battery replacement MAZDA MX-5 1994 User Guide

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 309 of 1708

G INDEX INDEX 1. Battery lnspection . . . . . . . . . . . . . . . . . page G- 8 Recharging . . . . . . . . . . . . . . . . page G- 9 Replacement . . . . . . . . . . . . . . page G-10 2. Alternator Removal / lnstallation . . . . . . . page G-10 Disassembly / Assembly . . . . page G-11 lnspection . . . . . . . . . . . . . . . . . page G-12 3. Drive belt lnspection . . . . . . . . . . . . . . . . . page G-13 Adjustment . . . . . . . . . . . . . . . . page G-14 4. Spark plug Removal / Installation . . . . . . . page G-18 Spark test . . . . . . . . . . . . . . . . . page G-18 lnspection . . . . . . . . . . . . . . . . . page G-18 5. Ignition coil lnspection . . . . . . . . . . . . . . . . . page G-19 Replacement . . . . . . . . . . . . . . page G-19 6. Igniter (in ignition coil) lnspection . . . . . . . . . . . . . . . . . page G-19 7. High-tension lead Removal / lnstallation . . . . . . . page G-20 lnspection . . . . . . . . . . . . . . . . . page G-20 8. Starter Removal / lnstallation . . . . . . . page G-22 Performance lnspection . . . . . page G-23 Disassembly / Assembly . . . . page G24 -' lnspection . . . . . . . . . . . . . . . . . page G26 9. Starter interlock switch (MT) lnspection . . . . . . . . . . . . . . . . . page G-28 Gartner Banana

Page 317 of 1708

CHARGING SYSTEM B TE S TERMINAL 1. Remove the battery cover. 2. Disconnect the battery cable from the battery. 3. Remove the battery from the vehicle. 4. Place the battery in a pan of the water to prevent it from ,-, over heating, but keep water away from the top of bat- tery. 5. Charge the battery. Replacement Note When replacing the battery, replace it with the same style Mazda genuine battery (with vent manifold). ALTERNATOR Caution Obtain the code number and deactivate the audio anti-theft system before disconnecting the bat- tery. (Refer to section T.) Caution Reversing the battery connections or using high- voltage testers will damage the rectifier. Caution Do not start the engine while the connector is dis- connected from L and S terminals. It can damage the alternator. Note .--,' Positive voltage is always present at alternator B ter- minal. Removal l Installation 1. Disconnect the negative battery cable. 2. Disconnect the steering pressure sensor connector. 3. Disconnect the water thermoswitch connector. 4. Disconnect the IAC valve connector. 5. Remove the intake air pipe. 6. Disconnect the wire and connector from the alternator. 7. Remove the alternator bolts and nut. 8. Remove the alternator. 9. Install in the reverse order of removal. Tightening torque Bolt 0: 38-51 N.m (3.8-5.3 kgf-m, 27-38 ftelbf) Bolt @ : 19-25 N.m j1.9-2.6 kgfem, 14--18 ft-lbf) Nut @I: 9.9--14 N.m (100-150 kgf-cm, 87-1 30 in-lbf) Gartner Banana

Page 440 of 1708

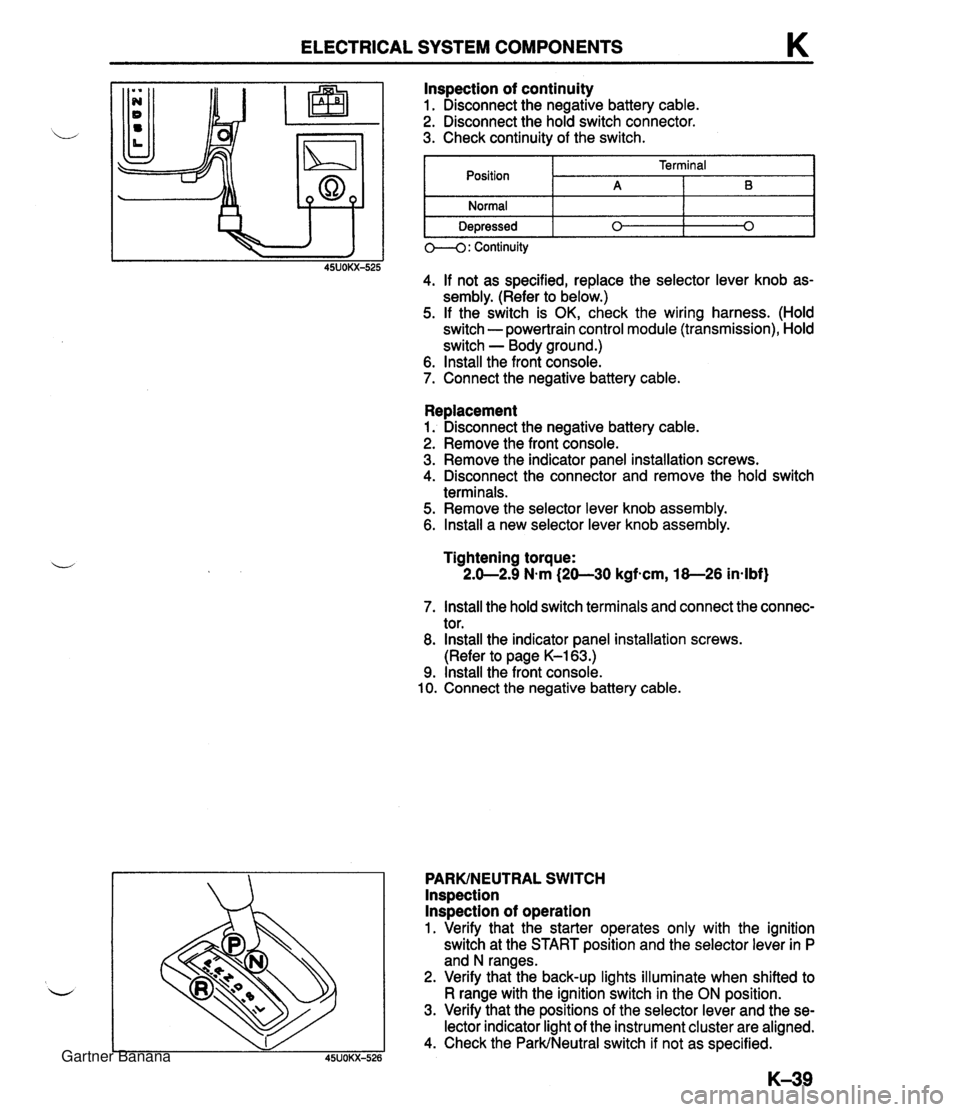

ELECTRICAL SYSTEM COMPONENTS K Replacement 1. Disconnect the negative battery cable. 2. Remove the front console. 3. Remove the indicator panel installation screws. 4. Disconnect the connector and remove the hold switch terminals. 5. Remove the selector lever knob assembly. 6. lnstall a new selector lever knob assembly. lnspection of continuity 1. Disconnect the negative battery cable. 2. Disconnect the hold switch connector. 3. Check continuity of the switch. Tightening torque: 2.0-2.9 N.m (20-30 kgfscm, 18-26 in-lbf) Position Normal Depressed 7. lnstall the hold switch terminals and connect the connec- tor. 8. lnstall the indicator panel installation screws. (Refer to page K-163.) 9. lnstall the front console. 10. Connect the negative battery cable. PARKINEUTRAL SWITCH lnspection lnspection of operation 1. Verify that the starter operates only with the ignition switch at the START position and the selector lever in P and N ranges. 2. Verify that the back-up lights illuminate when shifted to R range with the ignition switch in the ON position. 3. Verify that the positions of the selector lever and the se- lector indicator light of the instrument cluster are aligned. 4. Check the ParkINeutral switch if not as specified. 0--4: Continuity 45UOKX-525 4. If not as specified, replace the selector lever knob as- sembly. (Refer to below.) 5. If the switch is OK, check the wiring harness. (Hold switch - powertrain control module (transmission), Hold switch - Body ground.) 6. lnstall the front console. 7. Connect the negative battery cable. Terminal A 0 B 0 Gartner Banana

Page 442 of 1708

ELECTRICAL SYSTEM COMPONENTS K ATF THERMOSENSOR Inspection 1. Refer to "Replacement" below for removal of the ATF thermosensor. 2. Place the ATF thermosensor in ATF with a thermometer as shown, and heat the ATF gradually. 3. Measure resistance between the terminals of the ATF thermosensor. ATF temperature- {OF) 1 Resistance (kR) 20 (68) 2.5 4. If not correct, replace the ATF thermosensor. 5. Refer to "Replacement" for installation of the ATF ther- mosensor. Replacement 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 3. Disconnect the ATF thermosensor connector. 4. Remove the ATF thermosensor. 5. Install the new ATF thermosensor. Tightening torque: 7.9-1 0.7 N-m (80-11 0 kgf-cm, 70-95.4 in-lbf) 6. Connect the ATF thermosensor connector. 7. Connect the negative battery cable. VEHICLE SPEED PULSE GENERATOR Inspection 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 3. Disconnect the vehicle speed pulse generator connec- tor. 4. Measure resistance between the terminals of the vehicle speed pulse generator. Resistance: 24552 5. If not correct, replace the vehicle speed pulse generator. 6. Connect the vehicle speed pulse generator connector. 7. Connect the negative battery cable. Gartner Banana

Page 443 of 1708

K ELECTRICAL SYSTEM COMPONENTS Replacement 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. 4 3. Disconnect the vehicle speed pulse generator connec- tor. 4. Remove the vehicle speed pulse generator. 5. Install the new vehicle speed pulse generator. Tightening torque: 7.9--10.7 N-m (80-110 kgfecm, 70-95.4 in-lbf) 6. Connect the vehicle speed pulse generator connector. 7. Connect the negative battery cable. 1-2 SHIFT, 2-3 SHIFT, 3-4 SHIFT, 3-2 CONTROL SOLENOID VALVE Inspection 1. On level ground, jack up the vehicle and support it evenly on safety stands. 2. Disconnect the solenoid valve connector. d 3. Measure resistance between each terminal and ground. Resistance: l3-27a 4. If not correct, check the wiring harness for an open or short circuit. Replace the solenoid valve. Solenoid valve 1-2 shift 2-3 shift 3-4 shift 3-2 control LOCKUP CONTROL SOLENOID VALVE lnspection 1. Disconnect the solenoid valve connector. 2. Measure the resistance between the terminals. Terminal C D - A B Resistance: l3-2Sil 3. If not correct, replace the solenoid valve. Gartner Banana

Page 446 of 1708

ELECTRICAL SYSTEM COMPONENTS K Terminal 2D (Input) 2E (Output) 2F (Input) 2G (Output) 2H (Input) - !I (Output) !J (Input)' - !K (Output) - !L (Ground)' 'M (Output) 1-2 shift solenoid valve 1 2E (S range) 2-3 shift solenoid valve Connected to Voltmeter I I +terminal . ParWneutral switch (D range) 2D - - (L range) 3-4 shift solenoid lalve Jehicle speed pulse 2J lenerator .ockup control ;olenoid valve 2K lehicle speed pulse 2L lenerator - 1 - I I - , - Z - 1 d - _4 3 V - - ower) E P (Ground) - 2P Ground ov - Q (Battery sattery 2Q B+ lgnition switch ON ower) OV Ignition switch OFF R - - - - - s (Battery Battery 2s B+ lgnition switch ON ~wer) Ground OV lgnition switch OFF Throttle position sen- 2T 'I- (Input) sor Approx. Throttle valve closed throttle position to wide 0.44.1 V open throttle Checked with AC range 1-2 control solenoid 'alve I 2M 1 ( Blow l.5V I 1 B+ 3-2 or 4-2 downshift OV Other conditions - - - I I I I lattery 20 B+ Constant Replacement Disconnect the negative battery cable. Disconnect the powertrain control module (Transmis- sion) connector. Remove the bolt and nut shown in the figure, and re- move the powertrain control module (Transmission). Install the new powertrain control module (Transmis- sion). Tightening torque: 19-25 N-m (1 .S2.6 kgf-m, 14--18 ftslbf) Connect the powertrain control module (Transmission). Connect the negative battery cable. Gartner Banana

Page 559 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) Replacement 1. Disconnect the negative battery cable. 2. Remove the column cover. 3. Disconnect the key interlock solenoid connector. 4. Remove the screws and the key interlock solenoid. 5. Install the key interlock solenoid and tighten the screws. Tightening torque: 6.S-13 N-m (70-1 30 kgf-m, 61-11 3 ft-lbf} I I I 6. Verify that the key interlock solenoid operates. (Refer to 45UOKX-576 "Inspection" above.) 7. Connect the key interlock solenoid connector. 8. Install the column cover. 9. Connect the negative battery cable. KEY INTERLOCK UNIT Inspection 1. Remove the column cover. 2. Turn the ignition switch ON, and check terminal volt- ages, referring to the chart below. 3. If not as specified, repair the wiring harness andlor key -, interlock unit. B+: Battery positive voltage - - - Within 2 seconds of twning the P-range switch ON, and either the ACC or IG ON. Except above conditions Correct measurement valve 0 B+ E Condition Terminal I I I I terminal connected to I Ground 1 Constant M 0 Ignition switch ON Ignition switch OFF P-range switch and ACC are ON, or IG is ON Except above condition I B+ 0 S 0 B+ P-range switch ON P-range switch OFF I 0 B+ - ACC switch ON ACC switch OFF B+ 0 Gartner Banana

Page 560 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K TO GROUND FROM SHIFT-LOCK ACTUATOR Replacement 1. Disconnect the negative battery cable. 2. Disconnect the key interlock unit connector. 3. Remove the key interlock unit. 4. Install the new key interlock unit. 5. Connect the key interlock unit connector. 6. Connect the negative battery cable. P RANGE SWITCH Inspection Continuity 1. Disconnect the negative battery cable. 2. Remove the rear console. 3. Remove the screws and lift up the indicator panel. 4. Disconnect the P range switch connector. 5. Check continuity between the terminals. I Range I Selector lever release button I Continuity I 6. If not as specified, replace the P range switch. (Refer to page K-166.) I 7. Connect the P range switch connector. 8. Adjust the indicator panel. (Refer to page K-161.) Install the screws in the order shown in the figure. 9. Install the rear console. 10. Connect the negative battery cable. 11. Verify correct operation of the shift-lock system. SHIFT-LOCK ACTUATOR Inspection Terminal voltage and continuity 1. Remove the rear console 2. Remove the selector knob and indicator panel screws. Released Depressed Yes No Gartner Banana

Page 857 of 1708

T FUSE DESCRIPTION Main Fuse Block The main fuse block is located on the right side of the engine compartment and contains nine fuses and two relays. -1 Fuse Box Fuse block No.1 is located above the dead pedal of the driver side. The fuse box cover shows the speci- fied fuse locations. A circuit breaker is included in the fuse box to protect the heater blower motor circuit. Fuse block No.2 is located to the side of the battery in the trunk compartment. 45UOTX-016 REPLACEMENT Caution Determine and correct the cause of a burnt fuse before replacing it. If the fuse is replaced before doing this, it may burn again. Plate type 1. Disconnect the negative battery cable. 2. Replace the failed fuse with the fuse puller. 3. Reconnect the negative battery cable. Cartridge-type 80A fuse (Black) 1. Disconnect the negative battery cable. 2. Remove the fuse block mounting nuts, and remove the service cover. 3. Remove the fuse installation bolts, and pull out the fuse. 4. Install the new fuse and the fuse installation bolts. 5. Install the main fuse block. 6. Reconnect the negative battery cable. Gartner Banana

Page 863 of 1708

T SWITCH IGNITION SWITCH Replacement 1. Disconnect the negative battery cable. 2. Remove the column covers. 3. Remove the screw and the ignition switch. 4. Install in the reverse order of removal. Inspection 1. Check for continuity between terminals of the switch. ACC 82 IG1 45UOTX-OX I Terminal 1 Position I B1 1 82 1 ACC I IG1 I IG2 I ST LOCK M: Continuity 2. If not as specified, replace the combination switch. Gartner Banana