MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 531 of 1865

AIR INJECTION SYSTEM 4B

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switch.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause Air control valve Reed valve System inspection

Page 4B—69 4B—70 4B—69

Checking order 2 3 1

76G04B-097

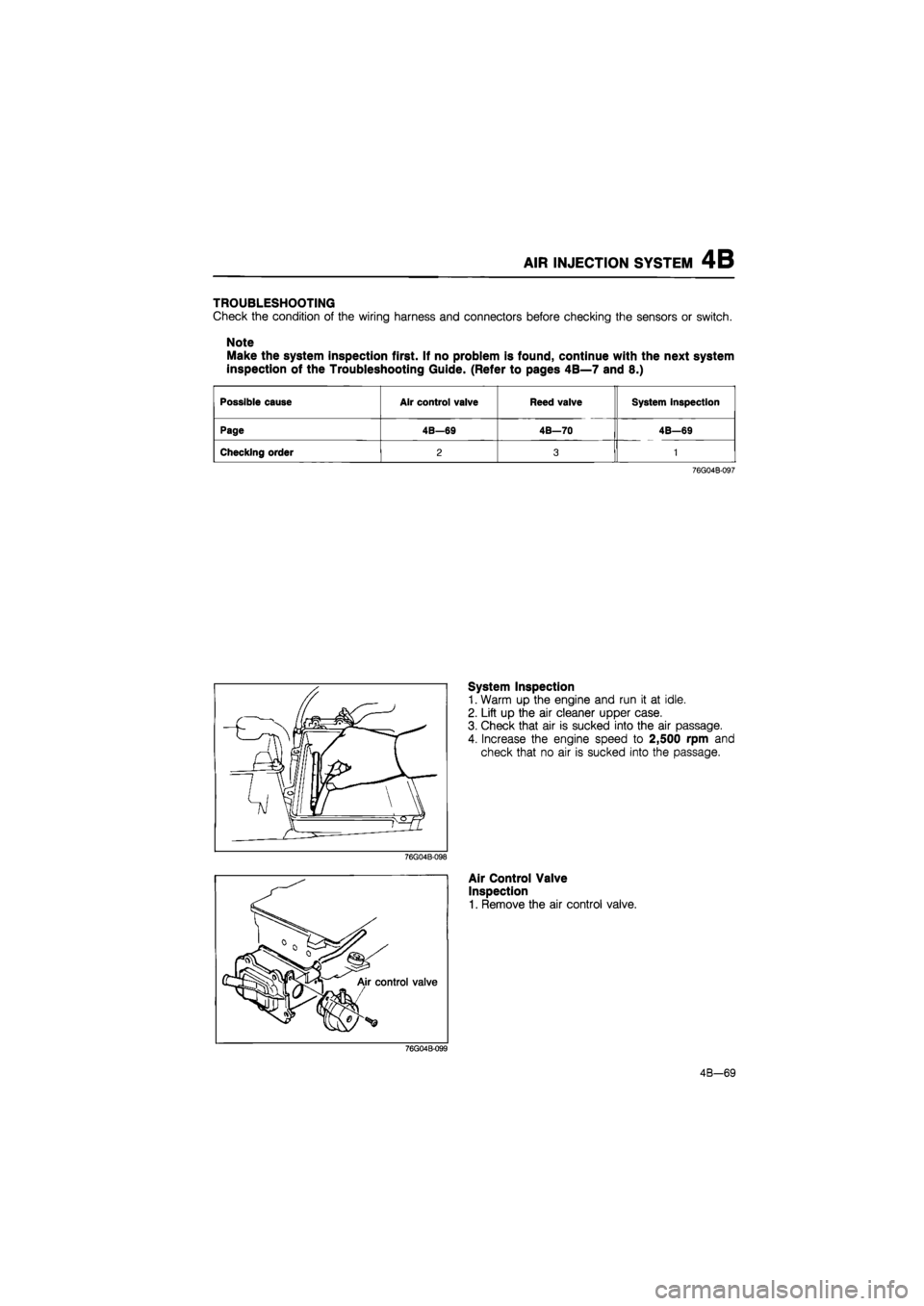

System Inspection

1. Warm up the engine and run it at idle.

2. Lift up the air cleaner upper case.

3. Check that air is sucked into the air passage.

4. Increase the engine speed to 2,500 rpm and

check that no air is sucked into the passage.

Air Control Valve

Inspection

1. Remove the air control valve.

4B-69

Page 532 of 1865

4B AIR INJECTION SYSTEM

56G04B-114p

76G04B-100

76U04A-066

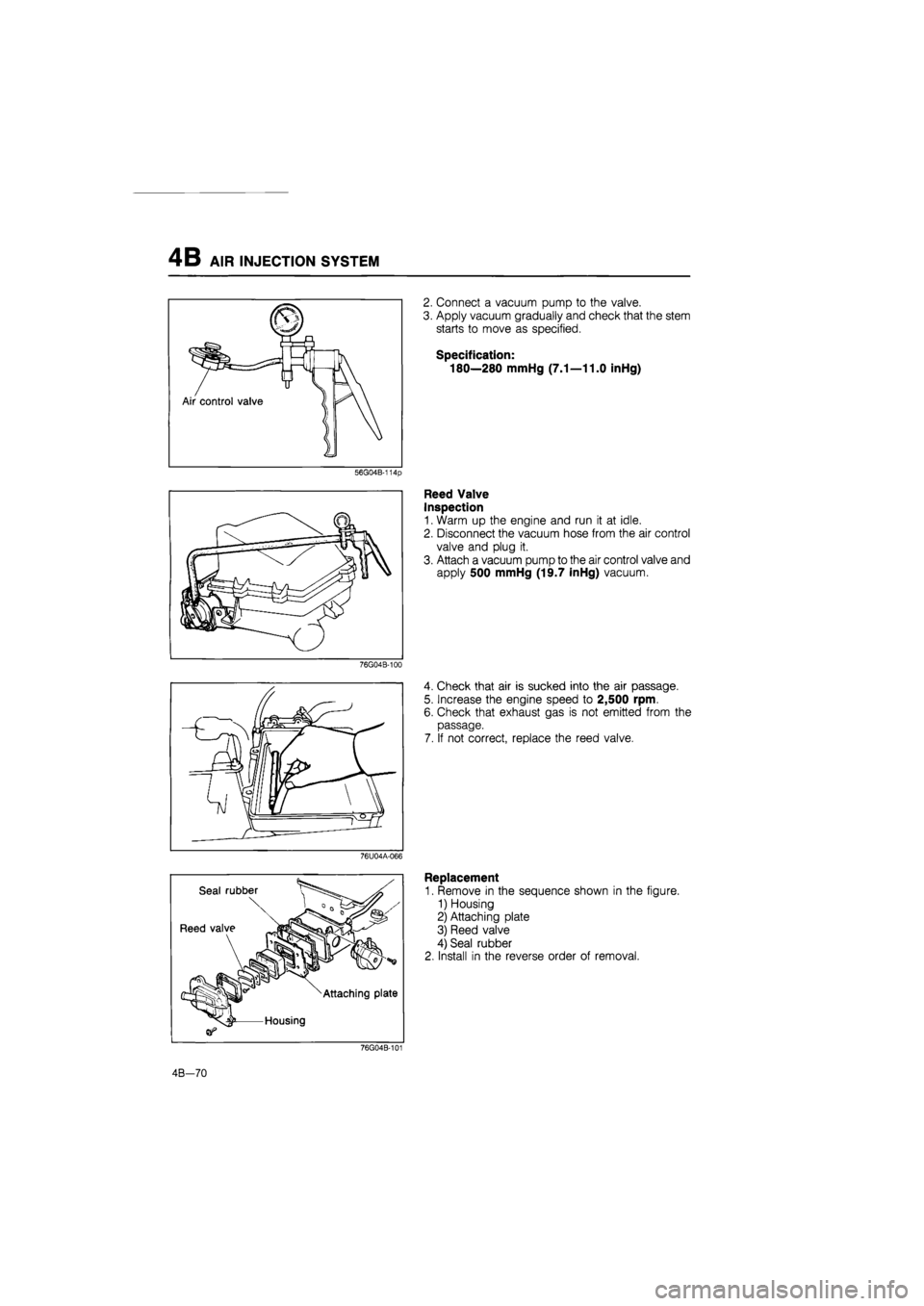

2. Connect a vacuum pump to the valve.

3. Apply vacuum gradually and check that the stem

starts to move as specified.

Specification:

180—280 mmHg (7.1—11.0 inHg)

Reed Valve

Inspection

1. Warm up the engine and run it at idle.

2. Disconnect the vacuum hose from the air control

valve and plug it.

3. Attach a vacuum pump to the air control valve and

apply 500 mmHg (19.7 inHg) vacuum.

4. Check that air is sucked into the air passage.

5. Increase the engine speed to 2,500 rpm.

6. Check that exhaust gas is not emitted from the

passage.

7. If not correct, replace the reed valve.

Replacement

1. Remove in the sequence shown in the figure.

1) Housing

2) Attaching plate

3) Reed valve

4) Seal rubber

2. Install in the reverse order of removal.

76G04B-101

4B—70

Page 533 of 1865

EGR SYSTEM 4B

EXHAUST GAS RECIRCULATION

(EGR)

SYSTEM

EGR modulator valve Solenoid valve (EGR)

86U04A-127

This system introduces exhaust gas into the intake manifold to reduce NOx in the exhaust gas. It oper-

ates depending on the engine load, engine speed (above 1,500 rpm), engine coolant temperature

(above 70°C, 158°F), and radiator coolant temperature (above 17°C, 63°F).

COMPONENT DESCRIPTIONS

Component Function Remarks

EGR control valve Recirculates portion of exhaust gas

EGR modulator valve Controls vacuum acting on EGR control

valve

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (EGR)

Ignition coil (-) terminal Detects engine speed; sends signal to engine control unit

Solenoid valve (EGR) Controls vacuum line to EGR control

valve

Throttle sensor Detects throttle valve opening angle; sends signal to engine control unit Integrated idle switch

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo switch Detects radiator coolant temperature; sends signal to engine control unit

ON: above 17°C (63°F)

76G04B-102

4B-71

Page 534 of 1865

4B EGR SYSTEM

TROUBLESHOOTING

Check the condition of the wiring harness and connectors before checking the sensors or switches below.

Note

Make the system inspection first. If no problem is found, continue with the next system

inspection of the Troubleshooting Guide. (Refer to pages 4B—7 and 8.)

Possible cause

Solenoid

valve (EGR)

EGR modula-tor valve

EGR con-trol valve

Water

thermo sensor

Water

thermo switch

Engine control unit

terminal

System in-spection

2N

Page 4B—72 4B—73 4B—73 4B—97 4B—97 4B—90 4B—72

Checking order 3 2 4 6 5 7 1

76G04B-103

86U04A-130

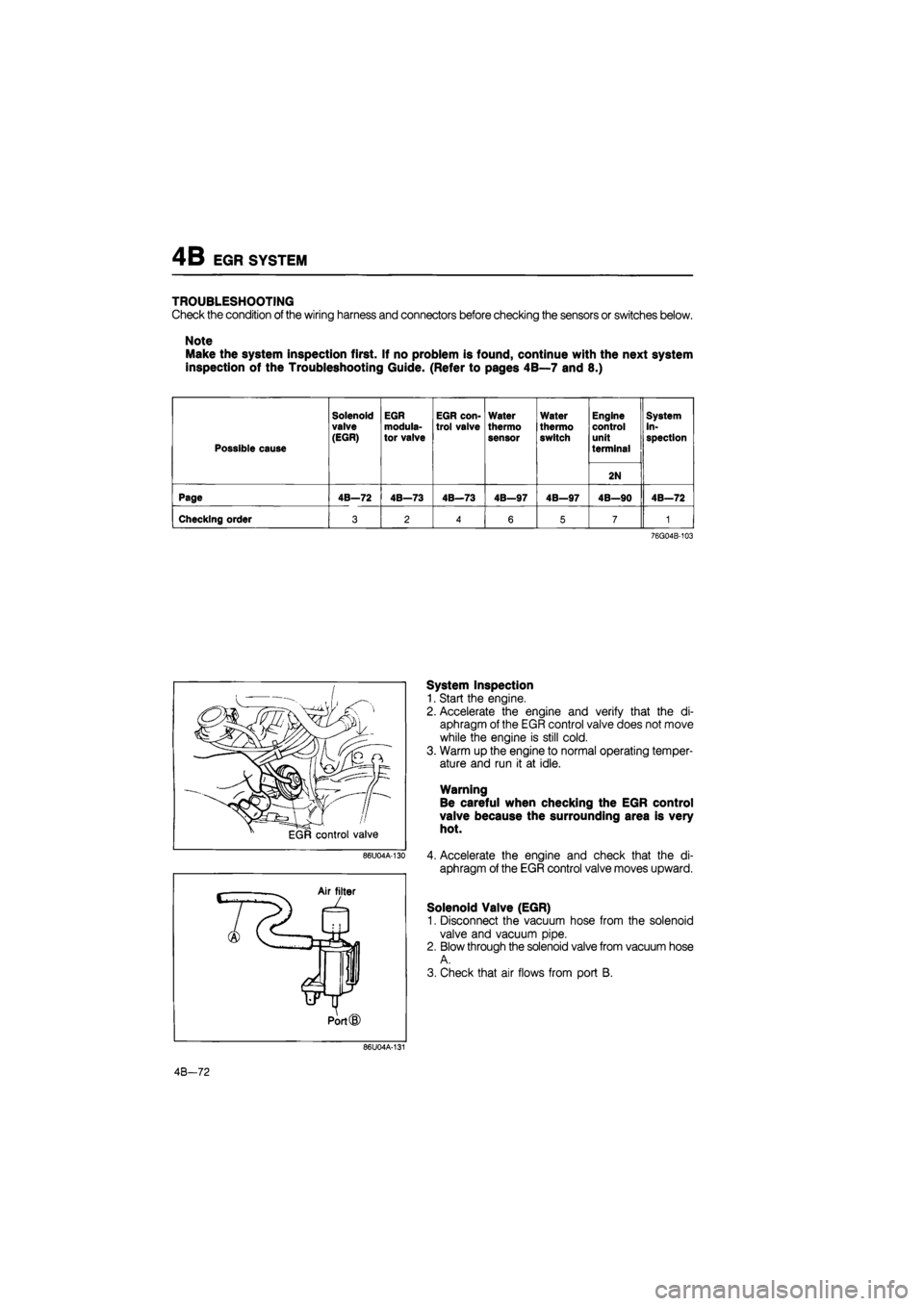

System Inspection

1. Start the engine.

2. Accelerate the engine and verify that the di-

aphragm of the EGR control valve does not move

while the engine is still cold.

3. Warm up the engine to normal operating temper-

ature and run it at idle.

Warning

Be careful when checking the EGR control

valve because the surrounding area is very

hot.

4. Accelerate the engine and check that the di-

aphragm of the EGR control valve moves upward.

Solenoid Valve (EGR)

1. Disconnect the vacuum hose from the solenoid

valve and vacuum pipe.

2. Blow through the solenoid valve from vacuum hose

A.

3. Check that air flows from port B.

86U04A-131

4B-72

Page 535 of 1865

EGR SYSTEM 4B

Apply 12V

Air filter

L

Jt Port

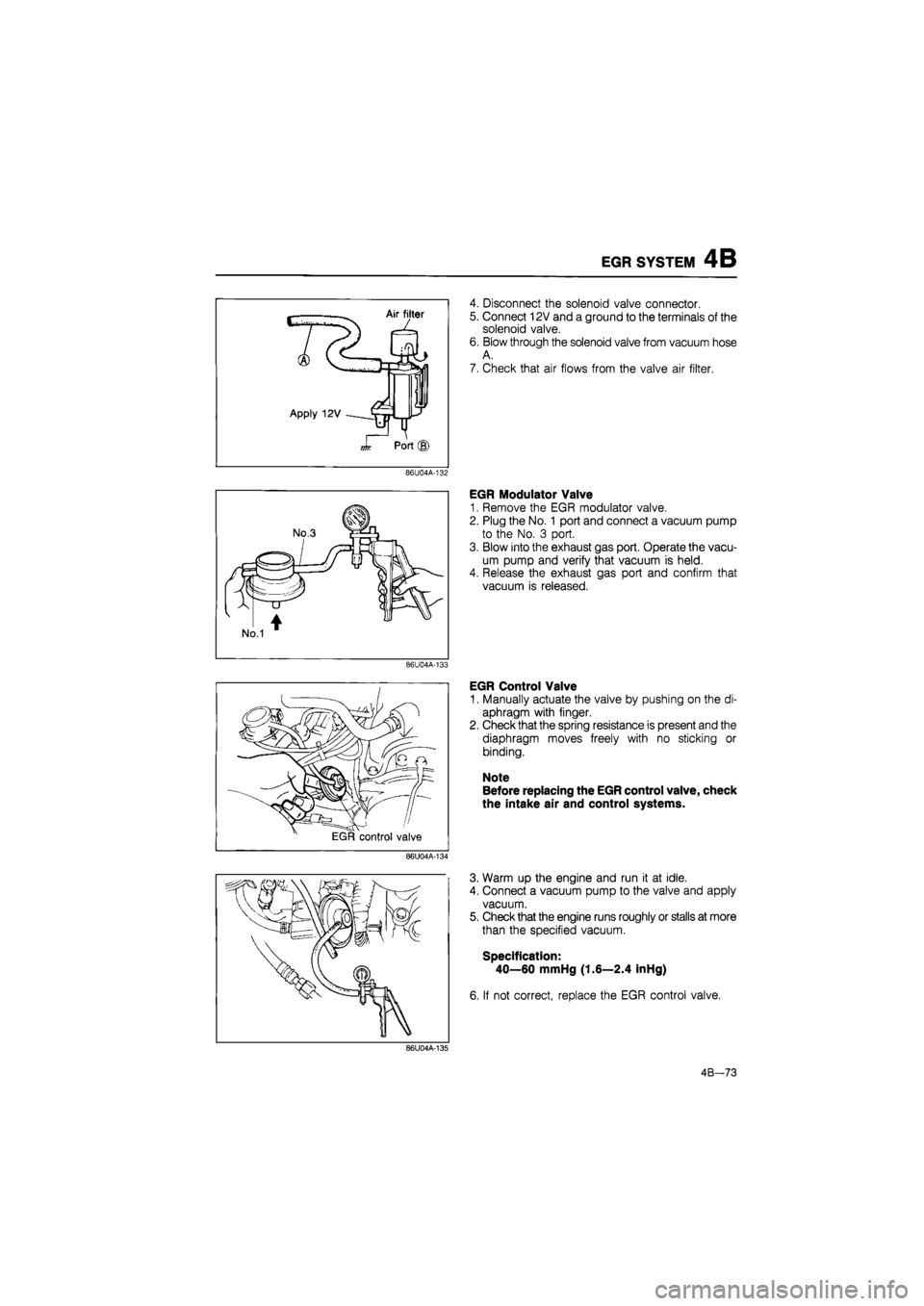

4. Disconnect the solenoid valve connector.

5. Connect 12V and a ground to the terminals of the

solenoid valve.

6. Blow through the solenoid valve from vacuum hose

A.

7. Check that air flows from the valve air filter.

86U04A-132

86U04A-133

86U04A-134

EGR Modulator Valve

1. Remove the EGR modulator valve.

2. Plug the No. 1 port and connect a vacuum pump

to the No. 3 port.

3. Blow into the exhaust gas port. Operate the vacu-

um pump and verify that vacuum is held.

4. Release the exhaust gas port and confirm that

vacuum is released.

EGR Control Valve

1. Manually actuate the valve by pushing on the di-

aphragm with finger.

2. Check that the spring resistance is present and the

diaphragm moves freely with no sticking or

binding.

Note

Before replacing the EGR control valve, check

the intake air and control systems.

3. Warm up the engine and run it at idle.

4. Connect a vacuum pump to the valve and apply

vacuum.

5. Check that the engine runs roughly or stalls at more

than the specified vacuum.

Specification:

40—60 mmHg (1.6—2.4 inHg)

6. If not correct, replace the EGR control valve.

86U04A-135

4B-73

Page 536 of 1865

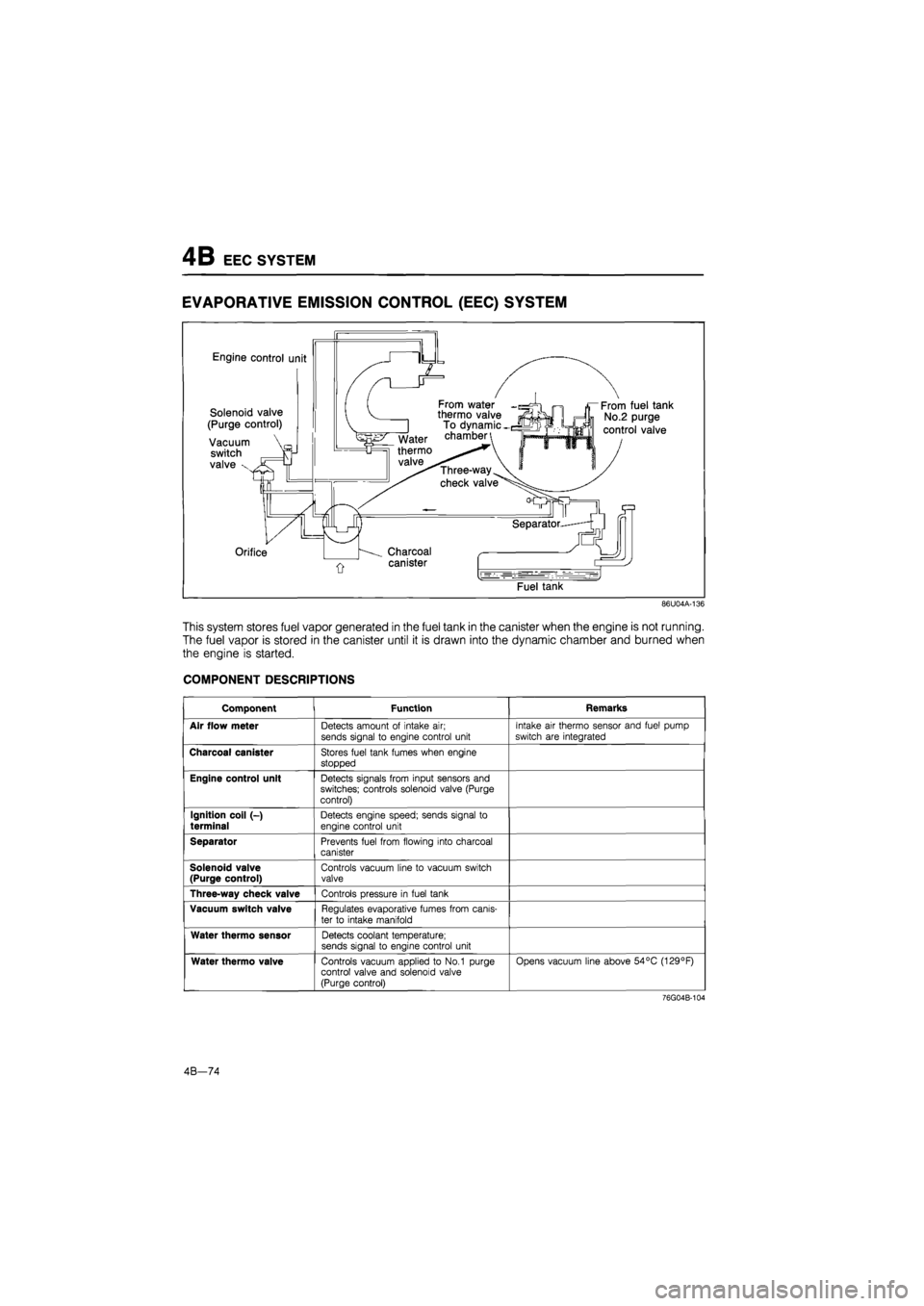

4B EEC SYSTEM

EVAPORATIVE EMISSION CONTROL

(EEC)

SYSTEM

Engine control unit

Solenoid valve

(Purge control)

Vacuum

switch

valve x

From water thermo valve To dynamic -chamber

Three-way

check valve

Orifice Charcoal

canister

From fuel tank

No.2 purge

control valve

Fuel tank

86U04A-136

This system stores fuel vapor generated in the fuel tank in the canister when the engine is not running.

The fuel vapor is stored in the canister until it is drawn into the dynamic chamber and burned when

the engine is started.

COMPONENT DESCRIPTIONS

Component Function Remarks

Air flow meter Detects amount of intake air; sends signal to engine control unit

Intake air thermo sensor and fuel pump

switch are integrated

Charcoal canister Stores fuel tank fumes when engine

stopped

Engine control unit Detects signals from input sensors and switches; controls solenoid valve (Purge control)

Ignition coil (-)

terminal Detects engine speed; sends signal to

engine control unit

Separator Prevents fuel from flowing into charcoal canister

Solenoid valve (Purge control) Controls vacuum line to vacuum switch valve

Three-way check valve Controls pressure in fuel tank

Vacuum switch valve Regulates evaporative fumes from canis-

ter to intake manifold

Water thermo sensor Detects coolant temperature; sends signal to engine control unit

Water thermo valve Controls vacuum applied to No.1 purge control valve and solenoid valve (Purge control)

Opens vacuum line above 54°C (129°F)

76G04B-104

4B—74

Page 537 of 1865

EEC SYSTEM

4B

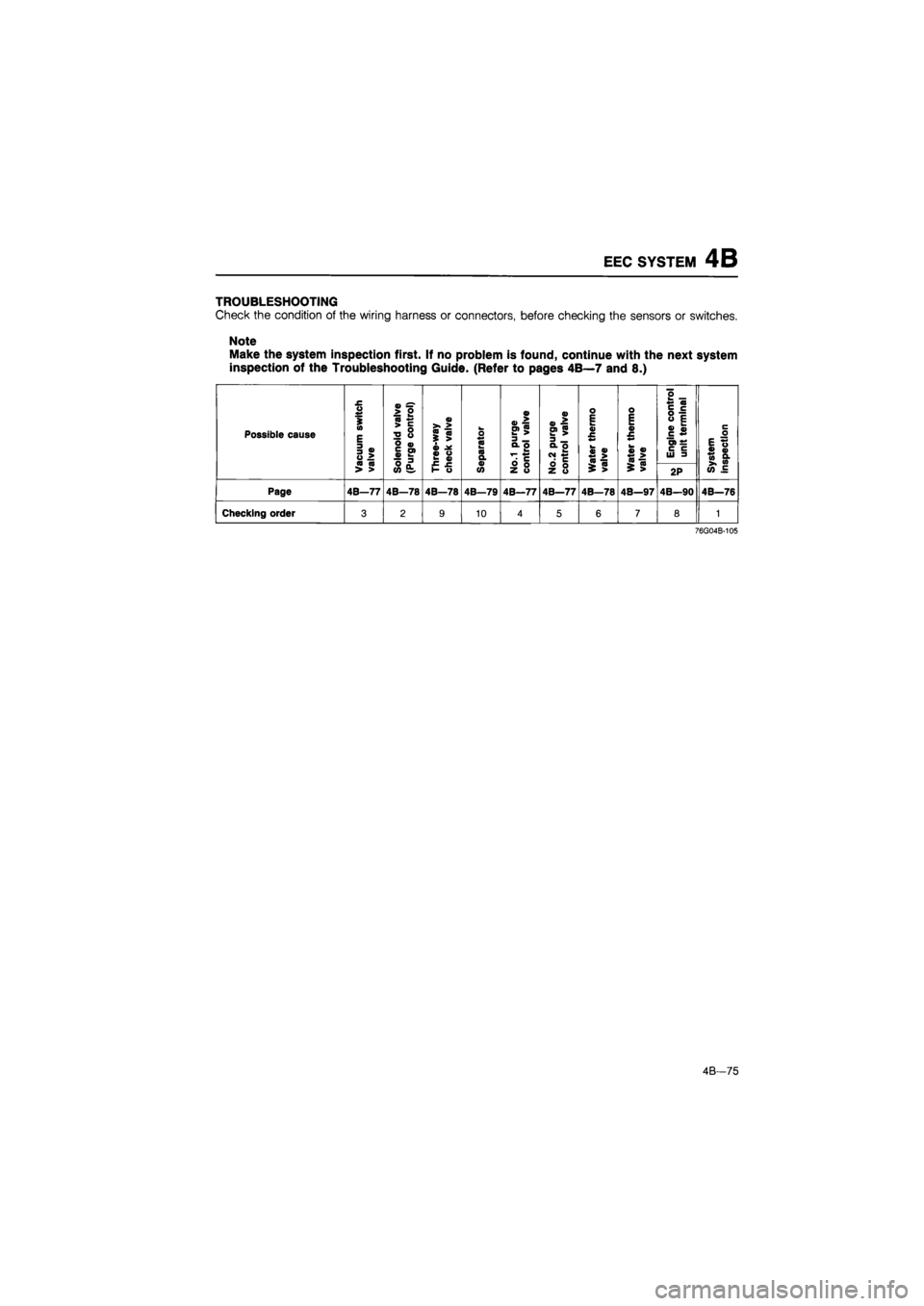

TROUBLESHOOTING

Check

the

condition

of the

wiring harness

or

connectors, before checking

the

sensors

or

switches.

Note

Make the system inspection first.

If no

problem

is

found, continue with

the

next system

inspection

of the

Troubleshooting Guide. (Refer

to

pages 4B—7 and

8.)

Possible cause

Vacuum

switch

valve

Solenoid

valve

(Purge

control)

0)

<0

m

i

>

« «

o

•C

?

o ** «0 a a

No.1

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

o E tm 0) £

«>

0)

^

>

Engine

control

unit

terminal

System inspection Vacuum

switch

valve

Solenoid

valve

(Purge

control)

purge

control

valve

No.2

purge

control

valve

Water

thermo

valve

$

>

2P

System inspection

Page 4B—77 4B—78 4B—78 4B—79 4B—77 4B—77 4B—78 4B—97 4B—90 4B—76

Checking order 3 2 9 10 4 5 6 7 8 1

76G04B-105

4B—75

Page 538 of 1865

4B EEC SYSTEM

86U04A-139

86U04A-141

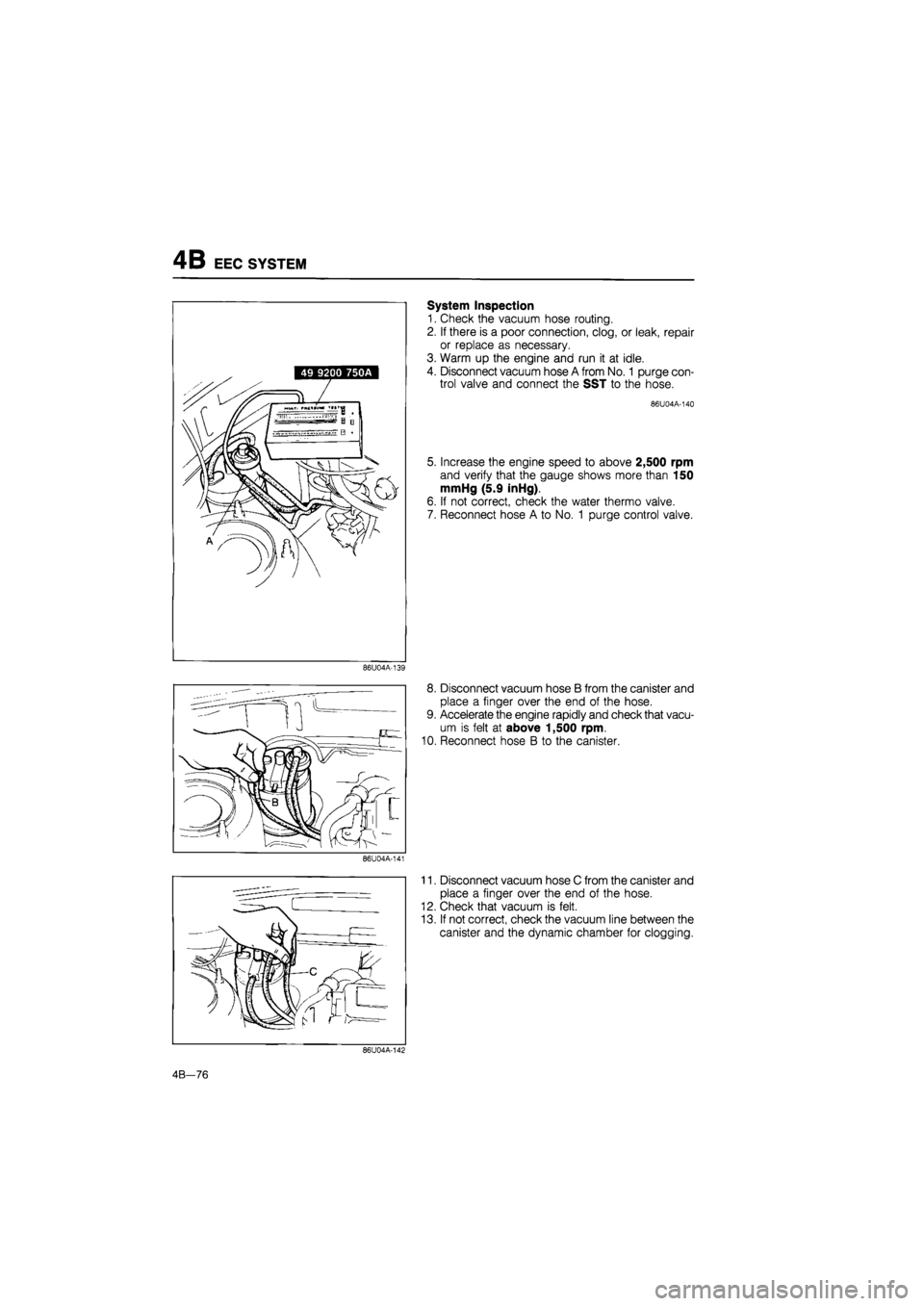

System Inspection

1. Check the vacuum hose routing.

2. If there is a poor connection, clog, or leak, repair

or replace as necessary.

3. Warm up the engine and run it at idle.

4. Disconnect vacuum hose A from No.

1

purge con-

trol valve and connect the SST to the hose.

86 U 04 A-140

5. Increase the engine speed to above 2,500 rpm

and verify that the gauge shows more than 150

mmHg (5.9 inHg).

6. If not correct, check the water thermo valve.

7. Reconnect hose A to No. 1 purge control valve.

8. Disconnect vacuum hose B from the canister and

place a finger over the end of the hose.

9. Accelerate the engine rapidly and check that vacu-

um is felt at above 1,500 rpm.

10. Reconnect hose B to the canister.

11. Disconnect vacuum hose C from the canister and

place a finger over the end of the hose.

12. Check that vacuum is felt.

13. If not correct, check the vacuum line between the

canister and the dynamic chamber for clogging.

86U04A-142

4B—76

Page 539 of 1865

EEC SYSTEM 4B

86U04A-143

86 U 04 A-144

86U04A-145

14. Disconnect the evaporation hose from the evapo-

ration pipe.

15. Connect the vacuum pump to the evaporation

pipe.

16. Operate the vacuum pump and verify that no vacu-

um is held.

17. If vacuum is held, check the evaporation pipe for

clogging.

No. 1 Purge Control Valve

1. Blow through the purge control valve from port A

and check that air does not flow.

2. Connect a vacuum pump to the purge control

valve.

3. Apply 110 mmHg (4.33 inHg) vacuum, and blow

through port A again; air should flow.

No. 2 Purge Control Valve

1. Disconnect vacuum hose B from the evaporation

pipe.

2. Blow through the hose and verify that air flows

freely.

Vacuum Switch Valve

1. Remove vacuum switch valve.

2. Connect a vacuum pump to the valve.

3. Blow through the valve from port A and verify that

air comes out of port B when vacuum is applied.

Specified vacuum:

66—106 mmHg (2.6—4.2 inHg)

86U04A-146

4B-77

Page 540 of 1865

4B EEC SYSTEM

Water Thermo Valve

1. Remove the water thermo valve.

2. Immerse the valve in a water-filled container.

3. Heat the water gradually and observe the tem-

perature.

4. Blow through the valve from one vacuum port and

verify that air comes out of the other port at

46—54°C (115—129°F).

86U04A-147

Three-way

check valve

86U04A-148

To canister

Pressure valve

3<> A To tank

Vacuum valve

Air filter

Three-Way Check Valve

1. Remove the check valve.

2. Blow through the valve from port A, and check that

air comes out of port B.

Next, block port B and check that air comes out

of port C.

3. Block port B.

4. Connect a vacuum pump to port A and verify that

no vacuum is held.

86U04A-149

Solenoid valve (Purge control)

Solenoid Valve (Purge control)

1. Remove the solenoid valve.

76G04B-128

4B-78