torque MAZDA 626 1987 Repair Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 144 of 1865

1 B ON-VEHICLE MAINTENANCE (TIMING BELT)

Installation

Install in the reverse order of removal referring to the installation note.

Torque Specifications 76G01A-109

8â12 N m (80â120 cm-kg, 69â104 In-lb)

Installation note

Timing belt

1. Check that the mark on the timing belt pulley is

aligned with the mating mark.

2. Check that the mating mark of the camshaft pul-

leys are aligned with the seal plate mating marks.

Note

For intake side camshaft pulley, align "I"

mark.

For exhaust side camshaft pulley, align "E"

mark.

76G01B-026

1Bâ13

Page 145 of 1865

1 B ON-VEHICLE MAINTENANCE (TIMING BELT)

3. Install the timing belt tensioner and spring. Tem-

porarily secure it with the spring fully extended.

Caution

Do not damage the pulleys when securing the

tensioner pulley.

76G01B-024

4. Install the timing belt so that there is no looseness

at the tension side, and at the two camshaft pulleys.

Caution

a) If the timing belt is being reused, it must be

reinstalled to rotate in the original direction.

b) Check that there is no oil, grease, or dirt on

the timing belt.

76G01B-025

5. Loosen the tensioner lock bolt.

6. Turn the crankshaft twice in the direction of rota-

tion, and align the mating marks.

7. Check that the timing marks are correctly aligned.

If not aligned, remove the timing belt tensioner and

timing belt, and repeat steps 1â6.

69G01B-027

8. Turn the crankshaft to align the "S" mark of the

right side camshaft pulley with seal plate mating

mark.

Tighten the timing belt tensioner lock bolt.

Tightening torque:

37â52 Nm (3.8â5.3 m-kg, 27â38 ft-lb)

76G01B-026

1Bâ14

Page 146 of 1865

ON-VEHICLE MAINTENANCE (TIMING BELT) 1 B

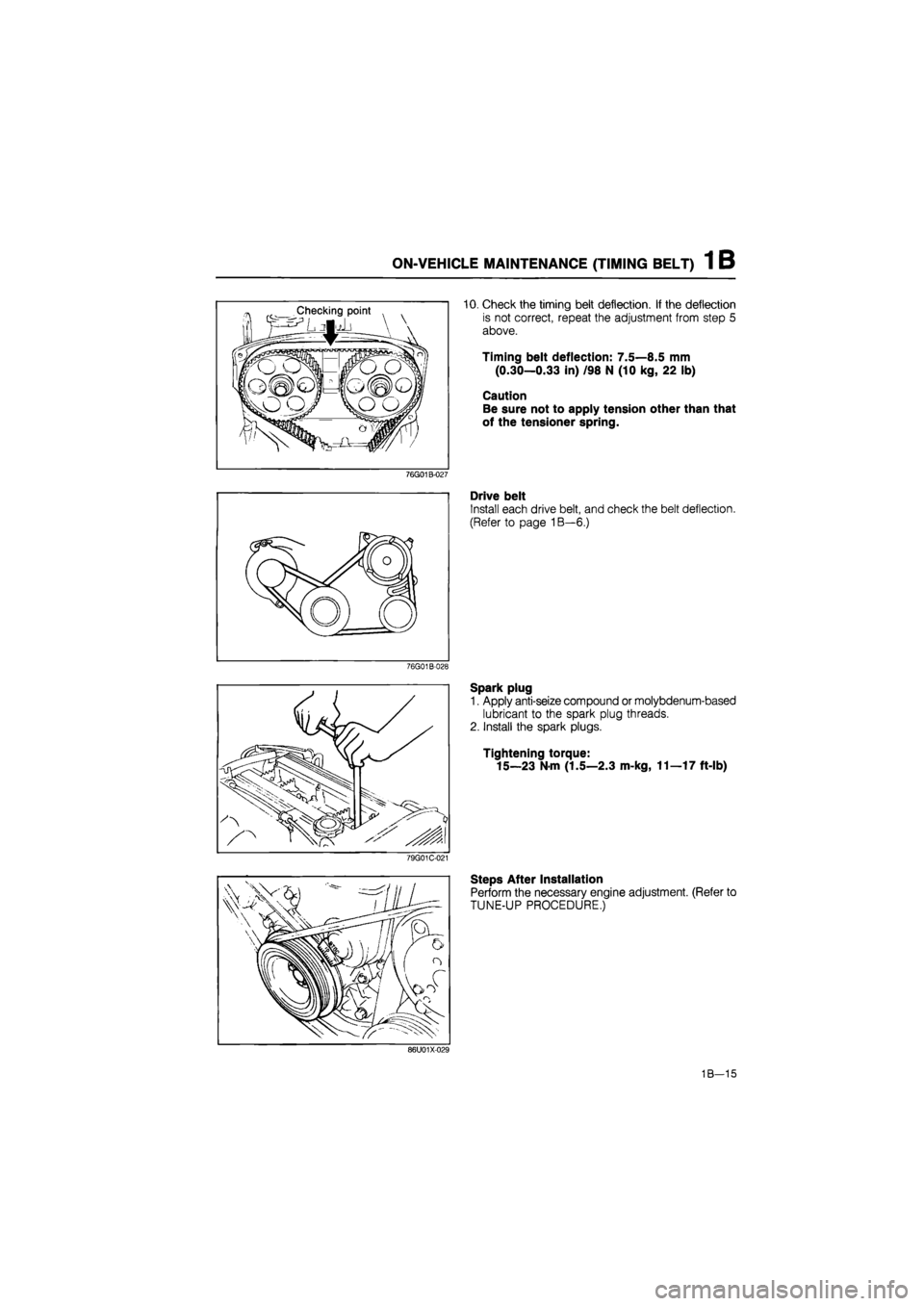

10. Check the timing belt deflection. If the deflection

is not correct, repeat the adjustment from step 5

above.

Timing belt deflection: 7.5â8.5 mm

(0.30â0.33 in) /98 N (10 kg, 22 lb)

Caution

Be sure not to apply tension other than that

of the tensioner spring.

76G01B-027

Drive belt

Install each drive belt, and check the belt deflection.

(Refer to page 1Bâ6.)

76G01B-028

Spark plug

1. Apply anti-seize compound or molybdenum-based

lubricant to the spark plug threads.

2. Install the spark plugs.

Tightening torque:

15â23

N

m (1.5â2.3 m-kg, 11â17 ft-lb)

79G01C-021

Steps After Installation

Perform the necessary engine adjustment. (Refer to

TUNE-UP PROCEDURE.)

86U01X-029

1Bâ15

Page 150 of 1865

1 B ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

Installation

Install in the reverse order of removal referring to the installation note.

Note a) Position the hose clamp in the original location on the hose.

b) Squeeze the clamp lightly with large pliers to ensure a good fit.

Torque Specifications

8â12 N-m (80â120 cm-kg, 69â104

4â6 N-m (40â60 cm-kg, 35â52 in

15â23 N-m (1.5â2.3 m-kg, 11â17 ft-lb)

7â10 N-m (70â100 cm-kg, 61â87 In-lb)

â11 N-m (80â110 cm-kg, 69â95 In-lb)

37â52 N-m (3.8â5.3 m-kg. 27â38 ft-lb)

80â86 N-m (8.2â8.8 m-kj, 59â64 ft-lb)

~t/â- -19â30 N-m (1.9â3.1 m-kg, g^ 14-22 ft-lb)

\34â44

N-m (3.5â4.5 m-kg, ' 25â33 ft-lb)

19-30 N-m (1.9â3.1 m-kg, 14â22 ft-lb)

19â30 N-m (1.9â3.1 m-kg, 14â22 ft-lb)

37â52 N-m (3.8â5.3 m-kg, 27â38 ft-lb)

76G01A-112

1Bâ19

Page 151 of 1865

1 B ON-VEHICLE MAINTENANCE (CYLINDER HEAD)

Installation note

Cylinder head

1. Thoroughly remove all dirt and oil from the top of

the cylinder block with a rag.

2. Place a new cylinder head gasket in position.

86U01X-035

® © © (D ® 3. Set the cylinder head in place.

4. Apply engine oil to the bolt threads and seat faces.

5. Tighten the cylinder head bolts in two or three steps

in the order shown in the figure.

Tightening torque:

80â86

N

m (8.2â8.8 m-kg, 59â64 ft-lb)

86U01X-036

Cylinder head cover

1. Apply silicon sealant to the shaded area as shown

in the figure.

2. Install the cylinder head cover and gasket.

Tightening torque:

4â6 N-m (40â60 cm-kg, 35â52 in-lb)

76G01B-033

Timing belt

1. Align the mating marks of the camshaft pulleys with

the seal plate timing mark.

Note

For intake side camshaft pulley, align "I"

mark.

For exhaust side camshaft pulley, align "E"

mark.

2. Install the timing belt. (Refer to TIMING BELT of

ON-VEHICLE MAINTENANCE.)

76G01B-034

1Bâ20

Page 164 of 1865

DISASSEMBLY (CYLINDER BLOCK) 1 B

76G01B-048

76G01B-049

79G01C-050

Main bearing cap

Before removing the main bearing caps, clean the

bearings, main journals, and caps, and measure the

following points.

1. Crankshaft end play. (Refer to page 1Bâ52.)

2. Main journal oil clearance. (Refer to page 1Bâ51.)

Pilot bearing

Remove the pilot bearing from the crankshaft with the

SST

Piston and connecting rod

1. Before disassembling the piston and connecting

rod, check the oscillation torque as shown in the

figure.

If the large end does not drop by its own weight,

replace the piston or the piston pin.

2. Remove the piston pin with the SST.

76G01B-050

1 Bâ33

Page 171 of 1865

1 B INSPECTION AND REPAIR

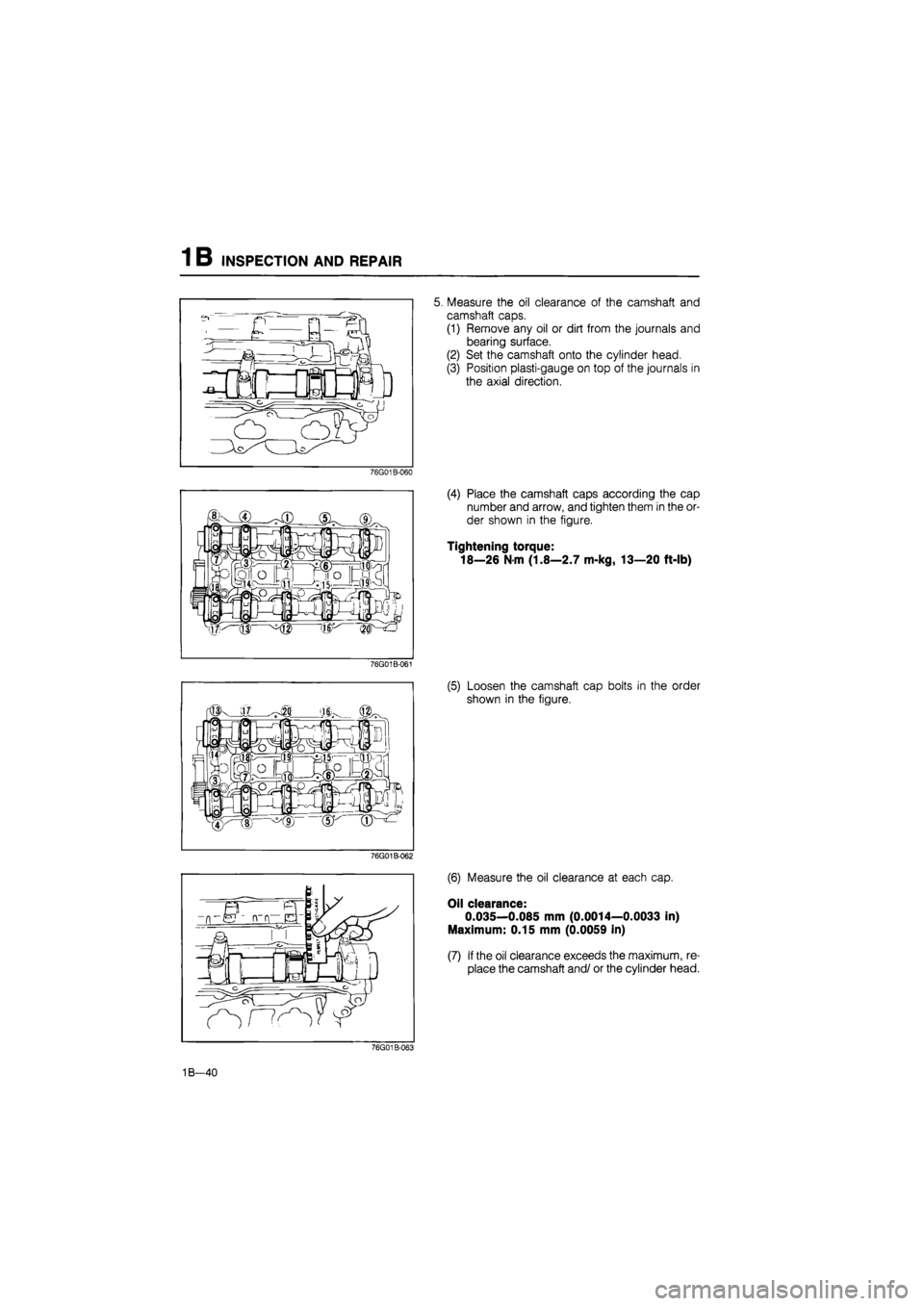

5. Measure the oil clearance of the camshaft and

camshaft caps.

(1) Remove any oil or dirt from the journals and

bearing surface.

(2) Set the camshaft onto the cylinder head.

(3) Position plasti-gauge on top of the journals in

the axial direction.

76G01B-060

(4) Place the camshaft caps according the cap

number and arrow, and tighten them in the or-

der shown in the figure.

Tightening torque:

18â26 N-m (1.8â2.7 m-kg, 13â20 ft-lb)

76G01B-061

(5) Loosen the camshaft cap bolts in the order

shown in the figure.

76G01B-062

(6) Measure the oil clearance at each cap.

Oil clearance:

0.035â0.085 mm (0.0014â0.0033 in)

Maximum: 0.15 mm (0.0059 in)

(7) If the oil clearance exceeds the maximum, re-

place the camshaft and/ or the cylinder head.

76G01B-063

1Bâ40

Page 179 of 1865

1 B ASSEMBLY (CYLINDER BLOCK)

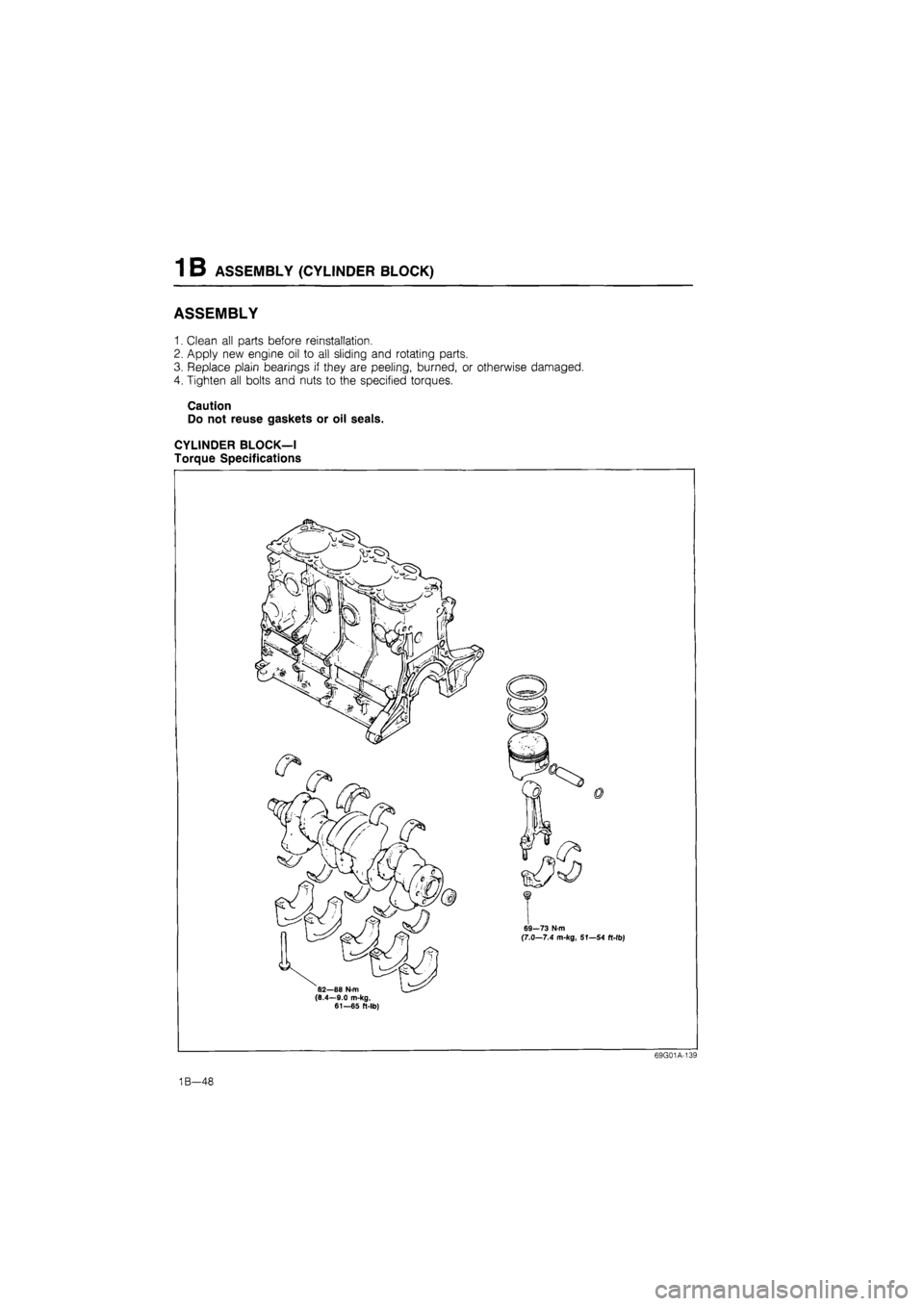

ASSEMBLY

1. Clean all parts before reinstallation.

2. Apply new engine oil to all sliding and rotating parts.

3. Replace plain bearings if they are peeling, burned, or otherwise damaged.

4. Tighten all bolts and nuts to the specified torques.

Caution

Do not reuse gaskets or oil seals.

CYLINDER BLOCKâI

Torque Specifications

69G01A-139

1Bâ48

Page 180 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 B

76G01B-070

76G01B-071

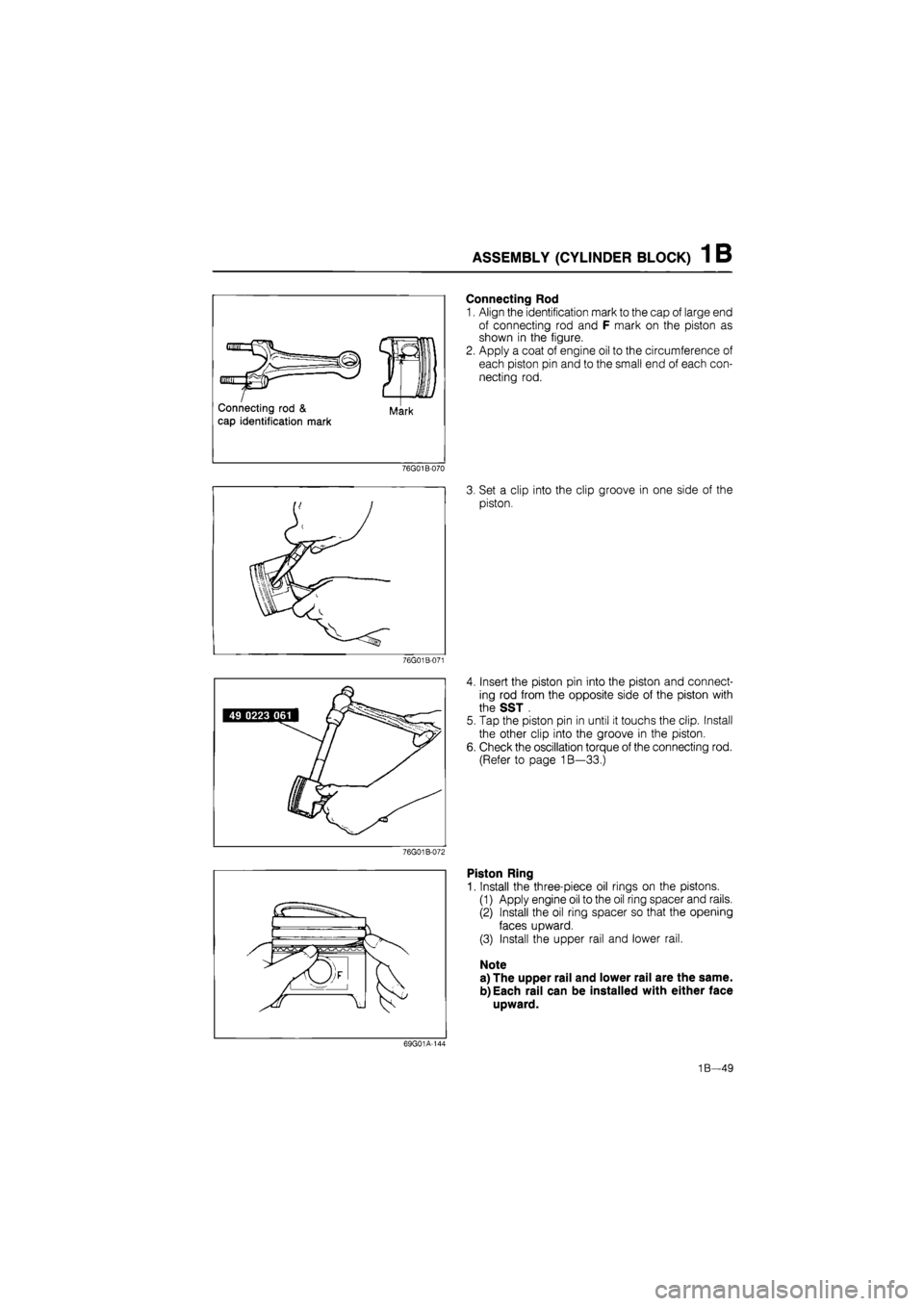

Connecting Rod

1. Align the identification mark to the cap of large end

of connecting rod and F mark on the piston as

shown in the figure.

2. Apply a coat of engine oil to the circumference of

each piston pin and to the small end of each con-

necting rod.

3. Set a clip into the clip groove in one side of the

piston.

4. Insert the piston pin into the piston and connect-

ing rod from the opposite side of the piston with

the SST .

5. Tap the piston pin in until it touchs the clip. Install

the other clip into the groove in the piston.

6. Check the oscillation torque of the connecting rod.

(Refer to page 1Bâ33.)

Piston Ring

1. Install the three-piece oil rings on the pistons.

(1) Apply engine oil to the oil ring spacer and rails.

(2) Install the oil ring spacer so that the opening

faces upward.

(3) Install the upper rail and lower rail.

Note

a) The upper rail and lower rail are the same.

b)Each rail can be installed with either face

upward.

69G01A-144

1Bâ49

Page 182 of 1865

ASSEMBLY (CYLINDER BLOCK) 1 B

Oil clearance inspection

(1) Remove any foreign material and oil from the

journals and bearings.

(2) Install the upper main bearings in the cylinder

block.

(3) Set the crankshaft into the cylinder block.

(4) Position the plasti-gauge on top of the journals

in the axial direction.

86U01X-122

(5) Install the main bearing caps along with the

lower main bearings according to the cap num-

ber and mark.

(6) Tighten the caps in two or three steps in the

order in the figure.

Tightening torque:

82â88 Nm (8.4â9.0 m-kg, 61â65 ft-lb)

Caution

Do not rotate the crankshaft when measuring

the oil clearances.

86U01X-123

(7) Remove the main bearing caps, and measure

the plasti-gauge at each journal at the widest

point for the smallest clearance, and at the nar-

rowest point for the largest clearance.

If the oil clearance exceeds specification, grind

the crankshaft and use undersize main bear-

ings. (Refer to page 1Bâ45.)

Oil clearance

No. 1, 2, 4, 5:

0.025â0.043 mm (0.0010â0.0017 in)

No. 3:

0.031â0.049 mm (0.0012â0.0019 in)

Maximum: 0.08 mm (0.0031 in)

Apply a liberal amount of engine oil to the main

bearings and main journals.

Install the crankshaft and the main bearing caps

according to the cap number and ^ mark.

86U01X-125

1Bâ51