engine MAZDA 626 1987 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 665 of 1865

4C CONTROL SYSTEM

Jjf (Terminal A)

n PI

WRED r^j

BLACK

BLACK 1 (Terminal C)

76G04C-189

Replacement

1. Disconnect the connector.

2. Loosen the air hose clamps.

3. Replace the air flow sensor.

Caution

Install the air flow sensor so that the arrow on

the sensor aligns with air flow direction.

4. Tighten the hose clamps.

5. Reconnect the connector to the sensor.

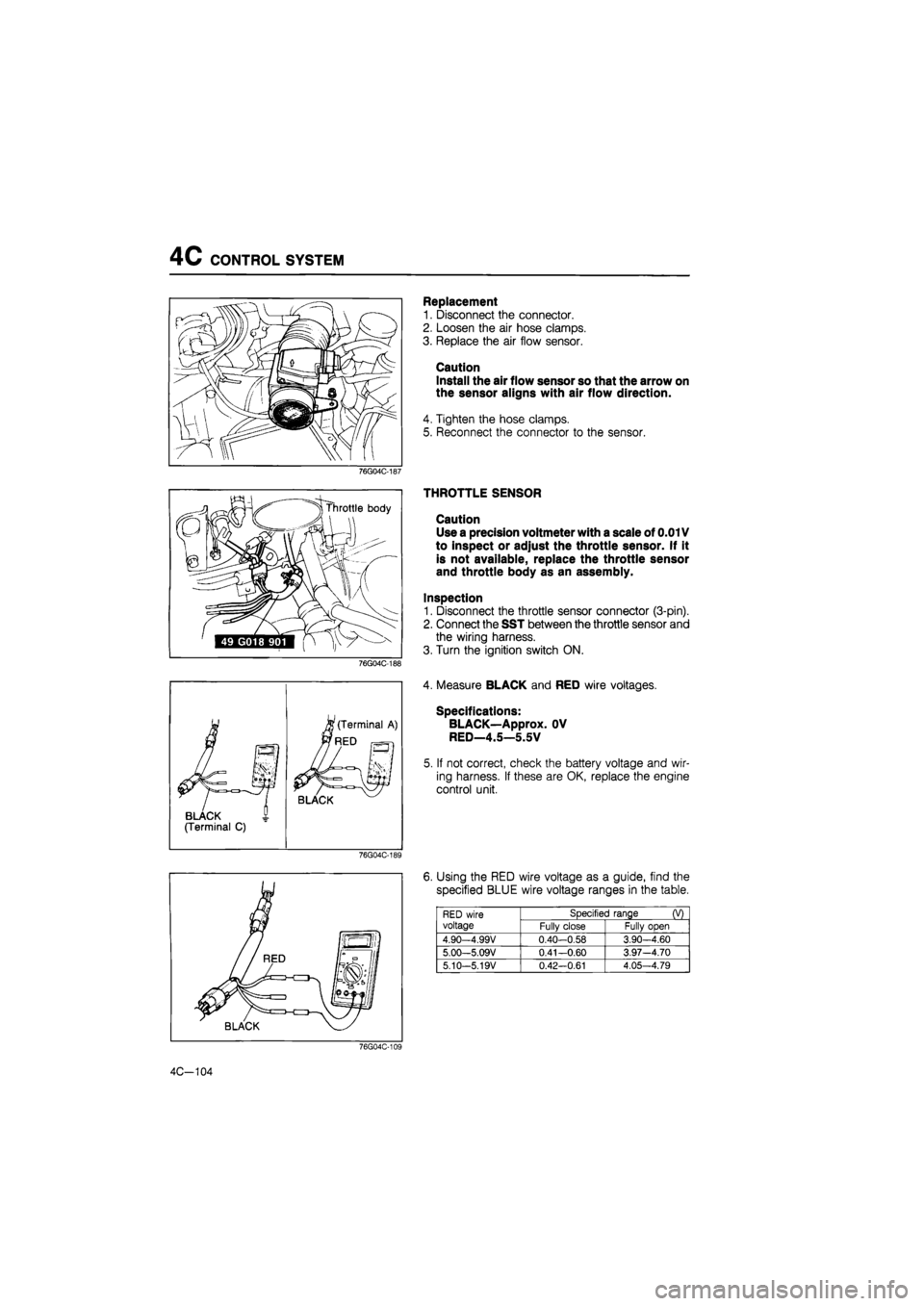

THROTTLE SENSOR

Caution

Use a precision voltmeter with a scale of 0.01V

to inspect or adjust the throttle sensor. If it

is not available, replace the throttle sensor

and throttle body as an assembly.

Inspection

1. Disconnect the throttle sensor connector (3-pin).

2. Connect the SST between the throttle sensor and

the wiring harness.

3. Turn the ignition switch ON.

4. Measure BLACK and RED wire voltages.

Specifications:

BLACK—Approx. OV

RED—4.5—5.5V

5. If not correct, check the battery voltage and wir-

ing harness. If these are OK, replace the engine

control unit.

6. Using the RED wire voltage as a guide, find the

specified BLUE wire voltage ranges in the table.

RED wire voltage

Specified range (V) RED wire voltage Fully close Fully open

4.90—4.99V 0.40-0.58 3.90-4.60

5.00—5.09V 0.41—0.60 3.97-4.70

5.10-5.19V 0.42—0.61 4.05—4.79

4C-104

Page 668 of 1865

CONTROL SYSTEM 4C

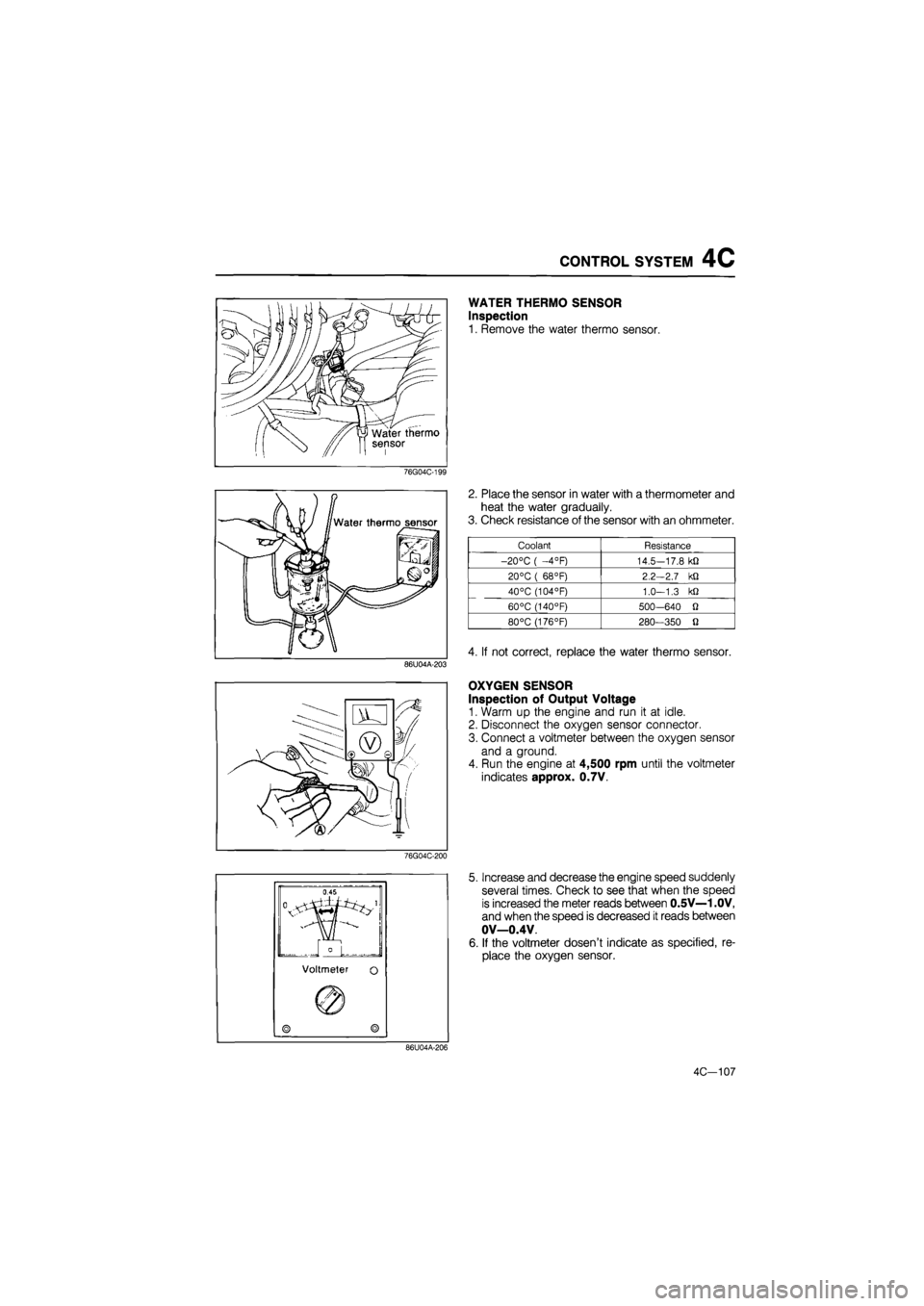

WATER THERMO SENSOR

Inspection

1. Remove the water thermo sensor.

76G04C-199

86U04A-203

2. Place the sensor in water with a thermometer and

heat the water gradually.

3. Check resistance of the sensor with an ohmmeter.

Coolant Resistance

-20°C ( —4°F) 14.5—17.8 kfl

20°C ( 68°F) 2.2-2.7 kQ

40°C (104°F) 1.0—1.3 kQ

60°C (140°F) 500—640 O

80°C (176°F) 280—350 fl

4. If not correct, replace the water thermo sensor.

OXYGEN SENSOR

Inspection of Output Voltage

1. Warm up the engine and run it at idle.

2. Disconnect the oxygen sensor connector.

3. Connect a voltmeter between the oxygen sensor

and a ground.

4. Run the engine at 4,500 rpm until the voltmeter

indicates approx. 0.7V.

76G04C-200

5. Increase and decrease the engine speed suddenly

several times. Check to see that when the speed

is increased the meter reads between 0.5V—1 .OV,

and when the speed is decreased it reads between

OV—0.4V.

6. If the voltmeter dosen't indicate as specified, re-

place the oxygen sensor.

86U04A-206

4C—107

Page 669 of 1865

4C CONTROL SYSTEM

Check connector: Green (6 pin)

cable

49 H018 9A1

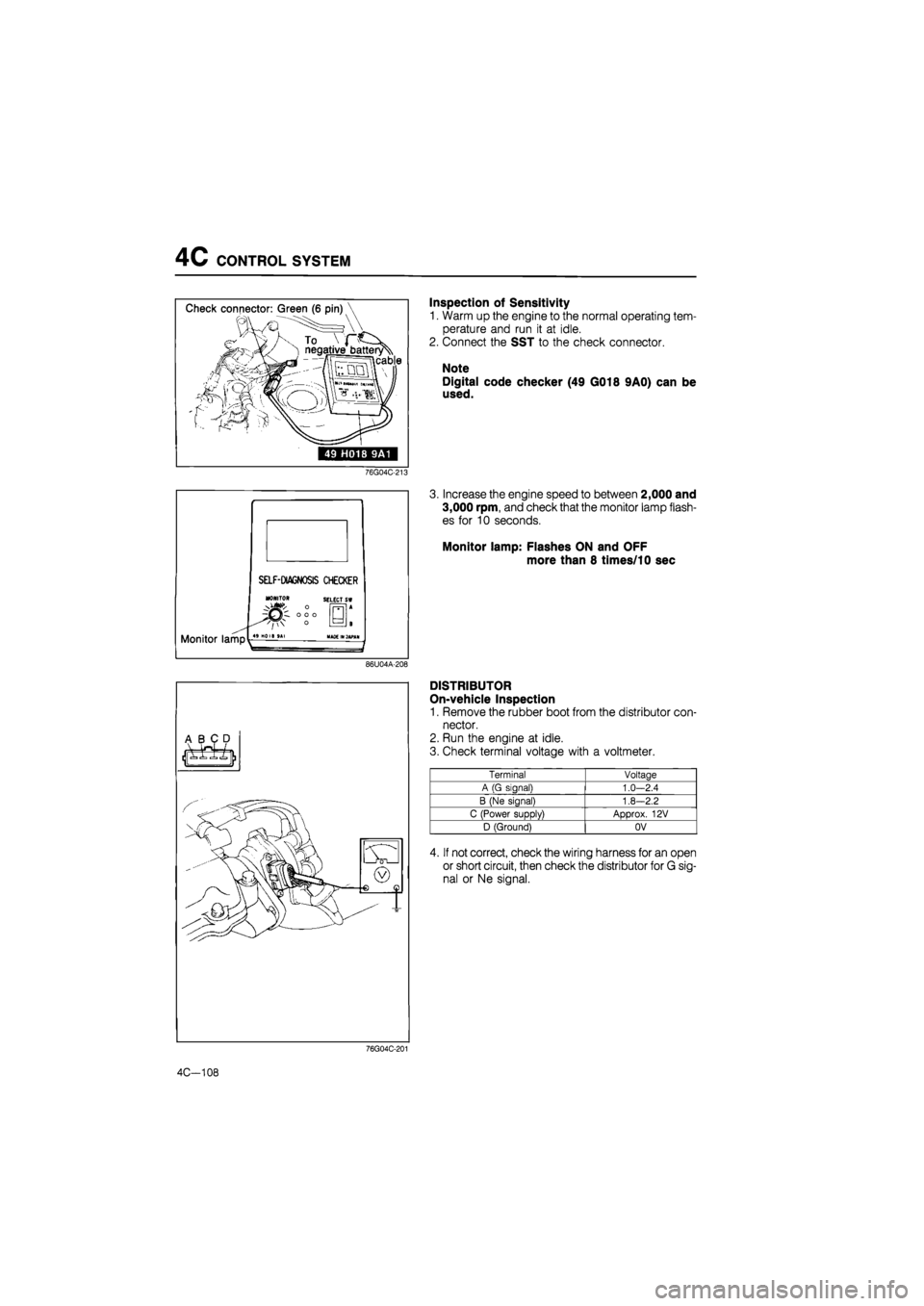

Inspection of Sensitivity

1. Warm up the engine to the normal operating tem-

perature and run it at idle.

2. Connect the SST to the check connector.

Note

Digital code checker (49 G018 9A0) can be

used.

76G04C-213

Increase the engine speed to between 2,000 and

3,000 rpm, and check that the monitor lamp flash-

es for 10 seconds.

Monitor lamp: Flashes ON and OFF

more than 8 times/10 sec

86U04A-208

A B C D

/llkw^ - ®

I « ^

76G04C-201

4C—108

DISTRIBUTOR

On-vehicle Inspection

1. Remove the rubber boot from the distributor con-

nector.

2. Run the engine at idle.

3. Check terminal voltage with a voltmeter.

Terminal Voltaae

A (G signal) 1.0—2.4

B (Ne sianaB 1.8—2.2

C (Power supply) Approx. 12V

D (Ground) OV

4. If not correct, check the wiring harness for an open

or short circuit, then check the distributor for G sig-

nal or Ne signal.

Page 670 of 1865

CONTROL SYSTEM 4C

76G04C-203

76G04C-204

76G04C-205

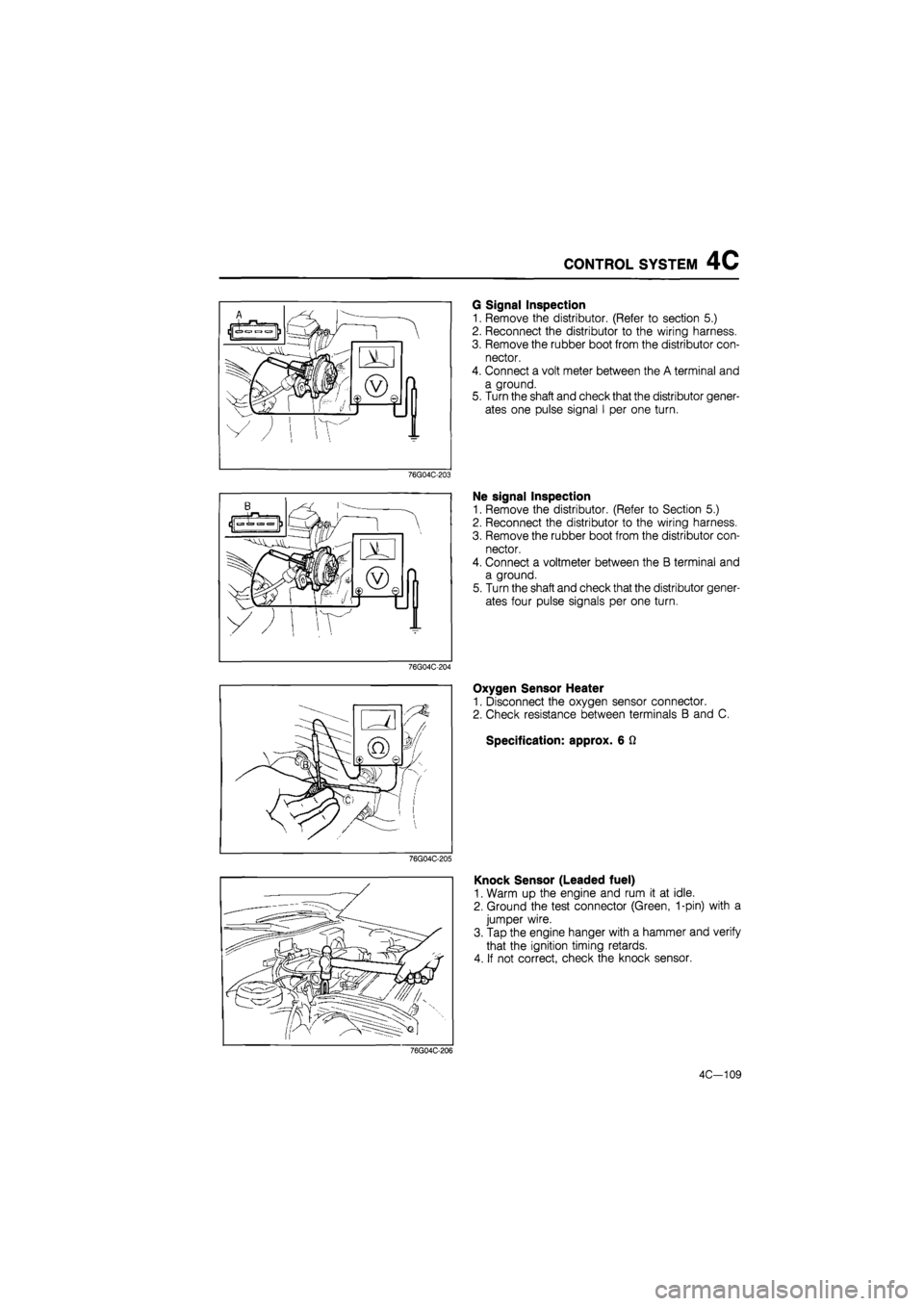

G Signal Inspection

1. Remove the distributor. (Refer to section 5.)

2. Reconnect the distributor to the wiring harness.

3. Remove the rubber boot from the distributor con-

nector.

4. Connect a volt meter between the A terminal and

a ground.

5. Turn the shaft and check that the distributor gener-

ates one pulse signal I per one turn.

Ne signal Inspection

1. Remove the distributor. (Refer to Section 5.)

2. Reconnect the distributor to the wiring harness.

3. Remove the rubber boot from the distributor con-

nector.

4. Connect a voltmeter between the B terminal and

a ground.

5. Turn the shaft and check that the distributor gener-

ates four pulse signals per one turn.

Oxygen Sensor Heater

1. Disconnect the oxygen sensor connector.

2. Check resistance between terminals B and C.

Specification: approx. 6 Q

Knock Sensor (Leaded fuel)

1. Warm up the engine and rum it at idle.

2. Ground the test connector (Green, 1-pin) with a

jumper wire.

3. Tap the engine hanger with a hammer and verify

that the ignition timing retards.

4. If not correct, check the knock sensor.

76G04C-206

4C-109

Page 673 of 1865

4D OUTLINE

OUTLINE

The Mazda 626 offers two diesel engines; a Comprex supercharged RF-CX engine, and a normally

aspirated RF-N engine.

SPECIFICATIONS

—Engine model

Item ———

ECE UK, GENERAL —Engine model

Item ——— RF-CX RF-N

Fuel tank Capacity liters (US gal, Imp gal) 60 (15.9, 13.2)

Fuel filter Type Cartridge, paper element

Sedimenter Type With detector

Injection pump

Type Bosch VE distributor

Injection pump

Manufacturer Diesel Kiki Co,, Ltd.

Injection pump

Direction of rotation Clockwise Injection pump

Drive method Timing belt

Injection pump

Plunger diameter mm (in) 9.0 (0.35) 8.0 (0.31)

Injection pump

Cam lift mm (in) 2.2 (0.087)

Injection nozzle Type Throttle Injection nozzle

Injection pressure kPa (kg/cm2, psi) 13,240 (135 , 1,920)

Injection timing ATDC

1

° TDC 0°

Idle speed rpm 720 _+f0

Fast idle speed (A/C ON) rpm 700-750

Cold start device Engine speed rpm 1.100 Cold start device

Advance degree 6°

Air cleaner Type Cartridge, paper element Air cleaner Type

Wet Dry

PCV system Type Open Closed

76G04D-002

4D—2

Page 674 of 1865

TROUBLESHOOTING GUIDE 4D

TROUBLESHOOTING GUIDE

Condition Condition Cause Remedy

Hard starting Fuel filter

Clogged Replace

Water or air in filter Repair

Fuel injection pump Faulty fuel cut solenoid Replace Incorrect injection timing Adjust

Air in pump Bleed

Faulty pump Replace

Fuel injection nozzle Seized needle valve Replace

Fuel dripping from nozzle Replace Incorrect valve opening pressure Adjust

Faulty glow plug Replace

Faulty cold start device Adjust or replace

Faulty supercharging system Refer to page 4D—10

Rough idle Fuel filter (Refer to "Hard starting") Fuel injection pump (Refer to "Hard starting")

Fuel injection nozzle

Seized needle valve Replace

Incorrect valve opening pressure Adjust

Improper mounting to nozzle holder Repair

Leakage of nozzle holder copper washer Replace

Fuel injection pipe Cranks Replace

Leaking from joint Repair

Improper idle speed adjustment Adjust

Engine knocking Incorrect injection timing Adjust

Low quality fuel Replace

Incorrect injection nozzle opening pressure Ajust

Seized injection nozzle needle valve Replace

Fuel dripping from injection nozzle Replace

Faulty supercharging system Refer to page 4D—10

High fuel Fuel injection pump consumption Incorrect injection timing Adjust consumption High idle speed Adjust, Inspect the dashpot

Fuel injection nozzle Incorrect valve opening pressure Repair

Fuel dripping from nozzle Replace

Leakage of nozzle holder copper washer Replace

Fuel leaking from connection Repair

Clogged fuel filter Replace

Clogged air cleaner Replace

Poor acceleration Fuel injection nozzle (Refer to "Hard starting")

Fuel injection pump (Refer to "Hard starting")

Fuel injection pipe (Refer to "Rough idle") Fuel filter (Refer to "Hard starting") Clogged air cleaner Clean or replace

Faulty supercharging system Refer to page 4D—10

Excessive exhaust Clogged air cleaner Clean or replace

smoke Improper injection timig Adjust

Faulty nozzle or nozzle holder Adjust or replace

Faulty supercharging system Refer to page 4D—10

76G04D-003

4D-3

Page 677 of 1865

4D ON-VEHICLE MAINTENANCE

IDLE SPEED

1. Warm up the engine to normal operating tem-

perature.

2. Be sure the A/C switch is OFF.

3. Connect a tachometer and check the engine

speed.

Idle speed: 720 :

20

rpm

76G04D-012

4. If necessary, adjust the idle by turning the idle ad-

justing screw.

76G04D-013

Fast Idle Speed (A/C equipped model)

1. Turn ON the A/C switch and blower motor switch.

2. Check the engine speed.

Fast idle speed: 725 ± 25 rpm

3. If necessary, turn the adjusting screw on the idle-

up actuator, and adjust the fast idle speed.

76G04D-014

EXHAUST SMOKE

Increase and decrease the engine speed several

times and check that there is no black smoke.

If

there

is, refer to the Troubleshooting Guide.

76G04D-015

4D—6

Page 681 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

SUPERCHARGING SYSTEM (RF-CX)

TROUBLESHOOTING GUIDE

Engine

hard

starting

Poor

acceleration

Excessive

blue

smoke

Excessive

black

smoke

Excessive

compressed

air

temperature

(Buzzser

sounds)

Excessive

noise

Possible Cause Remedy (reference page)

*

*

Comprex supercharger Rotor stuck Casing damaged Rotor bearing damaged

Replace (4D—14)

* * * Drive system

of

Comprex supercharger Drive belt loose

or

worn Repair

or

replace

(4D-12) * Idler pulley damaged

Repair

or

replace

(4D-12) * Pulley bolt loose

or

worn

Repair

or

replace

(4D-12)

* Wastegate

Valve

not

open Clean

or

repace (4D-12) ik * Valve

not

closed

Clean

or

repace (4D-12)

* * Starting valve

Valve

not

open Repair

or

replace (4D-15)

* * Valve

not

closed

Repair

or

replace (4D-15) * Bypass valve

not

open

Repair

or

replace (4D-15)

* * Bypass valve

not

closed

Repair

or

replace (4D-15)

* Intercooler dirty Clean

or

replace (4D-16)

* * * * Intake

air

system Fresh

air

side clogged (Air cleaner

ele-

ment,

etc.)

Repair

or

replace * Compressed

air

side clogged (Intercool-

er,

etc.)

Repair

or

replace

* Fresh

air

side leaks

Repair

or

replace

* * * Compressed

air

side leaks

Repair

or

replace

* Exhaust system

Exhaust

gas

breaked Repair

* * * * * Exhaust pipe clogged

Repair

* Silencer damaged

(in

fender,

in air

clean-er,

in air

funnel, Comprex insulator) Repair

or

replace

* Bolt

and nut

loosend Repair

76G04D-022

4D—10

Page 682 of 1865

4D SUPERCHARGING SYSTEM (RF-CX)

ON-VEHICLE INSPECTION

Boost Pressure

1. Connect a pressure gauge to the hose from the

intake manifold.

2. (On chassis dynomometer, full load)

(1) Set the vehicle on a chassis dynomometer.

(2) Run the vehicle in gear at 3,000 rpm with the

acceleration pedal fully depressed.

(3) Measure the boost pressure.

Boost pressure:

82 kPa (0.87 kg/cm2, 8.1 psi)

Note

The above inspection should be done on a

chassis dynomometer. If a dynomometer is

not available follow the below procedure.

3. (Off chassis dynomometer, no load)

(1) Shift the transaxle out off gear.

(2) Run the engine in neutral at 3,000 rpm of the

engine no load.

Measure the boost pressure.

Boost pressure:

5 kPa (0.05 kg/cm2, 0.7 psi)

Note

The boost pressure is varied by engine speed

and engine load.

(3) Remove the starting valve bypass hose.

(4) Check that the bypass valve is closed at 3,000

rpm.

4.

If

the pressure is below specification, check the fol-

lowing. Replace the Comprex supercharger if

necessary.

(1) Intake air and exhaust passages leakage

(2) Intake air and exhaust passages clogged

(3) Wastegate (Refer to 4D—12.)

(4) Starting valve (Refer to 4D—15.)

(5) Fuel system (Injection nozzle... refer to page

4D—31, injection pump...refer to page 4D—24,

etc.)

5. If the pressure exceeds specification, check the

wastegate operation. (Refer to page 4D—12.)

4D—11

Page 695 of 1865

4D FUEL SYSTEM

INJECTION PUMP

On-Vehicle Inspection

Fuel cut solenoid valve

1. Run the engine at idle.

2. Disconnect the solenoid valve connector, and let

the engine stop.

3. If the engine does not stop, replace the fuel cut

solenoid valve.

76G04D-055

Pick up coil

1. Disconnect the pick up coil connector.

2. Check for continuity of the coil using an ohmmeter.

3. Replace it if there is not continuity.

76G04D-056

O

o

>=

=<

t= —i V

' 1 -4

n

5-

U

o

1 mm (0.39 in) Injection Timing Adjustment

Inspection

Check the injection timing. (Refer to page 4D—5.)

Injection timing

RF-CX: ATDC 10

RF-N : TDC 0°

76G04D-057

Adjustment

1. Loosen the injection pump mounting nut.

2. Loosen the injection pump bracket bolt.

76G04D-058

4D—24