clutch MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 896 of 1865

7B TROUBLESHOOTING (G4A-EL)

STEP 5 (TIME LAG TEST)

If the selector lever is shifted while the engine is idling, there will be a certain time lapse, or time lag,

before shock is felt. This step checks this time lag for checking condition of the 1-2, N-R, and N-D

accumulators, forward, and one-way clutches, 2-4 brake band, and low and reverse brake.

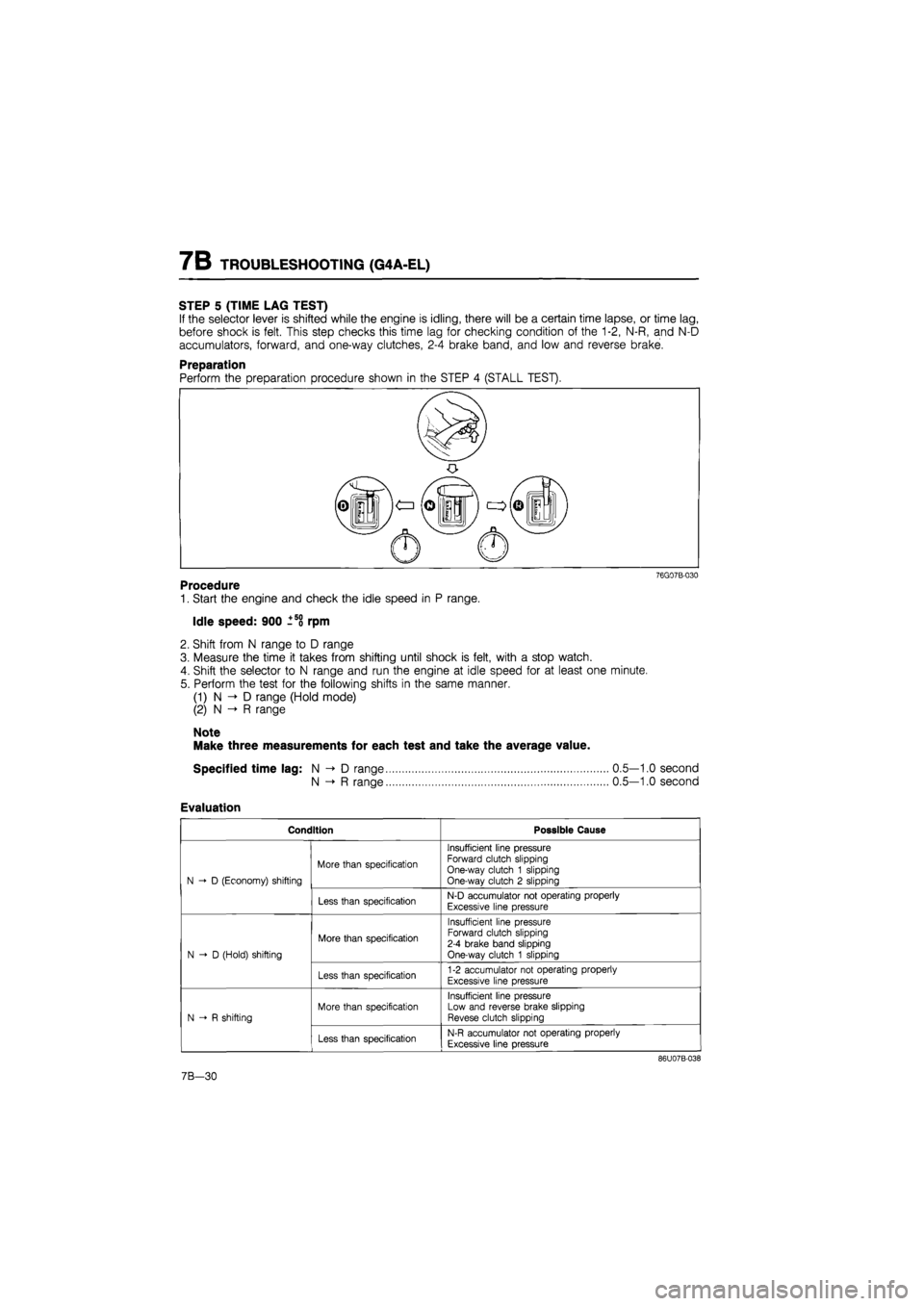

Preparation

76G07B-030

Procedure

1. Start the engine and check the idle speed in P range.

Idle speed: 900 ±58 rpm

2. Shift from N range to D range

3. Measure the time it takes from shifting until shock is felt, with a stop watch.

4. Shift the selector to N range and run the engine at idle speed for at least one minute.

5. Perform the test for the following shifts in the same manner.

(1) N D range (Hold mode)

(2) N -» R range

Note

Make three measurements for each test and take the average value.

Specified time lag: N -> D range

N -»• R range

Evaluation

Condition Possible Cause

N D (Economy) shifting

More than specification

Insufficient line pressure Forward clutch slipping One-way clutch 1 slipping One-way clutch 2 slipping N D (Economy) shifting

Less than specification N-D accumulator not operating properly

Excessive line pressure

N-D (Hold) shifting

More than specification

Insufficient line pressure Forward clutch slipping 2-4 brake band slipping One-way clutch 1 slipping N-D (Hold) shifting

Less than specification 1-2 accumulator not operating properly

Excessive line pressure

N R shifting

More than specification

Insufficient line pressure Low and reverse brake slipping Revese clutch slipping N R shifting

Less than specification N-R accumulator not operating properly

Excessive line pressure

86U07B-038

0.5—1.0 second

0.5—1.0 second

7B-30

Page 898 of 1865

7B TROUBLESHOOTING (G4A-EL)

Specified line pressure:

Line pressure kPa, (kg/cm2, psi)

Range DSL R

When idling 353-432 (3.6-4.4, 51-63) 598—942 (6.1-9.6, 87—137)

At stall speed 873-1040 (8.9-10.6, 127-151) 1668-2011 (17.0-20.5, 242-292)

76G07B-032

Evaluation

Line pressure Possible location of problem

Low pressure in every position

Worn oil pump

Fluid leaking from oil pump, control valve body, or transaxle case

Pressure regulator valve sticking

Low pressure in D and S only Fluid leaking from hydraulic circuit of forward clutch

Low pressure in R only Fluid leaking from hydraulic circuit of low and reverse brake

Higher than specification

Throttle valve sticking

Throttle modulator valve sticking

Pressure regulator valve sticking

76G07B-033

7B—32

Page 902 of 1865

7B TROUBLESHOOTING (G4A-EL)

Evaluation

Condition Possible Cause

No 1-2 up- or down-shift Stuck 1-2 shift solenoid valve

Stuck

1

-2 shift valve

No 2-3 up- or down-shift Stuck 2-3 shift solenoid valve Stuck 2-3 shift valve

No 3-OD up- or down-shift Stuck 3-4 shift solenoid valve Stuck 3-4 shift valve

No lock-up shift Stuck lock-up control solenoid valve Stuck lock-up control valve

Incorrect shift point Mis-adjusted throttle sensor Sticking shift valves

Excessive shift shock or slippage

Excessive shift shock Stuck accumulators Stuck or no one-way check orifice

Worn clutches, brakes, or one-way clutch

No engine braking effect Worn clutches or brakes

76G07B-035

Noise and vibration

Drive the vehicle in OD (lock-up), OD (no lock-up), 3rd (Hold) and check for abnormal noise or vibration.

Note

Abnormal noise and vibration can also be caused by the torque converter, drive shaft, or

differential. Therefore, checking of cause must be made with extreme care.

Kick-down

Drive the vehicle in OD, 3rd and 2nd gears and check that kick-down occurs for OD->3, OD->2, OD->1,

3->2, 3-+1, 2-> 1, and the shift points are as shown in the shift diagram.

S Range Test

Shift pattern

1. Shift the selector lever to S range and select the Economy mode.

2. Accelerate the vehicle and check that 1-2 and 2-3 up-shifts and down-shifts are obtained, and that

no overdrive and no lock-up are obtained.

Note

a) Inspections of shift shock and shift point are not necessary because these are the same

as those of the D Range Test.

b)ln S range, the shift patterns for Economy and Power modes are the same.

c) Shift points are the same as those of the D range (Power) shift diagram.

3. While driving in S range (Economy mode) and 3rd gear, select the Hold mode and check that 3rd

gear is held until the 3-2 down-shift point as shown in the S range (Hold) shift diagram is achieved.

4. Accelerate the vehicle with S range (Hold mode) and check that 2nd gear is held.

7B i—36

Page 906 of 1865

7B TROUBLESHOOTING (G4A-EL)

Slippage Test

This step is performed to inspect slippage of the friction elements.

Preparation 1. Perform the preparation procedure shown in STEP 4 (STALL TEST). 2. Connect a tachometer to the engine and set it in the cabin.

3. Connect the EC-AT Tester and the adaptor harness between the EC-AT control unit and wiring

harness.

Procedure

Drive the vehicle in each of the gears indicated below and check whether the vehicle speed or engine

speed is above or below specification excessively as shown by the drum speed.

Driving condition

Speed

Drum speed (rpm)

No. Gears Other condition Speed

1,000 2,000 3,000 4,000

1 1st L range, Hold mode 11 (7) 22 (14) 33 (20) 44 (27)

2 1st D range, Economy mode 11 (7) 22 (14) 33 (20) 44 (27)

3 2nd S range, Hold mode Vehicle speed km/h (mph) 20 (12) 40 (25) 60 (37) 80 (50)

4 3rd D range, Hold mode 31 (19) 61 (38) 92 (57) 123 (76)

5 OD D range, Economy

mode 44 (27) 88 (55) 131 (81) 173 (107)

6 OD D range, Economy mode, Lock-up Engine speed (rpm) 1,000 2,000 3,000 4,000

76G07B-038

Evaluation

When there is no malfunction in the electrical system or hydraulic system, but vehicle speed or engine

speed is below specification, the problem can be attributed to slippage of the friction elements.

Driving conditions below specification Possible Cause

No.1 condition only Low and reverse brake

No.2 condition only One-way clutch

No.3 condition only 2-4 brake band

No.4 condition only Coasting clutch

No.5 condition only 3-4 clutch

No.1-No,5 conditions Forward clutch

No.6 condition only Lock-up piston (in torque converter)

76G07B-039

7B—40

Page 917 of 1865

TROUBLESHOOTING (G4A-HL) 7B

Evaluation

Condition Possible cause

Above specification

In all ranges Insufficient line pressure

Worn oil pump

Above specification

In all ranges Insufficient line pressure Oil leakage from oil pump, control valve, and/or transaxle case

Stuck pressure regulator valve

Above specification

In D 2, and 1 One-way clutch 1 slipping

Above specification

In D range only One-way clutch 2 slipping

Above specification In 2 range only 2-4 brake slipping Above specification

In R range only

Low and reverse brake slipping

Above specification

In R range only

Reverse clutch slipping

Above specification

In R range only Perform a road test, to determine if this is caused by the low and reverse brake or the reverse clutch, as follows:

a) Effective engine braking in 1 range Front clutch

b) No engine braking in 1 range Low and reverse brake

Within specification All shift control elements within transaxle are functioning

normally.

Below specification

Engine out of tune

Below specification One-way clutch slipping within torque converter

76G07B-055

7B—51

Page 918 of 1865

7B TROUBLESHOOTING (G4A-HL)

STEP 4 (TIME LAG TEST)

If the selector lever is shifted while the engine is idling, there will be a certain time lapse, or time lag,

before shock is felt. This step checks this time lag for checking the condition of the N-D and N-R ac-

cumulators, forward, reverse and one-way clutches, and low and reverse brake.

Preparation

Perform the preparation procedure shown in the STEP 3 (STALL TEST).

Procedure

1. Start the engine and check that the idle speed is 900 l5o rpm.

2. Shift from N range to D range

3. Measure the time it takes from shifting until shock is felt using a stop watch.

4. Shift the selector to N range and run the engine at idle speed for at least one minute.

5. Perform the test for the shift from N range to R range in the same manner.

Note

Make three measurements for each test and take the average value.

Specified time lag: N -> D range 0.4—1.2 second

N -> R range 0.4—1.5 second

Evaluation

Condition Possible Cause

N D shift

More than specification

Insufficient line pressure

N D shift

More than specification Forward clutch slipping

N D shift

More than specification One-way clutch 1 slipping N D shift

More than specification

One-way clutch 2 slipping N D shift

Less than specification N-D accumulator not operating properly

N D shift

Less than specification Excessive line pressure

N-R shift

More than specification

Insufficient line pressure

N-R shift

More than specification Low & reverse brake slipping

N-R shift

More than specification

Reverse clutch slipping N-R shift

Less than specification N-R accumulator not operating properly

N-R shift

Less than specification Excessive line pressure

76G07B-056

7B-52

Page 925 of 1865

TROUBLESHOOTING (G4A-HL) 7B

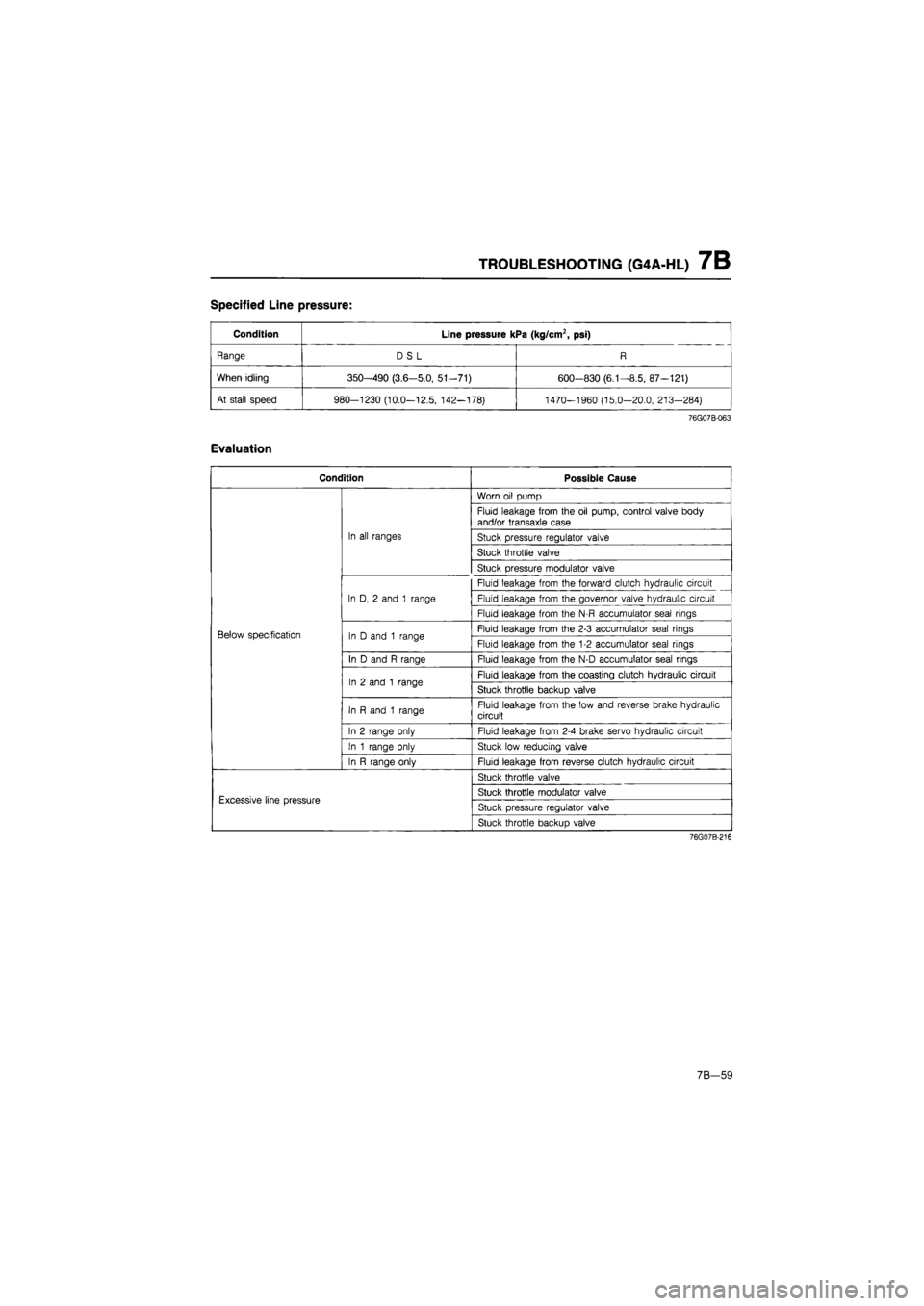

Specified Line pressure:

Condition Line pressure kPa (kg/cm2, psi)

Range DSL R

When idling 350-490 (3.6-5.0, 51-71) 600-830 (6.1-8.5, 87-121)

At stall speed 980-1230 (10.0—12.5, 142—178) 1470-1960 (15.0-20.0, 213-284)

76G07B-063

Evaluation

Condition Possible Cause

Below specification

In all ranges

Worn oil pump

Below specification

In all ranges

Fluid leakage from the oil pump, control valve body

and/or transaxle case

Below specification

In all ranges Stuck pressure regulator valve

Below specification

In all ranges

Stuck throttle valve

Below specification

In all ranges

Stuck pressure modulator valve

Below specification

In D, 2 and 1 range

Fluid leakage from the forward clutch hydraulic circuit

Below specification

In D, 2 and 1 range Fluid leakage from the governor valve hydraulic circuit

Below specification

In D, 2 and 1 range

Fluid leakage from the N-R accumulator seal rings

Below specification In D and 1 range Fluid leakage from the 2-3 accumulator seal rings Below specification In D and 1 range Fluid leakage from the 1-2 accumulator seal rings Below specification

In D and R range Fluid leakage from the N-D accumulator seal rings

Below specification

In 2 and 1 range Fluid leakage from the coasting clutch hydraulic circuit

Below specification

In 2 and 1 range Stuck throttle backup valve

Below specification

In R and 1 range Fluid leakage from the low and reverse brake hydraulic

circuit

Below specification

In 2 range only Fluid leakage from 2-4 brake servo hydraulic circuit

Below specification

In 1 range only Stuck low reducing valve

Below specification

In R range only Fluid leakage from reverse clutch hydraulic circuit

Excessive line pressure

Stuck throttle valve

Excessive line pressure Stuck throttle modulator valve Excessive line pressure Stuck pressure regulator valve Excessive line pressure

Stuck throttle backup valve

76G07B-216

7B—59

Page 960 of 1865

7B DISASSEMBLY

DISASSEMBLY-STEP 2

Components

1. Piston stem

2. Snap ring

3. Clutch assembly

4. 2-4 brake band

5. Small sun gear and one-way clutch

6. Anchor strut and shaft

7. Servo

8. One-way clutch and carrier hub assembly

86U07B-135

—Low and reverse brake—

9. Retaining plate

10. Drive and driven plates

11. Internal gear

12. O-ring

13. 3-4 clutch assembly

14. Turbine shaft

7B—94

Page 961 of 1865

DISASSEMBLY 7B

Procedure

1. Remove the piston stem from the servo.

86U07B-136

2. Remove the clutch assembly.

(1) Remove the turbine shaft snap ring.

86U07B-137

(2) Pull the reverse and forward drum and remove

the clutch assembly.

86U07B-138

3. Remove the 2-4 brake band.

Note

Use a piece of wire to secure the brake band

so that it is not damaged by being stretched.

86U07B-139

7B—95

Page 962 of 1865

7B DISASSEMBLY

86U07B-142

4. Remove the small sun gear and one-way clutch.

5. Pull the anchor shaft while holding the strut, then

remove the strut.

6. Remove the servo.

(1) Remove the snap ring with the SST.

(2) Remove the servo and spring.

7. Remove the one-way clutch and carrier hub as-

sembly.

(1) Remove the snap ring.

7B—96