ESP MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 9 of 1708

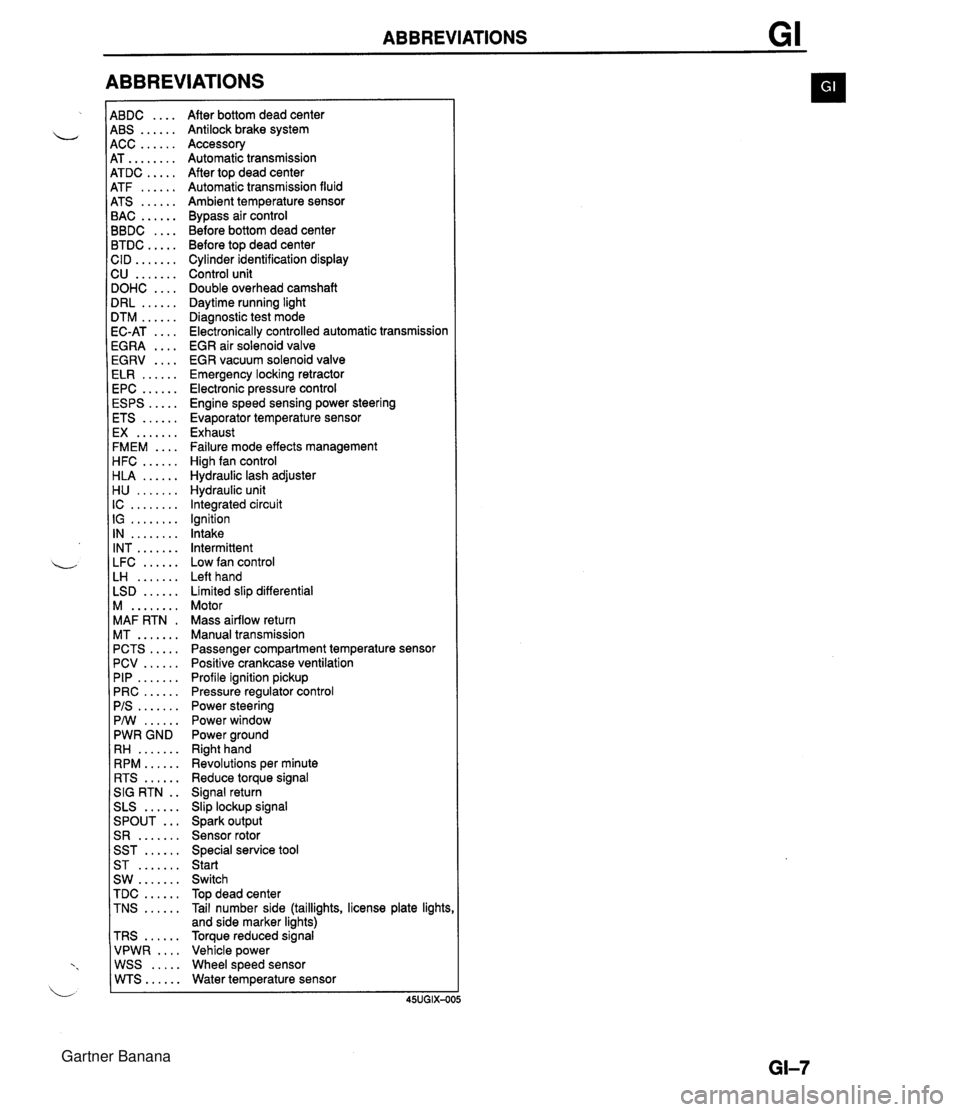

ABBREVIATIONS 4BDC .... 4BS ...... 4CC ...... 4T ........ 4TDC ..... 4TF ...... 4TS ...... 3AC ...... 3BDC .... 3TDC ..... :ID ....... 2U ....... IOHC .... IRL ...... ITM ...... IC-AT .... iGRA .... EGRV .... ELR ...... EPC ...... ESPS ..... ETS ...... EX ....... FMEM .... HFC ...... HLA ...... H U ....... IC ........ IG ........ IN ........ INT ....... LFC ...... LH ....... LSD ...... M ........ MAF RTN . MT ....... PCTS ..... PCV ...... PIP ....... PRC ...... PIS ....... PMI ...... PWR GND RH ....... RPM ...... RTS ...... SIG RTN . . SLS ...... ... SPOUT S R ....... SST ...... ST ....... SW ....... TDC ...... TNS ...... TRS ...... VPWR .... WSS ..... WTS...... After bottom dead center Antilock brake system Accessory Automatic transmission After top dead center Automatic transmission fluid Ambient temperature sensor Bypass air control Before bottom dead center Before top dead center Cylinder identification display Control unit Double overhead camshaft Daytime running light Diagnostic test mode Electronically controlled automatic transmission EGR air solenoid valve EGR vacuum solenoid valve Emergency locking retractor Electronic pressure control Engine speed sensing power steering Evaporator temperature sensor Exhaust Failure mode effects management High fan control Hydraulic lash adjuster Hydraulic unit Integrated circuit Ignition Intake Intermittent Low fan control Left hand Limited slip differential Motor Mass airflow return Manual transmission Passenger compartment temperature sensor Positive crankcase ventilation Profile ignition pickup Pressure regulator control Power steering Power window Power ground Right hand Revolutions per minute Reduce torque signal Signal return Slip lockup signal Spark output Sensor rotor Special service tool Start Switch Top dead center Tail number side (taillights, license plate lights and side marker lights) Torque reduced signal Vehicle power Wheel speed sensor Water temperature sensor Gartner Banana

Page 71 of 1708

ENGINE STAND MOUNTING 2. Install the SST (arms) to the holes as shown in the fig- ure, and hand tighten the SST (bolts). 3. Assemble the SST (bolts and plate) in the specified position. 4. Assemble the SST (nuts, hooks, and bolts). 5. Install the SST to the respective arms. 6. Adjust the SST (bolts) so that less than 20mm (0.79 in) of thread is exposed. 7. Make the SST (plate and arms) parallel by adjusting the SST (bolts and nuts). 8. Tighten the SST (bolts and nuts) to affix the SST firmly. 9. Mount the engine on the SST (engine stand). Gartner Banana

Page 85 of 1708

B INSPECTION / REPAIR 8' STEM TIP VALVE FACE MARGIN 1 ANGLE THICKNESST 450 6. Measure the manifold contact surface distortion in the four directions shown in the figure. Distortion: 0.15mm (0,006 in) max. u 7. If distortion exceeds specification, grind the surface or replace the cylinder head. Grinding: 0.20mm (0.008 in) max. VALVE MECHANISM Valve and Valve Guide 1. Inspect each valve for the following. Replace or resur- face the valve if necessary. (1) Damaged or bent stem (2) Rough or damaged face (3) Damaged or unevenly worn stem tip 2. Measure the valve head margin thickness of each valve. Replace the valve if necessary. Margin thickness IN: 0.9mm (0.035 in) EX: 1 .Omm (0.039 in) 3. Measure the length of each valve. Length Standard IN: lOl.89mm (4.0114 in) EX: 101.99mm (4.01 53 in) Minimum IN: 100.39mm (3.9524 in) EX: 100.49mm (3.9563 in) 4. Measure the stem diameter of each valve at the points shown. Diameter IN: 5.970-5.985mm (0.23514.2356 in) EX: 5.965-5.980mm (0,23494.2354 in) Minimum IN: 5.920mm (0.2331 in) EX: 5.9515mm (0.2329 in) 5. Measure the inner diameter of each valve guide at the points shown. Inner diameter IN: 5.99-6.03mm (0.2359-0.2374 in) EX: 5.99--6.03mm (0.23594.2374 in} 6. Calculate the valve stem-to-guide clearance. Subtract the outer diameter of the valve stem from the inner diameter of the corresponding valve guide. Clearance IN: 0.005-0.060mm (0.00024.0023 in) EX: 0.01 O-O.065mm (0.0004--0.0025 in) Maximum: 0.20mm (0.008 in) Gartner Banana

Page 162 of 1708

TROUBLESHOOTING GUIDE USING THIS SECTION Introduction Most of the fuel and emission control system is electrically controlled, often making it difficult to diagnose '.-/ problems in the system, especially intermittent problems. Before undertaking actual checks, take a few minutes to talk with a customer who approaches with a driveability complaint. The customer is often a good source of information on such problems, especially intermittent ones. Through talks with the cus- tomer, one can find out what the symptoms are and under what conditions they occur. Work flow CHECK IN LISTEN TO CUSTOMER COMPLAINTS REFER TO TROUBLESHOOTING PAGE THAT - - - - - - - - - - - - - - - - - - Diagnostic index CORRESPONDS TO ACTUAL SYMPTOM (Refer to page F-18) 1-CHECKFORWHATISBADINSYSTEM--------------------- Inspection CHECKFORWHATPARTISBAD----------------------- Action Diagnostic index No.: / Each troubleshooting item is as- signed a number. TROUBLESHOOTING ITEM: There are 34 troubleshooting items. Choose the item that most closely corresponds to the actual symp- ,, tom. yes 1 CHECK OUT ---- -- TROUBLESHOOTING GUIDE F DESCRIPTION: Describes each troubleshooting item. ' PAGE: Shows the reference page. Gartner Banana

Page 398 of 1708

J TRANSMISSION TRANSMISSION CASE SNAP RING Countershaft front bearing Install the countershaft front bearing by using the SST, and secure it with a new snap ring. d Adjustment shim After measuring dimensions (A) and (B) shown in the fig- ure, use an adjustment shim(s), as specified below, of the thickness corresponding to the value of (A) minus (B), so that bearing end play will be within specification. Bearing end play: 04.lmm (0-0.004 in) Adjustment shim thickness: 0.lOmm (0.004 in), 0.15mm (0.006 in), 0.30mm (0.012 in) Clutch release fork 1. Apply Mori White TA No.2 or equivalent organic rnolyb- denum grease to the shaded areas of the clutch release collar and release fork. 2. Install the clutch release collar and clutch release fork. Gartner Banana

Page 625 of 1708

M DIFFERENTIAL Thrust washers (Standard) 1. Adjust the backlash of the side gears and pinion gear as follows. (Standard) (1) Set a dial gauge against the pinion gear as shown. ,+, (2) Secure one of the side gears. (3) Move the pinion gear, and measure the backlash at the end of it. If not within specification, replace the dif- ferential gear as an assembly. ("TORSEN" LSD) Standard backlash: 04.1 mm (0-0.004 in) (4) If the backlash exceeds the standard, use the select- able thrust washers for adjustment. 2. Install the new knock pin to secure the pinion shaft. Stake the pin with a punch to prevent it from coming out of the case. Thrust washer thickness: 3. Apply thread-locking compound to bolt threads @ and points @I of the gear back face. Apply approximately 0.04 cm3 I0.04 cc, 0.0024 cu in} of thread-locking com- pound at each point and bolt thread. 4. lnstall the ring gear onto the gear case. Identification mark 0 0.5 1 1.5 2 Tightening torque: 69-83 N.m (7.0--8.5 kgf-m, 51-61 ft-lbf) Thickness 2.00mm i0.0787 in} 2.05mm (0.0807 in) 2.10mm {0.0827 in) 2.15mm (0.0846 in} 2.20mm i0.0866 in} 5. Press the bearing inner races (side bearing) on by using the SST. 6. Install the differential gear assembly in the carrier. 7. Note the identification marks on the adjusting nuts, and install them on their respective sides. 8. lnstall the differential bearing caps, making sure that the identification mark on the cap corresponds with the one on the carrier by using the SST. Then temporarily tighten the bolts. Gartner Banana

Page 706 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P 4.8Y8TW VOLTAQE CHECKS * AFTER DISPLAY INDICATES A FAULT MESSAGE. REFER TO APPLCABLE SHOP MANUAL FOR ADDITIONAL DIAGNOSTIC INF OR- MATION. (Cont .) I TESTER AUTOMATICALLY PERFORMS MULTIPLE SYSTEM VOLTAGE TESTS IF NO FAULTS ARE IF FAULTS ARE DETECTED. TESTER DETECTED. TESTER WILL DISPLAY THE CORRESPOND- WILL ADVANCE TO ING FAULT MESSAGE(S) AS SHOWN NEXT TEST. BELOW. VALVE +, iLeI1 Fronl Valve Ogln) RF VALVE OPEN ( (R9M Fronl Valve Open) IREAR VALVE OPEN/ CHK ABS DIODE (Check ABS 01ode) CHK CONT MOD GND (Chock Control Module Ground) CHK SYSTEM GND (Check Syslrm Ground) CHK LF SPD SENS (Check Left Fronl SpHd Sm.wl CHK RF SPD SENS (Check R9hl Fronl Sped Sonsor) CHK LR SPD SENS (Check Left bar Sp..d Smw) CHK RR SPD SENS (Check Rghl Rear S.nror) I TESTER DISPLAY WlLL ALTERNATE ABOVE MESSAGES WITH I /YES CONTINUE? NO[ - & TESTER WlLL DISPLAY PRESS: -0A- SAME FAULT MESSAGE. 1 IF NO ADDITlbNAL FAULTS IF ADDITIONAL FAULTS ARE ARE DETECTED. TESTER WlLL DETECTED, TESTER WlLL ADVANCE TO NEXT TEST. DISPLAY NEXT FAULT I MESSAGE. 1 (Cant.) Gartner Banana

Page 708 of 1708

ANTILOCK BRAKE SYSTEM (ABS) P I*I (LISTEN) WSH EITHER SWITCH, AND LISTEN FOR PUMP MOTOR TO RUN. (NOTE: PUMP WlLL RUN FOR 5 SfCONDS MAXIMUM.) IF NO FA MT ECTE WlLL 01s 1 IF FAULT IS DETECTED TESTER WlLL DISPLAY: .TS ARE TESTER AY. THEN YOU MUST RESPOND WITHIN 5 SECONDS OR PUMP WlLL SHUT OFF, AND TESTER RETURNS TO START OF "SC PUMP TEST". PRESS: 6 I PRESS: -OR- 0-1' 1 STAT TEST DYNAM (Sc*iclb*l I TESTER WILL TESTER 9 WILL RETURN TO AWANCE TO "SA. ANTI-LOCK NEXT TEST LlQHT TEST". Gartner Banana

Page 946 of 1708

CRUISE CONTROL SYSTEM T Inspection Procedure Self-diagnosis 1. Connect a 1.4W test light between terminals D and F, of the cruise control unit connector. Note There is no wire in terminal D of the connector. Push the test light through the connector and touch the cor- responding pin on the control unit. 2. Turn the ignition switch to ON. 3. Turn the cruise control on by pressing the MAlN switch. The MAlN indicator light will come on. 4. Press and hold the RESUMEIACCEL switch for more than 3 seconds. The test light will illuminate for 3 se- conds and go out for 2 seconds. 5. The on-board diagnosis system is activated and the test light will flash if there is a problem. Refer to the chart be- low to obtain the problem code number. Note The cruise control system will not operate in self-diag- nosis mode. 6. After retrieving the code(s), drive the vehicle at more than 16 kmlh (10 MPH) or press the MAlN switch to deactivate self-diagnosis. The MAlN indicator light will go off. 7. Follow the action corresponding to the problem code. Service Code Table If there are two or more problems in the system, the problem with the highest priority will be indicated. Priority Pattern of output signal ON 2 OFF n 4 OFF ON 5 OFF I No. Code I Possible cause Defective wiring (Cruise actuator- Cruise control unit, Stoplight switch-Cruise control unit) 01 Defective actuator Defective stoplight switch (For O5 1 Defective wiring (Fuse - Cruise control unit) Both stoplight and brake switch (for 07 vehicle and cruise) are ON simulta- neously Defective SETICOAST, or RESUMEIACCEL switch l5 1 Defective cruise control unit Action Repair harness lnspect actuator (Refer to page T-107) Inspect brake switch (Refer to page T-105) Replace fuse Repair harness Inspect stoplight and brake switch (Refer to pages T-105 and T-56) Inspect cruise control switch (Refer to page T-106) Go to troubleshooting Gartner Banana

Page 947 of 1708

T 2 CRUISE CONTROL SYSTEM PRESS 45UOTX-209 Inspection Procedure Quick inspection 1. Connect a 1.4W test light between terminals D and F, of the cruise control unit connector. u Note There is no wire in terminal D of the connector. Push the test light through the connector and touch the cor- responding pin on the control unit. 2. Turn the ignition switch to ON. 3. Shift the selector lever to D or R range. 4. Verify that the MAlN switch is off. (The MAlN indicator light will be off .) 5. Turn the RESUMEIACCEL switch and the MAlN switch simultaneously to activate the system inspection. The MAlN indicator light will come on. 6. Operate each switch as described below and obtain the problem code numbers. Note The cruise control system will not operate in self-diag- nosis mode. 7. After retrieving the code(s), press the MAlN switch to deactivate the system inspection. The MAlN indicator light will go off. 8. Follow the action corresponding to the problem code. --, Service Code Table Press SETICOAST switch Procedure Press RESUMEIACCEL switch Pattern of output signal (Test light) ON OFF nn M nn Depress brake pedal ON OFF ON Drive vehicle above 40 km/h (25 MPH) Turn ignition switch to ON and shift the selector lever to P or N range (For AT) Depress clutch pedal (For MT) Code No. oN OFF Action lnspect cruise control switch (Refer to page T-106) lnspect cruise control switch (Refer to page T-106) lnspect stoplight switches (Refer to pages T-105 and T-56) lnspect parwneutral switch (Refer to section K) or clutch switch (Refer to page T-105) lnspect vehicle speed sensor or wire harness (Refer to page T-106) Gartner Banana