MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987,

Model line: 626,

Model: MAZDA 626 1987

Pages: 1865, PDF Size: 94.35 MB

MAZDA 626 1987 Workshop Manual

626 1987

MAZDA

MAZDA

https://www.carmanualsonline.info/img/28/57059/w960_57059-0.png

MAZDA 626 1987 Workshop Manual

Trending: jacking, tire pressure reset, fog light, load capacity, bulb, ECO mode, open gas tank

Page 581 of 1865

4C TROUBLESHOOTING WITH SST

76G04C-025

Code No. 15 (Oxygen sensor) PC: Possible Cause

76G04C-026

4C—20

Page 582 of 1865

TROUBLESHOOTING WITH SST 4C

Code No. 17 (Feedback system) PC: Possible Cause

Feedback system OK

76G04C-027

Code No. 25 (Solenoid valve-Pressure regulator control (PRC)) PC: Possible Cause

Repair or replace connector

Replace solenoid valve

76G04C-028

Warm up engine and run at 2,500—3,000 rpm for

three minutes Is Code No. still present?

Yes

Are there poor connections in solenoid valve circuit?

NO

Is there continuity of solenc )id valve?

YES

4C—21

Page 583 of 1865

4C TROUBLESHOOTING WITH SST

Code No. 26 (Solenoid valve—No. 1 purge control) PC: Possible Cause

YES

YES

Is there continuity between solenoid valve and engine control unit?

Solenoid valve Engine control unit

WG wire 2P

NO PC: Open circuit in wiring harness from solenoid valve to engine control unit

YES PC: • Engine control unit malfunction • Short circuit in wiring harness

76G04C-029

Code No. 27 (Solenoid valve—No. 2 purge control) PC: Possible Cause

Are there poor connections in solenoid valve circuit? YES Repair or replace connector

NO

NO Is there continuity of solenoid valve? NO Replace solenoid valve

YES

Is there battery voltage at RB wire of solenoid valve connector?

NO PC: Open circuit in wiring harness from RB wire to

control relay (for engine control unit)

YES

Is there continuity between solenoid valve and en-

gine control unit?

Solenoid valve Enaine control unit

WB wire 20

NO PC: Open circuit in wiring harness from solenoid valve to engine control unit

YES PC: • Engine control unit malfunction • Short circuit in wiring harness

76G04C-030

4C—22

Page 584 of 1865

TROUBLESHOOTING WITH SST 4C

Code No. 28 (Solenoid valve—EGR) PC: Possible Cause

Are there poor connections in solenoid valve circuit? YbS Repair or replace connector

NO

NO Is there continuity of solenoid valve? NO Replace solenoid valve

YES

Is there battery voltage of RB wire of solenoid valve connector?

NO PC: Open circuit in wiring harness from RB wire to control relay (for engine control unit)

YES

Is there continuity between solenoid valve and en-gine control unit?

Solenoid valve Engine control unit

WL wire 2N

NO^ PC: Open circuit in wiring harness from solenoid valve to engine control unit

YES PC: • Engine control unit malfunction • Short circuit in wiring harness

76G04C-031

Code No. 34 (Solenoid valve—Idle speed control (ISC)) PC: Possible Cause

YES PC: • Engine control unit malfunction • Short circuit in wiring harness

76G04C-032

4C-23

Page 585 of 1865

4C TROUBLESHOOTING WITH SST

No.36 Code (Oxygen sensor relay) PC: Possible Cause

YES

Is there continuity between Oxygen sensor relay engine control unit?

Oxygen sensor relay Engine control unit

RY 2M

NO^ PC: Open circuit in wiring harness from oxygen sensor relay to engine control unit

YES PC: • Engine control unit malfunction • Short circuit in wiring harness

76G04C-033

No.41 Code (Solenoid valve—Variable inertia control (VIC)) PC: Possible Cause

Are there poor connections in solenoid valve circuit? YES Repair or replace connector

NO

NO Is there continuity of VIC solenoid valve? NO Replace solenoid valve

YES

Is there battery voltage at RB wire of VIC solenoid valve connector?

NO PC: Open or short circuit in wiring harness from RG wire to control relay (for engine control unit)

YES

Is there continuity between VIC solenoid valve and engine control unit?

VIC solenoid valve Enaine control unit

L 1C

NO PC: Open circuit in wiring harness from VIC solenoid valve to engine control unit

YES PC: • Engine control unit malfunction • Short circuit in wiring harness

76G04C-034

4C—24

Page 586 of 1865

SWITCH MONITOR FUNCTION 4C

SWITCH MONITOR FUNCTION

Individual switches can be monitored by the SST (Self-Diagnosis checker 49 G018 9A0 or Digital

code checker 49 9200 180).

Note

The test connector must be grounded and the ignition switch ON (engine stopped).

Engine control unit

76G04C-035

Switch Self-Diagnosis Checker (Monitor lamp) Remark Switch Light ON Light OFF Remark

Clutch switch Pedal released Pedal depressed In gear

Neutral switch In gear Neutral Clutch pedal released

Idle switch Pedal depressed Pedal released —

Headlight switch ON OFF —

Rear defroster switch ON OFF —

Blower switch ON OFF Blower motor position: "3" or "4"

Water thermo switch (Elec-trical fan) Terminal disconnected Terminal connected While fan not operating

4C—25

Page 587 of 1865

4C SWITCH MONITOR FUNCTION

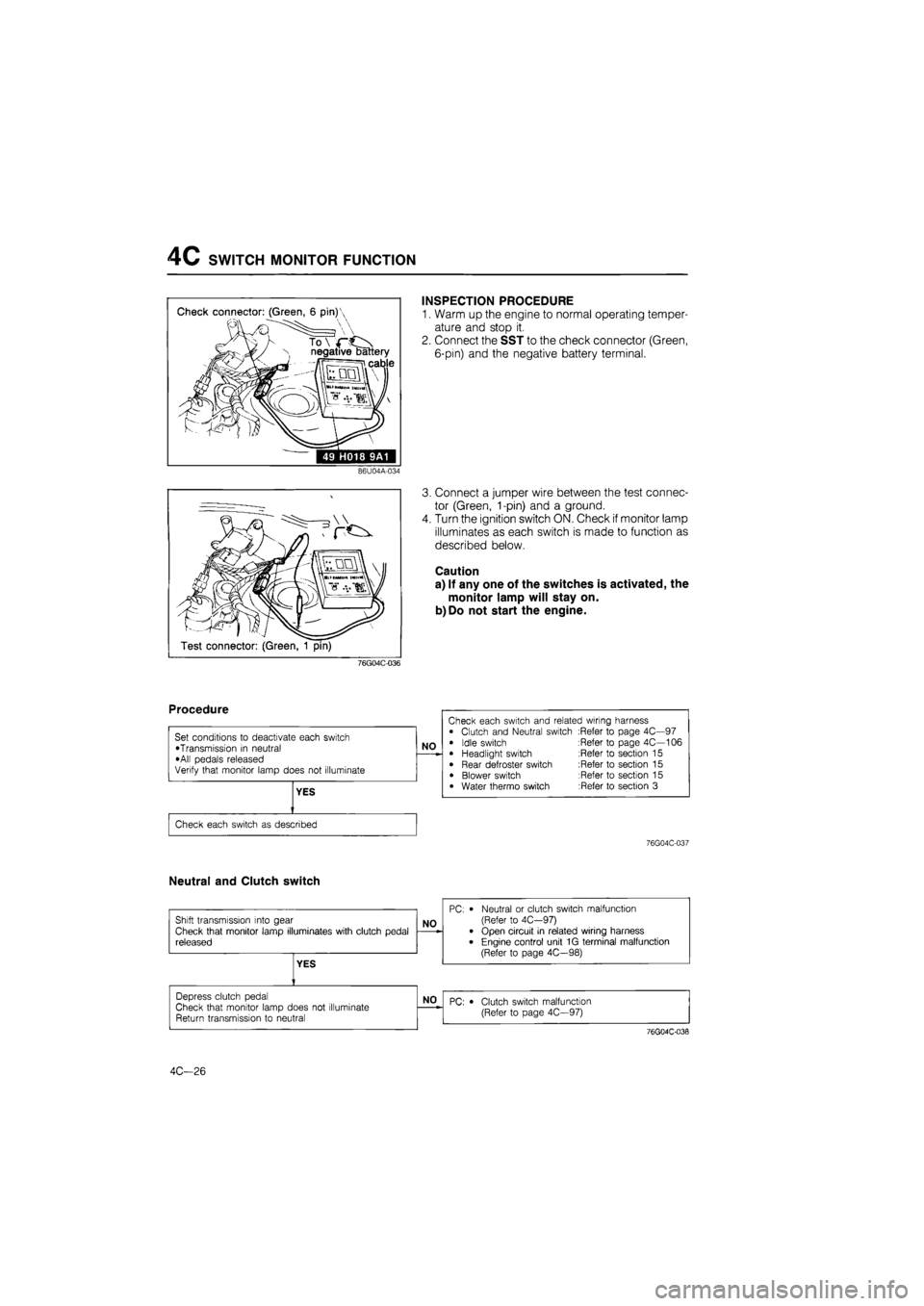

Check connector: (Green, 6 pin)'

N negative battery

ii cable

49 H018 9A1

INSPECTION PROCEDURE

1. Warm up the engine to normal operating temper-

ature and stop it.

2. Connect the SST to the check connector (Green,

6-pin) and the negative battery terminal.

86U04A-034

Test connector: (Green, 1 pin)

3. Connect a jumper wire between the test connec-

tor (Green, 1-pin) and a ground.

4. Turn the ignition switch ON. Check if monitor lamp

illuminates as each switch is made to function as

described below.

Caution

a) If any one of the switches is activated, the

monitor lamp will stay on.

b)Do not start the engine.

76G04C-036

76G04C-037

Neutral and Clutch switch

4C—26

Page 588 of 1865

SWITCH MONITOR FUNCTION 4C

Idle switch

76G04C-039

Blower switch

76G04C-040

Headlight switch

76G04C-041

Rear defroster switch

76G04C-042

4C—27

Page 589 of 1865

4C SWITCH MONITOR FUNCTION

Water thermo switch circuit

76G04C-043

4C-28

Page 590 of 1865

IDLE ADJUSTMENT 4C

Idle speed

Automatic

Control

Function

Engine Control Unit

IDLE

ADJUSTMENT

IDLE SPEED

The idle speed is controlled automatically by the

engine control unit through the idle speed con-

trol (ISC) solenoid valve, it is not necessary to

adjust the idle speed.

However, if the idle speed is not within specifi-

cation, the idle speed must be adjusted.

76G04C-044

Preparation

1) Check the condition of the engine (plugs, leaks in

hoses, etc.).

2) Make sure all accessories are OFF.

3) Warm up the engine and run it for three minutes

at 2,500—3,000 rpm in neutral.

4) Check the initial ignition timing and adjust it if

necessary.

76G04C-045

Inspection

1. Check that the idle speed is within specification

without grounding the test connector (Green,

1-pin).

Specification:

Applied load Idle speed

No load 750 ± 50 rpm

P/S load 750 ± 50 rpm

A/C and/or E/L load 800 ± 50 rpm

76G04C-046 2. If not correct, adjust the initial idle speed.

Adjustment

1. Ground the test connector (Green, 1-pin) with a

jumper wire.

2. Turn all accessories and loads OFF.

76G04C-047

4C—29

Trending: hood release, remote control, ad blue, horn, radio, ABS, fuel tank capacity