engine oil MAZDA MX-5 1994 Owners Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 657 of 1708

N ENGINE SPEED SENSING POWER STEERING I HOLDER OIL' SEAL 10-14mm (0.39-0.55 in) Backup ring and oil seal 1. Apply grease to a new oil seal. 2. lnstall the oil seal to the SST (Protector body and guide). 3. Remove the SST (guide). 4. Slide the oil seal and the SST over the rack from the gear side to the piston. Remove the SST. 5. lnstall the backup ring. Steering rack assembly 1. Apply grease to the teeth and friction surface of the rack. 2. Using the SST, slide the rack into the gear housing from the tube side. Holder 1. Apply grease to a new Y-packing and install it into the holder. 2. lnstall a new O-ring onto the holder. 3. lnstall the SST over the rack end and install the holder. 4. lnstall the new stop ring. Oil seal 1. Press in a new oil seal from tube side with a suitable pipe (Dia. 22mm (0.87 in)). Do not press over 3,920 N (400 kgf, 880 Ibf). 2. Verify that the distance between the end of the rack and the holder is 10-1 4mm (0.40-0.55 in}. Gartner Banana

Page 658 of 1708

ENGINE SPEED SENSING POWER STEERING N 60.5mm (2.38 in) Control valve 1. Install a new O-ring and a new seal ring onto the pinion shaft. 2. Pass the pinion shaft back and forth through the SST until the O-ring and the seal rings are set. 3. Fit new seal rings onto the control valve by using the SST. 4. Remove the SST from pinion shaft and align the pin posi- tion of the control valve with the thread of the pinion shaft assembly. lnstall the control valve assembly. 5. Install the new snap ring to the pinion shaft assembly. Pinion shaft assembly 1. Apply sufficient grease to the teeth of the pinion shaft. 2. Apply ATF to the seal ring and the friction surface of the control valve. 3. Attach the SST to the gear housing and install the pinion shaft. Plug assembly 1. Apply ATF to the upper bearing and the new oil seal. 2. Set the oil seal into the plug. 3. Press in the oil seal by using the SST. 4. Put the upper bearing into the plug. 5. Press in the upper bearing by using the SST. 6. Install a new O-ring to the plug assembly. Gartner Banana

Page 659 of 1708

N ENGINE SPEED SENSING POWER STEERING 7. Attach the SST to the pinion and install the plug assem- bly. Adjusting cover 1. Tighten the mounting bracket in a vise. 2. Set the rack to the center position. 3. Tighten the adjusting cover to 4.9 N.m (50 kgf.cm, 43 in4bf) with the SST three times, then return it 25". 4. Apply sealant to the threads of the locknut. 5. Attach the locknut. 6. Measure the pinion torque by using the SST and a pull scale. Standard Center of rack + 90": 1 .O-1 .I N-m {I 0-1 2 kgf-cm, 8.7-1 0.4 in-lbf) ii Scale reading: 1 .&I .2 kg (2.2-2.64 Ib) 7. If not within specification, repeat steps 3 through 6. 8. Install the locknut. Tightening torque: 59-74 N.m (6.0-7.5 kgf.m, 44--54 ftdbf) Hermetic sealing inspection 1. Connect the SST to the power cylinder section of the gear housing. 2. Apply 53.3 kPa (400 mmHg, 15.7 inHg) vacuum with a vacuum pump and verify that it is held for at least 30 seconds. 3. If the vacuum is not held, replace the oil seal. Tie rod 1. Secure the rack gear in a vise, and tighten the tie rods with the wrench. Tightening torque: 79-98 N.m (8.0-10.0 kgf-m, 58-72 ft-lbf) 2. Align the washer with the rack groove, and crimp the washer. Gartner Banana

Page 660 of 1708

ENGINE SPEED SENSING POWER STEERING N POWER STEERING OIL PUMP Removal / Installation 1. Remove in the order shown in the figure, referring to Removal Note. u 2. Install in the reverse order of removal. 3. After installation: (1) Check connections for fluid leakage. (Refer to page N-22.) (2) Bleed air from the system. (Refer to page N-21.) 1. Drive belt 3. Press~~re pipe ................... ............... w Inspection page N-37 Removal Note page N-34 Adjustment .................. page N-38 4. Return hose Replacement ................ page N-38 5. Power steering oil pump 2. Power steering pressure switch connector Gartner Banana

Page 663 of 1708

N ENGINE SPEED SENSING POWER STEERING Disassembly Note Oil pump Use the SSTwhen securing the oil pump in a vise, so that force is not applied to the pulley or shaft. Inspection Pump body front, rear lnspect the front and rear of the pump body for cracks and damage, and the friction surface of the rotor for wear. Replace the pump assembly if a problem is found. Cam ring, rotor, blade, side plate 1. lnspect the blade friction surface of the cam ring for wear. 2. lnspect the pump body of the rotor and side plate friction surface for wear. 3. lnspect the cam ring friction surface of the blade for -, wear. 4. lnspect clearance between the rotor and blade. Control valve, spring 1. lnspect the control valve for cracks, damage and block- age, and the friction surface for wear. 2. lnspect the spring for damage. Assembly Note Rotor Install the rotor with the indentification mark facing upward. Gartner Banana

Page 665 of 1708

N ENGINE SPEED SENSING POWER STEERING Adjustment Loosen PIS oil pump bolt @ and nuts @ and 0. Adjust the belt deflection by turning adjusting bolt @I. 4 Tightening torque @: 37-53 N.m (3.7-5.5 kgf.m, 27-39 ft-lbf) @: 37-53 N-m (3.7-4.5 kgf.m, 27-39 ft4bf) 0: 19-25 N-m (1 .S2.6 kgf.m, 14-1 8 ftlbf) I 15UONX-043 Replacement 1. Loosen bolt @, nuts @ and 0, and adjusting bolt @. 2. Remove and replace the drive belt. 3. Adjust the deflection (tension). (Refer to page N-37.) Gartner Banana

Page 736 of 1708

OUTLINE OUTLINE SPECIFICATIONS Front Suspension - Transmission item (Stabilizer Specifications MT I AT - I Susoension tvoe I . , . , I . , Shock absorber Cylindrical double acting, low-pressure-gas charged I Double-wishbone TY pe Torsion bar Coil spring I - Diameter mm linl I 20.0 10.79) Identification mark color 19.0 (0.75) White Wire diameter mm (in) Coil inner diameter mm {in) I Blue Free length mm {in) Coil number 11 .O (0.43) 83 i3.27) 11 .O (0.43) 83 (3.27) 292.5 (1 1 32) 6.32 3 +. 3 (0.12 + 0.12) 0°18' + 18' Total toe-in I - I 35UORX-001 Rear Suspension 302.0 (1 1.89) 6.32 mm {in) degree Total toe-in (per side) 1 degree Front wheel alignment (Unladedt1) 0°09' +. 09' Caster anglee3 4"26' +. 45' Kingpin angle 11 "20' Maximum steering angle Transmission Specifications MT I AT Item Differential - Suspension type Inner Outer "TORSEN" LSD 1 Standard Double-wishbone Coil springs 370 23' a 2" 32" 32' -t 2" Camber anglee2 Torsion bar 12.0 (0.47) 1 11.0 (0.43) 1 11 .O (0.43) Cylindrical double acting, low-pressure-gas charged - Stabilizer Identification mark color Wire diameter mm {in) 0°24' + 45' Type Diameter mm {in) I Coil number I 7.68 I 7.96 I Shock absorber Yellow 10.1 {0.40} Coil inner diameter mm {in) Free length mm {in) Green 10.2 {0.40) 35UORX-002 *I Fuel tank full; radiator coolant and engine oil at specified levels; spare tire, jack, and tools in designated positions. '2 Difference between left and right must not exceed I O. '3 Difference between left and right must not exceed 1'30'. "TORSEN" is a registered trademark of ZEXEL-GLEASON USA.INC 83 I3.27) 348.5 j13.72) Rear wheel alignment (Unladed*') 83 (3.27) 356.5 (1 4.04) Total toe-in Total toe-in (per side) mm (in) degree degree 3 -c 3 (0.12 + 0.121 0°18' + 18' 0°09' + 09' Camber angle*2 -0°43' 2 30' Gartner Banana

Page 737 of 1708

TROUBLESHOOTING GUIDE TROUBLESHOOTING GUIDE Problem General instabllity Body "rolls" "Heavy" steering wheel operation Steering wheel pulls to one side Excessive steering wheel play Body leans Abnormal noise from suspension system Shake (Steering wheel tibrates upldown) Shimmy (Steering wheel vibrates leftlright) Possible cause Weak coil spring Malfunction of shock absorber Worn or damaged stabilizer and/or suspension arm bushings Worn or damaged upper or lower arm ball joint Improperly adjusted wheel alignment Weak stabilizer Worn or damaged stabilizer and/or suspension arm bushings Insufficiently lubricated or stuck upper arm lower arm ball joint lmproperly adjusted wheel alignment Weak coil spring Worn or damaged stabilizer and/or suspension arm bushings Deformed upper or lower arm or knuckle Loose upper or lower arm bushing Worn or damaged upper or lower arm bushing Worn or damaged upper or lower arm ball joint Weak coil spring Weak stabilizer andlor suspension arm bushings Loose mounting component Poorly lubricated or worn upper or lower arm ball joint Malfunction of shock absorber Worn or damaged stabilizer and/or suspension arm bushings Excessive tire or wheel runout Loose lug nuts Unbalanced wheel@) Cracked or worn engine mounting rubber Cracked or worn steering gear mounting rubber Loose steering gear mounting bolts Stuck or damaged steering ball joint Excessive tire or wheel runout Loose lug nuts Unbalanced wheel(s) Insufficient tire pressure Unevenly worn tires Malfunction of shock absorber Loose shock absorber mounting bolts Stuck or damaged upper or lower arm ball joint Cracked or worn suspension bushings Damaged or worn front wheel bearing lmproperly adjusted front wheel alignment Action Replace Replace Replace Replace Adjust Replace Replace Replace Adjust Replace Replace Replace Replace Replace Replace Replace Replace Tighten Replace Replace Replace Replace Tighten Adjust or replace Replace Replace Tighten Replace Replace Tighten Adjust or replace Adjust Replace Replace Tighten Replace Replace Replace Adjust Page R-13 R-12,22 R-16, 18, 19, 23,24,25 section M R-15,17 R- 6 R-19,25 R-16, 18,19, 23, 24,25 section M R-15,17 R- 6 R-13 R-16, 18,19, 23, 24,25 R-15,17 section M R-16,18 R-16,18 R-15,17 R-13 R-16, 18, 19, 23,24,25 section M 7 R-15,17 R-l2,22 R-16, 18,19, 23,24,25 section M - section Q section Q section B section N section N section N - section Q section Q section Q section Q R-l2,22 R-12,22 R-15, 17 R-16,18,19 section M R- 6 15UORX-00 Gartner Banana

Page 738 of 1708

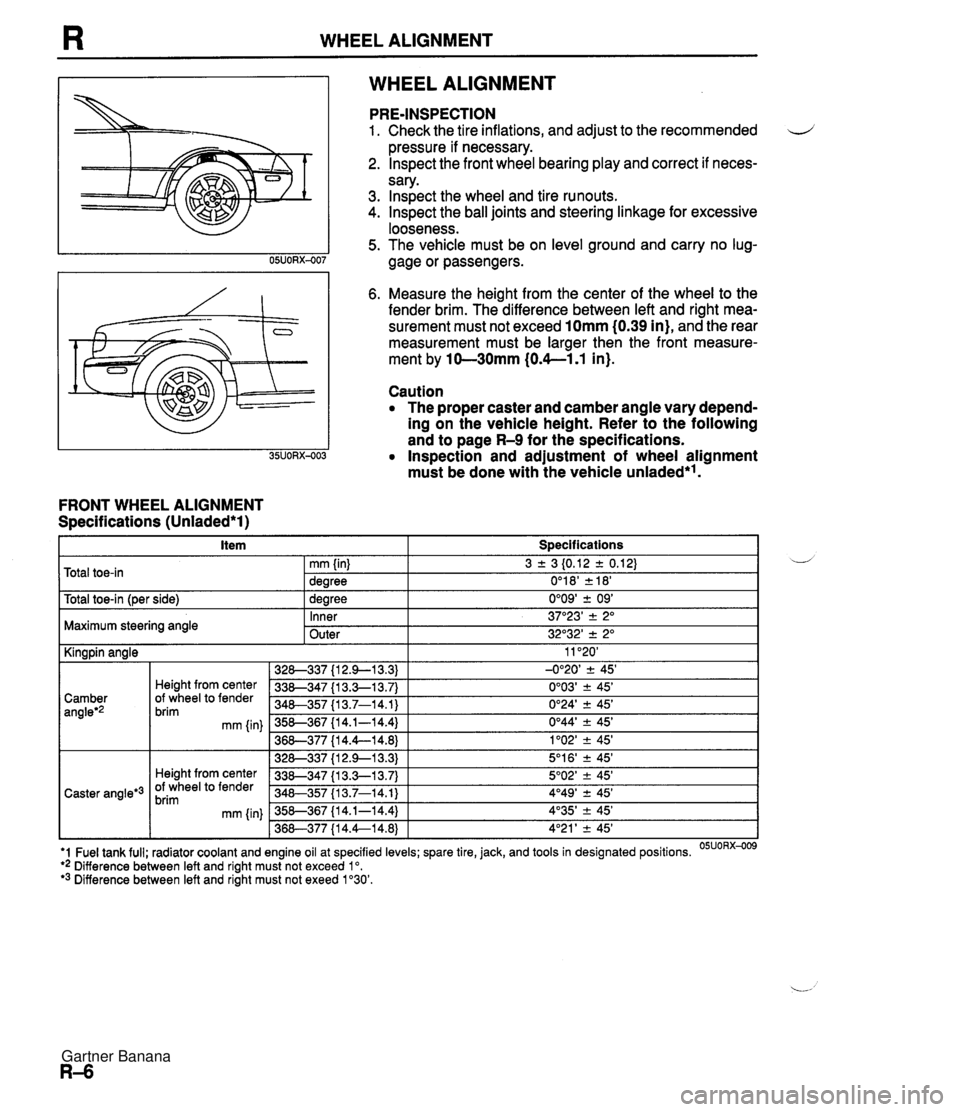

WHEEL ALIGNMENT WHEEL ALIGNMENT FRONT WHEEL ALIGNMENT Specifications (Unladed*l) PRE-INSPECTION 1. Check the tire inflations, and adjust to the recommended d pressure if necessary. 2. lnspect the front wheel bearing play and correct if neces- sary. 3. lnspect the wheel and tire runouts. 4. Inspect the ball joints and steering linkage for excessive looseness. 5. The vehicle must be on level ground and carry no lug- gage or passengers. 6. Measure the height from the center of the wheel to the fender brim. The difference between left and right mea- surement must not exceed 10mm (0.39 in), and the rear measurement must be larger then the front measure- ment by 10-30mm (0.4--1.1 in). Caution The proper caster and camber angle vary depend- ing on the vehicle height. Refer to the following and to page R-9 for the specifications. Inspection and adjustment of wheel alignment must be done with the vehicle unladed*'. . . I Y -- t~otal toe-in l~er side) I 1 dearee 0'09' + 09' I Total toe-in 3 2 3 I0.12 2 0.12) 0'1 8' 2 18' mm (in) dearee Maximum steering angle U - Inner Outer 11 '20' -0°20' 2 45' 0'03' ? 45' 0'24' 2 45' 0°44' -+ 45' 1'02' -+ 45' 5'1 6' ? 45' 5O02' -+ 45' 4O49' 2 45' 4'35' -+ 45' 4'21 ' -+ 45' I Kingpin angle 37"23' -+ 2" 32O32' 2 2" '1 Fuel tank full; radiator coolant and engine oil at specified levels; spare tire, jack, and tools in designated positions. OSUORX-009 ** Difference between left and right must not exceed lo. '3 Difference between left and right must not exeed 1'30'. 328-337 {I 2.9-1 3.3) 338-347 {I 3.3-1 3.7) 340-357 I13.7-14.1) 358-367 {I 4.1-14.4) 36&377 {I 4.4--14.8) 328-337 {I 2.9--13.3) 338-347 {I 3.3-1 3.7) 348-357 113.7-14.1) 358-367 {I 4.1-14.4) 368-377 {I 4.4--14.8) Camber angleg2 Caster angle*3 Height from center Of wheel to fender brim mm {in) Height from center Of wheel to fender brim mm (in) Gartner Banana

Page 741 of 1708

WHEEL ALIGNMENT REAR WHEEL ALIGNMENT Specifications (Unladed*) I Item I Specifications I L *' Fuel tank full; radiator coolant and engine oil at specified levels; spare tire, jack, and tools in designated positions. 05Uo~x-01~ *2 Difference between the leff and right must be exeed lo. 3 + 3 i0.12 * 0.12) 0'18' k18' 0'09' 2 09' -1 "08' +. 30' Total toe-in Total toe-in (per side) Camber angle'' LEFT WHEEL - mm {in) degree degree INCREASE I 1 346-355 (1 3.6-1 4.0) Height from center of wheel to fender brim'2 mm Iin) RIGHT WHEEL C INCREASE 356-3135 {14.0-14.4) 366-375 {I 4.4--14.8) 376-385 {I 4.8-1 5.2) 386--395 {I 5.2-1 5.6) LEFT WHEEL -C -0°54' r 30' -0'43' 2 30' -0°35' r 30' -0'30' +. 30' Toe-in Toe-in is adjusted by turning the front and/or rear adjust- ing cam bolts at the lower arm. Caution Adjust the toe-in before adjusting the camber. 1. Loosen the front and/or rear cam nuts. 2. Turn the front and/or rear adjusting cam bolts to provide the correct toe-in. I Counter- Counter- Decrease Clockwise Clockwise clockwise clockwise Toe-in Note Turning the front cam one graduation changes the toe-in about 2.8mm (0.11 in} and the camber about 15'. Turning the rear cam one graduation changes the toe-in about 2.8mm I0.11 in} and the camber about 6'. 3. 'Adjust the camber. Left wheel Camber Camber is adjusted by turning the front and rear cams at the lower arm. Right wheel Caution Adjust the camber after adjusting the toe-in. Front cam I Rear cam I Front cam I Rear cam 1. Loosen the front and rear cam nuts. 2. Turn the front and rear adjusting cam bolts the same amount in the opposite direction to provide the correct camber angle. Gartner Banana