transaxle MAZDA 626 1987 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 1071 of 1865

ASSEMBLY 7B

11. Install the one-way clutch.

(1) Hold the one-way clutch horizontally.

(2) Install it by turning the carrier hub assembly

counterclockwise.

(3) Install the snap ring.

86U07B-406

49 G019 028

12. Install the servo to the transaxle case.

(1) Install the servo spring and servo.

(2) Compress the servo with the SST.

(3) Install the snap ring.

(4) Remove the SST.

(5) Install the piston stem.

86U07B-407

13. Install the anchor strut.

86U07B-408

14. Install the 2-4 brake band in the transaxle case so

that it is expanded fully.

Note

Interlock the 2-4 brake band and anchor strut

as shown.

86U07B-409

7B-205

Page 1073 of 1865

ASSEMBLY 7B

(2) Install the clutch assembly by rotating it.

86U07B-414

Note

Measure the height difference between the re-

verse and forward drum and transaxle case.

Standard height: 0.8 mm (0.032 in)

76G07B-185

17. Install the snap ring into the bottom ring groove

of the turbine shaft.

86U07B-416

7B—207

Page 1075 of 1865

ASSEMBLY 7B

86U07B-418

86U07B-419

76G07B-223

Procedure

1. Use the following procedure to adjust the total end

play and select a suitable bearing race.

(1) Set the thrust bearing onto the clutch assembly.

(2) Remove the previous race and gasket.

(3) Set the thickest bearing race 2.2 mm (0.087

in) onto the oil pump.

(4) Set the oil pump onto the clutch assembly.

(5) Measure clearance between the transaxle case

and oil pump.

(6) Select a suitable bearing race from the chart

below.

Clearance mm (in) Select this bearing race mm (in)

0.91-1.10 (0.036—0.043) 1.2 (0.047)

0.71-0.90 (0.028-0.035) 1.4 (0.055)

0.51-0.70 (0.020—0.027) 1.6 (0.063)

0.31-0.50 (0.012-0.019) 1.8 (0.071)

0.11-0.30 (0.004-0.011) 2.0 (0.078)

0-0.10 (0-0.003) 2.2 (0.087)

(7) Remove the oil pump.

(8) Place the selected bearing race and a new gas-

ket onto the oil pump.

(9) Install the oil pump onto the clutch assembly.

Tightening torque:

19—26 Nm (1.9—2.6 m-kg, 14—19 ft-lb)

86U07B-421

7B-209

Page 1076 of 1865

7B ASSEMBLY

2. Adjust the 2-4 brake band.

(1) Loosen the locknut and tighten the piston stem

to the specified torque.

Tightening torque:

9—11

N

m (90—110 cm-kg, 78—95 in-lb)

86U07B-422

(2) Loosen the piston stem 2 turns.

(3) Tighten the locknut to the specified torque.

Tightening torque:

25—39 N-m (2.5—4.0 m-kg, 18—29 tt-lb)

86U07B-423

Install the oil strainer along with a new O-ring to

the transaxle.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

86U07B-424

4. Install the oil pan along with a new gasket.

Tightening torque:

8—11 N-m (85—110 cm-kg, 74—95 in-lb)

Note

Install the magnets in the positions shown in

the illustration.

86U07B-425

7B—210

Page 1077 of 1865

ASSEMBLY 7B

5. Align the manual valve with the pin on the manual

plate, and install the control valve body into the

transaxle case.

Tightening torque:

11—15 Nm

(110—150 cm-kg, 95—130 in-lb)

86U07B-426

6. Install the solenoid connector and a new O-ring in

the transaxle case.

86U07B-427

7. Install a new O-ring on the bracket; then feed the

throttle cable through the transaxle case and con-

nect it to the throttle cam.

8. Install the throttle cable attaching bolts and bracket.

Tightening torque:

(§)8—11 Nm

(80—110 cm-kg, 69—95 in-lb)

(1)19—26

N

m

(1.9—2.6 m-kg, 14—19 ft-lb)

86U07B-428

9. Install the control valve body cover along with a

new gasket.

Tightening torque:

8—11

N

m (85—110 cm-kg, 74—95 in-lb)

86U07B-429

7 B—211

Page 1079 of 1865

ASSEMBLY 7B

12. Install the pulse generator and fluid temperature

switch.

Tightening torque:

Pulse generator

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

Fluid temperature switch

29—39 N-m (3.0—4.0 m-kg, 22—29 in-lb)

76G07B-190

76G07B-191

13. Install the inhibitor switch.

(1) Turn the manual shaft to the "N" position.

(2) Install the inhibitor switch and loosely tighten

the bolts.

(3) Remove the screw and move the inhibitor

switch so that the alignment hole is aligned with

the screw hole.

(4) Insert a 2.0 mm (0.079 in) diameter pin

through the holes.

(5) Install the screw; then tighten the bolts to the

specified torque.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

14. Install the harness with the remaining clip.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

15. Remove the transaxle from the SST.

76G07B-192

16. Install the oil level gauge and tube along with a new

O-ring to the transaxle case.

Tightening torque:

7—10 N-m (70—100 cm-kg, 61—87 in-lb)

76G07B-193

7B-213

Page 1082 of 1865

7B INSTALLATION

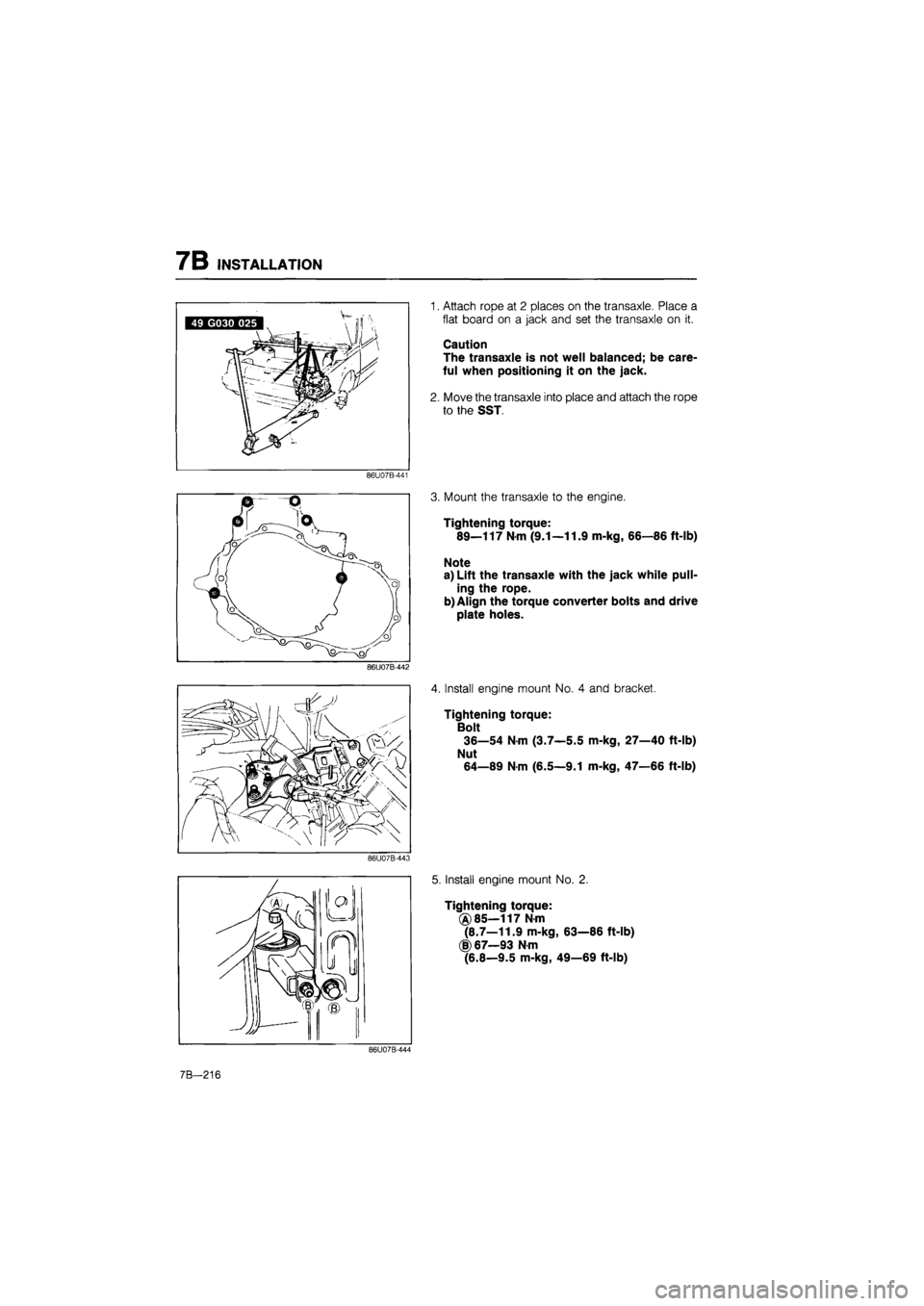

1. Attach rope at 2 places on the transaxle. Place a

flat board on a jack and set the transaxle on it.

Caution

The transaxle is not well balanced; be care-

ful when positioning it on the jack.

2. Move the transaxle into place and attach the rope

to the SST.

86U07B-441

3. Mount the transaxle to the engine.

Tightening torque:

89—117

N m

(9.1—11.9 m-kg, 66—86 ft-lb)

Note

a) Lift the transaxle with the jack while pull-

ing the rope.

b) Align the torque converter bolts and drive

plate holes.

86U07B-442

4. Install engine mount No. 4 and bracket.

Tightening torque:

Bolt

36—54 Nm (3.7—5.5 m-kg, 27—40 ft-lb)

Nut

64—89

N

m (6.5—9.1 m-kg, 47—66 ft-lb)

86U07B-443

5. Install engine mount No. 2.

Tightening torque:

(A)

85—117

N

m

(8.7—11.9 m-kg, 63—86 ft-lb)

(|)67—93 Nm

(6.8—9.5 m-kg, 49—69 ft-lb)

86U07B-444

7B—216

Page 1084 of 1865

7B INSTALLATION

86U07B-449

Standard bolt Reamer bolt

86U07B-450

86U07B-451

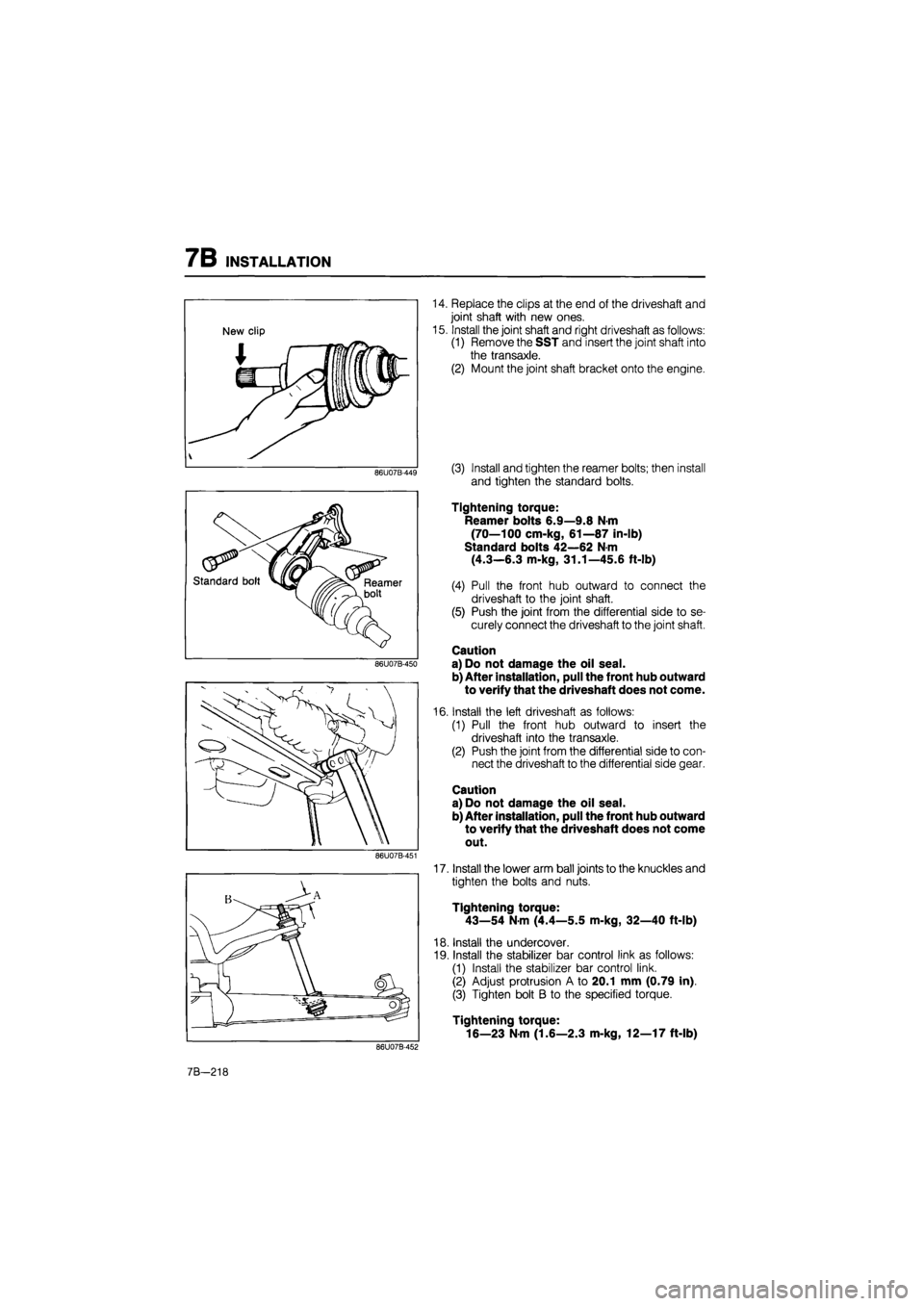

14. Replace the clips at the end of the driveshaft and

joint shaft with new ones.

15. Install the joint shaft and right driveshaft as follows:

(1) Remove the SST and insert the joint shaft into

the transaxle.

(2) Mount the joint shaft bracket onto the engine.

(3) Install and tighten the reamer bolts; then install

and tighten the standard bolts.

Tightening torque:

Reamer bolts 6.9—9.8 N-m

(70—100 cm-kg, 61—87 in-lb)

Standard bolts 42—62 N-m

(4.3—6.3 m-kg, 31.1—45.6 ft-lb)

(4) Pull the front hub outward to connect the

driveshaft to the joint shaft.

(5) Push the joint from the differential side to se-

curely connect the driveshaft to the joint shaft.

Caution

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to verify that the driveshaft does not come.

16. Install the left driveshaft as follows:

(1) Pull the front hub outward to insert the

driveshaft into the transaxle.

(2) Push the joint from the differential side to con-

nect the driveshaft to the differential side gear.

Caution

a) Do not damage the oil seal.

b) After installation, pull the front hub outward

to verify that the driveshaft does not come

out.

17. Install the lower arm ball joints to the knuckles and

tighten the bolts and nuts.

Tightening torque:

43—54 N-m (4.4—5.5 m-kg, 32—40 ft-lb)

18. Install the undercover.

19. Install the stabilizer bar control link as follows:

(1) Install the stabilizer bar control link.

(2) Adjust protrusion A to 20.1 mm (0.79 in).

(3) Tighten bolt B to the specified torque.

Tightening torque:

16—23 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

86U07B-452

7B-218

Page 1085 of 1865

INSTALLATION 7B

86U07B-453

86U07B-454

76G07B-198

20. Install the tie-rod ends and cotter pins.

Tightening torque:

29—44 N-m (3.0—4.5 m-kg, 22—33 ft-lb)

21. Install the oil cooler outlet and inlet hoses.

22. Install the splash shields.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

23. Install the front wheels.

Tightening torque:

88—118 N-m (9—12 m-kg, 65—87 ft-lb)

24. Connect the throttle cable.

Note

Adjust the throttle cable with the oil pressure

test. (Refer to page 7B—75, 76)

25. Connect the selector cable.

Tightening torque:

Nut

29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

Bolts

16—22 N-m (1.6—2.3 m-kg, 12—17 ft-lb)

26. Connect the ground wires to the transaxle case.

Tightening torque:

8—11 N-m (80—115 cm-kg, 69—99 in-lb)

86U07B-456

7B—219

Page 1086 of 1865

7B INSTALLATION

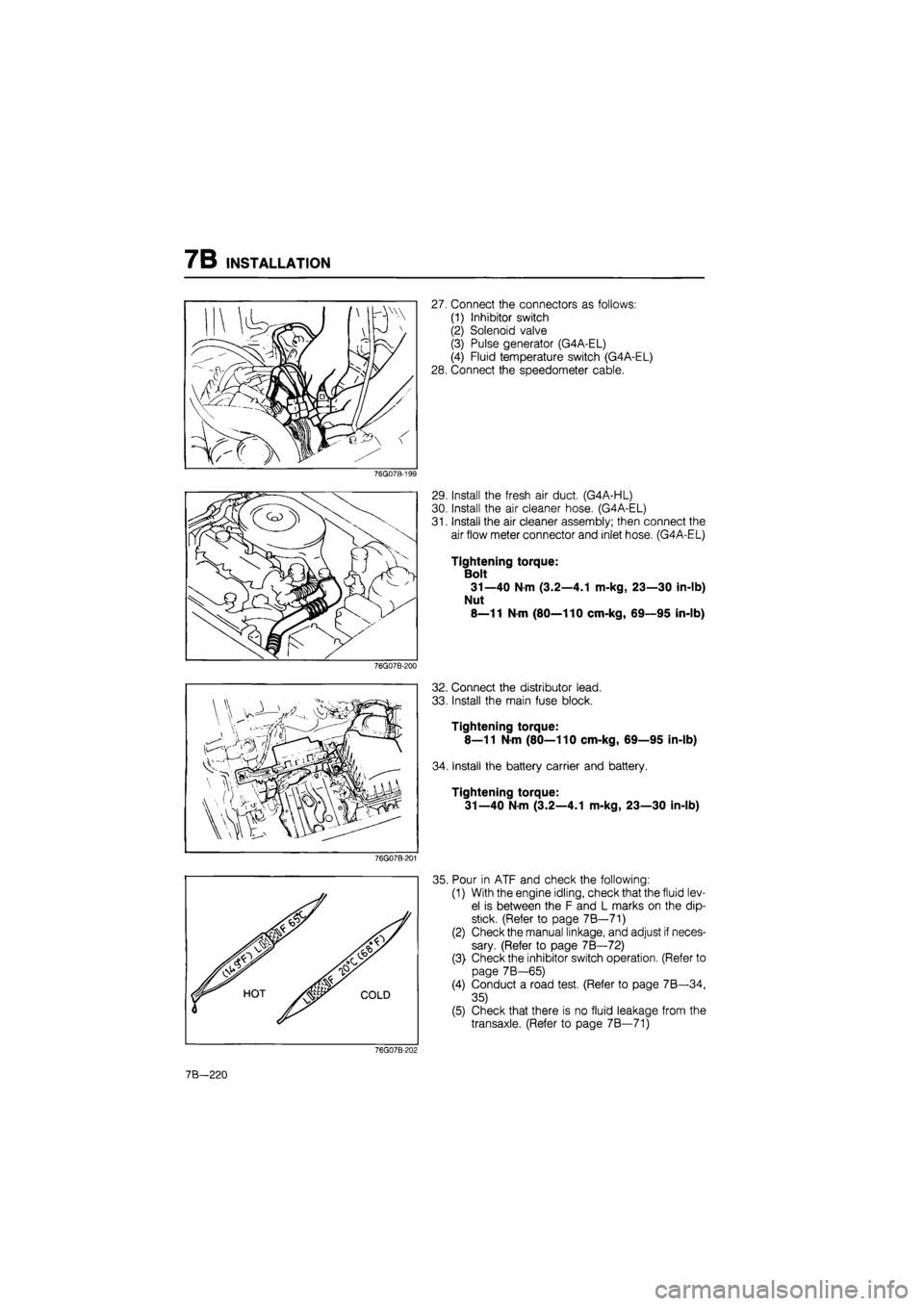

27. Connect the connectors as follows:

(1) Inhibitor switch

(2) Solenoid valve

(3) Pulse generator (G4A-EL)

(4) Fluid temperature switch (G4A-EL)

28. Connect the speedometer cable.

76G07B-199

76G07B-200

76G07B-201

29. Install the fresh air duct. (G4A-HL)

30. Install the air cleaner hose. (G4A-EL)

31. Install the air cleaner assembly; then connect the

air flow meter connector and inlet hose. (G4A-EL)

Tightening torque:

Bolt

31—40 N-m (3.2—4.1 m-kg, 23—30 in-lb)

Nut

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

32. Connect the distributor lead.

33. Install the main fuse block.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

34. Install the battery carrier and battery.

Tightening torque:

31—40 N-m (3.2—4.1 m-kg, 23—30 in-lb)

35. Pour in ATF and check the following:

(1) With the engine idling, check that the fluid lev-

el is between the F and L marks on the dip-

stick. (Refer to page 7B—71)

(2) Check the manual linkage, and adjust if neces-

sary. (Refer to page 7B—72)

(3) Check the inhibitor switch operation. (Refer to

page 7B—65)

(4) Conduct a road test. (Refer to page 7B—34,

35)

(5) Check that there is no fluid leakage from the

transaxle. (Refer to page 7B—71)

76G07B-202

7B—220