engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 587 of 1865

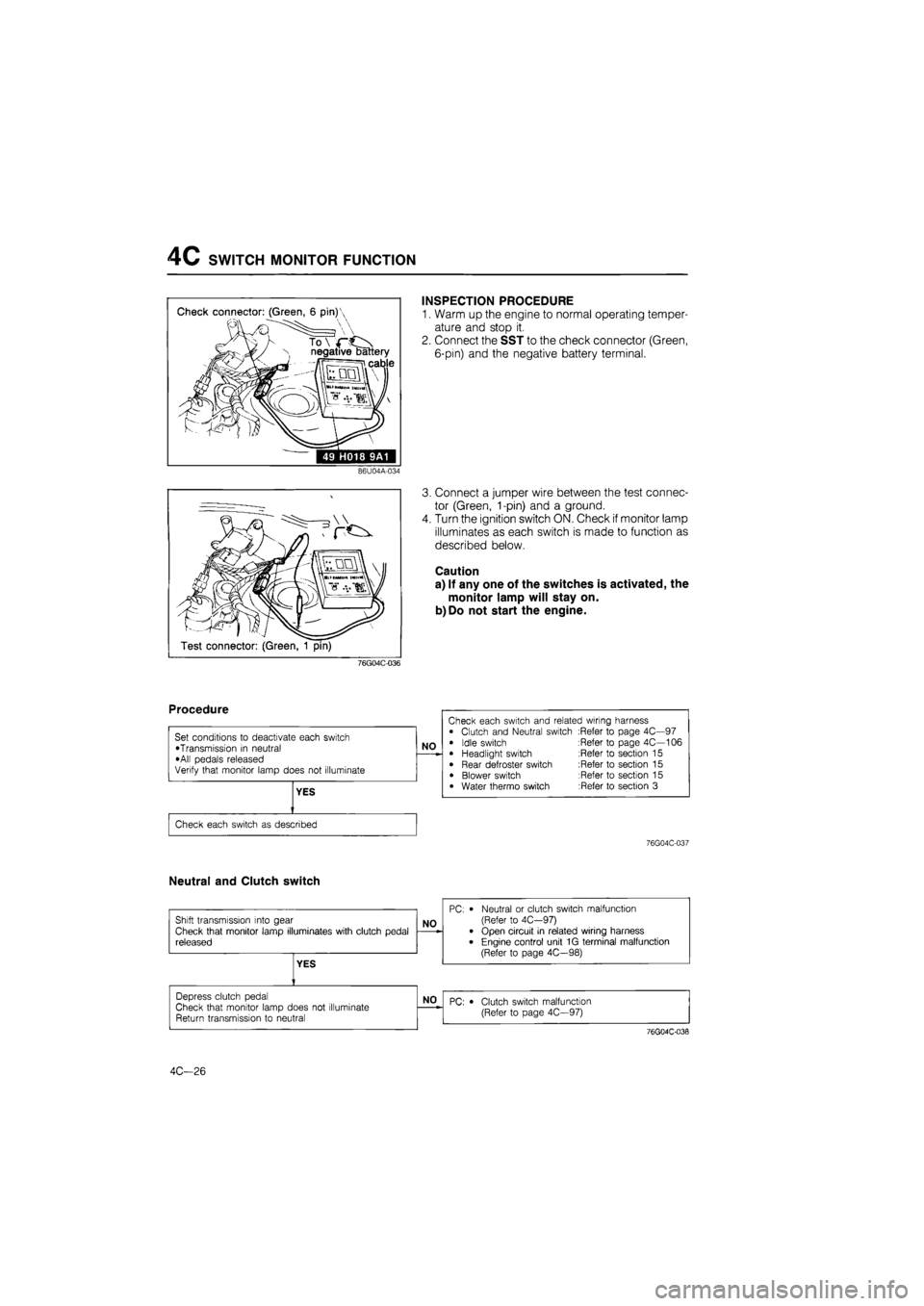

4C SWITCH MONITOR FUNCTION

Check connector: (Green, 6 pin)'

N negative battery

ii cable

49 H018 9A1

INSPECTION PROCEDURE

1. Warm up the engine to normal operating temper-

ature and stop it.

2. Connect the SST to the check connector (Green,

6-pin) and the negative battery terminal.

86U04A-034

Test connector: (Green, 1 pin)

3. Connect a jumper wire between the test connec-

tor (Green, 1-pin) and a ground.

4. Turn the ignition switch ON. Check if monitor lamp

illuminates as each switch is made to function as

described below.

Caution

a) If any one of the switches is activated, the

monitor lamp will stay on.

b)Do not start the engine.

76G04C-036

76G04C-037

Neutral and Clutch switch

4C—26

Page 590 of 1865

IDLE ADJUSTMENT 4C

Idle speed

Automatic

Control

Function

Engine Control Unit

IDLE

ADJUSTMENT

IDLE SPEED

The idle speed is controlled automatically by the

engine control unit through the idle speed con-

trol (ISC) solenoid valve, it is not necessary to

adjust the idle speed.

However, if the idle speed is not within specifi-

cation, the idle speed must be adjusted.

76G04C-044

Preparation

1) Check the condition of the engine (plugs, leaks in

hoses, etc.).

2) Make sure all accessories are OFF.

3) Warm up the engine and run it for three minutes

at 2,500—3,000 rpm in neutral.

4) Check the initial ignition timing and adjust it if

necessary.

76G04C-045

Inspection

1. Check that the idle speed is within specification

without grounding the test connector (Green,

1-pin).

Specification:

Applied load Idle speed

No load 750 ± 50 rpm

P/S load 750 ± 50 rpm

A/C and/or E/L load 800 ± 50 rpm

76G04C-046 2. If not correct, adjust the initial idle speed.

Adjustment

1. Ground the test connector (Green, 1-pin) with a

jumper wire.

2. Turn all accessories and loads OFF.

76G04C-047

4C—29

Page 591 of 1865

4C IDLE ADJUSTMENT

76G04C-048

Idle speed

Automatic

Control

Function

Engine Control Unit

76G04C-049

76G04C-050

3. Remove the blind cap and adjust the initial idle

speed to specification by turning the air adjust

screw.

Initial idle speed: 750 ± 50 rpm

4. After adjusting the idle speed, install the blind cap

and disconnect the jumper wire from the test con-

nector.

5. Recheck the idle speed.

6. If not within specification, check the idle speed con-

trol (ISC) system.

IDLE MIXTURE (Unleaded Fuel)

An automatic compensation function for air/fuel

mixture is built into the engine control unit, it

is not necessary to check and adjust the idle

mixture.

IDLE MIXTURE (Leaded Fuel)

Note

Before checking or adjusting the idle mixture,

check and adjust the idle speed, if necessary.

1. Insert a gas analyzer pick-up into the tail pipe.

2. Check that the CO and HC concentrations are with-

in specification.

CO concentration: 1.5 ± 0.5%

HC concentration: Less than 1,000 PPM

3. If the CO or HC concentration is not within specifi-

cation, turn the adjust screw

with

the SST to adjust.

76G04C-051

4C-30

Page 592 of 1865

INTAKE AIR SYSTEM 4C

INTAKE AIR SYSTEM

76G04C-052

This system controls the air required by the engine for operation. The system consists of the air duct,

resonance chamber, air cleaner, air flow sensor, throttle body, dynamic chamber, and intake manifold.

COMPONENT DESCRIPTION

Component Function Remark

Air cleaner Filters air entering throttle body Dry type

Air flow sensor Detects amount of intake air; sends signal to engine control unit Hot-wire type

Resonance chamber Minimizes intake air noise

Throttle body Controls intake air quantity Integrated throttle sensor and idle switch

4C—31

Page 594 of 1865

INTAKE AIR SYSTEM 4C

76G04C-054

76G04C-055

76G04C-056

Removal Note

Water hose

Before disconnecting the water hose, drain two liters

of engine coolant.

Delivery pipe assembly.

1. Separate the fuel return pipe from the delivery pipe

assembly.

2. Remove the delivery pipe assembly and the fuel

return pipe.

PARTS INSPECTION

Air Cleaner Element

1. Check the condition of the air cleaner element.

2. Blow out the dust with compressed air, if

necessary.

Caution

a) The air cleaner must be replaced at the in-

tervals outlined in the maintenance

schedule.

b) Never drive the vehicle without the air

cleaner element, otherwise, damage to the

air flow sensor (hot wire) will occur.

c) Never use an oil permeated air cleaner ele-

ment, otherwise, contamination of the hot

wire will occur.

4C—33

Page 599 of 1865

4C INTAKE AIR SYSTEM

Installation Note

Water hose spring clamps

Face the clamp end as shown in the figure.

Gasket

Use new gaskets at the intake manifold, dynamic

chamber, and throttle body.

86U04A-056

• . v 1

Engine 1 Ml' ' •-

hanger ^ •

• i::£?^Solenoid valve bracket

Air cleaner. r^I. ^jUvW;

Th V

Ground harnesses

Make sure that the ground harnesses are tightened

securely at the following positions.

(1) Air cleaner upper case

(2) Solenoid valve braket

(3) Engine hanger

76G04C-062

Solenoid valve connectors

Connect the solenoid valve connectors at the posi-

tions shown in the figure.

76G04C-063

Inspection after installation

1. After completing installation, fill up the engine with

the specified engine coolant.

2. Warm up the engine and run it at idle.

3. Check for any vacuum, coolant, or fuel leaks.

76G04C-064

4C-38

Page 600 of 1865

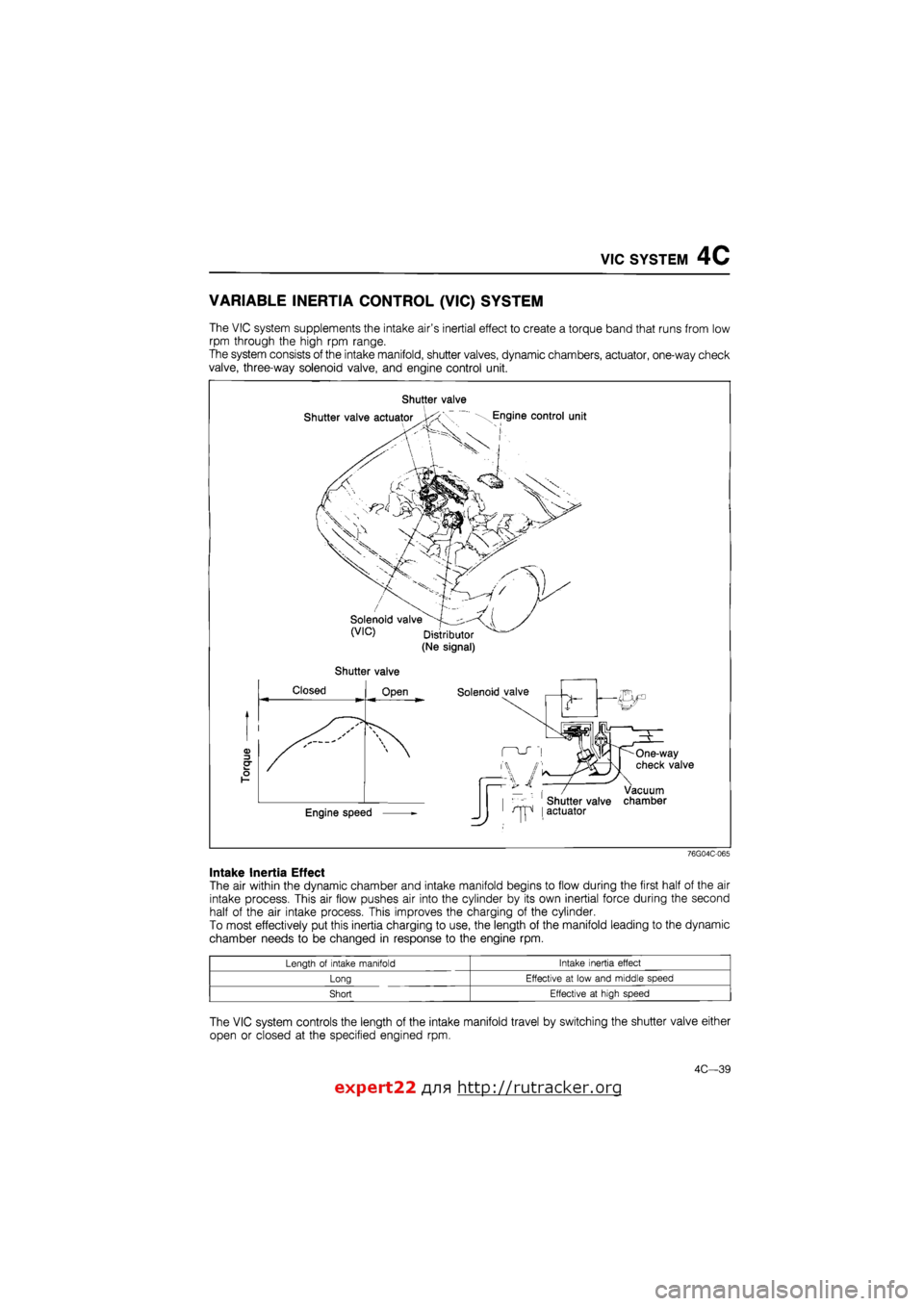

VIC SYSTEM 4C

VARIABLE INERTIA CONTROL

(VIC)

SYSTEM

The VIC system supplements the intake air's inertial effect to create a torque band that runs from low

rpm through the high rpm range.

The system consists of the intake manifold, shutter valves, dynamic chambers, actuator, one-way check

valve, three-way solenoid valve, and engine control unit.

Shutter valve

Shutter valve

76G04C-065

Intake Inertia Effect

The air within the dynamic chamber and intake manifold begins to flow during the first half of the air

intake process. This air flow pushes air into the cylinder by its own inertial force during the second

half of the air intake process. This improves the charging of the cylinder.

To most effectively put this inertia charging to use, the length of the manifold leading to the dynamic

chamber needs to be changed in response to the engine rpm.

Length of intake manifold Intake inertia effect

Long Effective at low and middle speed

Short Effective at high speed

The VIC system controls the length of the intake manifold travel by switching the shutter valve either

open or closed at the specified engined rpm.

expert22 fl/i* http://rutracker.org

4C—39

Page 601 of 1865

7C VIC SYSTEM

COMPONENT DESCRIPTION

Component Function Remark

Dynamic chamber Provides chamber for VIC system operation Integrates one-way check valve

Engine control unit Monitors engine rpm, controls solenoid valve Unleaded fuel: ON at above 5200 rpm Leaded fuel: ON at above 5400 rpm

Intake manifold Provides short and long length of intake travel Integrates shutter valve

One-way check valve Holds vacuum in vacuum chamber Installed between dynamic chamber and vacuum chamber

Ne signal pick-up Detects crank angle at 180° intervals; sends signal to control unit Installed in distributor

Solenoid valve (Vlfc) Controls vacuum to shutter valve actuator

Shutter valve Closes short intake port

Shutter valve actuator Actuates shutter valve according to

vacuum from solenoid valve

76G04C-066

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensor or switches.

Note

Make the system inspection first. If no problem is found, continue with inspection of the

next system of the Troubleshooting Guide. (Refer to pages 4C—10 and 11.)

Possible cause

\Page\.

Symptom

Vacuum chamber (Vacuum leak)

Shutter valve actuator

One-way check valve

Solenoid valve (VIC) Engine control unit (1C)

System

Inspection

Possible cause

\Page\.

Symptom

Vacuum chamber (Vacuum leak)

Shutter valve actuator

One-way check valve Vacuum ' Electric signal | signal

Engine control unit (1C)

System

Inspection

Possible cause

\Page\.

Symptom 4C—42 4C—41 4C—43 4C—42 4C-98 4C—41

Rough idle

During warm up 2 3 4 — — — 1 Rough idle After warming up 2 3 4 — — — 1

Poor acceleration, hesitation,

or lack of power 6 5 7 2 3 4 1

Poor fuel consumption 6 5 7 2 3 4 1

76G04C-067

4C—40

Page 602 of 1865

VIC SYSTEM 4C

System Inspection

1. Warm up the engine to normal operating temper-

ature and run it at idle.

2. Check that the rod has been pulled into the ac-

tuator.

76G04C-068

3. Increase the engine speed and check that the rod

is released above specification.

Specification:

Approx. 5,200 rpm....Unleaded fuel

Approx. 5,400 rpm....Leaded fuel

76G04C-069

Shutter Valve Actuator

1. Disconnect the vacuum hose from the actuator,

and connect a vacuum pump to the actuator.

2. Apply approx. 200 mmHg (7.9 inHg) vacuum

and check that the rod is pulled into the actuator.

76G04C-070

VIC Solenoid Valve

1. Disconnect the vacuum hoses from the solenoid

valve.

2. Blow through the valve from port A and check that

air flows from port B.

76G04C-071

4C—41

Page 603 of 1865

4C VIC SYSTEM

3. Disconnect the solenoid valve connector and con-

nect 12V and a ground to the terminals of the sole-

noid valve.

4. Blow through the valve from port A and check that

air flows from the air filter.

76G04C-072

Electrical Signal

1. Connect a voltmeter to the VIC solenoid valve (O

wire).

2. Increase the engine speed and note the voltmeter

reading.

Voltmeter reading Unleaded fuel Leaded fuel

Approx. 12V Below 5,200 rpm Below 5,400 rpm

Below 2.0V Approx. 5,100 rpm Approx. 5,300 rpm

76G04C-073

Vacuum Signal

1. Disconnect the vacuum hose from the actuator.

2. Place a finger over the port opening and check

that air is pulled in at idle.

3. Increase the engine speed above specification and

check that air is not pulled in.

Specification:

Approx. 5,200 rpm Unleaded fuel

Approx. 5,400 rpm Leaded fuel

4. Connect the vacuum hose.

76G04C-074

76G04C-075

4C-42

Vacuum Chamber

1. Disconnect vacuum hose A from the dynamic

chamber.

2. Connect the vacuum pump to the dynamic

chamber.

3. Apply vacuum and check that it is held.

4. If not correct, check the one-way check valve for

vacuum leakage. (Refer to page 4C—43.)

Note

10 mm Hg (0.39 inHg) drop per 30 seconds is

allowable.

5. If the one-way check valve is good, check the dy-

namic chamber.