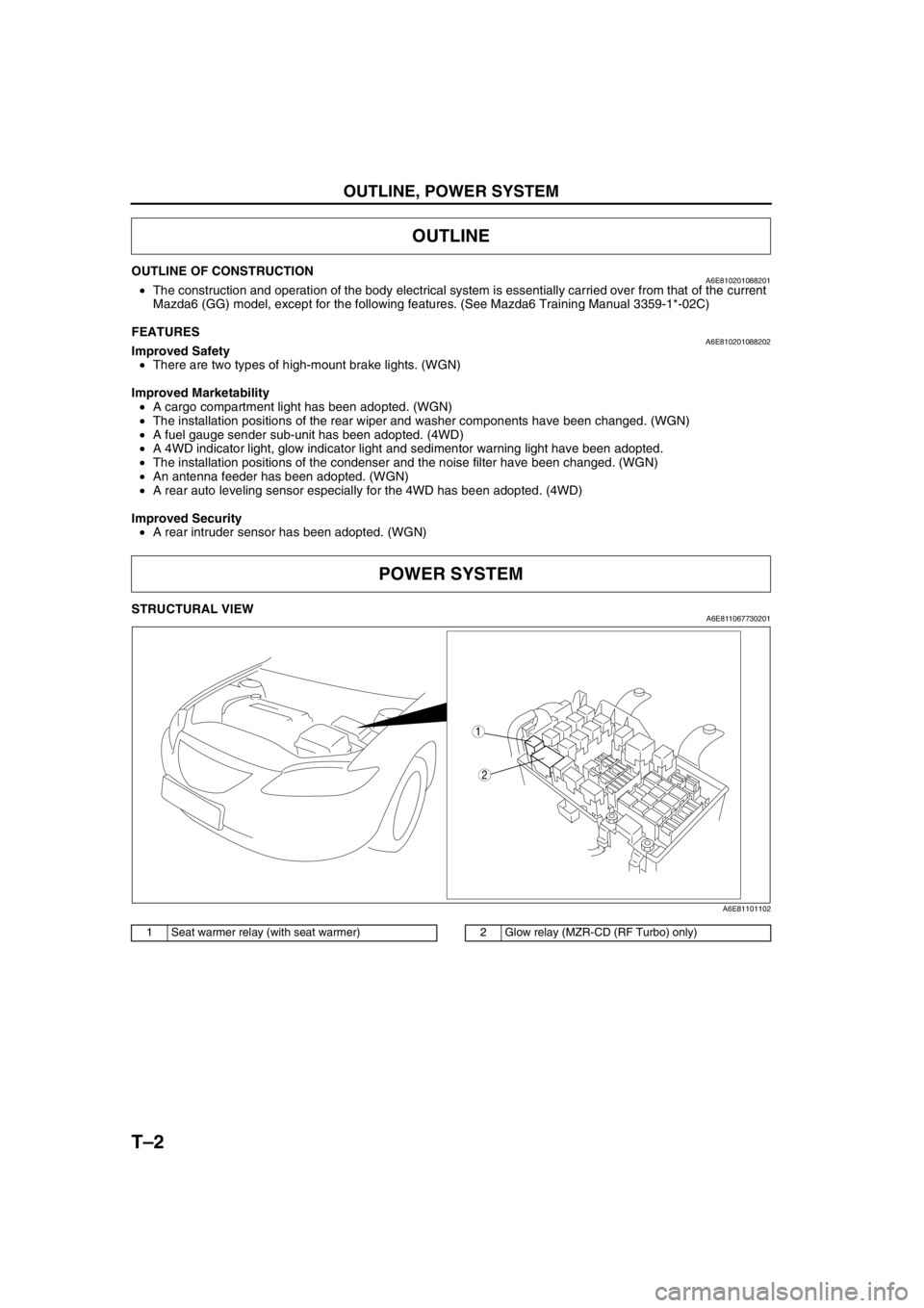

STRUCTURAL VIEWA6E811067730201

.

End Of Sie

OUTLINE

POWER SYSTEM

2

1

A6E81101102

1 Seat warmer relay (with seat warmer)2 Glow relay (MZR-CD (RF Turbo) only)

Page 848 of 909

AIR BAG SYSTEM

T–37

T

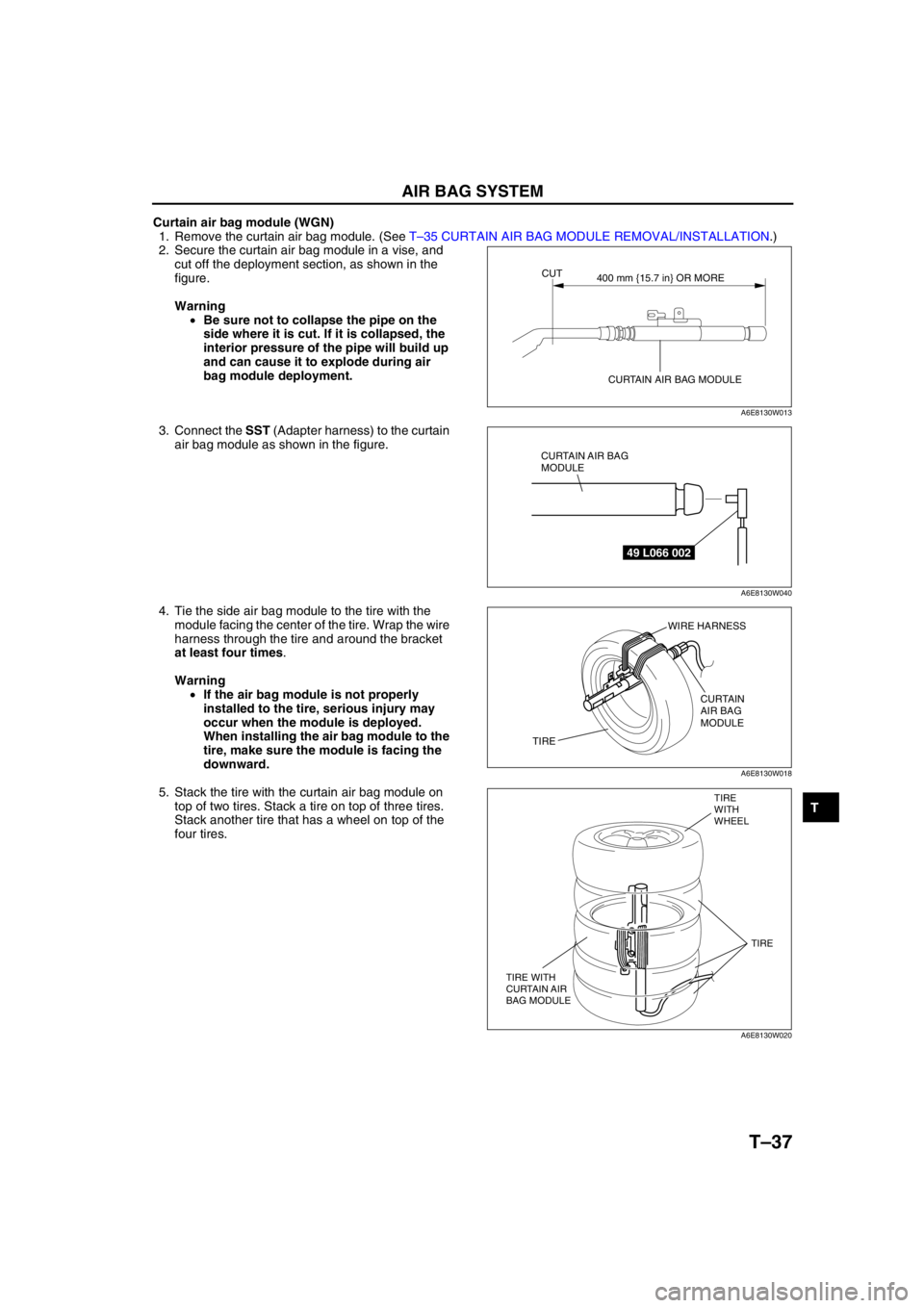

Curtain air bag module (WGN)

1. Remove the curtain air bag module. (See T–35 CURTAIN AIR BAG MODULE REMOVAL/INSTALLATION.)

2. Secure the curtain air bag module in a vise, and

cut off the deployment section, as shown in the

figure.

Warning

•Be sure not to collapse the pipe on the

side where it is cut. If it is collapsed, the

interior pressure of the pipe will build up

and can cause it to explode during air

bag module deployment.

3. Connect the SST (Adapter harness) to the curtain

air bag module as shown in the figure.

4. Tie the side air bag module to the tire with the

module facing the center of the tire. Wrap the wire

harness through the tire and around the bracket

at least four times.

Warning

•If the air bag module is not properly

installed to the tire, serious injury may

occur when the module is deployed.

When installing the air bag module to the

tire, make sure the module is facing the

downward.

5. Stack the tire with the curtain air bag module on

top of two tires. Stack a tire on top of three tires.

Stack another tire that has a wheel on top of the

four tires.

CUT

CURTAIN AIR BAG MODULE400 mm {15.7 in} OR MORE

A6E8130W013

49 L066 002

CURTAIN AIR BAG

MODULE

A6E8130W040

WIRE HARNESS

CURTAIN

AIR BAG

MODULE

TIRE

A6E8130W018

TIRE

WITH

WHEEL

TIRE WITH

CURTAIN AIR

BAG MODULETIRE

A6E8130W020