engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 536 of 1865

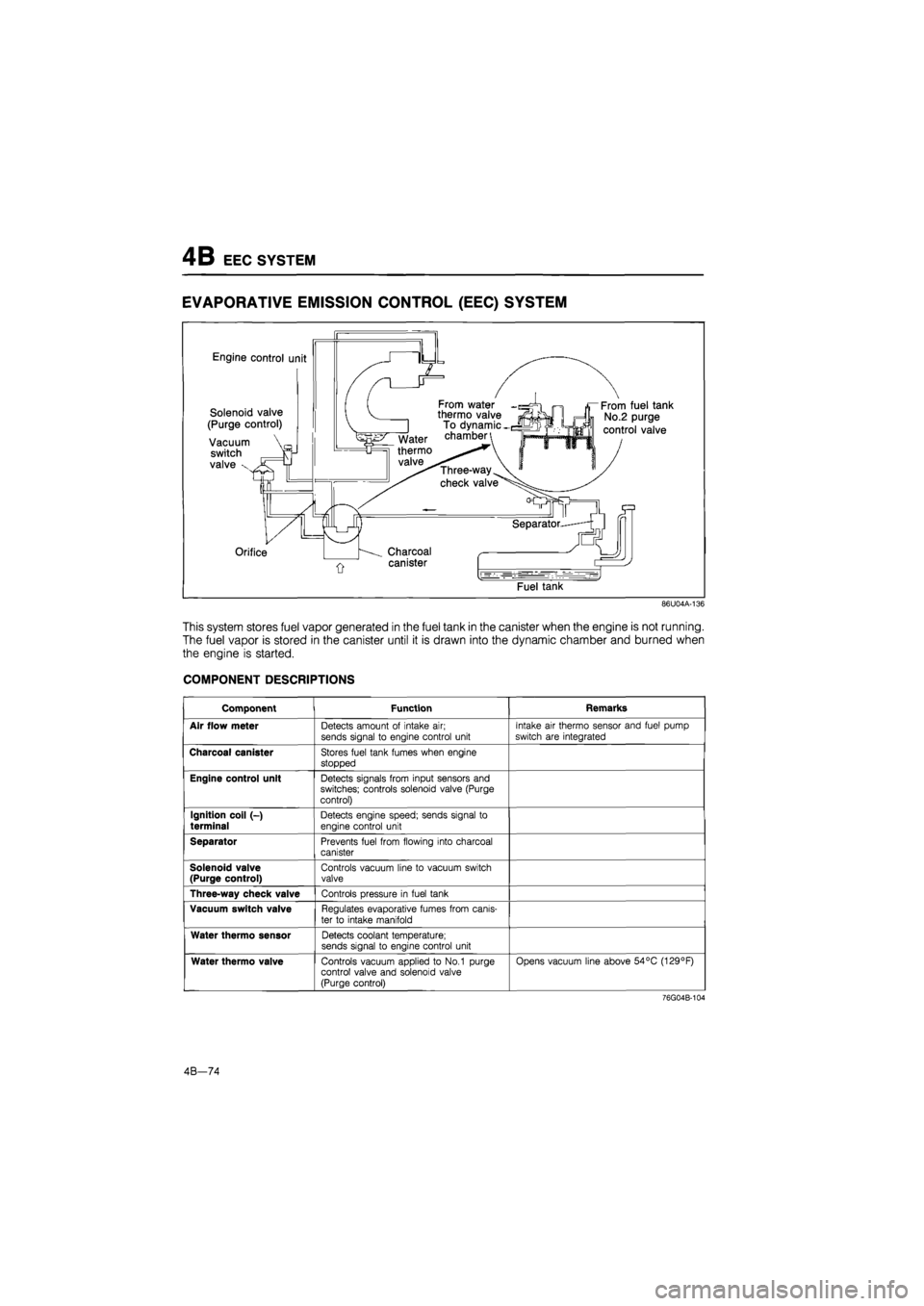

4B EEC SYSTEM

EVAPORATIVE EMISSION CONTROL

(EEC)

SYSTEM

Engine control unit

Solenoid valve

(Purge control)

Vacuum

switch

valve x

From water thermo valve To dynamic -chamber

Three-way

check valve

Orifice Charcoal

canister

From fuel tank

No.2 purge

control valve

Fuel tank

86U04A-136

This system stores fuel vapor generated in the fuel tank in the canister when the engine is not running.

The fuel vapor is stored in the canister until it is drawn into the dynamic chamber and burned when

the engine is started.

COMPONENT DESCRIPTIONS

Component Function Remarks

Air flow meter Detects amount of intake air; sends signal to engine control unit

Intake air thermo sensor and fuel pump

switch are integrated

Charcoal canister Stores fuel tank fumes when engine

stopped

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Purge control)

Ignition coil (-)

terminal Detects engine speed; sends signal to

engine control unit

Separator Prevents fuel from flowing into charcoal canister

Solenoid valve (Purge control) Controls vacuum line to vacuum switch valve

Three-way check valve Controls pressure in fuel tank

Vacuum switch valve Regulates evaporative fumes from canis-

ter to intake manifold

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo valve Controls vacuum applied to No.1 purge control valve and solenoid valve (Purge control)

Opens vacuum line above 54°C (129°F)

76G04B-104

4B—74

Page 537 of 1865

EEC SYSTEM

4B

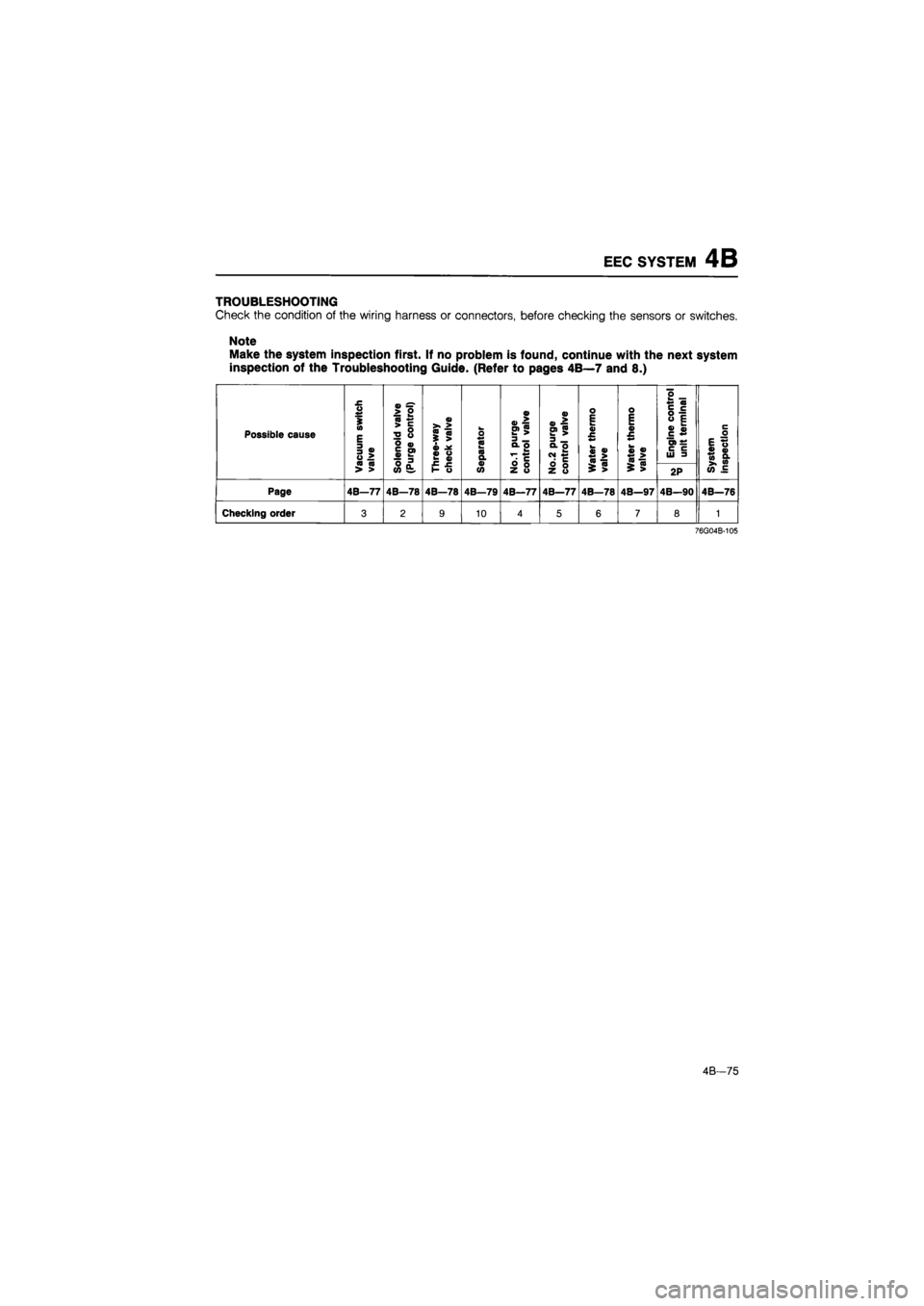

TROUBLESHOOTING

Check

the

condition

of the

wiring harness

or

connectors, before checking

the

sensors

or

switches.

Note

Make the system inspection first.

If no

problem

is

found, continue with

the

next system

inspection

of the

Troubleshooting Guide. (Refer

to

pages 4B—7 and

8.)

Possible cause

Vacuum

switch

valve

Solenoid

valve

(Purge

control)

0)

<0

m

i

>

« «

o

•C

?

o ** «0 a a

No.1

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

o E tm 0) £

«>

0)

^

>

Engine

control

unit

terminal

System inspection Vacuum

switch

valve

Solenoid

valve

(Purge

control)

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

$

>

2P

System inspection

Page 4B—77 4B—78 4B—78 4B—79 4B—77 4B—77 4B—78 4B—97 4B—90 4B—76

Checking order 3 2 9 10 4 5 6 7 8 1

76G04B-105

4B—75

Page 538 of 1865

4B EEC SYSTEM

86U04A-139

86U04A-141

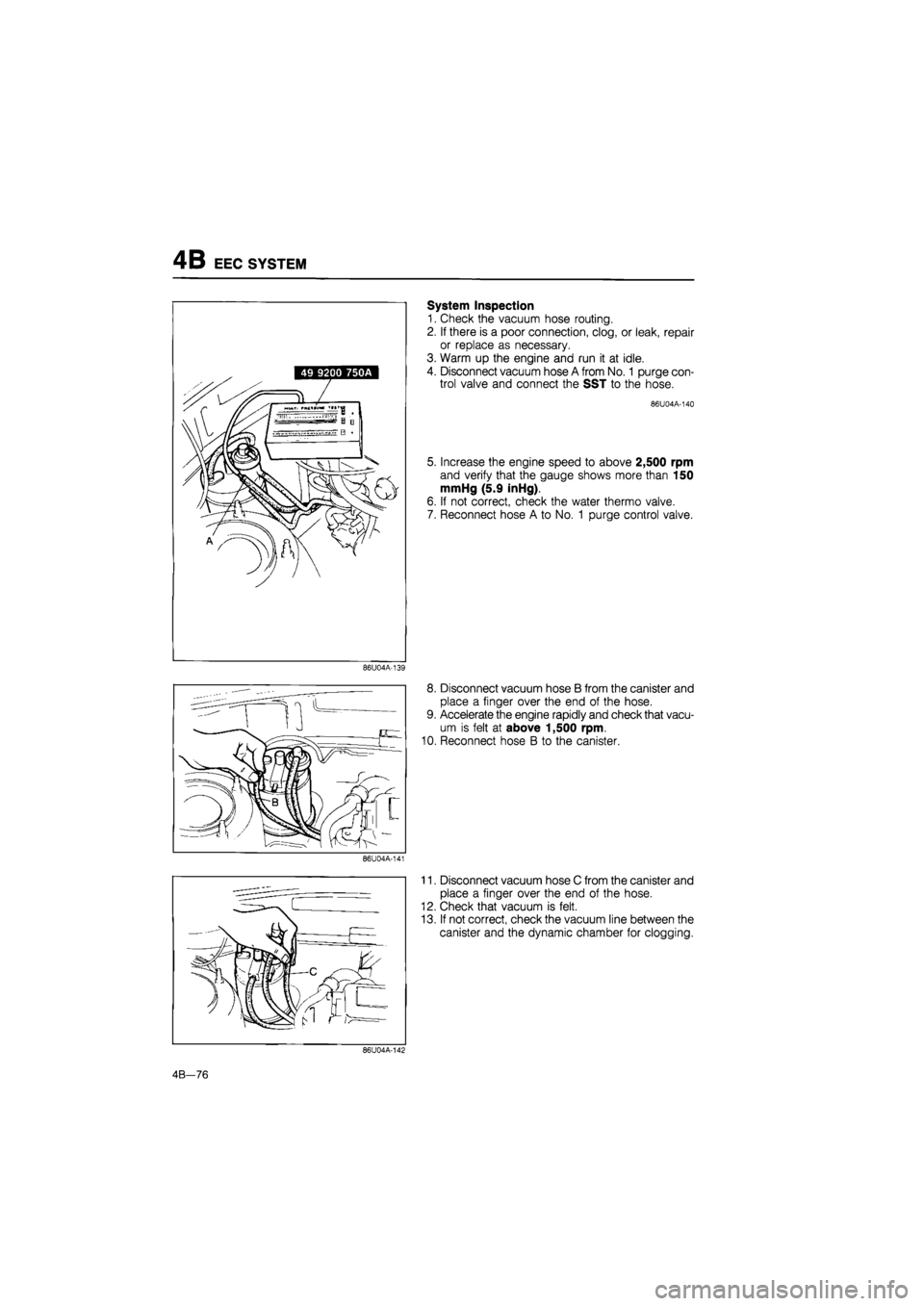

System Inspection

1. Check the vacuum hose routing.

2. If there is a poor connection, clog, or leak, repair

or replace as necessary.

3. Warm up the engine and run it at idle.

4. Disconnect vacuum hose A from No.

1

purge con-

trol valve and connect the SST to the hose.

86 U 04 A-140

5. Increase the engine speed to above 2,500 rpm

and verify that the gauge shows more than 150

mmHg (5.9 inHg).

6. If not correct, check the water thermo valve.

7. Reconnect hose A to No. 1 purge control valve.

8. Disconnect vacuum hose B from the canister and

place a finger over the end of the hose.

9. Accelerate the engine rapidly and check that vacu-

um is felt at above 1,500 rpm.

10. Reconnect hose B to the canister.

11. Disconnect vacuum hose C from the canister and

place a finger over the end of the hose.

12. Check that vacuum is felt.

13. If not correct, check the vacuum line between the

canister and the dynamic chamber for clogging.

86U04A-142

4B—76

Page 542 of 1865

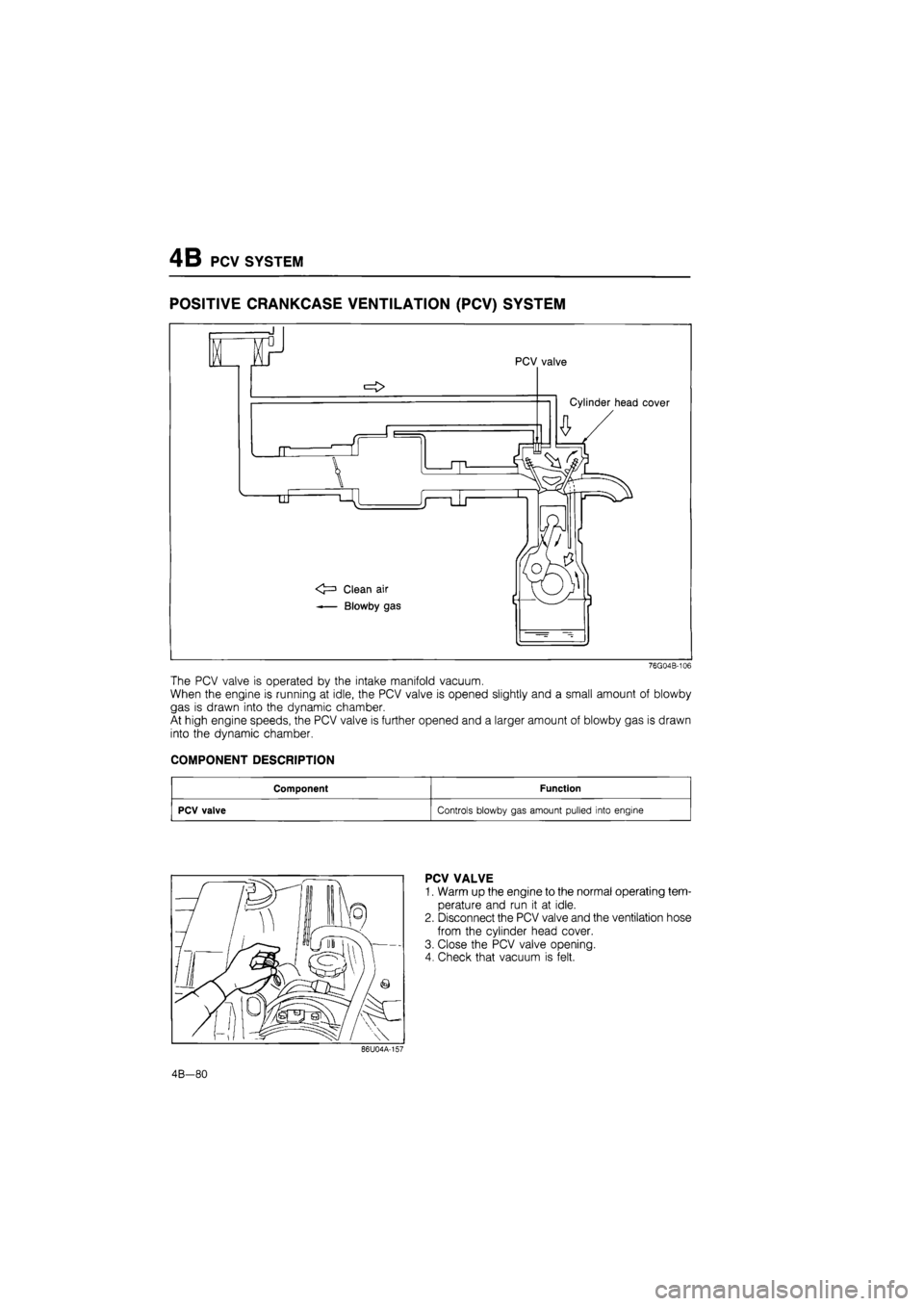

4B PCV SYSTEM

POSITIVE CRANKCASE VENTILATION

(PCV)

SYSTEM

76G04B-106

The PCV valve is operated by the intake manifold vacuum.

When the engine is running at idle, the PCV valve is opened slightly and a small amount of blowby

gas is drawn into the dynamic chamber.

At high engine speeds, the PCV valve is further opened and a larger amount of blowby gas is drawn

into the dynamic chamber.

COMPONENT DESCRIPTION

Component Function

PCV valve Controls blowby gas amount pulled into engine

PCV VALVE

1. Warm up the engine to the normal operating tem-

perature and run it at idle.

2. Disconnect the PCV valve and the ventilation hose

from the cylinder head cover.

3. Close the PCV valve opening.

4. Check that vacuum is felt.

4B—80

Page 545 of 1865

CONTROL SYSTEM 4B

CONTROL SYSTEM

Atmospheric

pressue sensor

Engine control unit

Brake light switch

Clutch switch

Circuti opening

relay

E/L control unit

Air flow meter

Neutral switch

76G04B-129

The control system consists of the input devices and the engine control unit. The engine control unit

controls the fuel injection amount (EGI), fuel injection pressure, bypass air amount, switch monitor func-

tion, and fail-safe function.

4B—83

Page 547 of 1865

CONTROL SYSTEM 4B

Output Devices and Engine Conditions

DC <

s UJ OC

Q. 3 O) c

CO

ffl <

> C o t: S CO

o x

03 "D > 16 O > -FC O O I O 0) .. .c CD

SB to ro

_Q

O O <

> c o t CO

o x

UJ O Z z ? ? ?5 n T (9 O oo: z r uj

c o o 31 c O 3 OC

o

I—

LU

> Q W0UJ> JW J

cc -J

-i -i

S5

Sxi-oo t >u-d

-<=

"O c y c « ir

co

aj

a ffl c o a c o o 0) 3 n> o n i_ > o CD

s <0^0

E 13 O tr C3 LU

->

o

111

E

UJ < o c "

UJ

3 o CD 13

o C CD

B ffl <° ro

"H

ui1

o cc _i o UJ C

o < rf OC 111

o <

o

Q UJ

£ OC <

£

o o

o (9 5 N ± UJ

| = 5o

I "O—_ ZqIIJ SjZ Z Oo < O z tt-UJ

r-D c o c ro ir

ro

a?

o be

T3 CD CO O o cc <3 UJ,

LL LL O

C o J5

o >

CD Q. CD O c o,

Q. 13 o O)

o

3 O) 03

03 3 cn cn CD Q. O

E 3 3 O ro

O

3 O

UJ

OC (3 LU

O

cn 0)

J5 CD Q. O 03 O) ro "So "O c CM

O

CO ro a >, _o

c 03 Q. O

3 O cr cd LU

T3 03 ro 03 a o o c CD o> ro tn "O c CM

o

c 03 a O

o CO CM

O o o

CD > o _o ro

fa _ffl O

CD >

O o LO LO 03 > o JD CO

Q. E 03

CD js: CO

c 03

c 03 CL O

| ro S <

CO

a

LL ° CM rri

$2 CM

CD

in

o §

O

s §

a£ E to

03 -S

CO •a 03 w o 03 £ iS >

"O •

03:

o ro

£ °

Q_ CD

"O

CD

J 3

Q_ CO

O

CO

ro 2

UJ 03

C > ffl ffl r ?

o c C

CD CD

5" o O

CO

(/> Z o

o o UJ z o z UJ

Oh

UJUJO

£ii

o

i- a

S5i

o

Ul cc

50

UJ >

< >

OC <

oc UJ O OC I-

in =J

UJ O

oc

UJ

o. oc

OC o UJ

UJ u OC 3 a.

a.

ui

ffl

a 3 I UJ

UJ

oo<

<0

z >

0

Q. 3 1 UJ

o

c/> . to Z HI < UJ > _ Q.

—J

—I

<

m

O O gc <

76G04B-109

4B-85

Page 549 of 1865

CONTROL SYSTEM 4B

ENGINE CONTROL UNIT

Engine Signal Monitor (49 9200 162) and Adapter (49 9200 163).

Adapter harness 49 9200 163

Engine wiring harnessN

Selector switch

Monitor switch

Engine control unit

terminal number

Terminals

(A and 8)

ENGINE SIGNAL MONITOR

86U04A-171

The Engine Signal Monitor (49 9200 162) was developed to check the control unit terminal voltages.

This monitor easily inspects the individual terminal voltages through selection of the monitor switch.

How to Use the Engine Signal Monitor

1. Connect the Engine Signal Monitor (49 9200 162) between the engine control unit and the en-

gine harness using the adapter (49 9200 163).

2. Turn the selector switch and monitor switch to select the terminal number.

3. Check the terminal voltage.

Caution

Never apply voltage to terminals A and B.

4B-87

Page 550 of 1865

4B CONTROL SYSTEM

Terminal Voltage

If the input and output devices and related wiring are normal, but the engine control unit terminal volt-

age is incorrect, replace the engine control unit.

Terminal Input Output Connection to Voltage (After warming-up) Remarks Terminal Input Output Connection to IGN: ON Idle Remarks

1A — — — — —

1B o Self-Diagnosis Checker (Code number)

For 3sec. after ignition switch OFF ->• ON: below 6.2V (Buzzer sounds) After 3sec.: Battery voltage (Buzzer does not sound)

• Using Self-Diagnosis Check-er and test con-nector grounded • Buzzer sounds: below 6.2V • Buzzer does not sound: Battery voltage

1C — — — — —

1D o Self-Diagnosis Checker (Monitor lamp)

Test connector grounded

For 3sec. after igni-tion switch OFF ON:

below 6.2V (light il-luminates) After 3sec.: Battery voltage (light does not illuminate)

(Test connector grounded) approx. 10V (Test connector not grounded) Monitor lamp ON: below 6.2V Monitor lamp OFF: Battery voltage

With Self-Diagnosis

Checker

1E O Idle switch Accelerator pedal released: below 1.5V

Accelerator pedal depressed: Battery voltage

1F o A/C relay A/C switch ON: below 2.5V A/C switch OFF: Battery voltage

Blower motor ON

1G — — — — —

1H o Water thermo switch Below 1,5V Radiator temp.:

above 17°C (63°F)

11 o Electrical load con-trol unit Electrical load ON: below 1.5V Electrical load OFF: Battery voltage Electrical load: Rear defroster Headlight Blower motor (3rd & 4th position) Electrical fan

1J o Brake light switch Brake pedal released: below 1.5V

Brake pedal depressed: battery voltage

1K — — — — — —

1L o A/C switch A/C switch ON: below 1.5V

A/C switch OFF: battery voltage

Blower motor: ON

1M o Ignition coil © terminal Battery voltage *1 Battery voltage *1 Engine Signal Monitor: green and red lights flash

1N — — — — —

10 — — — —

4B-88

Page 551 of 1865

CONTROL SYSTEM 4B

Terminal Input Output Connection to Voltage (After warming-up) Remarks Terminal Input Output Connection to IGN: ON Idle Remarks

1P — — — — —

1Q — — — — —

1R — — — — —

1S o Air bypass solenoid valve (Idle-up C) and P/S pressure switch

Battery voltage While solenoid ON (Refer to page 4B—35): below 1.5V

1T — — — — —

1U — — — — —

1V 0 MTX

Neutral and clutch switch

In-gear condition Clutch pedal depressed: battery voltage Clutch pedal released: below 1,5V

Neutral: constant battery voltage

1W O Test connector Test connector grounded: below 1,5V Test connector not grounded: battery voltage Green connector, 1-pin

1X — — — — —

2A o V ref 4.5—5.5V

2B 0 Air flow meter (Vc) 6-10V

2C — — Ground (E2) Approx. OV

2D o Oxygen sensor OV 0-1.OV • Cold engine: 0V at idle • After warming-up: Increase engine speed: 0.5—1.0V Deceleration: 0—0.4V

2E 0 Air flow meter (Vs) Approx. 1.7V Approx. 3—5V Increase engine speed:

voltage increases

2F — -— — —

2G 0 Throttle sensor Accelerator pedal released:

0.4—0.6 V

2H 0 Atmospheric pres-sure sensor At sea level: approx. 4.0V

21 0 Water thermo sensor 0.3—0.6 V Engine coolant temp. 20°C (68°F): approx. 2.5V

2J o Air flow meter (In-

take air thermo

sensor)

Approx. 2.3V at 20°C (68°F)

2K o Solenoid valve (Pres-

sure regulator

control)

For 120 sec. after ignition switch OFF - ON: below 1.5V

For 120 sec. after

starting: below 1.5V

Hot condition: Cool-ant temp, above 70°C (158°F) Intake air temp, above 10°C (50°F)

2K o Solenoid valve (Pres-

sure regulator

control)

Battery voltage Other conditions

2L — — — — —

2M — — —

4B-89

Page 552 of 1865

4B CONTROL SYSTEM

Terminal Input Output Connection to Voltage (After warming-up) Remarks Terminal Input Output Connection to IGN: ON Idle Remarks

2N o Solenoid valve (EGR) Below 1,5V • Cold engine: be-low 1,5V Radiator coolant temp.—below 17°C (63°F) or Engine coolant temp.—below 70°C (158°F)

• Engine above ap-prox. 1,500 rpm: Battery voltage

20 o Air bypass solenoid valve (Idle-up B) Battery voltage While solenoid ON (Refer to page 4B-35): below 1.5 V

2P o Solenoid valve

(Purge control valve)

Battery voltage • Medium and high

load: below 1,5V

2Q — — — —

2R — — Ground (E02) Below 1,5V

3A — — Ground (E01) Below 1.5V

3B O Ignition switch (Start position) Below 1,5V While cranking: bat-

tery voltage

3C o Injector (No. 4 and No. 2) Battery voltage *1 Battery voltage *1 Engine Signal Monitor green and red lights flash

3D o Inhibitor switch "N" or "P" range: below 2.0V

Other ranges: battery voltage

ATX

3E o Injector (No. 1 and No. 3) Battery voltage *

1

Battery voltage *1 Engine Signal Monitor: green and red lights flash

3F -— — — —

3G — Ground (Ei) Below 1.5V

3H — — — —

31 o — Ma ri relay Battery voltage

3J — — Battery Battery voltage For back-up

76G04B-110

31 3G 3E 3C 3A

3J 3H 3F 3D 3B

2Q 20 2M 2K 21 2G 2E 2C 2A

2R 2P 2N 2L 2J 2H 2F 2D 2B

1W 1U 1S 1Q 10 1M 1K 11 1G 1E 1C 1A

1X 1V 1T 1R 1P 1N 1L 1J 1H 1F 1D 1B

4B—90