engine MAZDA 626 1987 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 135 of 1865

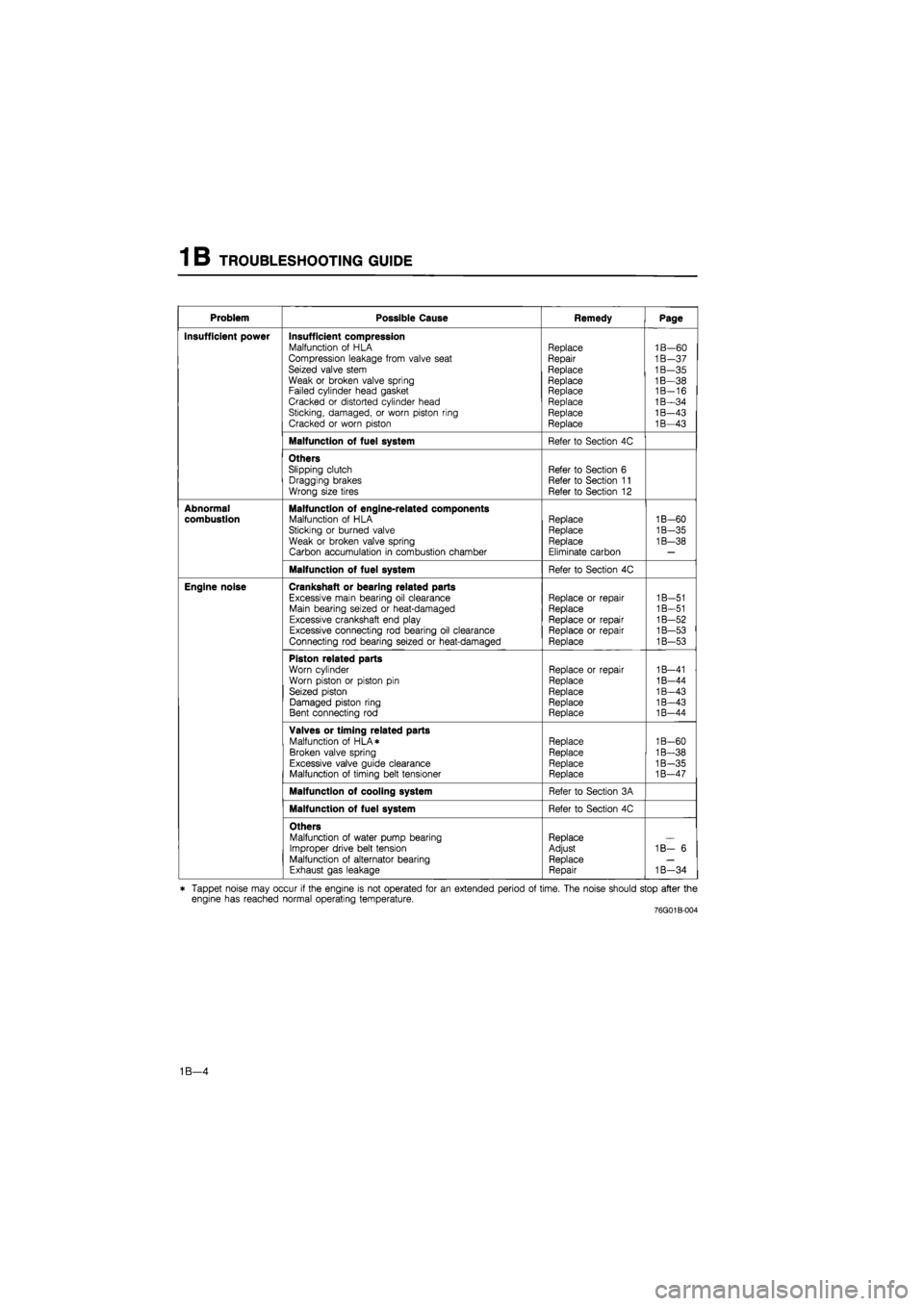

TROUBLESHOOTING GUIDE 1 B

Problem Possible Cause Remedy Page

Insufficient power Insufficient compression Malfunction of HLA Compression leakage from valve seat Seized valve stem Weak or broken valve spring Failed cylinder head gasket Cracked or distorted cylinder head Sticking, damaged, or worn piston ring Cracked or worn piston

Replace Repair

Replace

Replace Replace Replace Replace Replace

1B—60 1B—37 1B—35 1B—38 1B-16 1B—34 1B—43 1B—43

Malfunction of fuel system Refer to Section 4C

Others Slipping clutch Dragging brakes Wrong size tires

Refer to Section 6 Refer to Section 11 Refer to Section 12

Abnormal combustion Malfunction of engine-related components Malfunction of HLA Sticking or burned valve

Weak or broken valve spring Carbon accumulation in combustion chamber

Replace Replace Replace

Eliminate carbon

1B-60

1B-35

1B—38

Malfunction of fuel system Refer to Section 4C

Engine noise Crankshaft or bearing related parts

Excessive main bearing oil clearance Main bearing seized or heat-damaged Excessive crankshaft end play Excessive connecting rod bearing oil clearance Connecting rod bearing seized or heat-damaged

Replace or repair Replace

Replace or repair Replace or repair Replace

1B-51 1B—51 1B—52 1B—53 1B—53

Piston related parts

Worn cylinder Worn piston or piston pin Seized piston Damaged piston ring Bent connecting rod

Replace or repair

Replace

Replace Replace Replace

1B—41 1B-44 1B—43 1B—43 1B-44

Valves or timing related parts Malfunction of HLA* Broken valve spring Excessive valve guide clearance Malfunction of timing belt tensioner

Replace Replace Replace Replace

1B-60 1B—38 1B—35 1B—47

Malfunction of cooling system Refer to Section 3A

Malfunction of fuel system Refer to Section 4C

Others Malfunction of water pump bearing Improper drive belt tension Malfunction of alternator bearing Exhaust gas leakage

Replace Adjust Replace Repair

1B— 6

1B—34

* Tappet noise may occur if the engine is not operated for an extended period of time. The noise should stop after the engine has reached normal operating temperature. 76G01B-004

1B—4

Page 136 of 1865

TUNE-UP PROCEDURE 1 B

76G01A-102

TUNE-UP PROCEDURE

Tune the engine according to the procedures

described below.

Battery

1. Check for corrosion on the terminals, or loose ca-

ble connections.

If necessary, clean the clamps and tighten firmly.

2. Check that the electrolyte level is between the UP-

PER and LOWER marks.

Add distilled water if necessary.

3. Check the specific gravity by using a hydrometer.

If the specific gravity reading is 1.200 or less,

recharge the battery. (Refer to Section 5.)

76G01A-103

Air Cleaner Element

Visually check the air cleaner element for excessive

dirt, damage, or oil. Clean or replace if necessary.

Caution

When cleaning the air cleaner element, blow

dust off from the inside completely first, then

blow from the outside.

76G01B-005

Engine Oil

Check the engine oil level and condition with the oil

level gauge.

Add oil, or change it, if necessary.

4BG01A-010

1B—5

Page 137 of 1865

1B TUNE-UP PROCEDURE 1 B

86U01X-008

Coolant Level (Cold engine)

1. Check that the coolant level is near the radiator inlet

port.

2. Check that the level in the coolant reservoir is be-

tween the FULL and LOW marks.

Add coolant if necessary.

Warning

a) Never remove the radiator cap while the en-

gine is hot.

b) Wrap a thick cloth around the cap and care-

fully remove it.

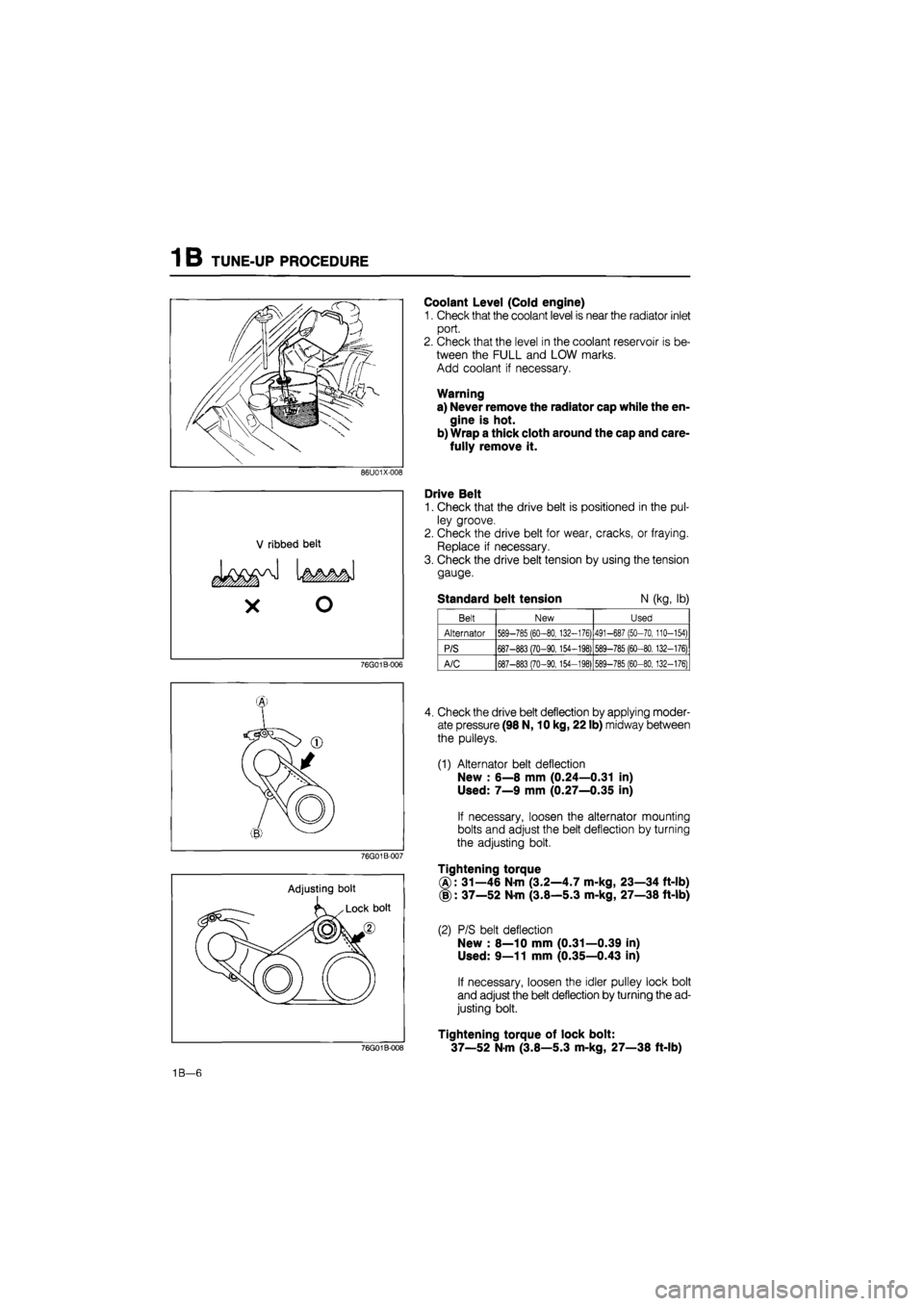

Drive Belt

1. Check that the drive belt is positioned in the pul-

ley groove.

2. Check the drive belt for wear, cracks, or fraying.

Replace if necessary.

3. Check the drive belt tension by using the tension

gauge.

Standard belt tension N (kg, lb)

76G01B-006

Belt New Used

Alternator 589-785 (60-80, 132-176) 491-687 (50-70, 110-154)

P/S 687-883 (70-90,154-198) 589-785 (60-80.132-176)

A/C 687-883 (70-90,154-198) 589-785 (60-80,132-176)

76G01B-007

Adjusting bolt

76G01B-008

4. Check the drive belt deflection by applying moder-

ate pressure (98 N, 10 kg, 22 lb) midway between

the pulleys.

(1) Alternator belt deflection

New : 6—8 mm (0.24—0.31 in)

Used: 7—9 mm (0.27—0.35 in)

If necessary, loosen the alternator mounting

bolts and adjust the belt deflection by turning

the adjusting bolt.

Tightening torque

®: 31—46 Nm (3.2—4.7 m-kg, 23—34 ft-lb)

(§): 37—52 Nm (3.8—5.3 m-kg, 27—38 ft-lb)

(2) P/S belt deflection

New : 8—10 mm (0.31—0.39 in)

Used: 9—11 mm (0.35—0.43 in)

If necessary, loosen the idler pulley lock bolt

and adjust the belt deflection by turning the ad-

justing bolt.

Tightening torque of lock bolt:

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

1B—6

Page 139 of 1865

TUNE-UP PROCEDURE 1 B

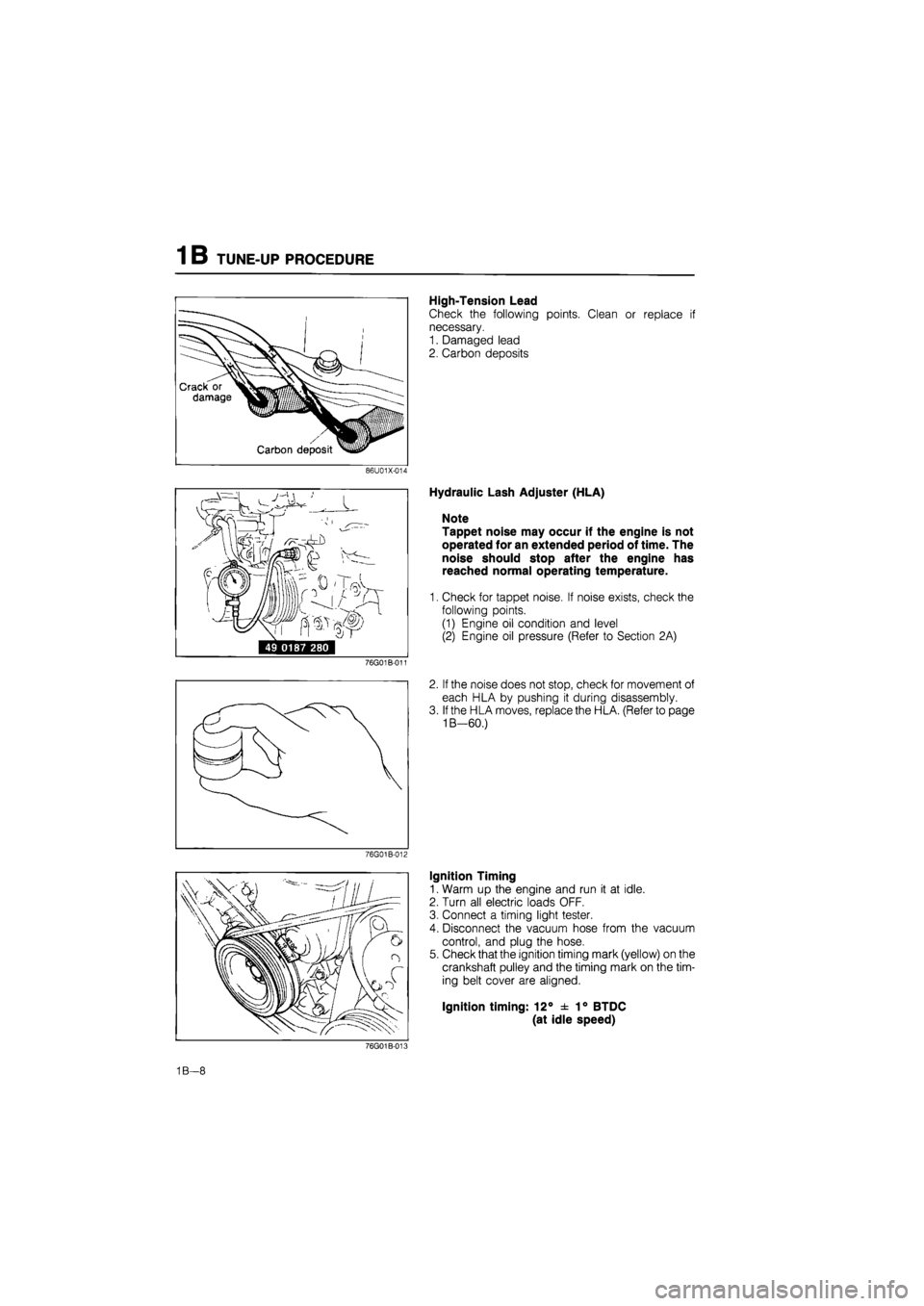

High-Tension Lead

Check the following points. Clean or replace if

necessary.

1. Damaged lead

2. Carbon deposits

86U01X-014

i^rrr ' /

49 0187 280

76G01B-011

76G01B-012

Hydraulic Lash Adjuster (HLA)

Note

Tappet noise may occur if the engine is not

operated for an extended period of time. The

noise should stop after the engine has

reached normal operating temperature.

1. Check for tappet noise. If noise exists, check the

following points.

(1) Engine oil condition and level

(2) Engine oil pressure (Refer to Section 2A)

2. If the noise does not stop, check for movement of

each HLA by pushing it during disassembly.

3. If the HLA moves, replace the HLA. (Refer to page

1B—60.)

Ignition Timing

1. Warm up the engine and run it at idle.

2. Turn all electric loads OFF.

3. Connect a timing light tester.

4. Disconnect the vacuum hose from the vacuum

control, and plug the hose.

5. Check that the ignition timing mark (yellow) on the

crankshaft pulley and the timing mark on the tim-

ing belt cover are aligned.

Ignition timing: 12° ± 1° BTDC

(at idle speed)

76G01B-008

1B—8

Page 140 of 1865

TUNE-UP PROCEDURE 1 B

76G01B-015

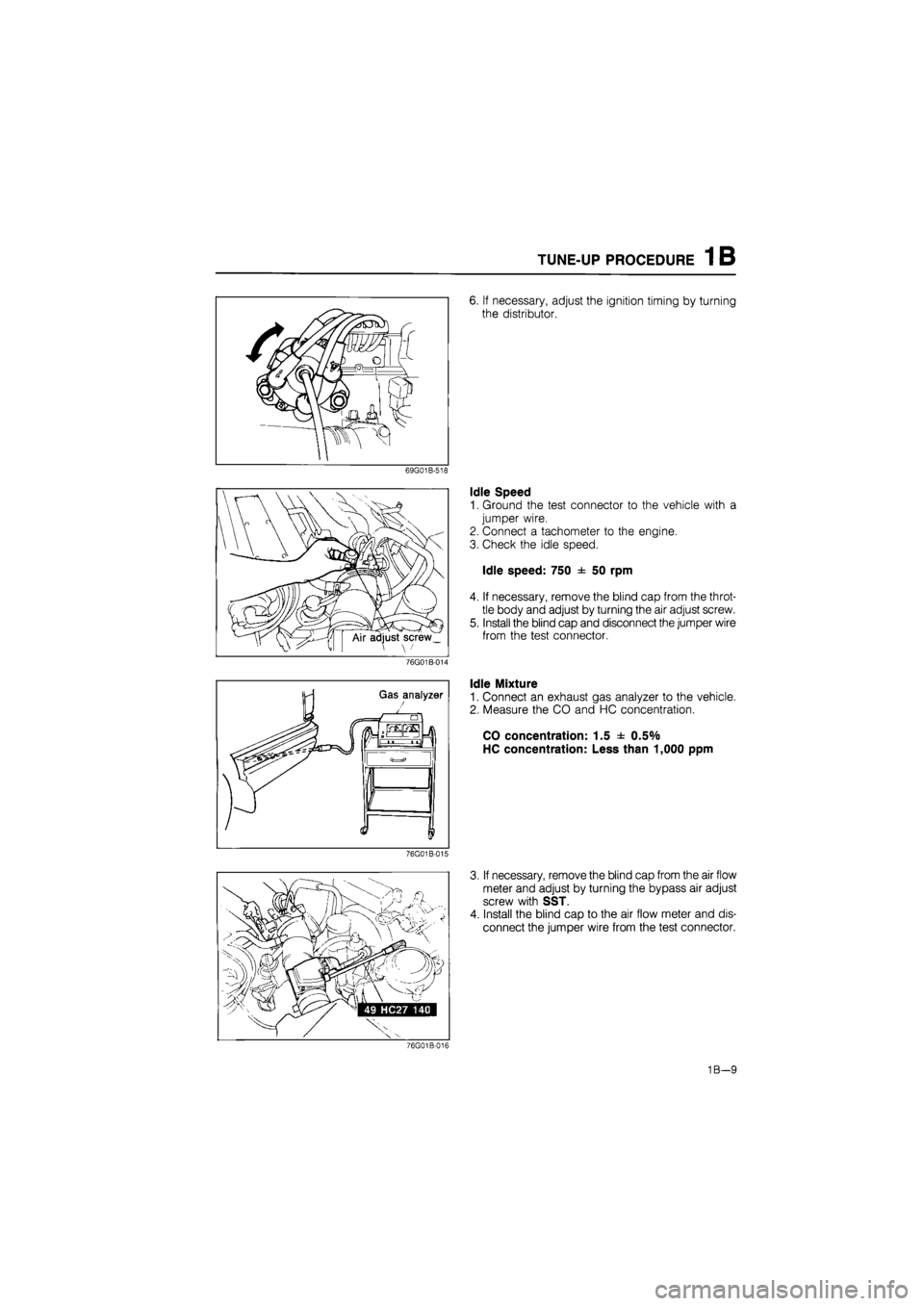

6. If necessary, adjust the ignition timing by turning

the distributor.

Idle Speed

1. Ground the test connector to the vehicle with a

jumper wire.

2. Connect a tachometer to the engine.

3. Check the idle speed.

Idle speed: 750 ± 50 rpm

4. If necessary, remove the blind cap from the throt-

tle body and adjust by turning the air adjust screw.

5. Install the blind cap and disconnect the jumper wire

from the test connector.

Idle Mixture

1. Connect an exhaust gas analyzer to the vehicle.

2. Measure the CO and HC concentration.

CO concentration: 1.5 ± 0.5%

HC concentration: Less than 1,000 ppm

3. If necessary, remove the blind cap from the air flow

meter and adjust by turning the bypass air adjust

screw with SST.

4. Install the blind cap to the air flow meter and dis-

connect the jumper wire from the test connector.

76G01B-016

1B—9

Page 141 of 1865

1 B ON-VEHICLE INSPECTION

76G01B-017

86U01X-020

76G01B-018

Possible Cause

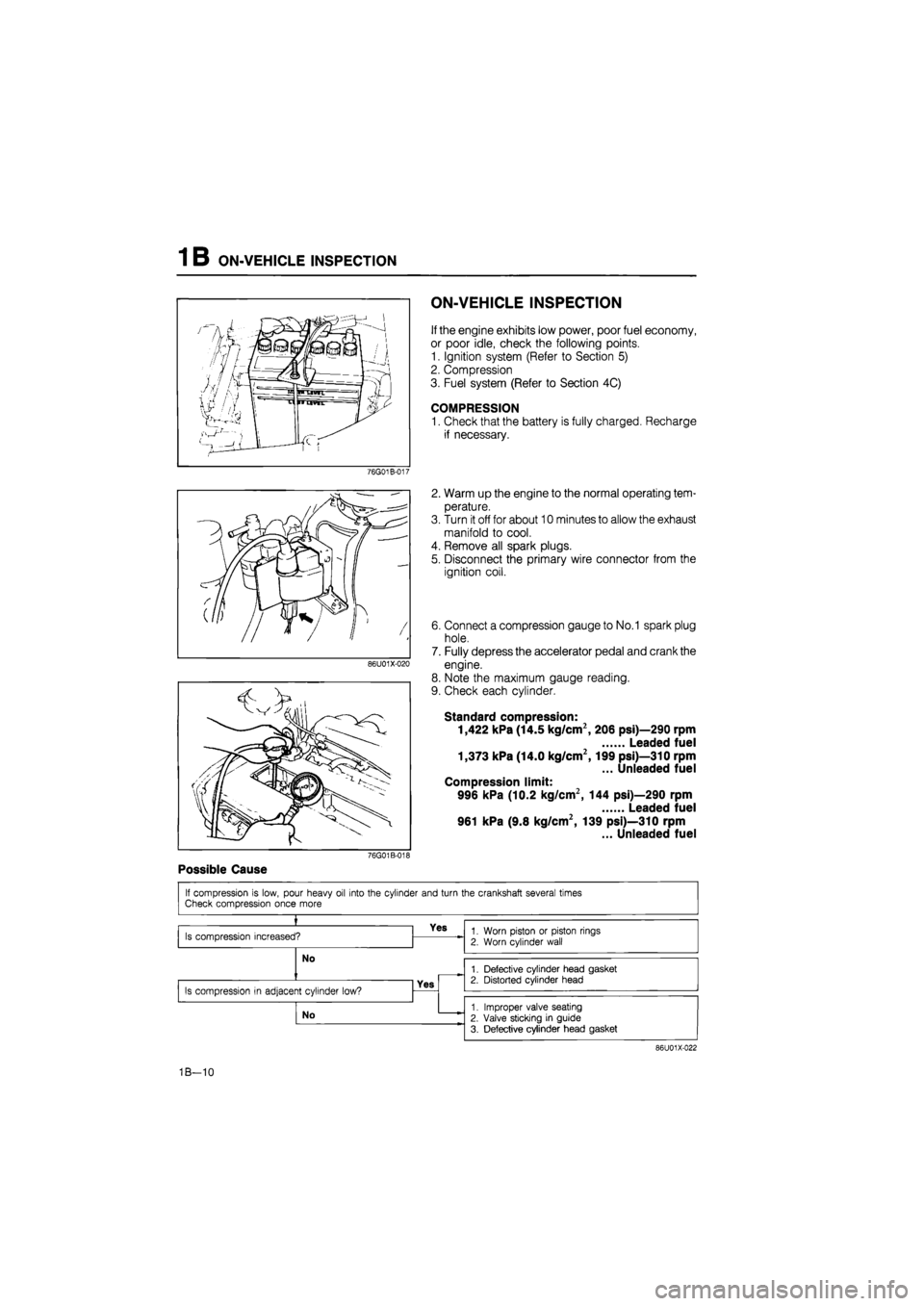

ON-VEHICLE INSPECTION

If the engine exhibits low power, poor fuel economy,

or poor idle, check the following points.

1. Ignition system (Refer to Section 5)

2. Compression

3. Fuel system (Refer to Section 4C)

COMPRESSION

1. Check that the battery is fully charged. Recharge

if necessary.

2. Warm up the engine to the normal operating tem-

perature.

3. Turn it off for about 10 minutes to allow the exhaust

manifold to cool.

4. Remove all spark plugs.

5. Disconnect the primary wire connector from the

ignition coil.

6. Connect a compression gauge to No.1 spark plug

hole.

7. Fully depress the accelerator pedal and crank the

engine.

8. Note the maximum gauge reading.

9. Check each cylinder.

Standard compression:

1,422 kPa (14.5 kg/cm2, 206 psi)—290 rpm

Leaded fuel

1,373 kPa (14.0 kg/cm2,199 psi)—310 rpm

... Unleaded fuel

Compression limit:

996 kPa (10.2 kg/cm2, 144 psi)—290 rpm

Leaded fuel

961 kPa (9.8 kg/cm2, 139 psi)—310 rpm

... Unleaded fuel

If compression is low, pour heavy oil into the cylinder and turn the crankshaft several times Check compression once more

»

Is compression increased? Yes 1. Worn piston or piston rings

2. Worn cylinder wall

No

1. Worn piston or piston rings

2. Worn cylinder wall

No 1. Defective cylinder head gasket 2. Distorted cylinder head

Is compression in adjacent cylinder low? Yes

1. Defective cylinder head gasket 2. Distorted cylinder head

Is compression in adjacent cylinder low?

No 1. Improper valve seating

2. Valve sticking in guide

3. Defective cylinder head gasket

86U01X-022

1B—10

Page 142 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 B

ON-VEHICLE MAINTENANCE

TIMING BELT

Removal

1. Disconnect the negative battery cable.

2. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

76G01A-108

76G01B-020

1. Center cover

2. High-tension lead and spark plug

3. Engine side cover

4. Drive belt

5. Crankshaft pulley

6. Engine mount bracket

7. Upper timing belt cover

8. Lower timing belt cover

9. Baffle plate

10. Timing belt tensioner

11. Timing belt tensioner spring

12. Timing belt

1B—11

Page 146 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 B

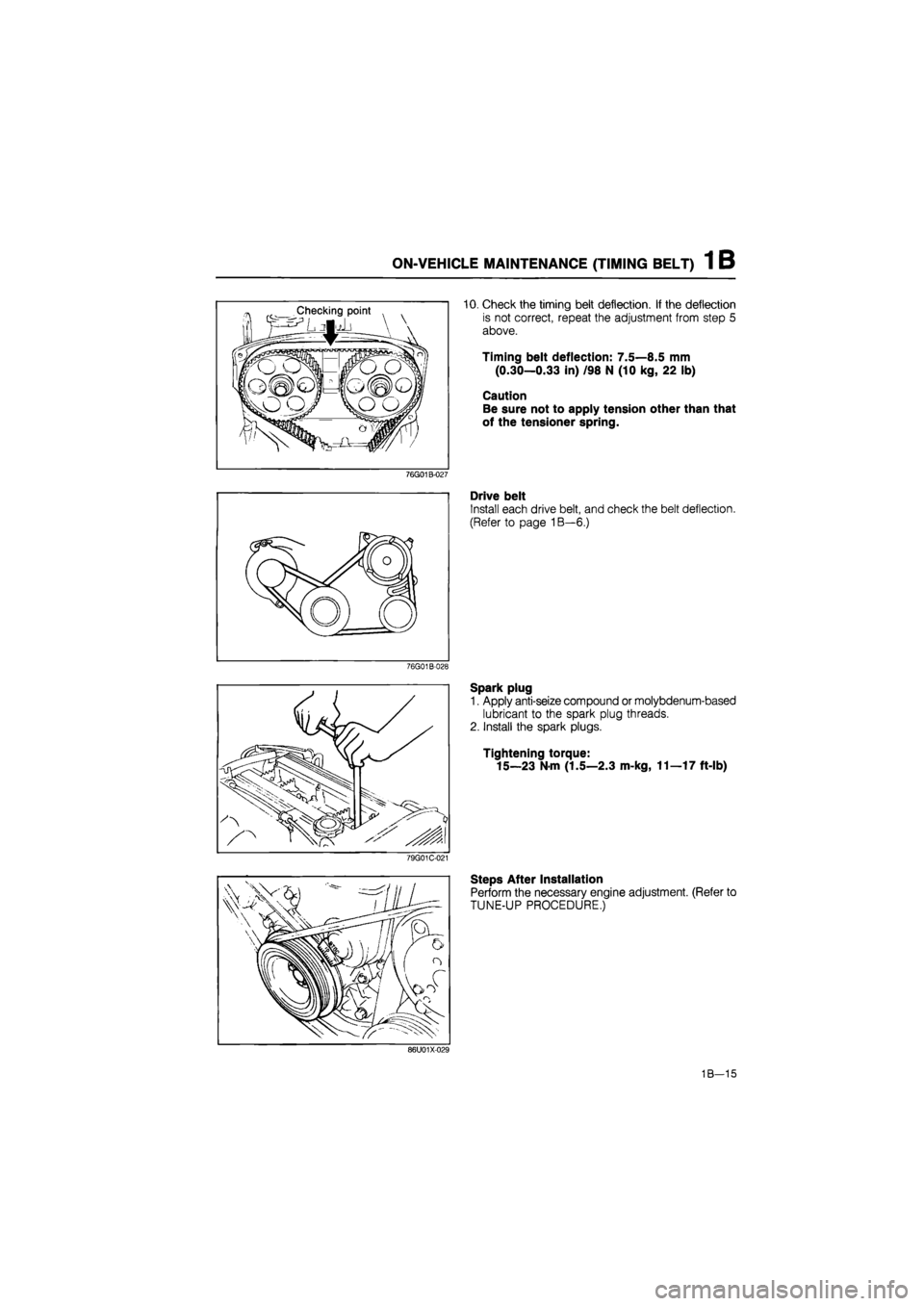

10. Check the timing belt deflection. If the deflection

is not correct, repeat the adjustment from step 5

above.

Timing belt deflection: 7.5—8.5 mm

(0.30—0.33 in) /98 N (10 kg, 22 lb)

Caution

Be sure not to apply tension other than that

of the tensioner spring.

76G01B-027

Drive belt

Install each drive belt, and check the belt deflection.

(Refer to page 1B—6.)

76G01B-028

Spark plug

1. Apply anti-seize compound or molybdenum-based

lubricant to the spark plug threads.

2. Install the spark plugs.

Tightening torque:

15—23

N

m (1.5—2.3 m-kg, 11—17 ft-lb)

79G01C-021

Steps After Installation

Perform the necessary engine adjustment. (Refer to

TUNE-UP PROCEDURE.)

86U01X-029

1B—15

Page 147 of 1865

1 B ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

CYLINDER HEAD

Removal

Warning: Release the fuel pressure. (Refer to Section 4C.)

1. Disconnect the negative battery cable.

2. Drain the engine coolant.

3. Remove in the sequence shown in the figure referring to the removal note for specially marked parts.

1B—16

76G01B-034

Page 148 of 1865

1 B ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

1. Center cover

2. High-tension lead and spark plug

3. Accelerator cable

4. Air intake pipe assembly

5. Fuel hose

6. Upper radiator hose

7. Heater hose

8. Brake vacuum hose

9. Canister hose (Unleaded fuel)

10. Engine harness connector and ground

11. EGR pipe (Unleaded fuel)

12. A/C compressor and bracket

13. Exhaust manifold insulator

14. Exhaust pipe

15. Exhaust manifold

16. Intake manifold bracket

17. Intake manifold assembly

18. Distributor

19. Engine mount stay

20. Upper timing belt cover

21. Timing belt tensioner spring

22. Timing belt

23. Cylinder head cover

24. Cylinder head and gasket

76G01B-030

Removal note

Fuel hose

Warning

a) Cover the hose with a rag because fuel will

spray out when disconnecting.

b) Keep sparks and open flame away from the

fuel area.

Plug the disconnected hoses to avoid fuel leakage.

86U01X-032

Timing belt

1. Before removing the timing belt, turn the crankshaft

to align the mating marks of the camshaft pulleys

with the seal plate timing mark.

Note

For intake side camshaft pulley, align "I"

mark.

For exhaust side camshaft pulley, align "E"

mark.

76G01B-031

2. Loosen the timing belt tensioner lock bolt.

3. Shift the tensioner outward as far as possible, then

temporarily tighten it.

76G01B-034

1B—17