fuel MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 711 of 1865

OUTLINE 5

SPECIFICATIONS

Gasoline Engine

item

Engine

F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE

(DOHC)

Battery

Voltage

Type and capacity

12. Negative ground

(20 hour rate) 34B19L(S) (33 Ah): General 50D20L (50 Ah), 55D23L (60 Ah): ECE

Alternator

Type A.C.

Output V-A 12-70

Regulator type Transistorized (built-in IC regulator)

Regulated voltage 14.1-14.7

Brush length

mm (in) Standard 16.5 (0.650)

Minimum 8.0 (0.315)

Drive belt tension

mm (in)/98 N (10 kg, 22 lb) New: 6-8 (0.24-0.32), Used: 7-9 (0.28-0.35)

Starter

Type Coaxial reduction: Middle East & General (FE • carburetor)

Non-reduction: Others

Output V-kW 12-0.85

Brush length

mm (in)

12-0.95

Standard 17.0 (0.669)

Minimum 11.5 (0.453)

Unleaded fuel

17.0 (0.669)

Others

17.51

Unleaded fuel 11.5(0.453) Others 10,0 (0.394)

12-1.4 12-0.95

17.0 (0.669)

11.5 (0.453)

Ignition timing 6 ± 10 BTDC (Vacuum hose disconnected)

12

±

1° BTDC

(Test connector

grounded)

Distributor

Type Fully transistorized (HEI)

Electronic spark advance

Centrifugal spark advance

(crank angle/engine speed)

degree/rpm

F6

-2-2/1,000 6-10/2,100 14-18/6,100

F8 -2—2/1,000 10-14/2,100 18-22/6,100

FE (8 VALVE)—Carburetor Unleaded fuel

(MTX)-2—2/1,760 12—16/3,360 22—26/5,320 (ATX)-2-2/1,300 12-16/3,360 22-26/5,320

Others

-2—2/1,460 10—14/2,540 22—26/5,540

FE (12 VALVE)—Carburetor -2-2/1,200 10—14/2,400 10—14/4,000 16-20/5,000

FE—Fuel injection (except FE DOHC) -2—2/1,000 10—14/2,600 10—14/4,600 16—20/5,800

Unleaded fuel model 76G05X-503

5-5

Page 712 of 1865

5 OUTLINE

Item

Engine F6 F8 FE

(8 VALVE)

FE (12 VALVE) FE (DOHC)

F6 and F8

-2-2/100 6-10/300

FE (8 VALVE)—Carbu retor Unleaded fuel -2—2/120 8—12/245

Distributor

Vacuum spark advance (Crank angle/Vacuum)

Others (MTX) -2-(ATX) -2--2/100 16-

-2/100 10-

-20/250

-14/200

degree/mmHg (inHg) FE (12 VALVE)—Carburetor

-2-2/120 11-15/300

FE—Fuel injection (except FE DOHC) [A chamber] -2-2/125 18-22/300

[B chamber] -2-2/125 -6 10/200

Spark plug

Type

FE (8 VALVE)*1 NGK: BPR5ES-11, BPR6ES-11 Nippon Denso: W16EXR-U11, W20EXR-U11 Others

NGK: BPR5ES, BPR6ES Nippon Denso: W16EXR-U, W20EXR-U

NGK:

BCPR5E, BCPR6E Nippon

Denso: Q16PR-U, Q20PR-U

Unleaded fuel

NGK: BCPR5E-11 BCPR6E-11 BCPR7E-11

Leaded fuel NGK: BCPR5E BCPR6E

Plug gap mm (in)

0.75-0.85 (0.030-0.033), FE (8 VALVE)*1 1.0-1.1 (0.039-0.043)

0.7-0.8

(0.028-0.031)

1.0-1.1 "

/n noo

n n/9

0.7-0.8 *2 (0.028-0.031)

Firing order 1-3—4-2 76G05X-504

Diesel Engine

——Engine Item RF-N RF-CX

Battery

Voltage V 12, Negative ground Battery Type and capacity

(20 hour rate) 80D26L (65)

50D20L, 50D20R (50)-ECE 80D26L (65)

65D23L, 65D23R (55)

Alternator

Type A.C.

Alternator

Output V-A 12-70 12-75

Alternator

Regulator type Transistorized (built-in IC regulator)

Alternator Regulated voltage V 14.1-14.7 Alternator

Brush length mm (in)

Standard 16.5 (0.650) 21.5 (0.846)

Alternator

Brush length mm (in) Minimum 8.0 (0.315) 8.0 fO.315)

Alternator

Drive belt tension

mm (in)/98 N (10 kg. 92 lb) New: 9-11 (0.35-0.43), Used: 12-14 (0.47-0.55)

Starter

Type Reduction

Starter Output V—kW 12—2.0, 12-2.2 (Cold area) Starter Brush length

mm (in)

Standard 2.0 kW: 17.0 (0.669). 2.2 kW: 18.0 (0.709) Starter Brush length

mm (in) Minimum 2.0 kW: 11.0 (0.453), 2.2 kW: 11.0 (0.453)

Firing order 1-3-4-2

Unleaded fuel model *2 Leaded fuel model

76G05X-505

5-6

Page 715 of 1865

SPARK PLUG 5

Slow Charge

1. Stop the engine

2. Turn all the accessories off.

3. Remove the negative battery cable.

4. Perform a slow charge (3.5A to 4.5A).

5. Add distilled water if necessary while charging.

6. Charge once more if the specific gravity is under

fully charged gravity.

4BG05X-010

SPARK PLUG

REMOVAL AND INSTALLATION

Note the following points:

1. When the high-tension lead is to be pulled off, be

sure to pull the boot itself, and not the wire.

2. Tighten the spark plugs to the specified torque.

Tightening torque: 15—23 N-m

(1.5—2.3 m-kg, 10.8—16.6 ft-lb)

76G05X-054

Wear and adhesion or cabon

INSPECTION

Check the following points. If a problem is found, re-

place the spark plug.

1. Damaged insulation

2. Worn electrodes

3. Carbon deposits

If cleaning is necessary, use a plug cleaner or a

wire brush. Clean the upper insulator also.

4. Damaged gasket

5. Burnt condition of spark insulator

6. If it is black with carbon deposits, either misfiring

due to improper proportions of gas and air or over-

heating of the plug may have occurred.

Plug gap:

FE (12VALVE) and FE DOHC Leaded fuel

model:

0.70—0.80 mm (0.028—0.031 in)

FE (8VALVE) and FE DOHC Unleaded fuel

model:

1.0—1.10 mm (0.039—0.043 in)

Others:

0.75—0.85 mm (0.030—0.034 in)

76G05X-005

5-9

Page 745 of 1865

STARTER (GASOLINE ENGINE, 0.85, 0.95 KW TYPE) 5

76G05X-040

REMOVAL AND INSTALLATION

1. Disconnect the negative battery cable.

2. Disconnect the wiring from the starter.

3. Raise the front of the vehicle and support it with

safety stands.

4. Remove the intake manifold bracket. (Fuel Injec-

tion Engine)

5. Remove the starter bolts.

6. Draw out the starter from lower side of the vehicle.

Installation in the revers order of removal.

Tightening torque

Bolts 37—52 N m

(3.8—5.3 m-kg, 27—38 ft-lb)

B terminal 9.8—11.8 N-m

(1.0—1.2 m-kg, 87—104 in-lb)

Intake manifold bracket bolt

37—52 N-m (3.8—5.3 m-kg, 27—38 ft-lb)

Nut

19—25 N-m (1.9—2.6 m-kg, 14—19 ft-lb)

DISASSEMBLY AND ASSEMBLY

1. Disassemble in the numbered order shown in the figure.

2. Assembly is the reverse order of disassembly. 4BG05X-049

4BG05X-075

1. Magnetic switch

2. Bolt

3. Rear cover

4. Brush-holder assembly

5. Yoke

6. Lever

7. Drive housing

(front cover)

8. Drive pinion

9. Armature

5-39

Page 1488 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

t

2. Bleed air from the system.

3. Depress the brake pedal, and compare the fluid

pressure of the front brake with that of the rear

brake.

Fluid pressure kPa (kg/cm2, psi)

Front brake side Rear brake side

A 2,943 (30,427)

A'

2,747-3,139

(28-32, 398-455)

A B

B 6,867 (70,995)

B'

3,924-4,316 (40-44, 569-626)

Front brake pressure kPa (kg/cm2, psi) 4. If the measurement is not within specification re-

place the hydraulic unit assembly. 86U11X-194

REMOVAL

Caution

a) Brake fluid will damage painted surfaces. If it does get on the painted surfaces, wipe

it off immediately.

b) Oo not tip the hydraulic unit to prevent the brake fluid in the reservoir from draining.

1. Remove the nuts mounting the fuel filter and ignitor to the bracket and move them toward the engine.

2. Remove the air cleaner assembly.

3. Remove the master cylinder. (Refer to page 11—14.)

4. Remove the hydraulic unit in the sequence shown in the figure.

76G11X-062

11—96

Page 1490 of 1865

1 1 ANTI-LOCK BRAKE SYSTEM (ABS)

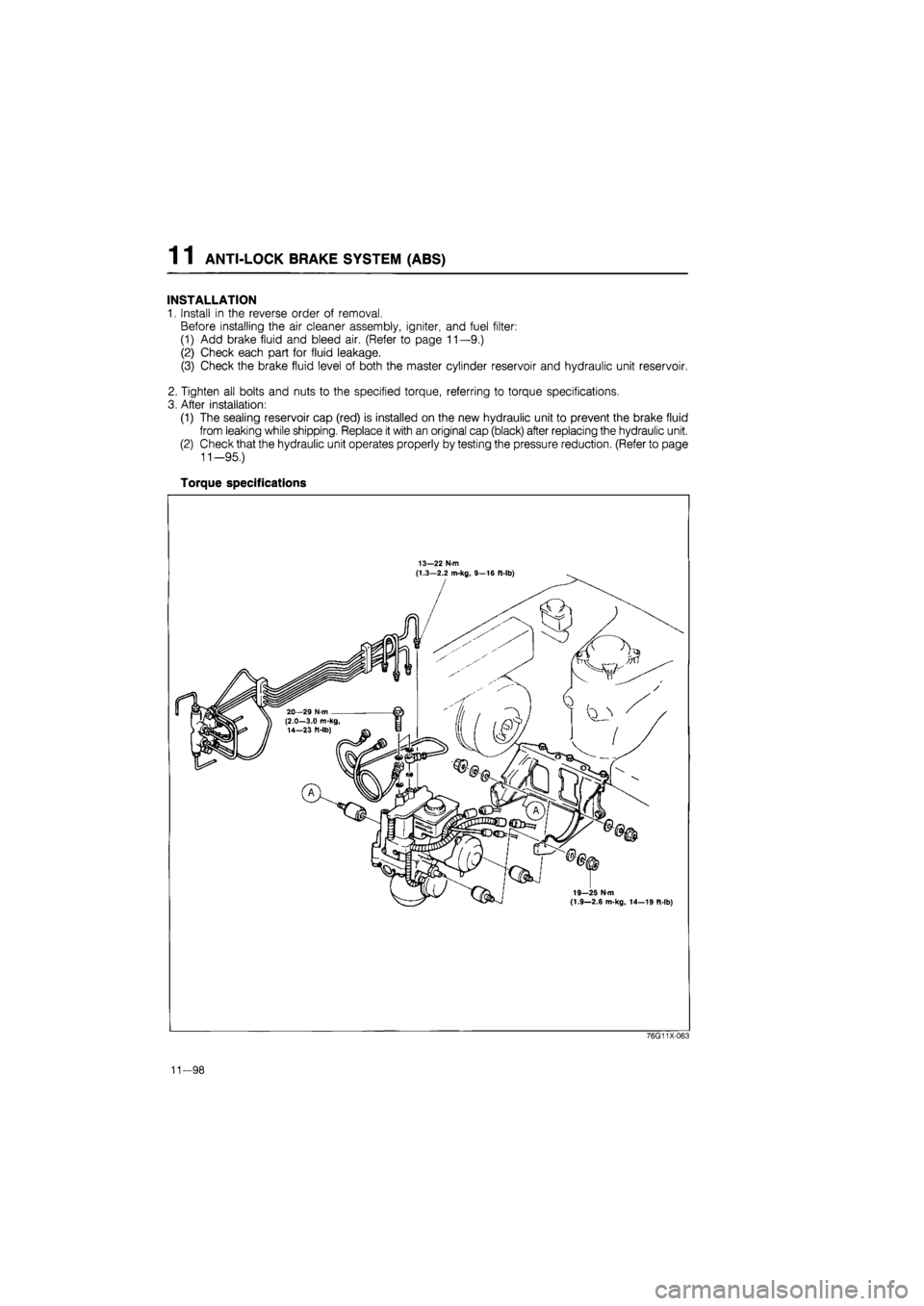

INSTALLATION

1. Install in the reverse order of removal.

Before installing the air cleaner assembly, igniter, and fuel filter:

(1) Add brake fluid and bleed air. (Refer to page 11—9.)

(2) Check each part for fluid leakage.

(3) Check the brake fluid level of both the master cylinder reservoir and hydraulic unit reservoir.

2. Tighten all bolts and nuts to the specified torque, referring to torque specifications.

3. After installation:

(1) The sealing reservoir cap (red) is installed on the new hydraulic unit to prevent the brake fluid

from leaking while shipping. Replace it with an original cap (black) after replacing the hydraulic unit.

(2) Check that the hydraulic unit operates properly by testing the pressure reduction. (Refer to page

11-95.)

Torque specifications

11-98

Page 1502 of 1865

OUTLINE 13

Front Coil Springs

Transa-

xle

Sun-

roof

Identification color

Model Market Engine Transa-

xle

Sun-

roof AAS ABS Green Light

green Pink Brown Purple Gray Orange

Sedan ECE F8 M4 — — — O

M5 — — — 0

4HAT — — — O

FE M5 — — — O

0 — — O

— o — o

o o — o

4HAT -— — o

— o — O

— — — o

o — — o

FE (DOHC) M5 — — — o

— o — 0

— o o o

— — o o

0 — — o

o o — o

0 0 o o

o — 0 o

FE (Fuel M5 — — — o

Injection) — 0 — O

EC-AT O — — o

o o — o

RF-N M5 — — — 0

RF-CX — — — o

Left Hand F8 M5 — — — o

Drive „ o — o

4HAT — — — o

RF-N M5 — — — o

Middle East FE M5 — — — o

-o — o

4HAT — — — o

— o — 0

Right Hand F6 3AT — — — 0

Drive M5 — — — o

FE M5 — — — 0

— o _ o

4HAT — — — o

— 0 — o

FE (DOHC) M5 — — — o

— o o 0

RF-N M5 — — — o

F8 M5 — — — 0

4HAT — — — o

76G13X003

O Available M4, M5.... ...Manual transaxle

— Not available EC-AT ....Electronically controlled automatic transaxle 4HAT ....Hydrallic controlled automatic transaxle

4WS ... 4-Wheel steering

AAS ....Auto adjusting suspention ABS ....Anti-lock brake system

3AT ... Automatic transaxle

13—5

Page 1505 of 1865

13 OUTLINE

Rear Coil Springs

Transa-xle

Sun-

roof

Identification color

Model Market Engine Transa-xle

Sun-

roof AAS ABS Orange White Yellow Brown Blue Green Red Pink

Sedan ECE F8 M4 — — — R L

M5 — — — R L

4HAT — — R L

FE M5 — — — R L

— — R L

— o — R L

O 0 — R L

4HAT — „ — R L

— 0 — R L

— — — R L

o — — R L

FE (DOHC) M5 — — — R L

— o — R L

— o 0 R L

— — o R L

0 — — R L

0 o — R L

o 0 0 R L

o — o R L

FE (Fuel M5 — — — R L

Injection) — o — R L

EC-AT o — — R L

o o — R L

RF-N M5 — — — R R L L

RF-CX _ — — R L

Left Hand F8 M5 — — — R L

Drive — o — R L

4HAT — — — R L

RF-N M5 — — — R L

Middle East FE M5 — — — R L

— o — n L

4HAT — — — R L

— o — L

Right Hand F6 3AT — — — L R

Drive M5 — — — L R

FE M5 — — — L

— o — L R

4HAT — — — L

— o — L R

FE (DOHC) M5 — — — L R — o o L R

RF-N M5 — — L R

F8 M5 — — — L R

4HAT — — — L R

76G13X-006

0 Available R Right side M4, M5 Manual transaxle 3AT Automatic transaxle — Not available L Left side EC-AT... Electronically controlled automatic transaxle 4HAT..., Hydrallic controlled automatic transaxle 4WS...... 4-wheef steering AAS Auto adjusting suspention ABS Anti-lock brake system

13-8

Page 1552 of 1865

14

BONNET 14— 2

STRUCTURAL VIEW 14— 2

REMOVAL 14— 3

INSTALLATION 14— 4 ADJUSTMENT 14— 4 TRUNK LID 14— 5 STRUCTURAL VIEW (SEDAN AND COUPE/MX-6) 14— 5 REMOVAL 14— 6 INSTALLATION 14— 7 ADJUSTMENT 14— 8

REAR HATCH 14— 9 STRUCTURAL VIEW 14— 9 REMOVAL 14— 10 INSTALLATION 14— 12 ADJUSTMENT 14— 12 FRONT DOORS 14—13

STRUCTURAL VIEW 14— 13

REMOVAL 14—15

INSTALLATION 14—17 ADJUSTMENT 14— 18 REAR DOORS 14—19 STRUCTURAL VIEW 14— 19 REMOVAL 14— 20

INSTALLATION 14— 21 ADJUSTMENT 14— 22 FRONT BUMPER 14— 23

STRUCTURAL VIEW 14—23 REMOVAL 14— 24 INSTALLATION 14—24 REAR BUMPER 14— 25

STRUCTURAL VIEW 14— 25 REMOVAL 14— 26

INSTALLATION 14— 26 RADIATOR GRILLE 14— 27 REMOVAL AND INSTALLATION 14— 27 HEADLIGHT AND COMBINATION LIGHT 14— 28 REMOVAL AND INSTALLATION 14— 28

AIMING 14— 31 REAR COMBINATION LIGHTS 14— 32 REMOVAL AND INSTALLATION 14— 32

REPLACEMENT OF REAR COMBINATION LIGHT LENS 14— 33

LICENSE PLATE LIGHT AND CARGO ROOM LIGHT 14— 35 REMOVAL AND INSTALLATION 14— 35

INTERIOR LIGHT AND MAP LIGHT 14- 36 REMOVAL AND INSTALLATION 14— 36

MOLDING AND GARNISH 14— 37

STRUCTURAL VIEW 14— 37 WINDSHIELD MOLDING 14— 38 WINDSHIELD LOWER MOLDING 14— 38 DRIP MOLDING 14— 38 BELT LINE MOLDING 14— 38 REAR WINDOW SIDE MOLDING (SEDAN) .14— 39 REAR WINDOW LOWER MOLDING

(SEDAN AND COUPE/MX-6) 14— 39 REAR WINDOW UPPER MOLDING 14— 39

BONNET MOLDING

(SEDAN AND HATCHBACK) 14— 39 QUARTER WINDOW MOLDING (COUPE/MX-6) 14— 40 QUARTER WINDOW MOLDING

(HATCHBACK) 14—40 QUARTER WINDOW MOLDING (SEDAN)... 14— 40 REAR WINDOW SIDE MOLDING (COUPE/MX-6) 14— 40

TRUNK LID MOLDING (SEDAN AND HATCHBACK) 14— 41

CENTER PILLAR GARNISH

(SEDAN AND HATCH BAC K/MX-6) 14— 41 REAR FINISHER (COUPE/MX-6 AND SEDAN) 14— 41 REAR FINISHER (HATCHBACK) 14— 41

SAIL GARNISH 14— 42

SIDE PROTECTOR MOLDING 14— 42 DOOR MIRROR 14— 44 DISASSEMBLY 14— 44 ASSEMBLY 14— 44 TRUNK-LID LOCK REMOTE RELEASE 14— 45 REMOVAL AND INSTALLATION 14— 45 FUEL FILLER LID REMOTE RELEASE 14— 46

REMOVAL AND INSTALLATION 14— 46 WINDSHIELD GLASS 14—47 STRUCTURAL VIEW 14—47 REMOVAL 14— 48 INSTALLATION 14— 49 REAR WINDOW GLASS 14— 52

STRUCTURAL VIEW 14— 52 REMOVAL 14— 54

INSTALLATION 14— 55 REAR HATCH GLASS 14— 58 STRUCTURAL VIEW 14— 58 REMOVAL 14— 59 INSTALLATION 14— 59 QUARTER WINDOW GLASS 14— 62 STRUCTURAL VIEW 14— 62

REMOVAL 14— 64 INSTALLATION 14—64

HEADLINER 14- 67 STRUCTURAL VIEW 14—67 REMOVAL 14— 69 INSTALLATION 14— 72 INSTRUMENT PANEL 14— 73 STRUCTURAL VIEW 14— 73

INSTALLATION VIEW 14— 74

REMOVAL 14— 75 INSTALLATION 14— 80 SLIDING SUNROOF 14— 81 STRUCTURAL VIEW 14— 81 REMOVAL 14— 82 INSTALLATION 14— 85 WINDSHIELD WIPER 14— 91

STRUCTURAL VIEW 14— 91

REMOVAL 14— 92

INSTALLATION 14— 93 ADJUSTMENT 14— 93 REAR WINDOW WIPER 14—94 STRUCTURAL VIEW (HATCHBACK) 14— 94 REMOVAL 14— 95 INSTALLATION 14—95 ADJUSTMENT 14— 96

HEADLIGHT WASHER 14— 97 REMOVAL AND INSTALLATION 14— 97 SEAT 14— 98 STRUCTURAL VIEW 14— 98 INSPECTION 14—100 SEAT BELTS 14—101

STRUCTURAL VIEW 14—101 INSPECTION 14—101

UNDERBODY PROJECTED DIMENSIONS.... 14—102 UNDERBODY STRAIGHT-LINE DIMENSIONS 14—104 76G14X-001

Page 1597 of 1865

1 4 FUEL FILLER

LID

REMOTE RELEASE

FUEL FILLER

LID

REMOTE RELEASE

REMOVAL AND INSTALLATION

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

1. Screws 4. Cover 7. Release wire

2. Scuff plate 5. Bolts

3. Screws 6. Release lever

14—46