MAZDA MX-5 1994 Workshop Manual

Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 521 of 1708

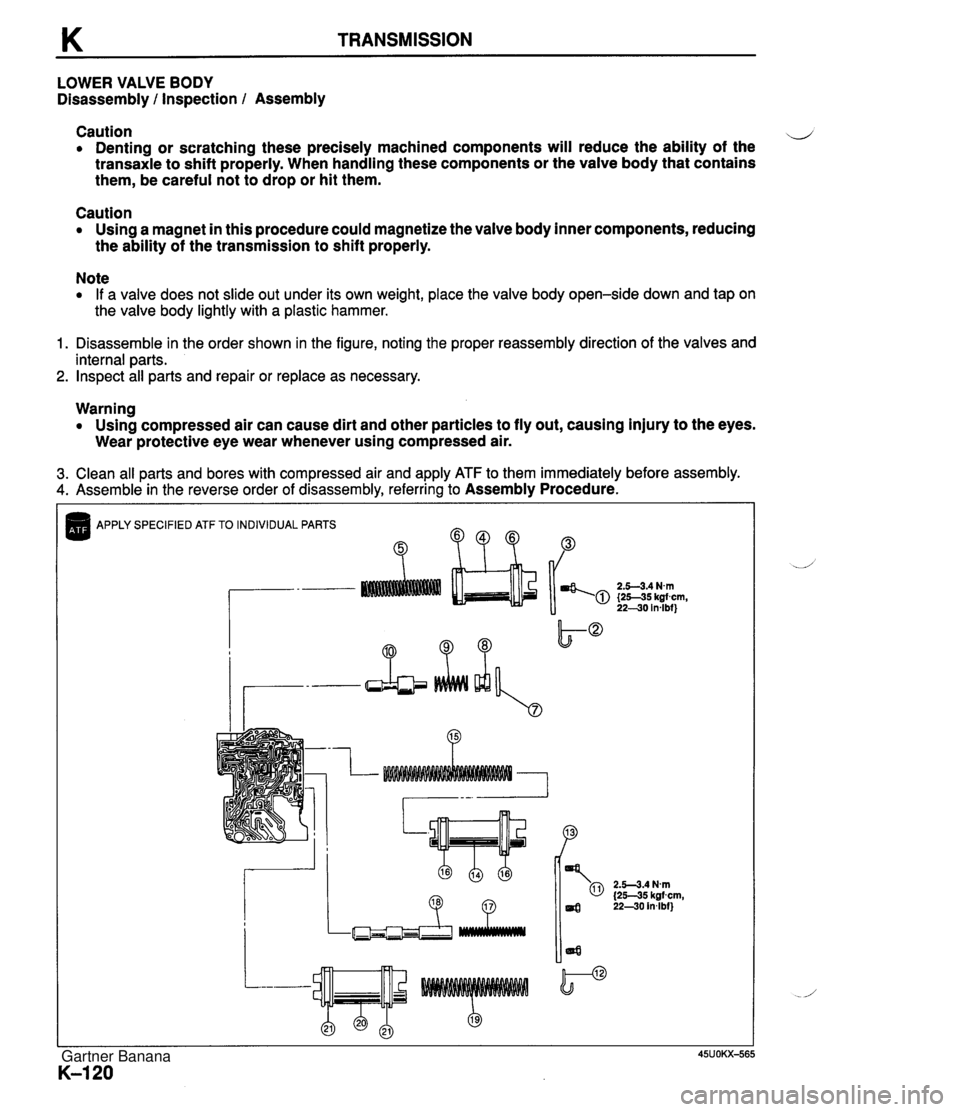

K TRANSMISSION LOWER VALVE BODY Disassembly l Inspection l Assembly Caution d Denting or scratching these precisely machined components will reduce the ability of the transaxle to shift properly. When handling these components or the valve body that contains them, be careful not to drop or hit them. Caution Using a magnet in this procedure could magnetize the valve body inner components, reducing the ability of the transmission to shift properly. Note If a valve does not slide out under its own weight, place the valve body open-side down and tap on the valve body lightly with a plastic hammer. 1. Disassemble in the order shown in the figure, noting the proper reassembly direction of the valves and internal parts. 2. Inspect all parts and repair or replace as necessary. Warning Using compressed air can cause dirt and other particles to fly out, causing injury to the eyes. Wear protective eye wear whenever using compressed air. 3. Clean all parts and bores with compressed air and apply ATF to them immediately before assembly. 4. Assemble in the reverse order of disassembly, referring to Assembly Procedure. APPLY SPECIFIED ATF TO INDIVIDUAL PARTS B ?? "P 2.5-3.4 Nm {25-35 kgfcm, 22-30 in4bf) Gartner Banana

Page 522 of 1708

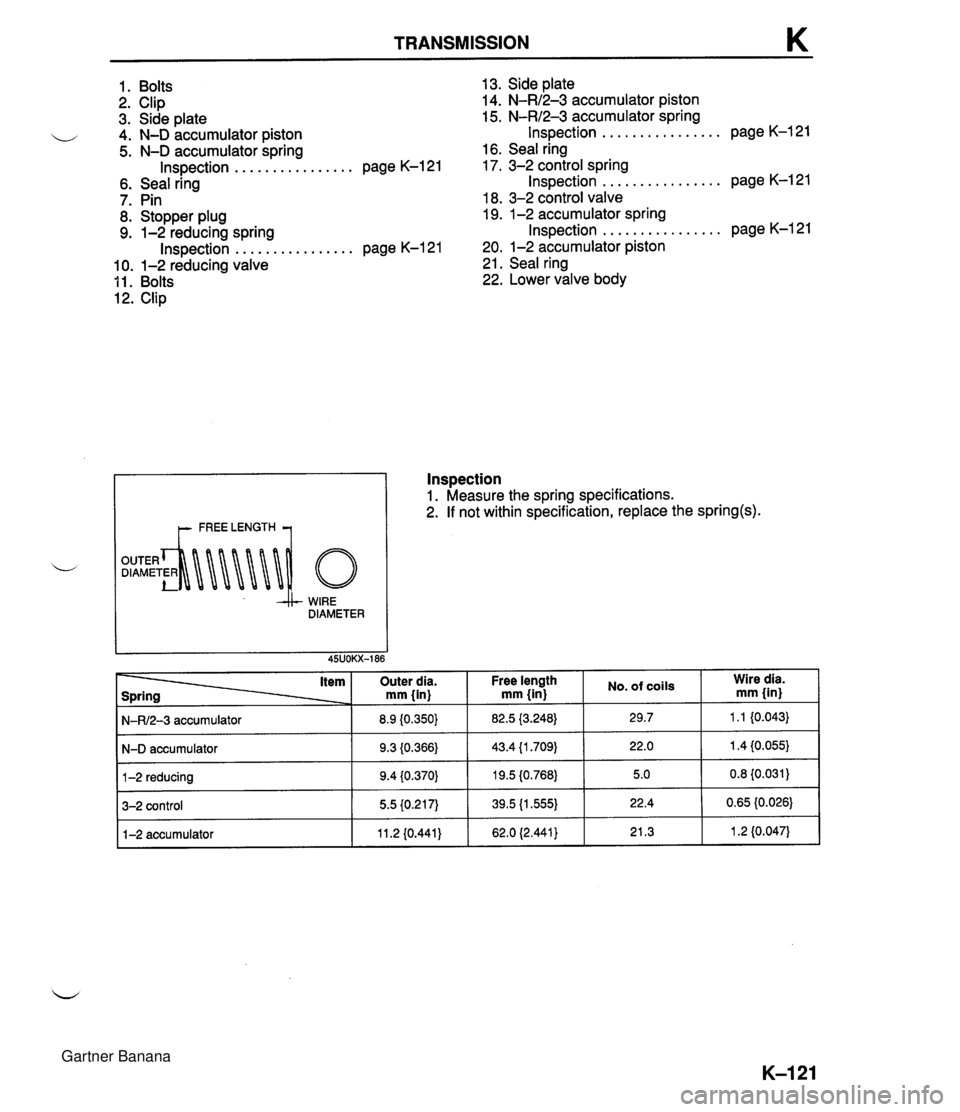

TRANSMISSION K 1. Bolts 13. Side plate 2. Clip 14. N-R/2-3 accumulator piston 3. Side plate 15. N-R/2-3 accumulator spring ................ i/ 4. N-D accumulator piston Inspection page K-121 5. N-D accumulator spring 16. Seal ring Inspection ................ page K-121 17. 3-2 control spring 6. Seal ring Inspection ................ page K-121 7. Pin 18. 3-2 control valve 8. Stopper plug 19. 1-2 accumulator spring ................ 9. 1-2 reducing spring Inspection page K-121 Inspection ................ page K-121 20. 1-2 accumulator piston 10. 1-2 reducing valve 21. Seal ring 11. Bolts 22. Lower valve body 12. Clip i- FREE LENGTH 1 --k WIRE DIAMETER lnspection 1. Measure the spring specifications. 2. If not within specification, replace the spring(s). - 3-2 control Item Spring N-R/2-3 accumulator N-D accumulator 1-2 reducing Free length mm {in) 82.5 13.248) Outer dia. mm {in} 8.9 10.3501 9.3 {0.366) 9.4 10.370) 1-2 accumulator No. of coils 29.7 Wire dia. mm {in) 1.1 10.043) 43.4 {I .709) 19.5 {0.768) 11.2 I0.441) 22.0 5.0 62.0 (2.441) 1.4 I0.055) 0.8 {0.031) 21.3 1.2 (0.047) Gartner Banana

Page 523 of 1708

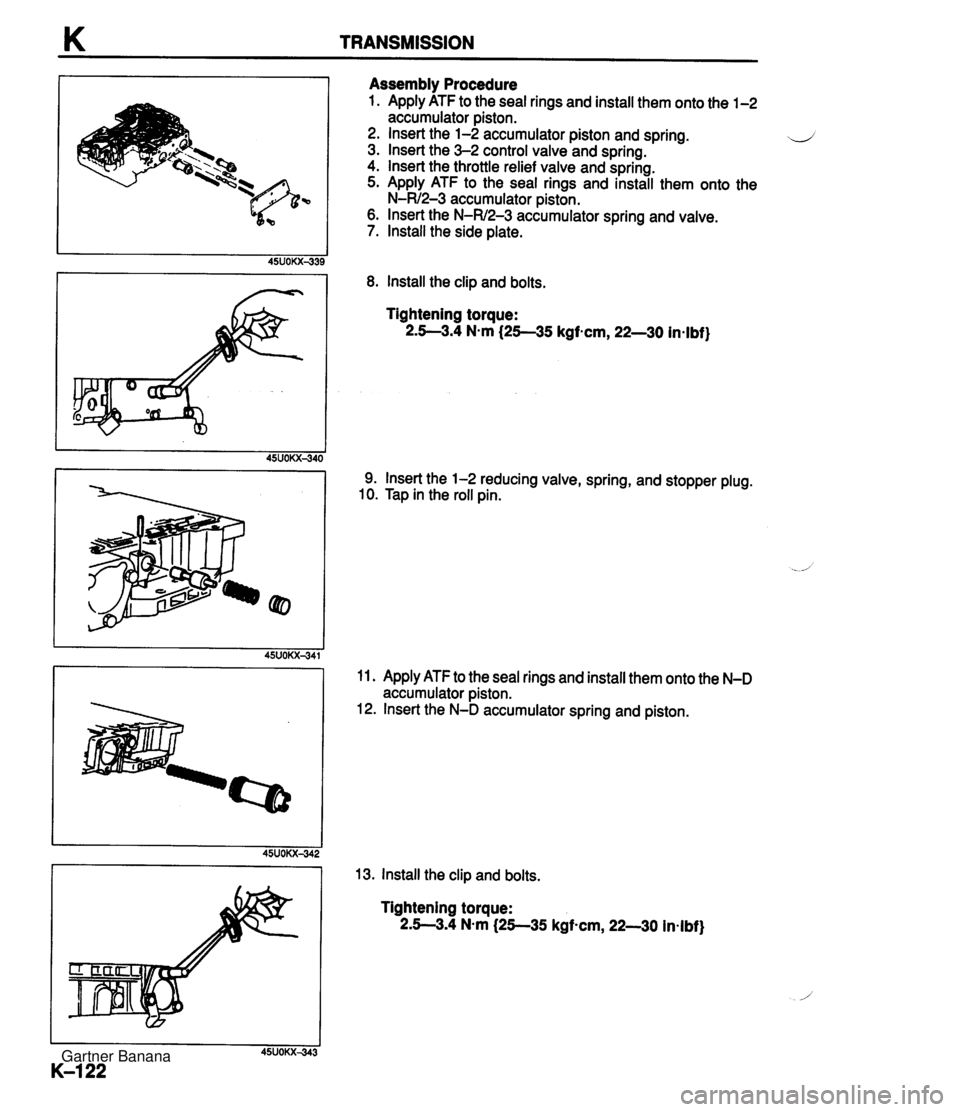

K TRANSMISSION Assembly Procedure 1. Apply ATF to the seal rings and install them onto the 1-2 accumulator piston. 2. lnsert the 1-2 accumulator piston and spring. 3. lnsert the 3-2 control valve and spring. 4. lnsert the throttle relief valve and spring. 5. Apply ATF to the seal rings and install them onto the N-W2-3 accumulator piston. 6. lnsert the N-W2-3 accumulator spring and valve. 7. lnstall the side plate. 8. Install the clip and bolts. Tightening torque: 2.5-3.4 N-m (25-35 kgfmcm, 22-30 in-lbf) 9. lnsert the 1-2 reducing valve, spring, and stopper plug. 10. Tap in the roll pin. 11. Apply ATF to the seal rings and install them onto the N-D accumulator piston. 12. lnsert the N-D accumulator spring and piston. 13. Install the clip and bolts. Tightening torque: 2.5-3.4 N-m (25--35 kgf-cm, 22-30 in-lbf) Gartner Banana

Page 524 of 1708

![MAZDA MX-5 1994 Workshop Manual TRANSMISSION K Bolt locations 0 A-W 0 B-W 0 K.W 0 0 A-W K.W 0 C.W C.W W: DISHED WASHER DISHED WASHER DIRECTION Bolts Torque specification 59mm (2.32 in} C I? 82mm f3.23 in] 4- ;. 11-15 Nm (1 .l-1.5 kg MAZDA MX-5 1994 Workshop Manual TRANSMISSION K Bolt locations 0 A-W 0 B-W 0 K.W 0 0 A-W K.W 0 C.W C.W W: DISHED WASHER DISHED WASHER DIRECTION Bolts Torque specification 59mm (2.32 in} C I? 82mm f3.23 in] 4- ;. 11-15 Nm (1 .l-1.5 kg](/img/28/57072/w960_57072-523.png)

TRANSMISSION K Bolt locations 0 A-W 0 B-W 0 K.W 0 0 A-W K.W 0 C.W C.W W: DISHED WASHER DISHED WASHER DIRECTION Bolts Torque specification 59mm (2.32 in} C I? 82mm f3.23 in] 4- ;. 11-15 Nm (1 .l-1.5 kgf-m, 8.0-11 ftdbf} Gartner Banana

Page 525 of 1708

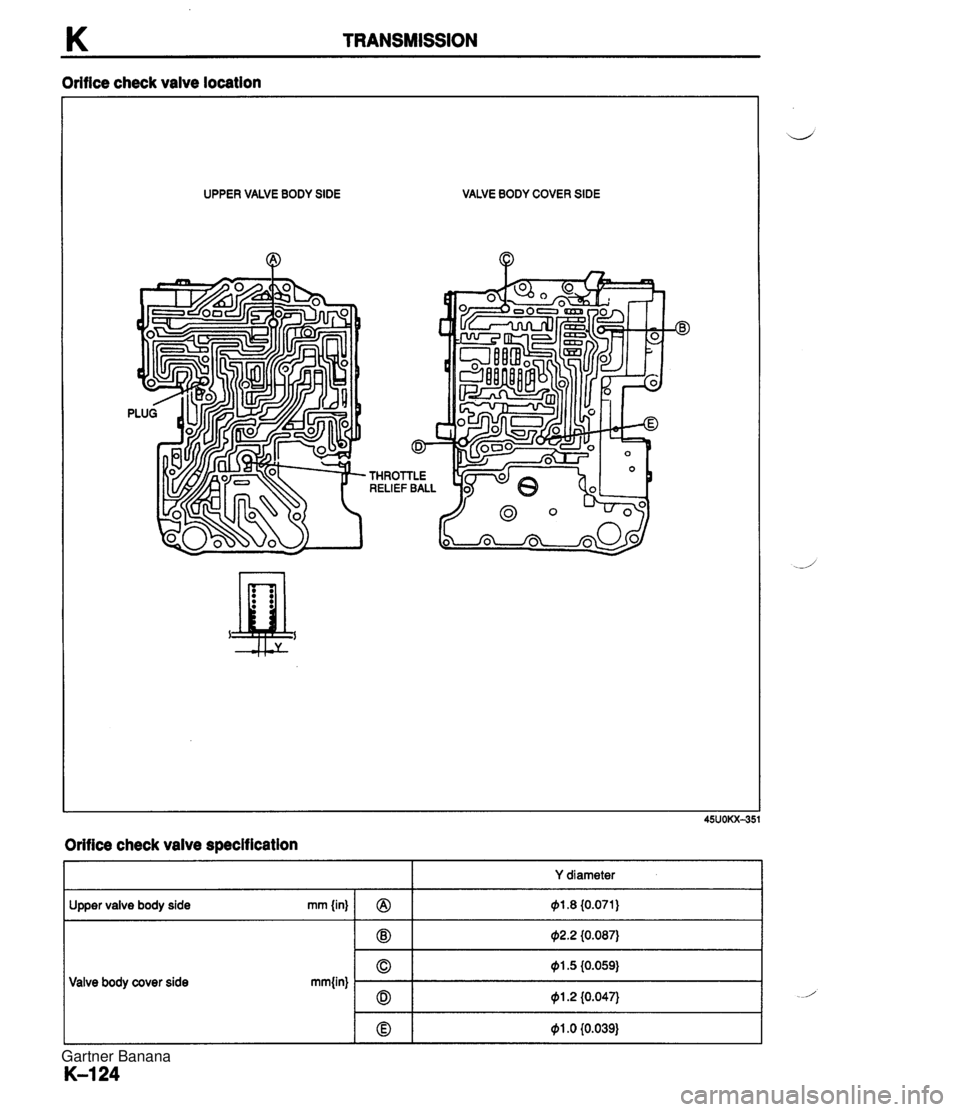

K TRANSMISSION Orifice check valve location UPPER VALVE BODY SlDE @3 VALVE BODY COVER SlDE Valve body cover side Orifice check valve specification Y diameter @1.8 {0.071) Upper valve body side mm{in) @) Gartner Banana

Page 526 of 1708

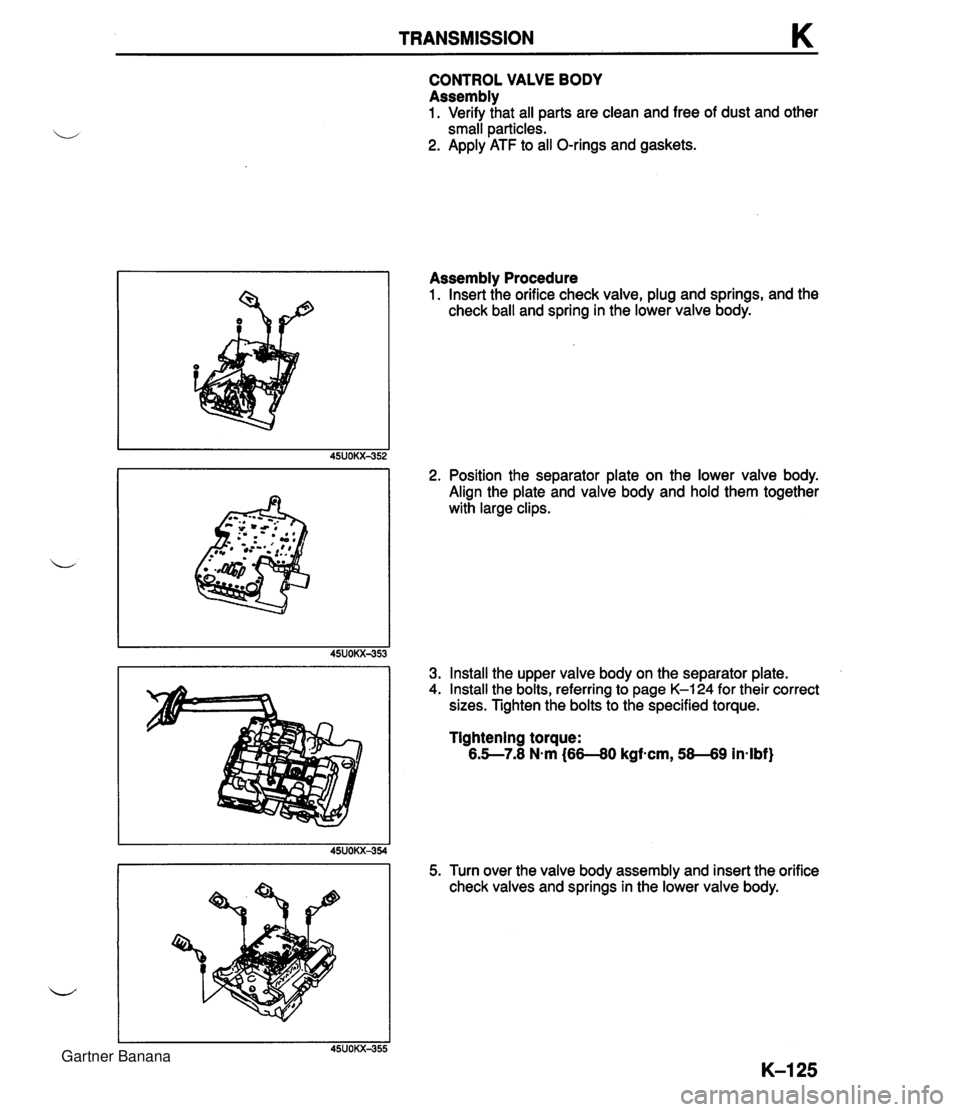

TRANSMISSION K CONTROL VALVE BODY Assembly 1. Verify that all parts are clean and free of dust and other small particles. 2. Apply ATF to all O-rings and gaskets. Assembly Procedure 1. Insert the orifice check valve, plug and springs, and the check ball and spring in the lower valve body. 2. Position the separator plate on the lower valve body. Align the plate and valve body and hold them together with large clips. 3. Install the upper valve body on the separator plate. 4. Install the bolts, referring to page K-124 for their correct sizes. Tighten the bolts to the specified torque. Tightening torque: 6.5--7.8 N-m (6-0 kgf-cm, 5-9 in-lbf) 5. Turn over the valve body assembly and insert the orifice check valves and springs in the lower valve body. Gartner Banana

Page 527 of 1708

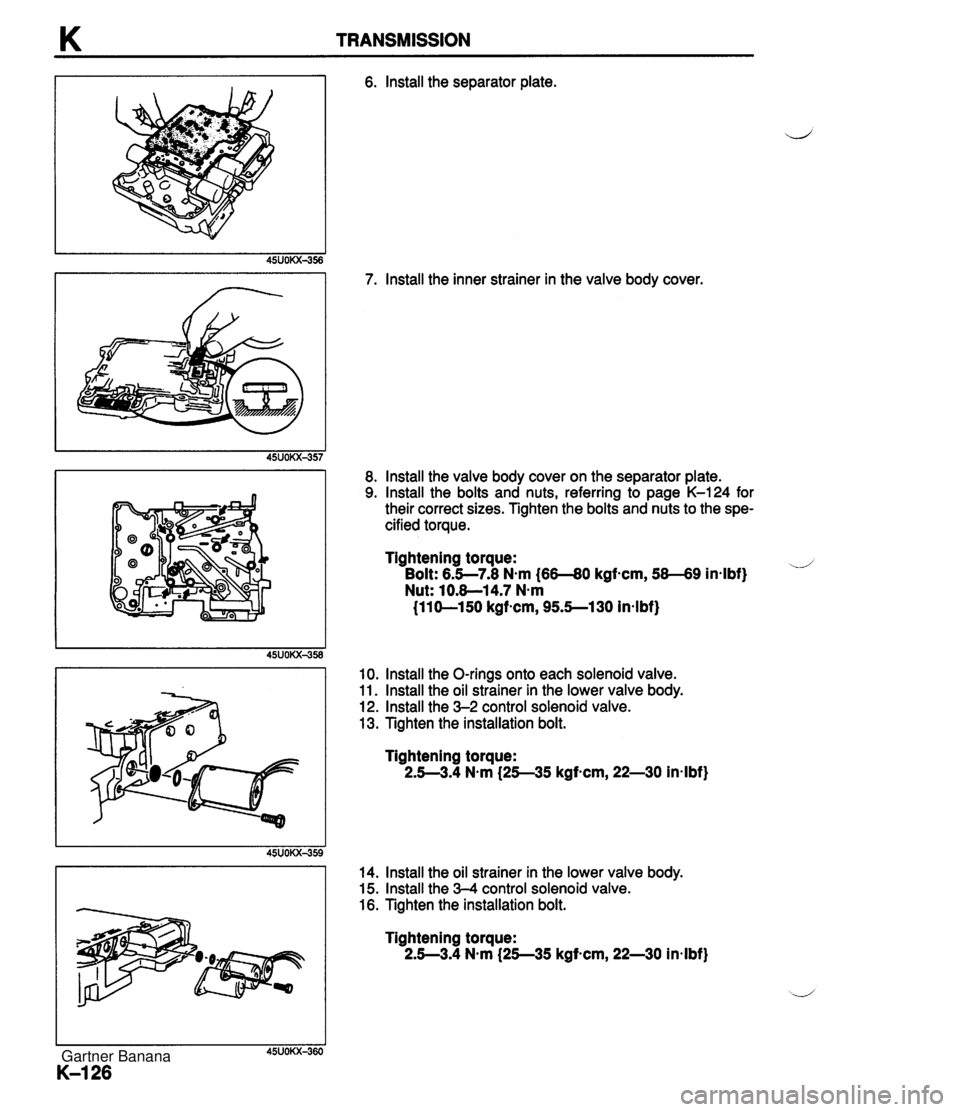

K TRANSMISSION 6. lnstall the separator plate. 7. lnstall the inner strainer in the valve body cover. 8. lnstall the valve body cover on the separator plate. 9. lnstall the bolts and nuts, referring to page K-124 for their correct sizes. Tighten the bolts and nuts to the spe- cified torque. Tightening torque: d Bolt: 6.5--7.8 N.m (66-80 kgfecm, 58-69 in-lbf) Nut: 10.8-14.7 Nem (11 0-150 kgf-cm, 95.5-1 30 in-lbf) 10. lnstall the O-rings onto each solenoid valve. 11. lnstall the oil strainer in the lower valve body. 12. lnstall the 3-2 control solenoid valve. 13. Tighten the installation bolt. Tightening torque: 2.5--3.4 N.m (25-35 kgf-cm, 22-30 in4bf) 14. lnstall the oil strainer in the lower valve body. 15. lnstall the 3-4 control solenoid valve. 16. Tighten the installation bolt. Tightening torque: 2.5--3.4 N-m (25--35 kgf-cm, 22-30 in-lbf) Gartner Banana

Page 528 of 1708

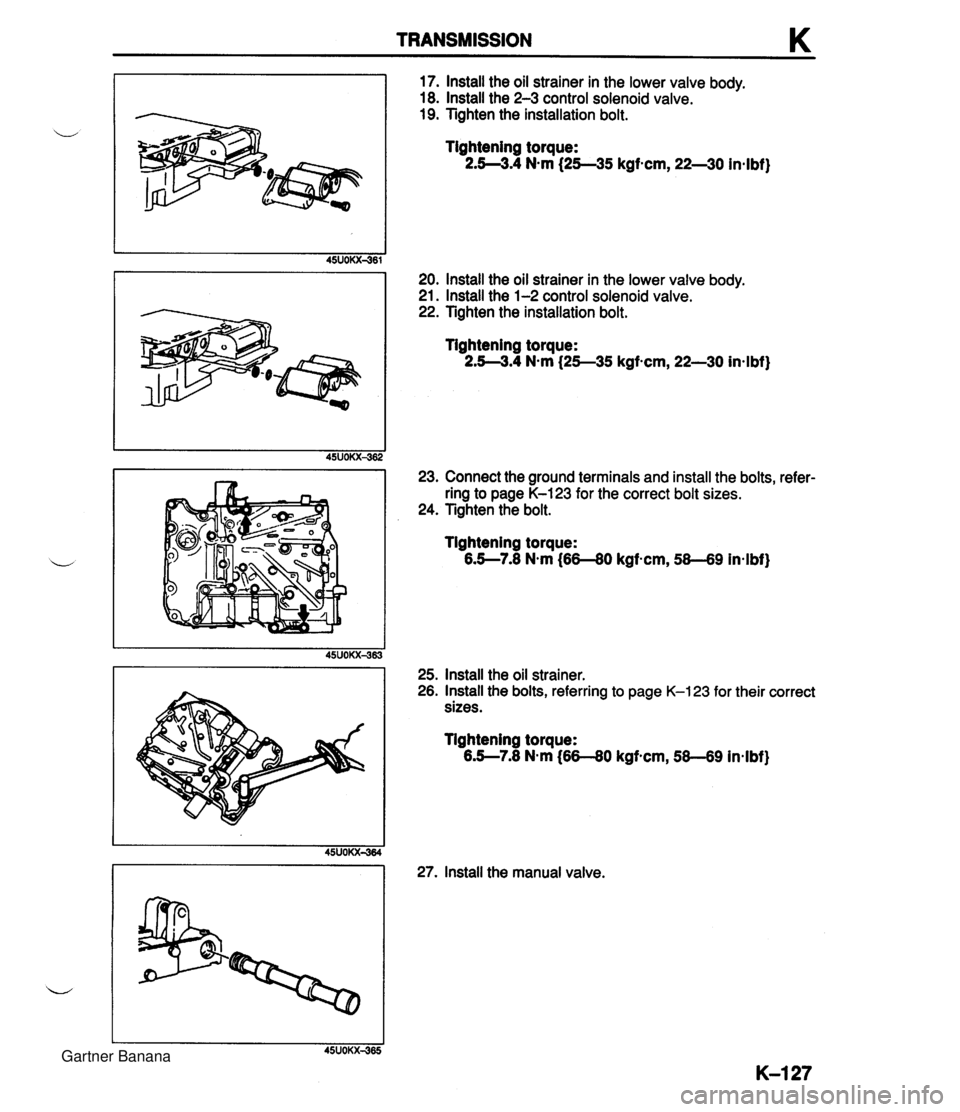

TRANSMISSION K 17. lnstall the oil strainer in the lower valve body. 18. lnstall the 2-3 control solenoid valve. 19. Tighten the installation bolt. Tightening torque: 2.5--3.4 N-m (2545 kgf-cm, 22--30 in4bf) 20. lnstall the oil strainer in the lower valve body. 21. lnstall the 1-2 control solenoid valve. 22. Tighten the installation bolt. Tightening torque: 2.54.4 N-m {25--35 kgf-cm, 22-30 inslbf) 23. Connect the ground terminals and install the bolts, refer- ring to page K-123 for the correct bolt sizes. 24. Tighten the bolt. Tightening torque: 6.5--7.8 N.m (66-80 kgf-cm, 58-69 in-lbf) 25. lnstall the oil strainer. 26. lnstall the bolts, referring to page K-123 for their correct sizes. Tightening torque: 6.5--7.8 N-m (66-80 kgf-cm, 58-69 in-lbf) 27. lnstall the manual valve. Gartner Banana

Page 529 of 1708

K TRANSMISSION On-vehicle Removal 1. Disconnect the negative battery cable. 2. On level ground, jack up the vehicle and support it evenly on safety stands. w 3. Remove the exhaust pipe. (Refer to page K-45.) Warning When the transmission and the ATF are hot, they can cause burns to the skin. Allow the transmis- sion and the ATF to cool before doing this proce- dure. 4. Loosen the oil pan installation bolts, and drain the ATF into a container. 5. Disconnect the vacuum hose. 6. Remove the vacuum diaphragm, O-rings, and vacuum diaphragm rod. 7. Remove the oil pan, and the gasket. 8. Disconnect the solenoid valve connector. 9. Remove the harness from the bracket. 10. Remove the control valve body assembly. Gartner Banana

Page 530 of 1708

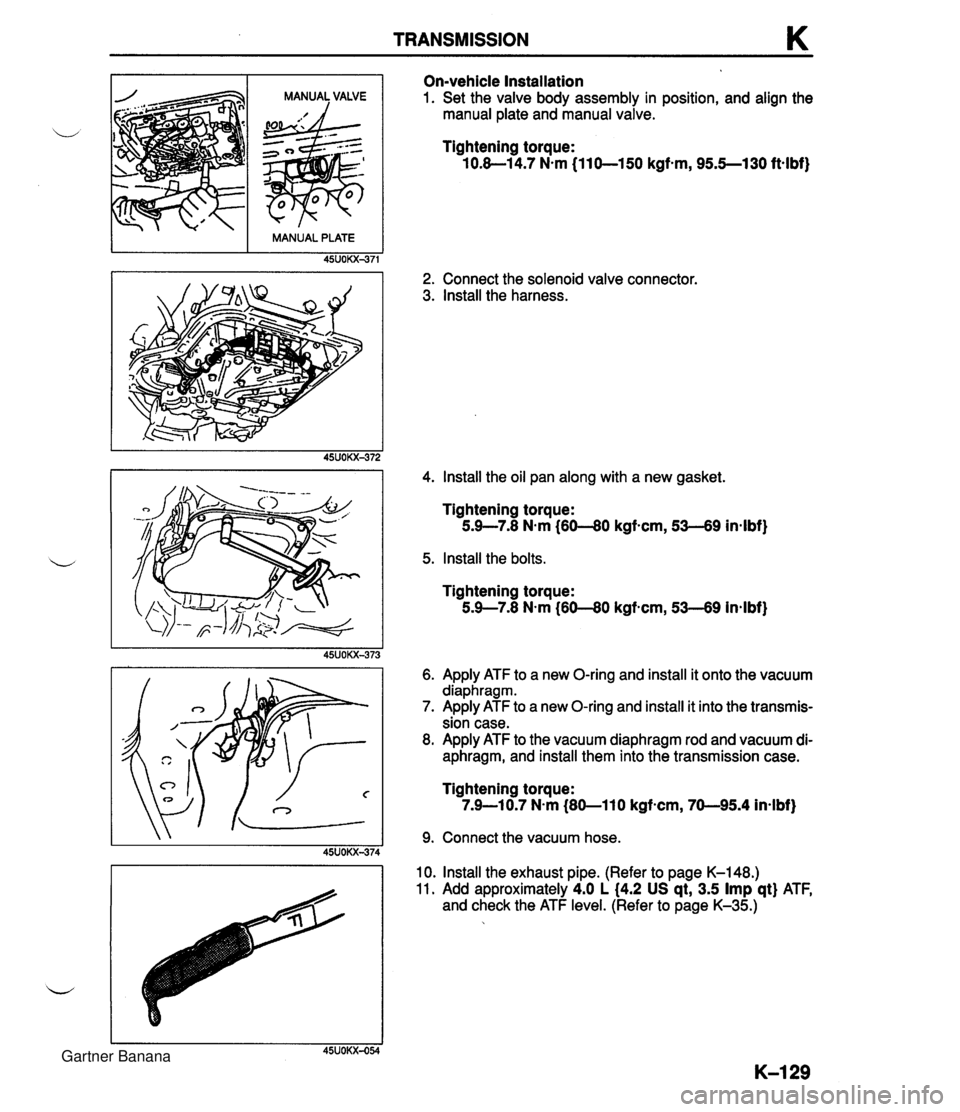

TRANSMISSION K On-vehicle Installation 1. Set the valve body assembly in position, and align the manual plate and manual valve. Tightening torque: 10.8-1 4.7 N.m (11 0-150 kgf-m, 95.5--130 ftalbf) 2. Connect the solenoid valve connector. 3. Install the harness. , . 4. Install the oil pan along with a new gasket. MANUAL PLATE Tightening torque: 5.9-7.8 N.m (60-80 kgf-cm, 53-69 in4bf) 45UOKX-371 5. Install the bolts. Tightening torque: 5.9-7.8 Nsm (60--80 kgf-cm, 53--69 inalbf) 6. Apply ATF to a new O-ring and install it onto the vacuum diaphragm. 7. Apply ATF to a new O-ring and install it into the transmis- sion case. 8. Apply ATF to the vacuum diaphragm rod and vacuum di- aphragm, and install them into the transmission case. Tightening torque: 7.9-1 0.7 N-m (80-1 10 kgf-cm, 70-95.4 in-lbf) 9. Connect the vacuum hose. 10. Install the exhaust pipe. (Refer to page K-148.) 11. Add approximately 4.0 L (4.2 US qt, 3.5 Imp qt) ATF, and check the ATF level. (Refer to page K-35.) Gartner Banana