MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: seats, engine oil capacity, service reset, alternator belt, Exhaust, change time, steering wheel adjustment

Page 1361 of 1865

ENGINE SPEED SENSING POWER STEERING 1 0

3. Tap in a new roll pin.

86U10X-175

i V

vlM^lPl'' \f ) j//

/f

Boot

1. Apply grease to the inner surface of the small end

of the boot.

2. Install the boot. Wrap a new wire around the large

end of the boot two times and then twist it 4 to 4.5

times. Bend the twisted part toward the mounting

bracket.

Note

Be careful not to break the boot wire.

3. Install the spring clip on the small end of the boot.

86U10X-176

Tie-rod end

Align with the mark made before disassembly, and

then tighten the nut.

86U10X-177

Oil pipe

Secure the mounting bracket in a vise so that the oil

pipe connections face upward.

86U10X-178

10-73

Page 1362 of 1865

1 0 ENGINE SPEED SENSING POWER STEERING

Oil pressure switch

1. Install the pressure switch O-ring in the gear

housing.

2. Install the oil pressure switch.

Tightening torque:

31—36 N-m (3.2—3.7 m-kg, 23—27 ft-lb)

10—74

Page 1363 of 1865

ELECTRONICALLY-CONTROLLED POWER STEERING 1 0

ELECTRONICALLY-CONTROLLED POWER STEERING

DISASSEMBLY

Disassemble in the sequence shown in the figure, referring to the disassembly note for specially marked

parts.

Caution

a) Because adjustment of the spool valve is not possible, do not disassemble the gear box

for spool valve repairs. If repairs are necessary, replace the gear box assembly.

b) In order to prevent the entrance of dirt, all disassembly and assembly should be done

in a clean area.

c) Before disassembly, plug the openings of all pipe installation fittings; then thoroughly

clean the steering gear and linkage.

86U10X-180

1. Pipe

2. Solenoid valve

3. Tie-rod end

4. Tie-rod end locknut

5. Spring clip

6. Boot wire

7. Boot

8. Tie-rod

9. Adjust cover locknut

10. Adjust cover

11. Spring

12. Pressure pad

13. Outer box assembly

14. Oil seal

15. Mounting bracket

16. Mounting rubber

10—75

Page 1364 of 1865

1 0 ELECTRONICALLY-CONTROLLED POWER STEERING

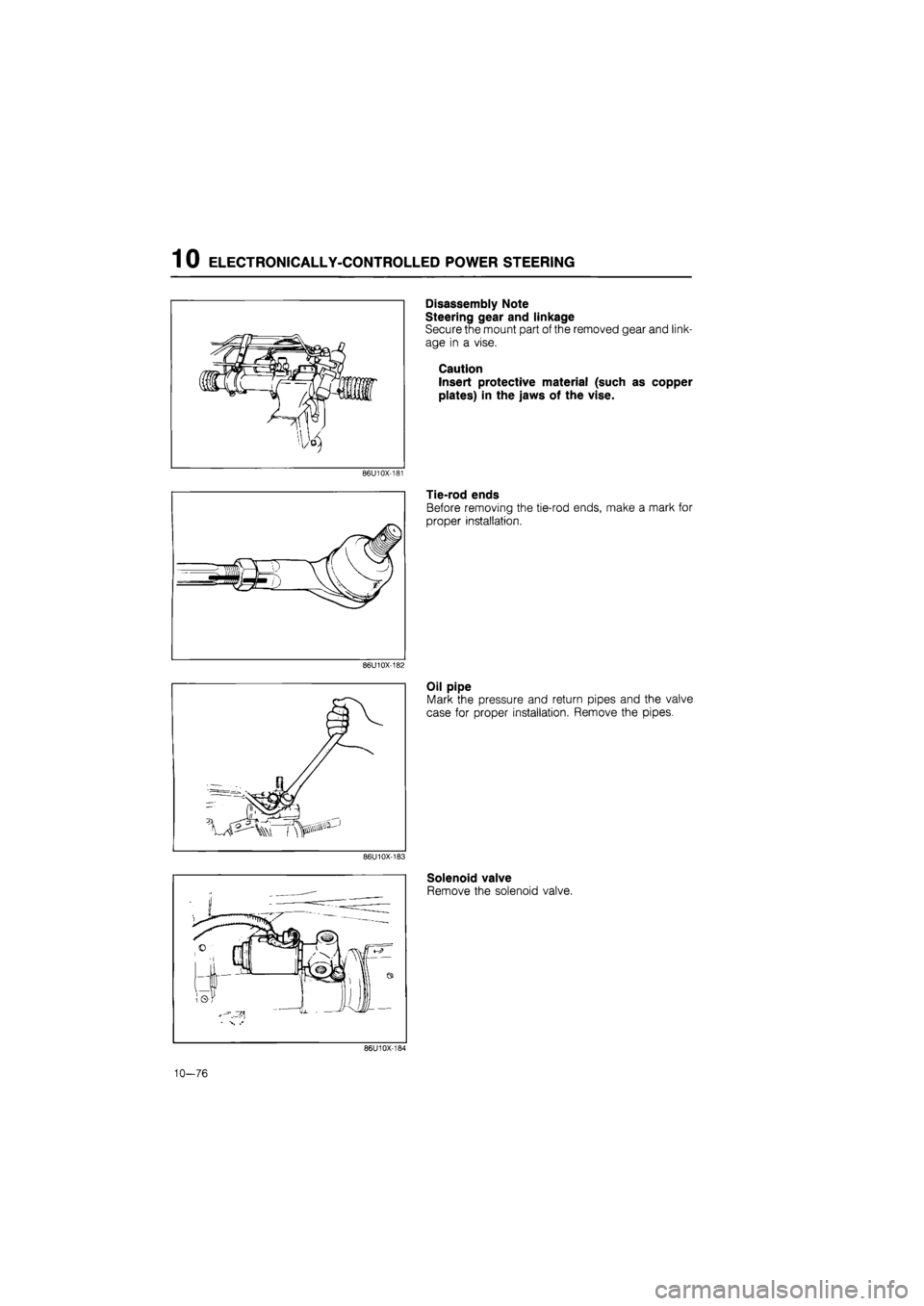

Disassembly Note

Steering gear and linkage

Secure the mount part of the removed gear and link-

age in a vise.

Caution

Insert protective material (such as copper

plates) in the jaws of the vise.

86U10X-181

Tie-rod ends

Before removing the tie-rod ends, make a mark for

proper installation.

86U10X-182

Oil pipe

Mark the pressure and return pipes and the valve

case for proper installation. Remove the pipes.

86U10X-183

Solenoid valve

Remove the solenoid valve.

86U10X-184

10—76

Page 1365 of 1865

ELECTRONICALLY-CONTROLLED POWER STEERING 1 0

/

I I

86U10X-185

63U10X-127

86U10X-186

Tie-rods

1. Uncrimp the washer as shown in the figure.

2. Remove the tie-rod from the rack.

Locknut and adjust cover

Loosen the locknut and remove the adjust cover,

spring, and pressure pad.

Outer box

Protect the outer box with cloth and remove it with

a pipe wrench.

86U10X-187

10—77

Page 1366 of 1865

1 0 ELECTRONICALLY-CONTROLLED POWER STEERING

Oil seal

Remove the oil seal with a screwdriver.

86U10X-188

INSPECTION

Check the following and replace any faulty parts.

1. Cracked, damaged, or deteriorated boots

2. Worn pressure pad friction surface

3. Loose or sticking tie-rod ball joint

4. Bent or damaged tie-rod or tie-rod end

86U10X-189

5. Worn outer box bushing

86U10X-190

6. Cracked or damaged gear housing

7. Steering gear oil leakage

86! I10X-191

10-78

Page 1367 of 1865

ELECTRONICALLY-CONTROLLED POWER STEERING 1 0

ASSEMBLY

Torque Specifications

29—39 N-m (3.0-4.0 m-kg, 22-29 ft-lb)

29—39 N m

(3.0—4.0 m-kg, 22—29 ft-lb)

29—39 N m

(3.0—4.0 m-kg, 22—29 ft-lb) 29—39 N-m (3.0—4.0 m-kg, 22—29 ft-lb)

15—25 N m (1.5—2.5 m-kg

3.9—4.9 N m (0.4—0.5 m-kg,

39—49 N-m (4.0—5.0 m-kg, 29—36 ft-lb) 78—98 N-m (8.0—10.0 m-kg, 58—72 ft-lb)

34—44 N m 34—44 N-m (3.5—4.5 m-kg, 25—33 ft-lb) (3.5-4.5 m-kg, 25—33 ft-lb) (7.0—ID, 0 m-kg, 51—72 ft-lb)

86U10X-252

1. Install the outer box in the rack housing.

Note

Coat the seals and O-rings with ATF.

86U10X-192

10—79

Page 1368 of 1865

1 0 ELECTRONICALLY-CONTROLLED POWER STEERING

2. Protect the outer box with cloth and tighten it with

a pipe wrench.

86U10X-193

3. Stake between the outer box and the rack hous-

ing with a center punch.

B6U10X-194

4. Install the oil seal with a suitable pipe.

86U10X-195

5. Install the pressure pad and spring in the gear

housing.

86U10X-196

10—80

Page 1369 of 1865

ELECTRONICALLY-CONTROLLED POWER STEERING 1 0

86U10X-197

86U10X-198

86U10X-199

6. Apply thread sealant to the threads of the adjust

cover.

7. Install the adjust cover to the gear housing and

tighten it as specified; then loosen it 35°.

Tightening torque:

4.5—5.5 Nm

(45—55 cm-kg, 39—48 in-lb)

8. Measure the pinion torque with the SST.

Pull scale: 1,000—1,400 g (35.3—49.4 oz)

9. If the pinion torque is not within specification, read-

just the adjust cover.

10. Lock the adjust cover with the locknut.

Tightening torque:

40—50

N

m

(4—5 m-kg, 29—36 ft-lb)

11. Set the rack in a vise and install the washer. Tight-

en the tie-rod.

Tightening torque:

60—80 N-m

(6—8 m-kg, 43—58 ft-lb)

Caution

Insert protective material (such as copper

plates) in the jaws of the vise.

76G10X-040

10—81

Page 1370 of 1865

1 0 ELECTRONICALLY-CONTROLLED POWER STEERING

12. Stake the washer in two places with a punch.

86U10X-201

13. Install the boot. Wrap a new wire around it two

times and twist it 4 to 4.5 times.

Caution

Be sure that the boot is not twisted or dented.

86U10X-202

14. Install the tie-rod ends, aligning them with the marks

made before disassembly.

86U10X-203

15. Install the solenoid valve and pressure switch.

16. Align the oil pipes with the marks made before dis-

assembly, then tighten them.

86U10X-204

10—82

Trending: load capacity, alternator belt, fog light, air suspension, engine oil, drain bolt, fuel pump relay