clutch MAZDA 6 2002 Suplement Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 398 of 909

H–4

CLUTCH RELEASE CYLINDER

CLUTCH RELEASE CYLINDER DISASSEMBLY/ASSEMBLY (A65M-R MANUAL TRANSAXLE MODELS)A6E4918419202021. Disassemble in the order indicated in the table.

2. Assemble in the reverse order of disassembly.

.

End Of Sie

56

7

5.9—8.8 N.

m

{60—90 kgf.

cm,53—78 in.

lbf}

4

BRAKEFLUID

BRAKEFLUID3

1

2

A6E4918W011

1 Boot

2 Push rod

3 Piston and cap

4 Return spring5 Bleeder cap

6 Bleeder screw

7 Release cylinder body

Page 399 of 909

CLUTCH UNIT

H–5

H

CLUTCH UNIT REMOVAL/INSTALLATION (A65M-R MANUAL TRANSAXLE MODELS)A6E4920160002011. Remove in the order indicated in the table.

2. Install in the reverse order oremoval.

.

CLUTCH UNIT

SST

SST

SSTSEALANT

25—33

{2.6—3.3, 19—24}

151.3—161.1

{15.43—16.42, 111.6—118.8} 18.6—25.5

{1.90—2.60, 13.8—18.8}

1

GREASE

GREASE

GREASE

GREASE

GREASE

5

6

7

8

4

3

2

(MOLYBDENUM SULFIDE) TRANSAXLE SIDE ENGINE SIDE

N·m {kgf·m, ft·lbf}

A6E4920W010

1 Clutch release cylinder

2 Manual transaxle

(See J2–7 MANUAL TRANSAXLE REMOVAL/

INSTALLATION)

3Boot

4 Clutch release collar

5 Clutch release fork6 Clutch cover

(See H–6 Clutch Cover and Disc Removal Note)

(See H–7 Clutch Cover Installation Note)

7Clutch disc

(See H–6 Clutch Cover and Disc Removal Note)

(See H–7 Clutch Disc Installation Note)

8 Flywheel

(See H–6 Flywheel Removal Note)

(See H–6 Flywheel Installation Note)

Page 400 of 909

H–6

CLUTCH UNIT

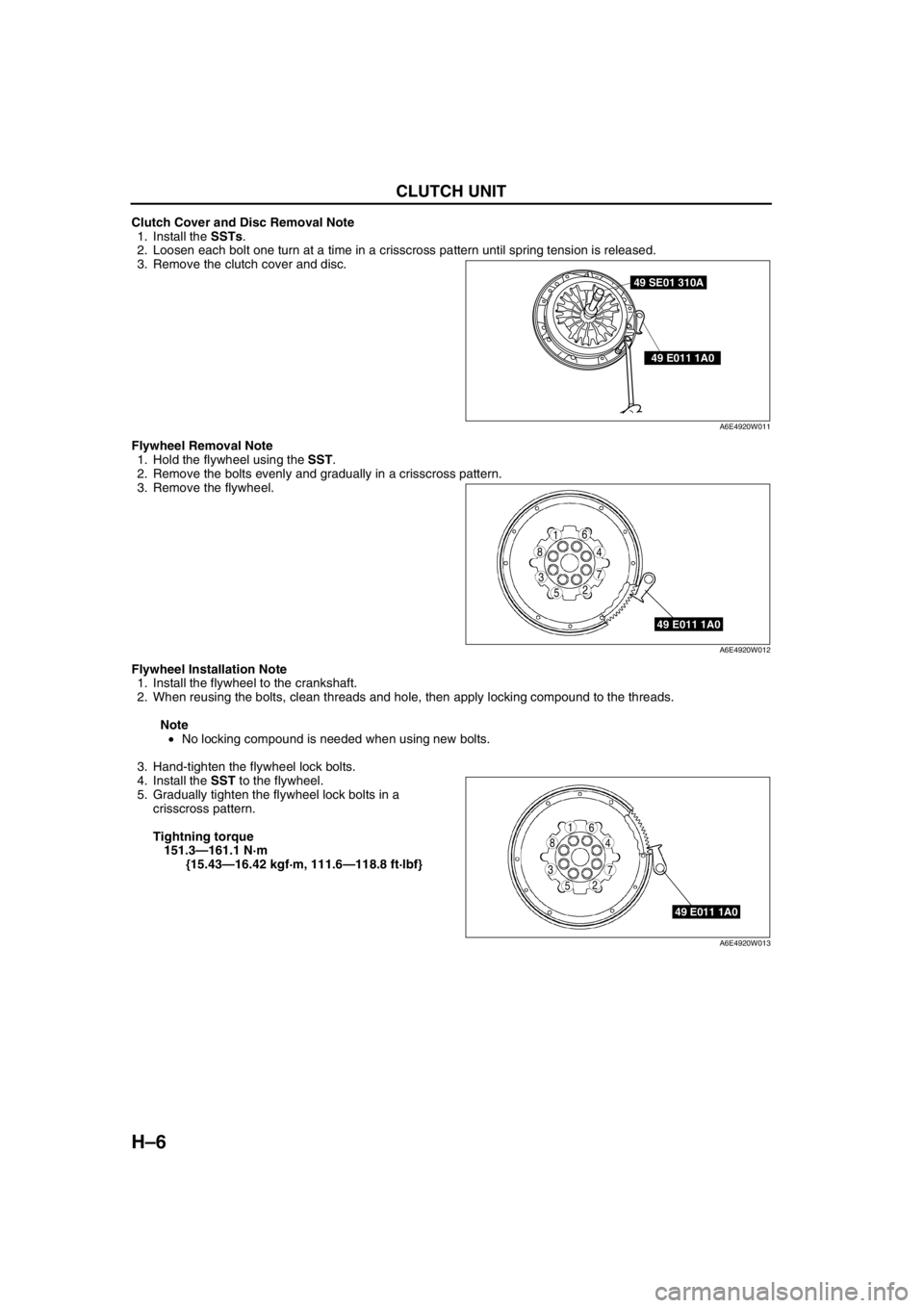

Clutch Cover and Disc Removal Note

1. Install the SSTs.

2. Loosen each bolt one turn at a time in a crisscross pattern until spring tension is released.

3. Remove the clutch cover and disc.

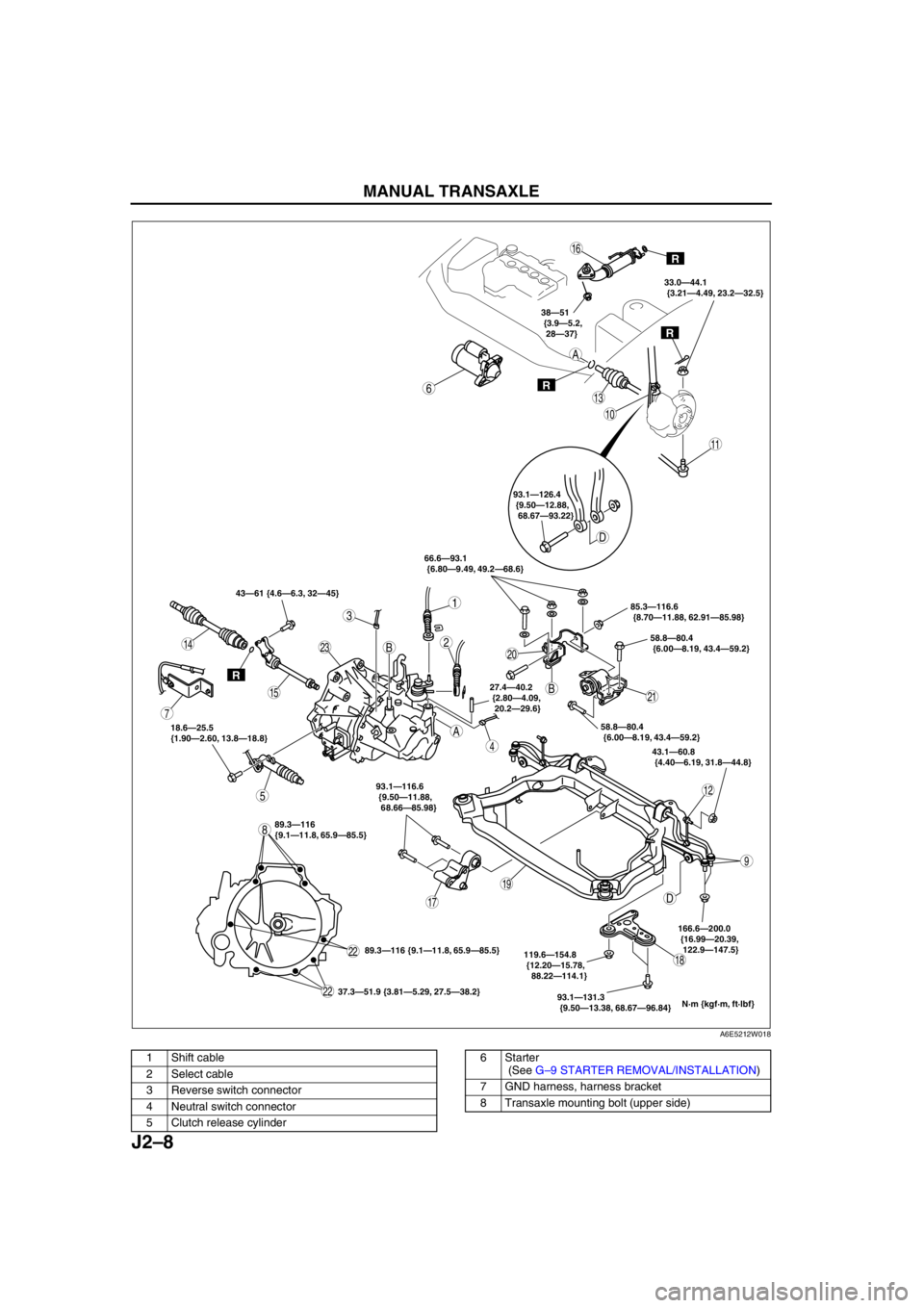

Flywheel Removal Note

1. Hold the flywheel using the SST.

2. Remove the bolts evenly and gradually in a crisscross pattern.

3. Remove the flywheel.

Flywheel Installation Note

1. Install the flywheel to the crankshaft.

2. When reusing the bolts, clean threads and hole, then apply locking compound to the threads.

Note

•No locking compound is needed when using new bolts.

3. Hand-tighten the flywheel lock bolts.

4. Install the SST to the flywheel.

5. Gradually tighten the flywheel lock bolts in a

crisscross pattern.

Tightning torque

151.3—161.1 N·m

{15.43—16.42 kgf·m, 111.6—118.8 ft·lbf}

49 SE01 310A

49 E011 1A0

A6E4920W011

49 E011 1A0

5

4

3

61

2

8

7

A6E4920W012

49 E011 1A0

5

4

3

61

2

8

7

A6E4920W013

Page 401 of 909

CLUTCH UNIT

H–7

H

Clutch Disc Installation Note

1. Hold the clutch disc position using the SST.

Clutch Cover Installation Note

1. Install the SSTs.

2. Tighten the bolts evenly and gradually in a

crisscross pattern.

Tightening torque

25—33 N·m {2.6—3.3 kgf·m, 19—24 ft·lbf}

End Of SieCLUTCH COVER INSPECTION (A65M-R MANUAL TRANSAXLE MODELS)A6E4920164102011. Measure the wear of the diaphragm spring

fingers.

•If not as specified, replace the clutch cover.

Depth

0.6 mm {0.024 in} max.

2. Measure the flatness of the pressure plate with a

straight edge and a feeler gauge.

•If not as specified, replace the clutch cover.

Maximum clearance

0.3 mm {0.012 in}

3. When checking the diaphragm spring fingers,

mount a dial indicator on the cylinder block.

49 SE01 310A

A6E4920W014

5

4

3

49 SE01 310A

49 E011 1A06

1

2

A6E4920W015

XME4920W010

XME4920W011

Page 402 of 909

H–8

CLUTCH UNIT, FLYWHEEL

4. Rotate the flywheel and check for misaligned

diaphragm spring fingers.

•If not as specified, replace the clutch cover.

Misalignment

0.6 mm {0.024 in} max.

End Of Sie

FLYWHEEL INSPECTION (A65M-R MANUAL TRANSAXLE MODELS)A6E4922115002011. Install a dial gauge on the cylinder block.

2. Measure the flywheel runout using a dial

indicator.

•If the runout is excessive, replace the

flywheel.

Runout

0.3 mm {0.012 in} max.

End Of Sie

A6E4920W016

FLYWHEEL

A6E4922W001

Page 410 of 909

J2–8

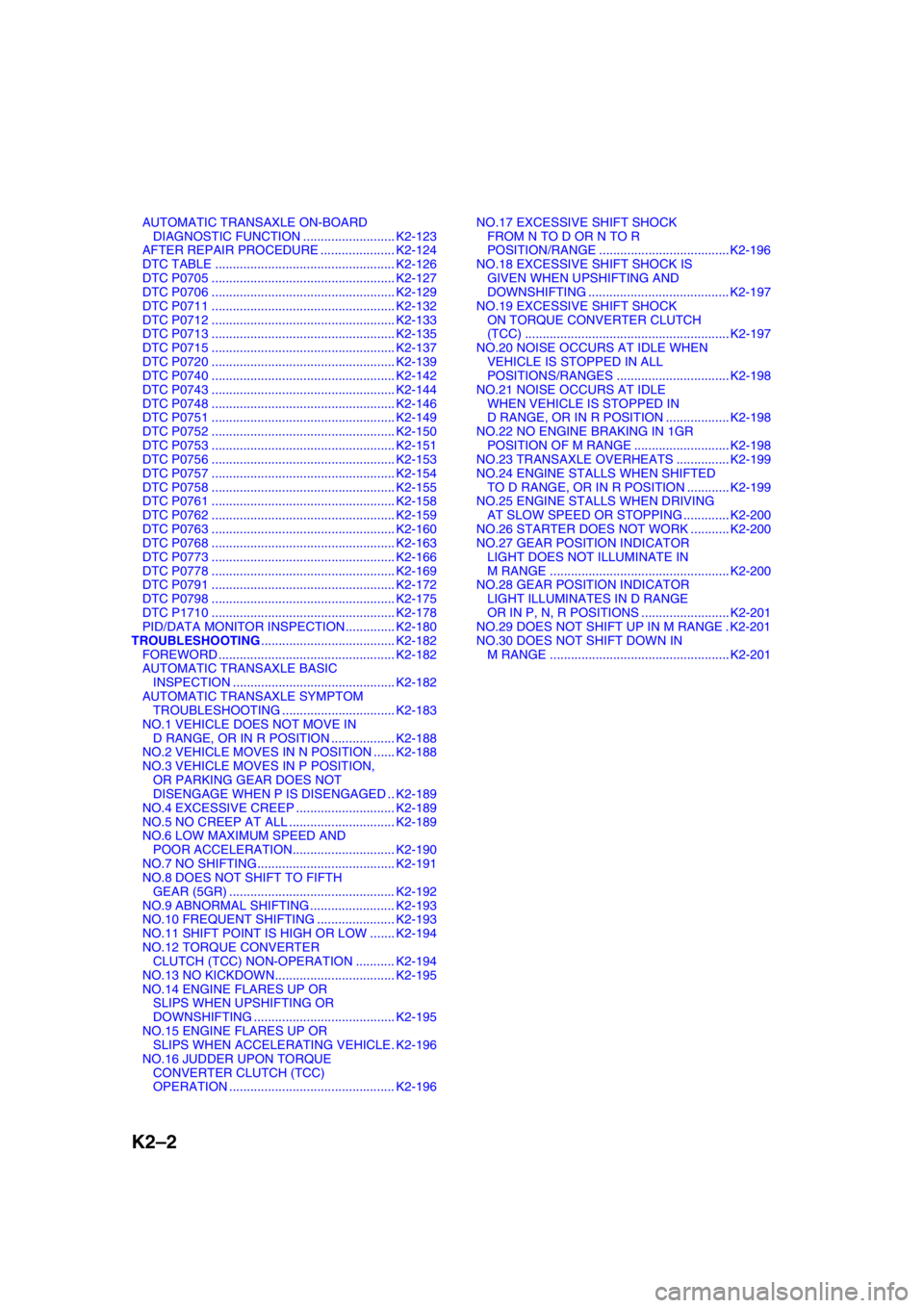

MANUAL TRANSAXLE

.

2

6

3

5

8

1

7

16

13

10

11

21

20

4

9

18

19

17

15

22

22

1423

12

R

R

R

R

85.3—116.6

{8.70—11.88, 62.91—85.98}

58.8—80.4

{6.00—8.19, 43.4—59.2}

58.8—80.4

{6.00—8.19, 43.4—59.2}

93.1—131.3

{9.50—13.38, 68.67—96.84} 119.6—154.8

{12.20—15.78,

88.22—114.1} 43—61 {4.6—6.3, 32—45}

18.6—25.5

{1.90—2.60, 13.8—18.8}

89.3—116

{9.1—11.8, 65.9—85.5}

89.3—116 {9.1—11.8, 65.9—85.5}

37.3—51.9 {3.81—5.29, 27.5—38.2}166.6—200.0

{16.99—20.39,

122.9—147.5} 43.1—60.8

{4.40—6.19, 31.8—44.8} 33.0—44.1

{3.21—4.49, 23.2—32.5}

38—51

{3.9—5.2,

28—37}

27.4—40.2

{2.80—4.09,

20.2—29.6}

93.1—116.6

{9.50—11.88,

68.66—85.98}93.1—126.4

{9.50—12.88,

68.67—93.22}

66.6—93.1

{6.80—9.49, 49.2—68.6}

A

B

B

A

D

D

N·m {kgf·m, ft·lbf}

A6E5212W018

1 Shift cable

2 Select cable

3 Reverse switch connector

4 Neutral switch connector

5 Clutch release cylinder6Starter

(See G–9 STARTER REMOVAL/INSTALLATION)

7 GND harness, harness bracket

8 Transaxle mounting bolt (upper side)

Page 416 of 909

![MAZDA 6 2002 Suplement Repair Manual K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATI MAZDA 6 2002 Suplement Repair Manual K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATI](/img/28/57057/w960_57057-415.png)

K2–1

K2

K2AUTOMATIC TRANSAXLE [JA5AX-EL]

OUTLINE.............................................................. K2-3

FEATURES ........................................................ K2-3

SPECIFICATIONS ............................................. K2-3

AUTOMATIC TRANSAXLE.................................. K2-4

OUTLINE ........................................................... K2-4

CROSS-SECTIONAL VIEW .............................. K2-6

ELECTRONIC CONTROL SYSTEM

STRUCTURAL VIEW...................................... K2-8

AUTOMATIC TRANSAXLE CONTROL SYSTEM

WIRING DIAGRAM ....................................... K2-10

AUTOMATIC TRANSAXLE BLOCK

DIAGRAM ..................................................... K2-11

AUTOMATIC TRANSAXLE DEVICE

RELATIONSHIP CHART .............................. K2-13

POWERTRAIN DESCRIPTION ....................... K2-15

TORQUE CONVERTER DESCRIPTION......... K2-40

OIL PUMP DESCRIPTION .............................. K2-41

CENTRIFUGAL BALANCE CLUTCH

DESCRIPTION ............................................. K2-42

CONTROL VALVE BODY DESCRIPTION ...... K2-43

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR DESCRIPTION ................... K2-45

INPUT/TURBINE SPEED SENSOR

DESCRIPTION ............................................. K2-45

INTERMEDIATE SENSOR DESCRIPTION..... K2-46

VEHICLE SPEEDOMETER SENSOR

DESCRIPTION ............................................. K2-46

SOLENOID VALVE DESCRIPTION ................ K2-47

CONTROLLER AREA NETWORK (CAN)

DESCRIPTION ............................................. K2-50

TRANSAXLE CONTROL MODULE

(TCM) DESCRIPTION .................................. K2-51

SHIFT CONTROL DESCRIPTION .................. K2-51

MANUAL MODE SHIFT CONTROL

DESCRIPTION ............................................. K2-52

LINE PRESSURE CONTROL DESCRIPTION K2-54

FEEDBACK CONTROL DESCRIPTION ......... K2-57

N-D SELECT CONTROL DESCRIPTION........ K2-59

TORQUE CONVERTER CLUTCH

(TCC) CONTROL DESCRIPTION ................ K2-59

SLOPE MODE CONTROL DESCRIPTION ..... K2-63

ON-BOARD DIAGNOSTIC (OBD)

SYSTEM DESCRIPTION.............................. K2-64

COOLING SYSTEM DESCRIPTION ............... K2-69

LOCATION INDEX............................................. K2-70

AUTOMATIC TRANSAXLE LOCATION

INDEX ........................................................... K2-70

AUTOMATIC TRANSAXLE................................ K2-72

MECHANICAL SYSTEM TEST ....................... K2-72

ROAD TEST .................................................... K2-75AUTOMATIC TRANSAXLE FLUID

(ATF) INSPECTION ...................................... K2-78

AUTOMATIC TRANSAXLE FLUID

(ATF) REPLACEMENT ................................. K2-80

TRANSAXLE RANGE (TR) SWITCH

INSPECTION ................................................ K2-80

TRANSAXLE RANGE (TR) SWITCH

REMOVAL/INSTALLATION .......................... K2-81

TRANSAXLE RANGE (TR) SWITCH

ADJUSTMENT .............................................. K2-83

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR INSPECTION ...................... K2-84

TRANSAXLE FLUID TEMPERATURE

(TFT) SENSOR REMOVAL/INSTALLATION K2-85

INPUT/TURBINE SPEED SENSOR

INSPECTION ................................................ K2-85

INPUT/TURBINE SPEED SENSOR

REMOVAL/INSTALLATION .......................... K2-86

INTERMEDIATE SENSOR INSPECTION ....... K2-86

INTERMEDIATE SENSOR

REMOVAL/INSTALLATION .......................... K2-86

VEHICLE SPEEDOMETER SENSOR

(VSS) INSPECTION...................................... K2-87

VEHICLE SPEEDOMETER SENSOR

(VSS) REMOVAL/INSTALLATION ............... K2-87

SOLENOID VALVE INSPECTION ................... K2-88

SOLENOID VALVE

REMOVAL/INSTALLATION .......................... K2-90

TCM INSPECTION .......................................... K2-90

TCM REMOVAL/INSTALLATION .................... K2-96

AUTOMATIC TRANSAXLE AND

TRANSFER REMOVAL/INSTALLATION...... K2-99

OIL SEAL REMOVAL/INSTALLATION .......... K2-104

CONTROL VALVE BODY

REMOVAL/INSTALLATION ........................ K2-105

OIL COOLER FLUSHING .............................. K2-106

OIL COOLER REMOVAL/INSTALLATION .... K2-108

OIL COOLER DISASSEMBLY/ASSEMBLY .. K2-110

DRIVE PLATE REMOVAL/INSTALLATION... K2-112

TRANSFER....................................................... K2-114

TRANSFER OIL INSPECTION ...................... K2-114

TRANSFER OIL REPLACEMENT ................. K2-114

TRANSFER REMOVAL/INSTALLATION....... K2-115

BREATHER PLUG

REMOVAL/INSTALLATION ........................ K2-116

AUTOMATIC TRANSAXLE SHIFT

MECHANISM................................................. K2-117

SELECTOR LEVER INSPECTION ................ K2-117

SELECTOR LEVER COMPONENT

INSPECTION .............................................. K2-117

SELECTOR CABLE ADJUSTMENT .............. K2-118

SELECTOR LEVER

REMOVAL/INSTALLATION ........................ K2-119

SELECTOR LEVER

DISASSEMBLY/ASSEMBLY ...................... K2-122

ON-BOARD DIAGNOSTIC............................... K2-123

FOREWORD .................................................. K2-123 FEATURES

SERVICE

Page 417 of 909

K2–2

AUTOMATIC TRANSAXLE ON-BOARD

DIAGNOSTIC FUNCTION .......................... K2-123

AFTER REPAIR PROCEDURE ..................... K2-124

DTC TABLE ................................................... K2-126

DTC P0705 .................................................... K2-127

DTC P0706 .................................................... K2-129

DTC P0711 .................................................... K2-132

DTC P0712 .................................................... K2-133

DTC P0713 .................................................... K2-135

DTC P0715 .................................................... K2-137

DTC P0720 .................................................... K2-139

DTC P0740 .................................................... K2-142

DTC P0743 .................................................... K2-144

DTC P0748 .................................................... K2-146

DTC P0751 .................................................... K2-149

DTC P0752 .................................................... K2-150

DTC P0753 .................................................... K2-151

DTC P0756 .................................................... K2-153

DTC P0757 .................................................... K2-154

DTC P0758 .................................................... K2-155

DTC P0761 .................................................... K2-158

DTC P0762 .................................................... K2-159

DTC P0763 .................................................... K2-160

DTC P0768 .................................................... K2-163

DTC P0773 .................................................... K2-166

DTC P0778 .................................................... K2-169

DTC P0791 .................................................... K2-172

DTC P0798 .................................................... K2-175

DTC P1710 .................................................... K2-178

PID/DATA MONITOR INSPECTION.............. K2-180

TROUBLESHOOTING...................................... K2-182

FOREWORD .................................................. K2-182

AUTOMATIC TRANSAXLE BASIC

INSPECTION .............................................. K2-182

AUTOMATIC TRANSAXLE SYMPTOM

TROUBLESHOOTING ................................ K2-183

NO.1 VEHICLE DOES NOT MOVE IN

D RANGE, OR IN R POSITION .................. K2-188

NO.2 VEHICLE MOVES IN N POSITION ...... K2-188

NO.3 VEHICLE MOVES IN P POSITION,

OR PARKING GEAR DOES NOT

DISENGAGE WHEN P IS DISENGAGED .. K2-189

NO.4 EXCESSIVE CREEP ............................ K2-189

NO.5 NO CREEP AT ALL .............................. K2-189

NO.6 LOW MAXIMUM SPEED AND

POOR ACCELERATION............................. K2-190

NO.7 NO SHIFTING....................................... K2-191

NO.8 DOES NOT SHIFT TO FIFTH

GEAR (5GR) ............................................... K2-192

NO.9 ABNORMAL SHIFTING ........................ K2-193

NO.10 FREQUENT SHIFTING ...................... K2-193

NO.11 SHIFT POINT IS HIGH OR LOW ....... K2-194

NO.12 TORQUE CONVERTER

CLUTCH (TCC) NON-OPERATION ........... K2-194

NO.13 NO KICKDOWN.................................. K2-195

NO.14 ENGINE FLARES UP OR

SLIPS WHEN UPSHIFTING OR

DOWNSHIFTING ........................................ K2-195

NO.15 ENGINE FLARES UP OR

SLIPS WHEN ACCELERATING VEHICLE. K2-196

NO.16 JUDDER UPON TORQUE

CONVERTER CLUTCH (TCC)

OPERATION ............................................... K2-196NO.17 EXCESSIVE SHIFT SHOCK

FROM N TO D OR N TO R

POSITION/RANGE ..................................... K2-196

NO.18 EXCESSIVE SHIFT SHOCK IS

GIVEN WHEN UPSHIFTING AND

DOWNSHIFTING ........................................ K2-197

NO.19 EXCESSIVE SHIFT SHOCK

ON TORQUE CONVERTER CLUTCH

(TCC) .......................................................... K2-197

NO.20 NOISE OCCURS AT IDLE WHEN

VEHICLE IS STOPPED IN ALL

POSITIONS/RANGES ................................ K2-198

NO.21 NOISE OCCURS AT IDLE

WHEN VEHICLE IS STOPPED IN

D RANGE, OR IN R POSITION .................. K2-198

NO.22 NO ENGINE BRAKING IN 1GR

POSITION OF M RANGE ........................... K2-198

NO.23 TRANSAXLE OVERHEATS ............... K2-199

NO.24 ENGINE STALLS WHEN SHIFTED

TO D RANGE, OR IN R POSITION ............ K2-199

NO.25 ENGINE STALLS WHEN DRIVING

AT SLOW SPEED OR STOPPING ............. K2-200

NO.26 STARTER DOES NOT WORK ........... K2-200

NO.27 GEAR POSITION INDICATOR

LIGHT DOES NOT ILLUMINATE IN

M RANGE ................................................... K2-200

NO.28 GEAR POSITION INDICATOR

LIGHT ILLUMINATES IN D RANGE

OR IN P, N, R POSITIONS ......................... K2-201

NO.29 DOES NOT SHIFT UP IN M RANGE . K2-201

NO.30 DOES NOT SHIFT DOWN IN

M RANGE ................................................... K2-201

Page 418 of 909

OUTLINE

K2–3

K2

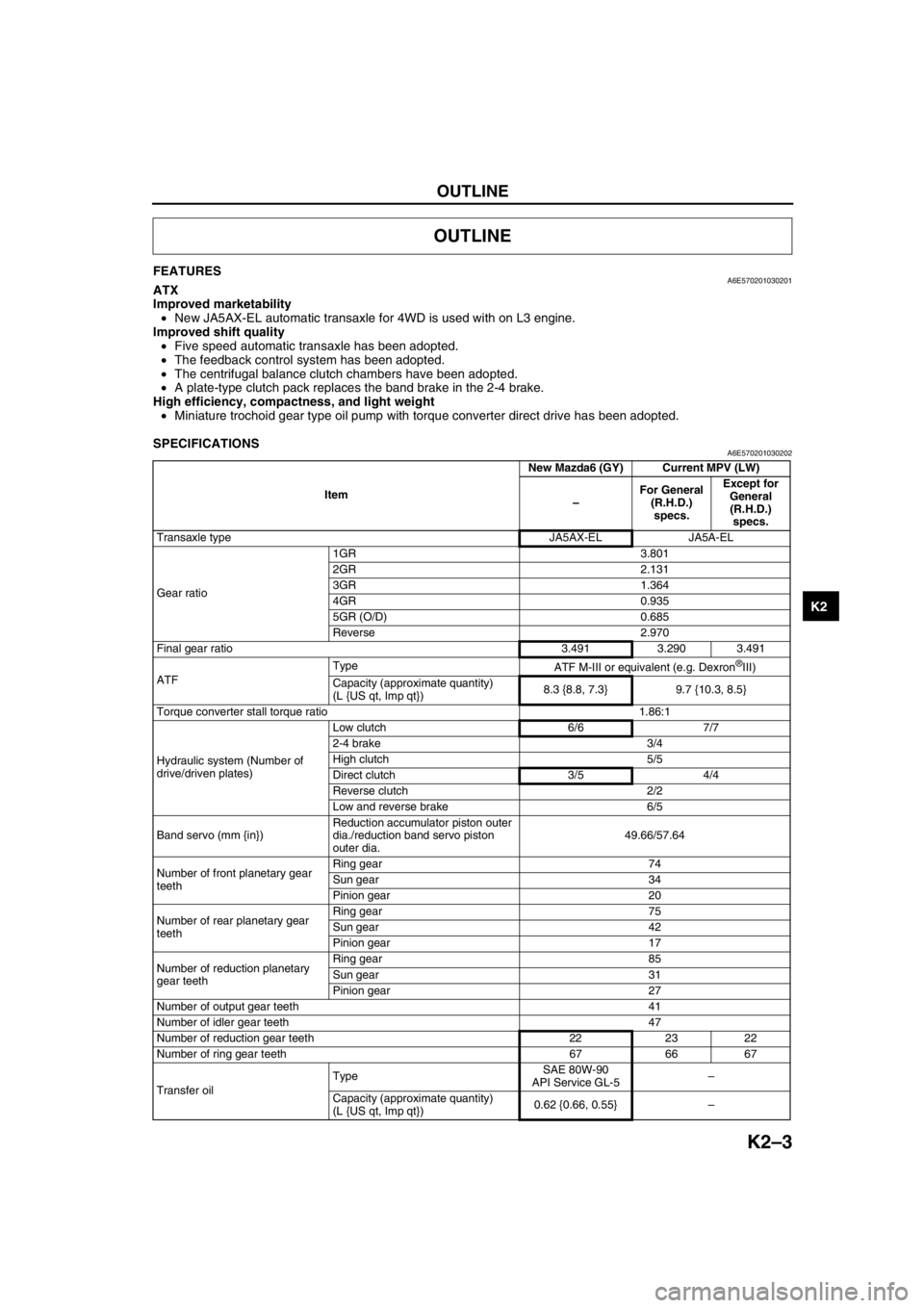

FEATURESA6E570201030201ATX

Improved marketability

•New JA5AX-EL automatic transaxle for 4WD is used with on L3 engine.

Improved shift quality

•Five speed automatic transaxle has been adopted.

•The feedback control system has been adopted.

•The centrifugal balance clutch chambers have been adopted.

•A plate-type clutch pack replaces the band brake in the 2-4 brake.

High efficiency, compactness, and light weight

•Miniature trochoid gear type oil pump with torque converter direct drive has been adopted.

End Of Sie

SPECIFICATIONSA6E570201030202

OUTLINE

ItemNew Mazda6 (GY) Current MPV (LW)

–For General

(R.H.D.)

specs.Except for

General

(R.H.D.)

specs.

Transaxle type JA5AX-EL JA5A-EL

Gear ratio1GR 3.801

2GR 2.131

3GR 1.364

4GR 0.935

5GR (O/D) 0.685

Reverse 2.970

Final gear ratio 3.491 3.290 3.491

ATFType

ATF M-III or equivalent (e.g. Dexron

®III)

Capacity (approximate quantity)

(L {US qt, Imp qt})8.3 {8.8, 7.3} 9.7 {10.3, 8.5}

Torque converter stall torque ratio 1.86:1

Hydraulic system (Number of

drive/driven plates)Low clutch 6/6 7/7

2-4 brake 3/4

High clutch 5/5

Direct clutch 3/5 4/4

Reverse clutch 2/2

Low and reverse brake 6/5

Band servo (mm {in})Reduction accumulator piston outer

dia./reduction band servo piston

outer dia.49.66/57.64

Number of front planetary gear

teethRing gear 74

Sun gear 34

Pinion gear 20

Number of rear planetary gear

teethRing gear 75

Sun gear 42

Pinion gear 17

Number of reduction planetary

gear teethRing gear 85

Sun gear 31

Pinion gear 27

Number of output gear teeth 41

Number of idler gear teeth 47

Number of reduction gear teeth 22 23 22

Number of ring gear teeth 67 66 67

Transfer oilTypeSAE 80W-90

API Service GL-5–

Capacity (approximate quantity)

(L {US qt, Imp qt})0.62 {0.66, 0.55}–

Page 419 of 909

K2–4

AUTOMATIC TRANSAXLE

Bold frames:New specifications

End Of Sie

OUTLINEA6E571401030201•Adopted new JA5AX-EL automatic transaxle.

•Newly designed FF type five-speed automatic transaxle.

—Use of 3 sets of planetary gears, and a wider gear ratio setting realizes improvement of acceleration-from-

standing-start performance, fuel economy, and quietness. Also, by placement of two sets of planetary gears

in parallel with one set, the automatic transaxle is more compact.

•Adopted 2-4 brake clutch.

—Adopted a wet-type, multi-plate 2-4 brake clutch instead of the 2-4 brake band used in the past, for

smoother gear switching performance.

•Adopted centrifugal balance clutch

—The newly adopted centrifugal balance clutch pushes the clutch piston forcefully to low and high clutch by

centrifugal hydraulic pressure for smoother gear switching with batter response.

•Adopted controller area network (CAN)

—By adopting CAN, The TCM is always in contact with other computers in the car and controls the automatic

transaxle properly. This has also made troubleshooting diagnosis easier for the entire vehicle.

•Solenoid, sensor

—Adoption of four duty-type solenoids, five ON-OFF type solenoids, and three revolving sensors realizes

finer, more expedient control of gear shifting performance.

•Adoption of revers inhibit control

—If the reverse position is selected by mistake while driving in forward motion, the reverse inhibit control

system will cancel the operation electronically and set the position to neutral as a safety enhancement.

Outline of Operation

•The operation of the electronic automatic transaxle is classified into three systems: the electronic control

system, the hydraulic pressure control system, and the powertrain system (includes the torque converter

system.)

Electronic control system

•According to the signals from the switches and sensors in the input system, the TCM outputs the signal

which matches the present driving condition to the ON/OFF type solenoids and the duty-cycle type

solenoids in the hydraulic pressure control system.

Hydraulic pressure control system

•According to the signals from the TCM, each solenoid operates to switch the hydraulic passages in the

control valve body and controls the clutch engagement pressure.

•The line pressure is adjusted by the duty-cycle type pressure control solenoid. The hydraulic passages

are switched by the ON/OFF type solenoids and the clutch engagement pressure is controlled by the

duty-cycle type solenoids.

Powertrain system

•The driving force from the engine is transmitted through the torque converter to the transaxle.

•The transmitted driving force operates each clutch and brake according to the clutch engagement

pressure from the duty-cycle type solenoid, and the planetary gears change the gear ratio to the

optimal driving force. The changed driving force is transmitted through the differential to the axle shaft

and then the tires.

AUTOMATIC TRANSAXLE