MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 571 of 1865

4C TROUBLESHOOTING GUIDE

The Troubleshooting Guide lists the systems most likely to cause

a

given symptom. After finding which

system(s)

to

check, refer

to the

pages shown

for

detailed guides.

iSystem

S UJ 1-tn > tn

INTAKE

AIR

SYSTEM

FUEL

SYSTEM

o oc a

_i o oc 1-z o o oc o i-<

-i

o UJ OC Ul oc 3 (0 tn Ul oc a.

IDLE

SPEED

CONTROL

(ISC)

SYSTEM

ELECTRONIC

SPARK

ADVANCE

(ESA)

CONTROL

SYSTEM

EXHAUST

GAS

RECIRCULATION

(EGR)

SYSTEM

EVAPORATIVE

EMISSION

CONTROL

(EEC)

SYSTEM

POSITIVE

CRANKCASE

VENTILATION

(PCV)

SYSTEM

DECELERATION

CONTROL

SYSTEM

EXHAUST

SYSTEM

VARIABLE

INERTIA

CONTROL

(VIC)

SYSTEM

Page

4C—31 4C—49 4C—68 4C—44 4C—75 4C—77 4C—80 4C—86 4C—72 4C—87

&

89

4C—39

2 3 2 — — 1 — — — — — —

3

4 3 — 1 — 2 — _ _ — — 3 5 4 — 2 — 3 — 1 — — —

4 5 4 -1 — 3 — 2 — — -4 6 5 — 2 — 3 4 1 — — —

o z 5 2 3 — 1 — — — — — — —

E o 6 3 4 — — — 1 2 — — 6 5

Q-E >> 7 4 3 — 2 — — — — 1 — —

(0 8 3 4 — 1 — — — — 2 — —

9 — 2 — — — 3 — — 1 5 4

10 — 2 1 — — — — — — — —

11 — — — — 1 — — — — — —

12 6 7 — 4 — 2 5 _ 3 1

76G04C-010

The numbers

of the

list show

the

priorities

of

inspections, from

the

most possible system

to

that with

the lowest possibility.

These were determined

on the

following basis:

• Ease

of

inspection

•

Most possible system

•

Most possible point

in

system

4C—10

Page 572 of 1865

TROUBLESHOOTING WITH SST 4C

TROUBLESHOOTING WITH SST

Engine control unit

76G04C-011

When troubles occur in the main input devices or output devices, check for the cause with the SST

(Self-Diagnosis checker 49 H018 9A1 or Digital code checker 49 G018 9A0 with Adaptor har-

ness 49 9200 180)

Failure of individual input and output devices is indicated and retrieved from the control unit as mal-

function code numbers.

Note

The control unit constantly checks for malfunction of the input devices. But, the control

unit checks for malfunction of output devices only in a 3 second period after the ignition

switch is turned ON and the test connector is grounded.

4C—11

Page 573 of 1865

4C TROUBLESHOOTING WITH SST

Check connector: (Green, 6 pin)

49 H018 9A1

86U04A-011

Test connector: (Green, 1 pin)'

INSPECTION PROCEDURE

1. Connect the SST to the check connector. (Green,

6-pin) and the negative battery terminal.

2. Set the select switch to position A.

Note

The check connector is located at the rear of

the left side wheel housing.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

Note

The test connector is located near the Self-

Diagnosis Checker check connector.

86U04A-012

OO

uu

SELF-DIAGNOSIS CHECKER

MONITOR LAMP SELECT SW «

o o o

o

76G04C-012

4. Turn the ignition switch ON.

5. Verify that 88 flashes on the digital display and that

the buzzer sounds for three seconds after turn-

ing the ignition switch ON.

6. If 88 does not flash, check the control relay (refer

to page 4C—96), power supply circuit, and check

connector wiring.

7. If 88 flashes and the buzzer sounds continuously

for more than 20 seconds check the check con-

nector wiring, then replace the engine control unit

and perform steps 3 and 4 again.

8. Note the code numbers and check for the causes

by referring to the check sequences shown on

pages 4C—16 to 4C—24. Repair as necessary.

Note

Cancel the code numbers by performing the

after-repair procedure after repairing.

AFTER-REPAIR PROCEDURE

1. Cancel the memory of malfunctions by disconnect-

ing the negative battery cable and depress the

brake pedal for at least five seconds.

76G04C-013

4C-12

Page 574 of 1865

TROUBLESHOOTING WITH SST 4C

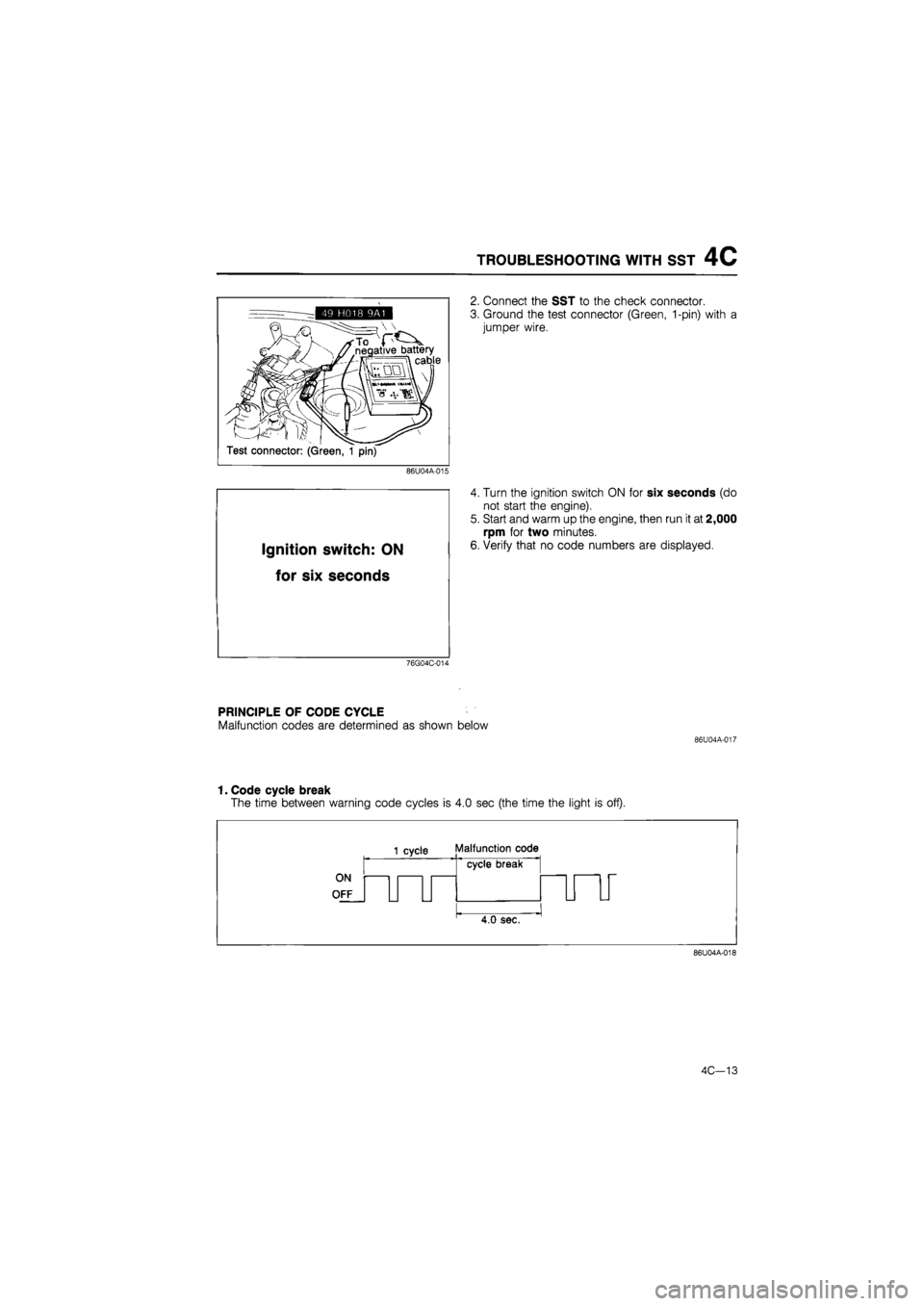

49 H018 9A1

negative battery cable

^ll

Test connector: (Green, 1 pin)

86U04A-015

Ignition switch:

ON

for six

seconds

76G04C-014

2. Connect the SST to the check connector.

3. Ground the test connector (Green, 1-pin) with a

jumper wire.

4. Turn the ignition switch ON for six seconds (do

not start the engine).

5. Start and warm up the engine, then run it at 2,000

rpm for two minutes.

6. Verify that no code numbers are displayed.

PRINCIPLE OF CODE CYCLE

Malfunction codes are determined as shown below

86U04A-017

1. Code cycle break

The time between warning code cycles is 4.0 sec (the time the light is off).

ON

OFF

1 cycle Malfunction code

cycle break

4.0 sec.

86U04A-018

4C—13

Page 575 of 1865

4C TROUBLESHOOTING WITH SST

2. Second digit of malfunction code (ones position)

The digit in the ones position of the malfunction code represents the number of times the buzzer

is on 0.4 sec during one cycle.

ON

OFF

1 cycle Malfunction code

1 2 3 cycle break

Malfunction

code: 03

n^j

0.4 0.4 sdc. sec.

4.0 sec.

76G04C-015

3. First digit of malfunction code (tens position)

The digit in the tens position of the malfunction code represents the number of times the buzzer

is on 1.2 sec during one cycle.

It should also be noted that the light goes off for 1.6 sec. between the long and short pulses of

the buzzer.

1 cycle Malfunction code

1 2

~U 0.4

1.2 sec. sec h

1 2|

flfl

First digit

1.6 sec.

cycle break

Malfunction

code: 22

nr

4.0 sec.

Second

digit

76G04C-016

CODE NUMBER

Malfunction display

Sensor or

subsystem Self-diagnosis Fail-safe Malfunction

code no.

Malfunction code output signal pattern

Sensor or

subsystem Self-diagnosis Fail-safe

02 o°nfJLJJL

Ne signal No Ne signal from crank angle sensor during craking

03 oppJUllUl

G signal No G signal Cancels sequencial

injection

05

Knock sensor (only

leaded fuel)

Open or short circuit • Retards ignition timing 4°

76G04C-017

4C—14

Page 576 of 1865

TROUBLESHOOTING WITH SST 4C

Malfunction display

Sensor or subsystem Self-diagnosis Fail-safe Malfunction

code no. Malfunction code output signal pattern

Sensor or subsystem Self-diagnosis Fail-safe

08

Air flow sensor Open or short circuit Maintains basic sig-nal at preset value

09 o°pNp II IIL •

Water thermo sensor Open or short circuit Maintains constant 35°C (95°F) command

11 0°FNFJUUL

Intake air thermo sensor (dynamic chamber)

Short circuit Maintains constant 20°C (68°F) command

12

Throttle sensor Open or short circuit Maintains constant command of throttle valve fully open

15 ON n

OFF •L 01

Oxygen sensor Sensor output con-tinues less than 0.55V 120 sec. after engine starts (1,500 rpm or over)

Cancels

EG I

feed-

back operation

17 ON n

OFF L HI il

Feedback system Sensor output not changed 20 sec. af-ter engine starts (1,500 rpm or over)

Cancels

EG I

feed-

back operation

25 0°nfJU1LJIL

Solenoid valve (pres-sure regulator control)

Open or short circuit

26 2LMJIL

Solenoid valve (No.1 purge control)

Open or short circuit

27 ON nn

OFF | _ •111

-ii-Solenoid valve (No.2

purge control)

Open or short circuit

28 ON nn

OFF L Hi nr

Solenoid valve (EGR)

Open or short circuit

34 ^jmiHum

Solenoid valve (Idle speed control)

Open or short circuit

36 °FFJMI«U

Oxygen sensor relay

Open or short circuit

41 <£jimjiuM

Solenoid valve (Vari-able inertia control)

Open or short circuit

76G04C-018

Caution

a) If there is more than one failure present, the lowest number malfunction code is dis-

played first, the remaining codes are displayed sequentially.

b) After repairing a failure, turn off the ignition switch and disconnect the negative battery

cable and depress the brake pedal for at least 5 seconds to erase the memory of a mal-

function code.

4C—15

Page 577 of 1865

4C TROUBLESHOOTING WITH SST

Code No.2 (Ne signal) PC: Possible Cause

YES

PC: Engine control unit malfunction

76G04C-019

Code No.3 (G signal) PC: Possible Cause

4C-16

Page 578 of 1865

TROUBLESHOOTING WITH SST 4C

76G04C-020

Code No.05 (Knock sensor) PC: Possible Cause

76G04C-021

Code No.08 (Air flow sensor) PC: Possible Cause

Next page

4C—17

Page 579 of 1865

4C TROUBLESHOOTING WITH SST

Is there continuity between air flow sensor and

engine control unit?

Air flow sensor Engine control unit

D (RB wire) 2E

E (RW wire) 2B

NO

YES

Is there 12V at terminal B of air flow sensor connector? (Refer to page 4C—103)

YES

Is there continuity between terminal F of air flow sensor and ground? (Refer to page 4C-103)

YES

NO

NO

PC: Open circuit in wiring harness

PC: Open or short circuit in wiring harness from terminal B to control relay

PC: Open circuit in wiring harness

PC: • Engine control unit malfunction • Short circuit in wiring from terminal D of air flow sensor to engine control unit

76G04C-022

Code No. 09 (Water thermo sensor)

Are there poor connections in water thermo sensor circuit?

NO

Is there continuity between water thermo sensor and engine control unit?

YES

Is resistance of the water thermo sensor OK? Resistance:

YES

Water thermo sensor Enaine control unit

A (YB wire) 21

B (LgY wire) 2C

NO

Coolant temp Resistance

-20°C ( —4°F) 14.5-17.8 kfl

20°C ( 68°F) 2.2- 2.7 kfi

40°C {104°F) 1.0- 1.3 kfi

60°C (140°F) 500-640 fi

80°C (176°F) 280-350 fi

NO

YES

Is same Code No. present after performing after-repair procedure? (Refer to page 4C—12)

YES

Are engine control unit 21 and 2C terminal voltages OK? (Refer to page 4C—98)

YES

NO

NO

PC: Possible Cause

Repair or replace connector

PC: Open circuit in wiring harness from water thermo sensor to engine control unit

Replace water thermo sensor

Water thermo sensor and circuit OK

PC: Short circuit in wiring harness

PC: Engine control unit malfunction

76G04C-023

4C—18

Page 580 of 1865

TROUBLESHOOTING WITH SST 4C

No. 11 Code (Intake air thermo sensor) PC: Possible Cause

NO

Is there continuity between intake air thermo sensor

(dynamic chamber) and engine control unit?

Intake air thermo sensor (dynamic chamber) Engine control unit

A (RC wire) 2J

B (LgY wire) 2C

YES

Is resistance of intake air thermo sensor (dynamic chamber) OK? Resistance:

NO PC: Open circuit in wiring harness

Temperature Resistance

20°C (68°F) 29.7-36.3 kQ

50°C (122°F) 8.4-10.2 kQ

85°C (185°F) 2.5-3.1 kQ

NO Replace intake air thermo sensor (dynamic chamber)

YES

76G04C-024

Code No. 12 (Throttle sensor) PC: Possible cause

Next step

4C-19