MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 541 of 1865

EEC SYSTEM 4B

2. Connect vacuum hoses to the valve as shown in

the figure.

3. Blow air through the valve from hose A and check

that air comes out of the valve air filter.

4. Apply 12V and ground the solenoid valve with jum-

per wires.

5. Blow air through the valve from hose A and check

that the air comes out of port B.

6. Replace, if necessary.

86U04A-151

Separator

1. Remove the separator.

2. Visually check the separator for damage.

3. Replace, if necessary.

86U04A-154

4B-79

Page 542 of 1865

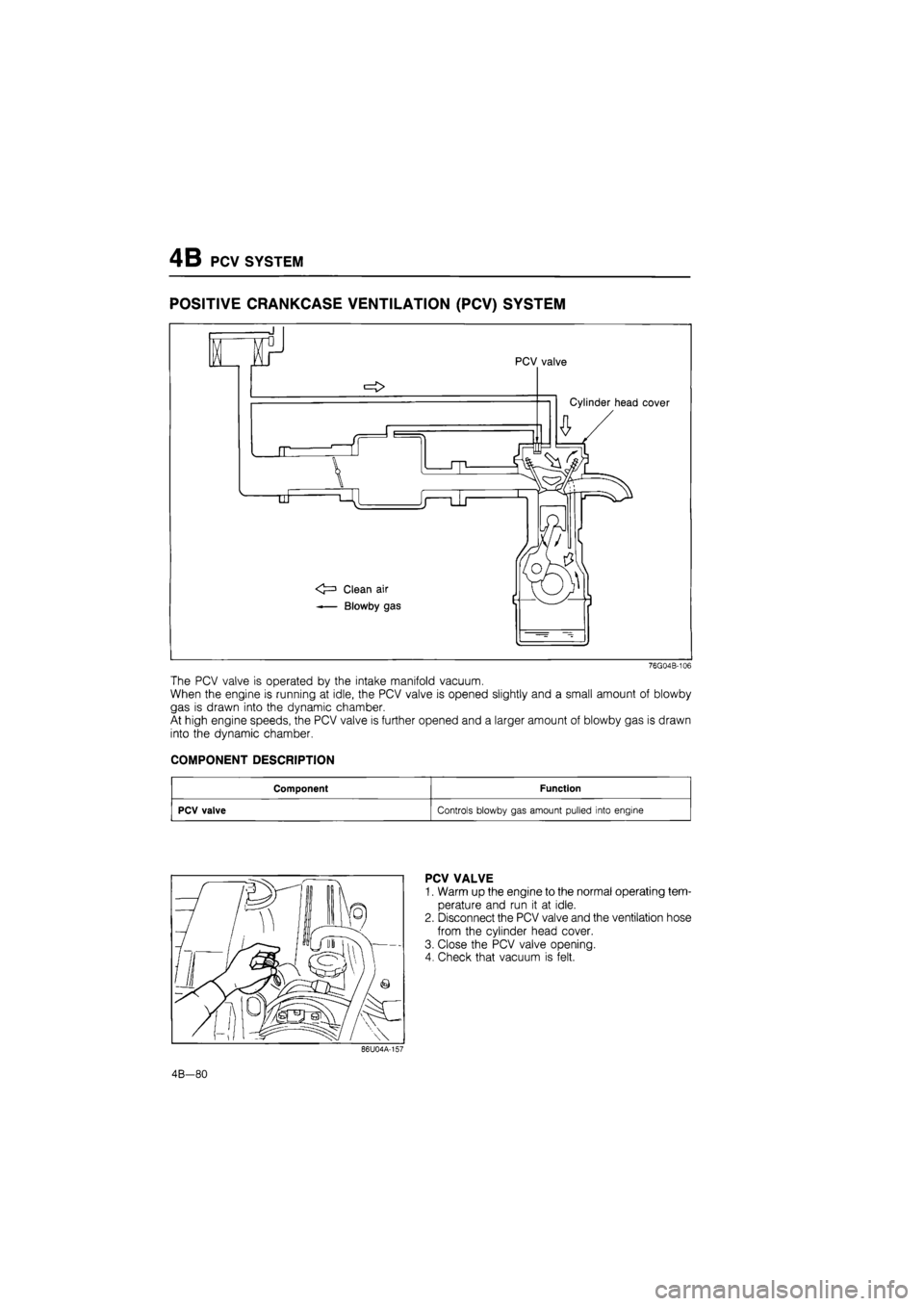

4B PCV SYSTEM

POSITIVE CRANKCASE VENTILATION

(PCV)

SYSTEM

76G04B-106

The PCV valve is operated by the intake manifold vacuum.

When the engine is running at idle, the PCV valve is opened slightly and a small amount of blowby

gas is drawn into the dynamic chamber.

At high engine speeds, the PCV valve is further opened and a larger amount of blowby gas is drawn

into the dynamic chamber.

COMPONENT DESCRIPTION

Component Function

PCV valve Controls blowby gas amount pulled into engine

PCV VALVE

1. Warm up the engine to the normal operating tem-

perature and run it at idle.

2. Disconnect the PCV valve and the ventilation hose

from the cylinder head cover.

3. Close the PCV valve opening.

4. Check that vacuum is felt.

4B—80

Page 543 of 1865

EXHAUST SYSTEM 4B

EXHAUST SYSTEM

f

76G04B-107

The catalytic converter is used to reduce CO, HC and NOx. The converter contains a compound of

platinum and rhodium. It is a three-way catalyst type with a volume of 1,600 cc (98 cu in).

4B—81

Page 544 of 1865

4B EXHAUST SYSTEM

REMOVAL AND INSTALLATION

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

Torque Specifications

1. Main silencer

2. Middle pipe

3. Pre-silencer

86U04A-159

4. Catalytic converter

5. Bracket

6. Front pipe

INSPECTION

1. Check the catalytic converter and exhaust pipe for

deterioration or restriction.

2. Check the insulation covers welded onto the cata-

lytic converter for damage.

Note

If the insulation cover is touching the catalytic

converter housing, excessive heat at the floor

will occur.

86U04A-160

4B—82

Page 545 of 1865

CONTROL SYSTEM 4B

CONTROL SYSTEM

Atmospheric

pressue sensor

Engine control unit

Brake light switch

Clutch switch

Circuti opening

relay

E/L control unit

Air flow meter

Neutral switch

76G04B-129

The control system consists of the input devices and the engine control unit. The engine control unit

controls the fuel injection amount (EGI), fuel injection pressure, bypass air amount, switch monitor func-

tion, and fail-safe function.

4B—83

Page 546 of 1865

4B CONTROL SYSTEM

RELATIONSHIP CHART

Input Devices and Output Devices

BRAKE LIGHT SWITCH O X X X X X X X X X

ELECTRICAL LOAD CONTROL UNIT X X X X X X X X O X

P/S PRESSURE SWITCH* X X X X X X X X O X

A/C SWITCH O X X X X O O X X O

IGNITION SWITCH

(STA

POSITION) O O X O X X X X O O

INHIBITOR SWITCH o X X X O X X X X O

NEUTRAL

AND

CLUTCH SWITCH o X X X X X X X X O

OXYGEN SENSOR o X X X X X X X X X

WATER THERMO SWITCH (RADIATOR) o X X X O X X X X X

ATMOSPHERIC PRESSURE SENSOR o X X X X O X O O X

INTAKE

AIR

THERMO SENSOR o X X O X X X O O X

WATER THERMO SENSOR o X X O O O X X o X

IDLE SWITCH o o X O X X X X o X

THROTTLE SENSOR o O X X O X X X X O

AIR FLOW METER o X X X X O X X X X

IGNITION COIL o O X O O O X X o O

INPUT

DEVICES

OUTPUT

DEVICES

FUEL

INJECTION

AMOUNT FUEL

INJECTION

TIMING

PRESSURE

REGULATOR

EGR

PURGE

IDLE-UP

(A)*

IDLE-UP

(B)

IDLE-UP

(C)

rr

INPUT

DEVICES

OUTPUT

DEVICES

INJECTOR

AIR

VALVE

SOLENOID

VALVE

AIR

BYPASS

SOLENOID

VALVE

AIR

CONDITIONEI

76G04B-108

4B-84

Page 547 of 1865

CONTROL SYSTEM 4B

Output Devices and Engine Conditions

DC <

s UJ OC

Q. 3 O) c

CO

ffl <

> C o t: S CO

o x

03 "D > 16 O > -FC O O I O 0) .. .c CD

SB to ro

_Q

O O <

> c o t CO

o x

UJ O Z z ? ? ?5 n T (9 O oo: z r uj

c o o 31 c O 3 OC

o

I—

LU

> Q W0UJ> JW J

cc -J

-i -i

S5

Sxi-oo t >u-d

-<=

"O c y c « ir

co

aj

a ffl c o a c o o 0) 3 n> o n i_ > o CD

s <0^0

E 13 O tr C3 LU

->

o

111

E

UJ < o c "

UJ

3 o CD 13

o C CD

B ffl <° ro

"H

ui1

o cc _i o UJ C

o < rf OC 111

o <

o

Q UJ

£ OC <

£

o o

o (9 5 N ± UJ

| = 5o

I "O—_ ZqIIJ SjZ Z Oo < O z tt-UJ

r-D c o c ro ir

ro

a?

o be

T3 CD CO O o cc <3 UJ,

LL LL O

C o J5

o >

CD Q. CD O c o,

Q. 13 o O)

o

3 O) 03

03 3 cn cn CD Q. O

E 3 3 O ro

O

3 O

UJ

OC (3 LU

O

cn 0)

J5 CD Q. O 03 O) ro "So "O c CM

O

CO ro a >, _o

c 03 Q. O

3 O cr cd LU

T3 03 ro 03 a o o c CD o> ro tn "O c CM

o

c 03 a O

o CO CM

O o o

CD > o _o ro

fa _ffl O

CD >

O o LO LO 03 > o JD CO

Q. E 03

CD js: CO

c 03

c 03 CL O

| ro S <

CO

a

LL ° CM rri

$2 CM

CD

in

o §

O

s §

a£ E to

03 -S

CO •a 03 w o 03 £ iS >

"O •

03:

o ro

£ °

Q_ CD

"O

CD

J 3

Q_ CO

O

CO

ro 2

UJ 03

C > ffl ffl r ?

o c C

CD CD

5" o O

CO

(/> Z o

o o UJ z o z UJ

Oh

UJUJO

£ii

o

i- a

S5i

o

Ul cc

50

UJ >

< >

OC <

oc UJ O OC I-

in =J

UJ O

oc

UJ

o. oc

OC o UJ

UJ u OC 3 a.

a.

ui

ffl

a 3 I UJ

UJ

oo<

<0

z >

0

Q. 3 1 UJ

o

c/> . to Z HI < UJ > _ Q.

—J

—I

<

m

O O gc <

76G04B-109

4B-85

Page 548 of 1865

4B CONTROL SYSTEM

69G04A-161

86U04A-169

76G04B-130

EGI MAIN FUSE

Inspection

Check the continuity of EGI main fuse.

MAIN RELAY

1. Check that a "clicking" sound is heard at the main

relay when turning the ignition switch ON and OFF.

2. Apply 12V and a ground to (A) and (B) terminals

of the main relay.

3. Check continuity at terminals using an ohmmeter.

-Operation

Terminals 12V Not applied 12V Applied

©- ® No continuity Continuity

CIRCUIT OPENING RELAY

Relay Circuit

1. Remove the circuit opening relay.

2. Check the circuit as described.

Terminal Checkina item Correct result

FD Resistance 0.2-300

Fc Continuity (crankinnl oo

B Voltaae (Ian: ON) Batterv voltaae

STA Voltaae (Crankincri Approx. 9V

Ei Continuity oo

Circuit Opening Relay

Apply 12V and a ground to the terminals below and

check the circuit opening relay as described.

12V Grounded Correct result

STA Ei B FP: Continuity

B Fc Fp: Battery voltage

Resistance

Check the resistance between the terminals using an

ohmmeter.

69G04A-164

Between terminals Resistance (Q)

STA <- E1 15-30

B

<-<•

Fc 80-150

B « Fp 00

4B—86

Page 549 of 1865

CONTROL SYSTEM 4B

ENGINE CONTROL UNIT

Engine Signal Monitor (49 9200 162) and Adapter (49 9200 163).

Adapter harness 49 9200 163

Engine wiring harnessN

Selector switch

Monitor switch

Engine control unit

terminal number

Terminals

(A and 8)

ENGINE SIGNAL MONITOR

86U04A-171

The Engine Signal Monitor (49 9200 162) was developed to check the control unit terminal voltages.

This monitor easily inspects the individual terminal voltages through selection of the monitor switch.

How to Use the Engine Signal Monitor

1. Connect the Engine Signal Monitor (49 9200 162) between the engine control unit and the en-

gine harness using the adapter (49 9200 163).

2. Turn the selector switch and monitor switch to select the terminal number.

3. Check the terminal voltage.

Caution

Never apply voltage to terminals A and B.

4B-87

Page 550 of 1865

4B CONTROL SYSTEM

Terminal Voltage

If the input and output devices and related wiring are normal, but the engine control unit terminal volt-

age is incorrect, replace the engine control unit.

Terminal Input Output Connection to Voltage (After warming-up) Remarks Terminal Input Output Connection to IGN: ON Idle Remarks

1A — — — — —

1B o Self-Diagnosis Checker (Code number)

For 3sec. after ignition switch OFF ->• ON: below 6.2V (Buzzer sounds) After 3sec.: Battery voltage (Buzzer does not sound)

• Using Self-Diagnosis Check-er and test con-nector grounded • Buzzer sounds: below 6.2V • Buzzer does not sound: Battery voltage

1C — — — — —

1D o Self-Diagnosis Checker (Monitor lamp)

Test connector grounded

For 3sec. after igni-tion switch OFF ON:

below 6.2V (light il-luminates) After 3sec.: Battery voltage (light does not illuminate)

(Test connector grounded) approx. 10V (Test connector not grounded) Monitor lamp ON: below 6.2V Monitor lamp OFF: Battery voltage

With Self-Diagnosis

Checker

1E O Idle switch Accelerator pedal released: below 1.5V

Accelerator pedal depressed: Battery voltage

1F o A/C relay A/C switch ON: below 2.5V A/C switch OFF: Battery voltage

Blower motor ON

1G — — — — —

1H o Water thermo switch Below 1,5V Radiator temp.:

above 17°C (63°F)

11 o Electrical load con-trol unit Electrical load ON: below 1.5V Electrical load OFF: Battery voltage Electrical load: Rear defroster Headlight Blower motor (3rd & 4th position) Electrical fan

1J o Brake light switch Brake pedal released: below 1.5V

Brake pedal depressed: battery voltage

1K — — — — — —

1L o A/C switch A/C switch ON: below 1.5V

A/C switch OFF: battery voltage

Blower motor: ON

1M o Ignition coil © terminal Battery voltage *1 Battery voltage *1 Engine Signal Monitor: green and red lights flash

1N — — — — —

10 — — — —

4B-88