light MAZDA 626 1987 Manual Online

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 932 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

76G07B-073

7B-66

3. Remove the screw and move the inhibitor switch

so that the small hole is aligned with the screw hole.

4. Set the alignment by inserting a 2.0 mm (0.079

in) diameter pin through the holes.

5. Loosely tighten the switch mounting bolts, remove

the pin, and reinstall the screw.

6. Tighten the switch mounting bolts to specification.

Tightening torque:

8—11 N-m (80—110 cm-kg, 69—95 in-lb)

7. Recheck the continuity of the individual terminals.

WATER TEMPERATURE SWITCH

Inspection

1. Remove the water temperature switch.

2. Place the switch in water with a thermometer and

heat up the water gradually.

3. Check the continuity of the terminals. If necessary

replace the switch.

Connection guide

Water temperature Continuity

Below 65°C (149°F) Yes

Above 72°C (162°F) \ No

FLUID TEMPERATURE SWITCH (G4A-EL)

Inspection

1. Remove the fluid temperature switch.

2. Place the switch in oil with a thermometer as shown

and heat it up gradually.

3. Check the continuity of the terminals. If necessary

replace the switch.

Connection guide

Fluid temperature Continuity

Above 150°C (302°F) Yes

Below 143°C (289°F) No

BRAKE LIGHT SWITCH (G4A-EL)

Inspection of Terminal Voltage

1. Turn the ignition switch ON.

2. Check the voltage between terminal (WG) and

ground while depressing the brake pedal.

Terminal voltage I Brake pedal

Approx. 12V Depressed

Below 1,5V Released

3. If not correct, check continuity of the switch.

Page 933 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

Inspection of Continuity

1. Disconnect the brake light switch connector.

2. Check for continuity between the terminals while

depressing the brake pedal.

79G07C-114

76G07B-076

KICK-DOWN SWITCH (G4A-HL)

Inspection of Terminal Voltage

1. Turn the ignition switch ON.

2. Check the voltage at terminal (V) with a voltmeter.

Depressing stroke Terminal voltage

7/8-8/8 (Full) Approx. 12V

0-7/8 Below 1,5V

3. If not correct, check the wiring harness, switch, or

adjust the switch position.

Inspection of Continuty

1. Disconnect the kick-down switch connector.

2. Check for continuity of the switch with an

ohmmeter.

Switch Continuity

Pushed Yes

Released No

3. If not correct, replace the kick-down switch.

76G07B-077

Adjustment

1. Loosen the kick-down switch locknuts.

2. Depress the accelerator pedal fully.

3. Turn the switch until the threaded case touches the

stopper.

4. Turn the switch counterclockwise by one half revo-

lution.

5. Secure the switch with the locknut.

76G07B-078

7B—67

Page 935 of 1865

ELECTRICAL SYSTEM COMPONENTS 7B

76G07B-083

EC-AT CONTROL UNIT (G4A-EL)

SOLENOID VALVES (G4A-EL)

Inspection of Resistance

1. Disconnect the negative battery cable.

2. Disconnect the solenoid valve connector.

3. Measure the resistance of the terminals except (A)

terminal, if necessary replace the solenoid valve.

Resistance: 13—271]

Note

1-2 solenoid valve : F

2-3 solenoid valve : C,E

3-4 solenoid valve : B

Lock-up solenoid valve : D

NO LOAD SIGNAL (G4A-EL)

Refer to STEP 3 in Troubleshooting.

MODE, AND HOLD INDICATOR LIGHT (G4A-EL)

Refer to Section 15.

OD OFF INDICATOR LIGHT (G4A-HL)

Refer to Section 15.

/ 1S 10 10 1M X 1G 1E 1C

1A

1T 1R 1P 1N 1L 1J 1H 1F 1D 1B

/—

20 2M 2K X 2E 2C 2A

2P 2N 2L 2J 2H 2F 2D 2B

Terminal Voltage Chart

Terminal Connected to Voltage Condition

1A (Input) Hold switch Approx. 12V Switch depressed 1A (Input) Hold switch Below 1.5 V Switch released

1B (Input) Mode switch (Power side) Below 1.5V POWER mode 1B (Input) Mode switch (Power side) Approx. 12V ECONOMY mode

1C (Input)

Inhibitor

switch

L range Approx. 12V L range 1C (Input)

Inhibitor

switch

L range Below 1.5V Other ranges

1D (Input) Inhibitor

switch

S range Approx. 12 V S range 1D (Input) Inhibitor

switch

S range Below 1,5V Other ranges

1E (Input)

Inhibitor

switch D range Approx. 12V D range 1E (Input)

Inhibitor

switch D range Below 1.5 V Other ranges

1F (Input)

Inhibitor

switch

N and P range

Below 1,5V N or P range 1F (Input)

Inhibitor

switch

N and P range Approx. 12V Other ranges

1G (Input) Water temperature switch Approx. 12V Above 72°C (162°F) 1G (Input) Water temperature switch Below 1,5V Below 65°C (149°F)

1H — —

11 — —

7B-69

Page 936 of 1865

7B ELECTRICAL SYSTEM COMPONENTS

Terminal Connected to Voltage Condition

1J — — —

1K — — —

1L (Input) Idle switch Below 1.5V At idle 1L (Input) Idle switch Approx. 12V Other speeds

1M — — —

1N (Input) Brake light switch Approx. 12V Brake pedal depressed 1N (Input) Brake light switch Below 1.5V Brake pedal released

10 (Input) Throttle sensor

Approx. 5V Ignition switch ON 10 (Input) Throttle sensor Below 1,5V Ignition switch OFF

1P (Input)

Throttle sensor

Approx. 0.5—4.3V Throttle valve fully closed to fully open

1Q (Input) Vehicle speed sensor

Approx. 4.5V During driving

1Q (Input) Vehicle speed sensor Approx. 4.5V or below 1.5V Vehicle stopped

1R (Ground) Throttle sensor Below 1,5V —

1S (Input) Pulse generator Approx. 12V Engine running 1S (Input) Pulse generator Below 1,5V Engine stopped

1S (Ground) Pluse generator Below 1.5V —

2A (Battery power) Battery Approx. 12V Ignition switch ON 2A (Battery power) Battery Below 1,5V Ignition switch OFF

2B (Ground) Body ground Below 1,5V —

2C (Memory power) Battery Approx. 12V —

2D (Ground) Body ground Below 1,5V —

2E (Output) 1-2 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2E (Output) 1-2 shift solenoid valve Below 1.5V Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Approx. 12V

Refer to page 7B—26 of solenoid valve

operation table

2F (Output) 2-3 shift solenoid valve Below 1,5V

Refer to page 7B—26 of solenoid valve

operation table

2G — — —

2H (Output) 3-4 shift solenoid valve Approx. 12V Refer to page 7B—26 of solenoid valve operation table 2H (Output) 3-4 shift solenoid valve Below 1.5V

Refer to page 7B—26 of solenoid valve operation table

21 — — —

2J (Output) Lock-up solenoid valve Approx. 12V Lock-up 2J (Output) Lock-up solenoid valve Below 1,5V Other

2K (Output) Hold indicator Below 1,5V Hold mode 2K (Output) Hold indicator Approx. 12V Other modes

2L (Output) Mode indicator Approx. 12V Hold mode 2L (Output) Mode indicator Below 1,5V Power or economy mode

2M (Output) EC-AT Tester

(malfunction code)

Approx. 12V Normal

2M (Output) EC-AT Tester

(malfunction code) Below 1,5V If malfunction present 2M (Output) EC-AT Tester

(malfunction code) Code signal Self-diagnosis check connector grounded

2N — — —

20 (Input) Fluid temperature switch Below 1,5V Above 150°C (302°F) 20 (Input) Fluid temperature switch Approx. 10—12V Below 143°C (289°F)

2P (Input) EC-AT check connect Approx. 12V —

76G07B-084

7B-70

Page 955 of 1865

DISASSEMBLY 7B

Procedure

Precaution

(1) Drain the ATF before removing the transaxle from the vehicle.

(2) Disassemble the transaxle in a clean area (dustproof workspace) to prevent dust entry into the

mechanisms.

(3) Clean the transaxle exterior thoroughly with steam and/or cleaning solvents prior to disassembly.

(4) Inspect the individual transaxle components in accordance with the Troubleshooting during disas-

sembly.

(5) Use plastic hammers when applying force to separate the light alloy case joints.

(6) Do not use rags during disassembly.

(7) Neatly arrange the removed parts in order during disassembly.

86U07B-117

7B—89

Page 966 of 1865

7B DISASSEMBLY

1. Remove the bolts; then remove the transaxle case

by tapping lightly with a plastic hammer.

86U07B-153

3. Remove the low and reverse brake piston

(1) Install the SST.

(2) Compress the spring and retainer assembly.

86U07B-154

(3) Remove the snap ring with snap ring pliers;

then remove the spring and retainer assembly.

86U07B-155

7B—100

Page 971 of 1865

DISASSEMBLY 7B

Outlet pipe

83U07B-168

83U07B-169

83U07B-170

3. Remove the governor outlet pipe, governor inlet

pipe, and O-rings.

4. Remove the 2-3 accumulator piston assembly and

O-rings.

5. Remove the bearing housing.

(1) Remove the bolt indicated in the figure.

(2) Remove the roll pin with a pin punch.

(3) Remove the bearing housing by tapping light-

ly with a plastic hammer.

6. Remove the idle gear assembly and output gear

assembly by tapping out from the torque convert-

er side.

83U07B-171

7B-105

Page 1008 of 1865

7B INSPECTION AND REPAIR

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm

(in) Wire dia.

mm (in)

Spring color

1-2 accumulator small spring 11.0 (0.433) 88.1 (3.348) 1.4 (0.055) Gray

1-2 accumulator large spring 16.0 (0.630) 78.0 (3.071) 2.0 (0.079) Blue

Bypass, Servo control spring 5.0 (0.197) 33.4 (1.315) 0.55 (0.022) Maroon

2-3 timing spring 8.3 (0.327) 26.5 (1.043) 0.8 (0.031)

—

N-R accumulator rear spring 11.1 (0.437) 62.0 (2.441) 1.2 (0.047) Light green

N-D accumulator front spring 9.8 (0.386) 52.9 (2.083) 1.0 (0.039) Brown

Coasting bypass spring 5.8 (0.228) 37.7 (1.484) 0.6 (0.024) Dark blue

3-2 timing spring 8.2 (0.323) 28.6 (1.126) 0.8 (0.031) Red

3-2 capacity spring 5.4 (0.213) 30.6 (1.205) 0.5 (0.020) White

Throttle relief ball spring 6.6 (0.260) 21.6 (0.850) 0.8 (0.031)

—

76G07B-151

Assembly

1. Install the 3-2 capacity valve, 3-2 capacity spring,

and stopper plug; then install the stopper pin.

2. Install the 3-2 timing valve, the 3-2 timing spring,

and retainer.

86U07B-280

3. Install the coasting bypass plug, coasting bypass

valve and coasting bypass spring.

4. Apply ATF to the O-rings, and install them to the

piston; then insert the N-R accumulator rear spring

and N-R accumulator piston.

5. Apply ATF to the O-rings, and install them to the

piston; then insert the N-D accumulator piston and

N-D accumulator front spring.

76G07B-152

7B—142

Page 1027 of 1865

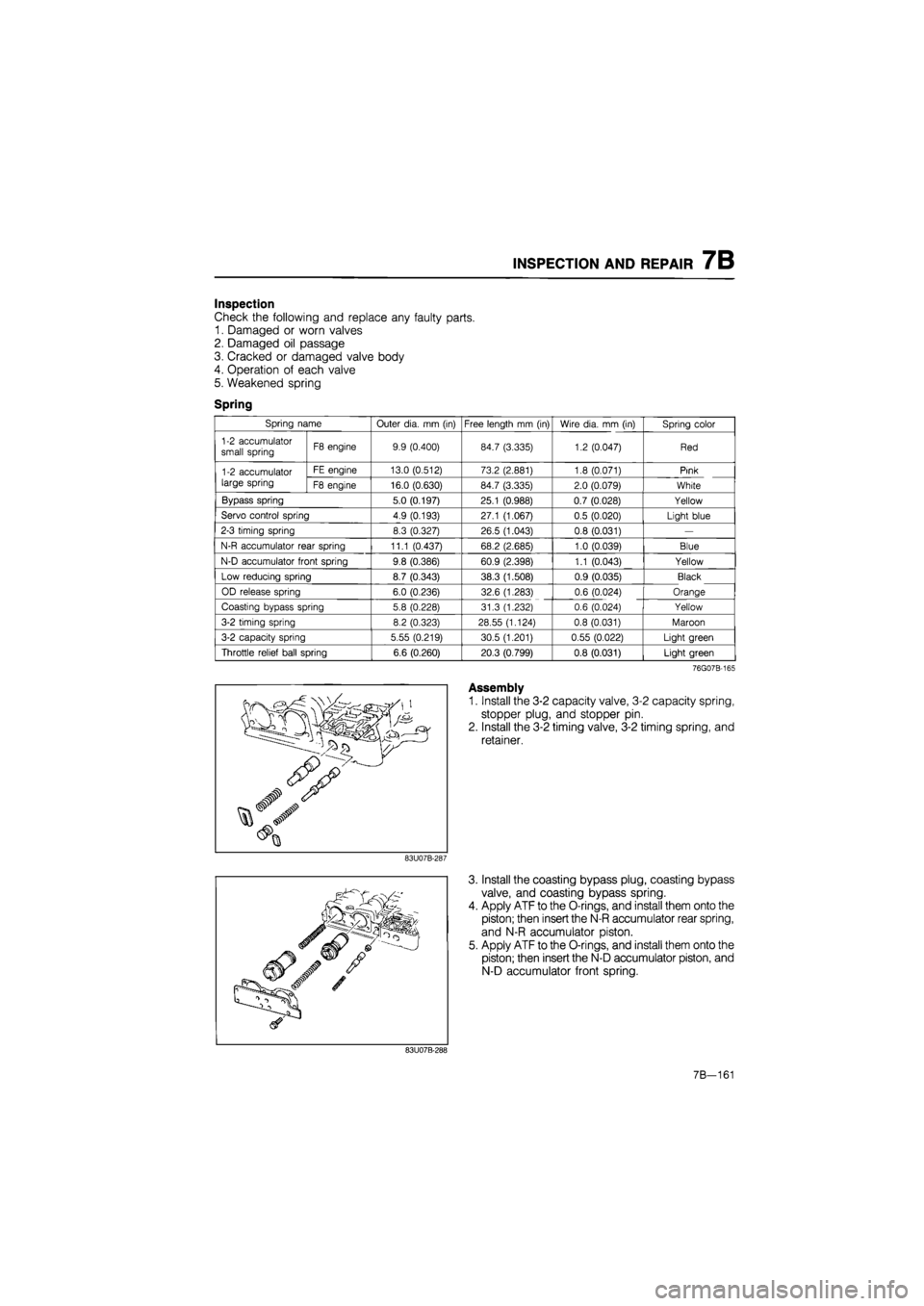

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm (in)

Wire dia.

mm

(in) Spring color

1-2 accumulator small spring F8 engine 9.9 (0.400) 84.7 (3.335) 1.2 (0.047) Red

1-2 accumulator large spring

FE engine 13.0 (0.512) 73.2 (2.881) 1.8 (0.071) Pink 1-2 accumulator large spring F8 engine 16.0 (0.630) 84.7 (3.335) 2.0 (0.079) White

Bypass spring 5.0 (0.197) 25.1 (0.988) 0.7 (0.028) Yellow

Servo control spring 4.9 (0.193) 27.1 (1.067) 0.5 (0.020) Light blue

2-3 timing spring 8.3 (0.327) 26.5 (1.043) 0.8 (0.031)

—

N-R accumulator rear spring 11.1 (0.437) 68.2 (2.685) 1.0 (0.039) Blue

N-D accumulator front spring 9.8 (0.386) 60.9 (2.398) 1.1 (0.043) Yellow

Low reducing spring 8.7 (0.343) 38.3 (1.508) 0.9 (0.035) Black

OD release spring 6.0 (0.236) 32.6 (1.283) 0.6 (0.024) Orange

Coasting bypass spring 5.8 (0.228) 31.3 (1.232) 0.6 (0.024) Yellow

3-2 timing spring 8.2 (0.323) 28.55 (1.124) 0.8 (0.031) Maroon

3-2 capacity spring 5.55 (0.219) 30.5 (1.201) 0.55 (0.022) Light green

Throttle relief ball spring 6.6 (0.260) 20.3 (0.799) 0.8 (0.031) Light green

76G07B-165

Assembly

1. Install the 3-2 capacity valve, 3-2 capacity spring,

stopper plug, and stopper pin.

2. Install the 3-2 timing valve, 3-2 timing spring, and

retainer.

83U07B-287

3. Install the coasting bypass plug, coasting bypass

valve, and coasting bypass spring.

4. Apply ATF to the O-rings, and install them onto the

piston; then insert the N-R accumulator rear spring,

and N-R accumulator piston.

5. Apply ATF to the O-rings, and install them onto the

piston; then insert the N-D accumulator piston, and

N-D accumulator front spring.

83U07B-288

7B—161

Page 1031 of 1865

INSPECTION AND REPAIR 7B

Inspection

Check the following and replace any faulty parts.

1. Damaged or worn valves

2. Damaged oil passage

3. Cracked or damaged valve body

4. Operation of each valve

5. Weakened spring

Spring

Spring name Outer dia.

mm

(in) Free length

mm

(in) Wire dia.

mm (in)

Spring color

1-2 shift control spring 5.5 (0.217) 46.0 (1.811) 0.5 (0.020) Light green

1-2 shift spring 5.0 (0.197) 24.9 (0.980) 0.5 (0.020) Gray

2-3 shift spring 6.1 (0.240) 39.7 (1.563) 0.65 (0.026) Pink

3-4 shift spring 6.4 (0.252) 37.0 (1.457) 0.6 (0.024)

—

Throttle backup spring 6.4 (0.252) 33.5 (1.319) 0.6 (0.024) Pink

Throttle modulator front spring 5.0 (0.197) 27.8 (1.094) 0.6 (0.024) Red

Throttle modulator rear spring 7.15 (0.281) 30.8 (1.213) 0.85 (0.033) Red

1 rang control spring 6.15 (0.242) 39.2 (1.543) 0.65 (0.026) White

2 rang control spring 3.95 (0.156) 32.1 (1.264) 0.45 (0.018)

—

Kick-down spring 5.4 (0.213) 38.1 (1.500) 0.8 (0.031)

—

Throttle assist spring 5.15 (0.203) 32.3 (1.272) 0,55 (0.022) Dark green

Throttle spring 5.4 (0.213) 48.3 (1.902) 0.8 (0.031)

—

Converter relief ball spring 6.9 (0.272) 24.1 (0.949) 0.9 (0.035) Maroon

Orifice check valve spring 5.0 (0.197) 12.5 (0.492) 0.23 (0.009)

-

76G07B-220

Assembly

1. Install the throttle adjust plug, throttle assist spring,

throttle valve, throttle spring, and throttle plug as-

sembly.

83U07B-296

Caution

Install the throttle plug assembly with the

groove aligned with the bolt hole.

83U07B-297

7B—165