transmission MAZDA MX-5 1994 Manual PDF

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 416 of 1708

ON-BOARD DIAGNOSIS SYSTEM K :TIC TROUBLE CODE No.55 VEHICLE SPEED PULSE GENERATOR ACTION Repair or replace connector INSPECTION control module (transmission) connector or terminal? I (+) term. 1 (-) term. I Voltage (v)( Condition I Are there any poor connections at vehicle speed pulse generator and powertrain No ' Go to next step Connect a circuit tester to terminal as shown Is input voltage of vehicle speed pulse generator at powertrain control module (transmission) OK? page K45 Engine Yes Engine I o ( stopped ( Yes Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 2J and ter- minal 2L OK? Go to step 5 I No I Go to next step Yes Go to step 5 Resistance: 200--400a Disconnect vehicle speed pulse genera- tor connector Is resistance between terminal E and ter- minal F OK? page K41 Resistance: 200--400n Disconnect the negative battery cable for at least 20 seconds and depress the brake mdal Sonnect the battery cable and recheck for jiagnostic trouble code Is diagnostic trouble code displayed? page K-21 45UOKX-019 Yes No Yes No Check wiring and connectors form powertrain control module (transmission) vehicle speed pules generator If OK, go to next step If not OK, repair wiring and/or connector Replace pulse generator Replace powertrain control module (transmission) us page K-45 Intermittent poor connection Check for cause Gartner Banana

Page 417 of 1708

K ON-BOARD DIAGNOSIS SYSTEM 1 KGNOSTIC TROUBLE CODE ~0.60 1-2 SHIFT SOLENOID VALVE INSPECTION Are there any poor connections at sole- noid valve and powertrain control module (transmission) connectors? shown Is output voltage of 1-2 shift solenoid valve at powertrain control module (trans- mission) OK? page K45 Bt: Battery positive voltage I (+) term. I (-) term. 1 voltage (v)I Condltlon 1 r B+ 1st gear 2E Ground o 2nd, 4GR Yes Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 2E and ground Resistance: 13-27Q Disconnect solenoid connector Is resistance between ground and termi- nal A of 1-2 shift solenoid valve OK? page K-42 Resistance: 13-278 Disconnect the negative battery cable for Yes at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code No Is diagnostic trouble code displayed? page K-21 ACTION Repair or replace connector GO to next step Check wiring and go to step 5 Go to next step Go to step 5 Go to next step Check wiring and connectors form powertrain control module (transmission) to 1-2 shift solenoid valve If OK, go to next step If not OK, repair wiring andlor connector Replace 1-2 shift solenoid valve Replace powertrain control module (transmission) page K-45 Intermittent poor connection Check for cause Gartner Banana

Page 418 of 1708

ON-BOARD DIAGNOSIS SYSTEM K ,GNOSTIC TROUBLE CODE N0.61 2-3 SHIFT SOLENOID VALVE INSPECTION Are there any poor connections at sole- noid valve and powertrain control module (transmission) connectors? Connect a -circuit tester to terminal as shown Is output voltage of 2-3 shift solenoid valve at powertrain control module (trans- amission) page K-45 r B+: Battery posltive voltage (+)term. I (-)term. I Voltage (v)I Condition Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 2G and ground OK? Resistance: 13--27R Disconnect solenoid connector Is resistance between ground and termi- nal B of 2-3 shift solenoid valve OK? page K-42 Resistance: 13-2721 ACTION Yes No 5 Repair or replace connector Go to next step Disconnect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code Is diagnostic trouble code displayed? page K-21 Check wiring and go to step 5 Yes No Go to next step Go to step 5 Go to next step Check wiring and connectors form powertrain control module (transmission) to 2-3 shift solenoid valve If OK, go to next step If not OK, repair wiring andlor connector - Replace 2-3 shift solenoid valve Replace powertrain control module (transmission) as page K-45 Intermittent poor connection Check for cause Gartner Banana

Page 419 of 1708

ON-BOARD DIAGNOSIS SYSTEM DIAGNOSTIC TROUBLE CODE No.62 3-4 SHIFT SOLENOID VALVE STEP 1 INSPECTION Are there anv Door connections at sole- noid valve a& 'powertrain control module (transmission) connectors? Connect a circuit tester to terminal as shown Is output voltage of 3-4 shift solenoid valve at ~owertrain control module (trans- mission) (+) term. If page K-45 B+: Battery posltive voltage -. - (-) term. I Voltage (v)I Condltlon I 1st 2nd, Ground Disconnect 20-pin powertrain control module (transmission) connector Is resistance between terminal 21 and ground OK? Resistance: 13-27R Disconnect solenoid connector Is resistance between ground and termi- nal B of 3-4 shift solenoid valve OK? page K-42 Resistance: 13-278 Disconnect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code Is diagnostic trouble code displayed? page K-21 Yes ACTION Repair or replace connector No Go to next step No Go to next step Yes Check wiring and connectors form powertrain control module (transmission) to 3-4 shift solenoid valve If OK, go to next step If not OK, repair wiring and/or connector Replace 3-4 shift solenoid valve Go to step 5 No Go to next step Yes Replace powertrain control module (transmission) a page K45 No Intermittent poor connection Check for cause Gartner Banana

Page 420 of 1708

ON-BOARD DIAGNOSIS SYSTEM - DIAGNOSTIC TROUBLE CODE No.63 LOCKUP CONTROL SOLENOID VALVE STEP INSPECTION ACTION re there any poor connections at sole- id valve and powertrain control module ransmission) connectors? Yes Repair or replace connector Go to next step onnect a circuit tester to terminal as 10wn output voltage of lockup control sole- >id valve at powertrain control module ransmission) Yes Check wiring and go to step 5 page K-45 (+) term. 2K B+: Battery positive voltage Go to next step (-)term. Lockup Ground Solenoid - - isconnect 20-pin powertrain control ~odule (transmission) connector , resistance between terminal 2K and ,ound OK? Voltage (V) B+ Yes Condition Solenoid ON, Go to step 5 No Yes Go to next step Resistance: 13--2752 isconnect solenoid connector resistance between ground and termi- 31 B of lockup control solenoid valve OK? page K-42 Check wiring and connectors form powertrain control module (transmission) to lockup control solenoid valve If OK, go to next step If not OK, repair wiring and/or connector Resistance: 13--2752 No Yes No Replace lockup control solenoid valve isconnect the negative battery cable for :least 20 seconds and depress the brake sdal onnect the battery cable and recheck for ~de diagnostic trouble code displayed? page K-21 Replace powertrain control module (transmission) page K-45 Intermittent poor connection Check for cause Gartner Banana

Page 421 of 1708

K ON-BOARD DIAGNOSIS SYSTEM DIAGNOSTIC TROUBLE CODE N0.64 3-2 CONTROL SOLENOID VALVE ACTION STEP I INSPECTION Yes 1 3epair or replace connector Are there any poor connections at sole- noid valve and powertrain control module (transmission) connectors? 30 to next step shown Is output voltage of 3-2 control solenoid valve at powertrain control module (trans- mission) OK? Yes ;heck wiring and go to step 5 page K-45 B4 (-) term, Battery positive voltage Voltage (V) Condition downshift Other condition (+) term. 2M 30 to next step Grounc I I I I I 3 1 Disconnect 20-pin powertrain control Yes 30 to step 5 module (transmission) connector Is resistance between terminal 2M and ground Resistance: 13-2752 30 to next step Disconnect solenoid connector Is resistance between ground and termi- nal A of 3-2 control solenoid valve OK? page K-42 Yes ;heck wiring and connectors form powertrain control module transmission) to 3-2 control solenoid valve If OK, go to next step If not OK, repair wiring and/or connector Resistance: 13-2752 qeplace 3-2 control solenoid valve Disconnect the negative battery cable for at least 20 seconds and depress the brake pedal Connect the battery cable and recheck for code Is diagnostic trouble code displayed? page K-21 Yes 3eplace powertrain control module (transmission) page K-45 ntermittent poor connection :heck for cause Gartner Banana

Page 424 of 1708

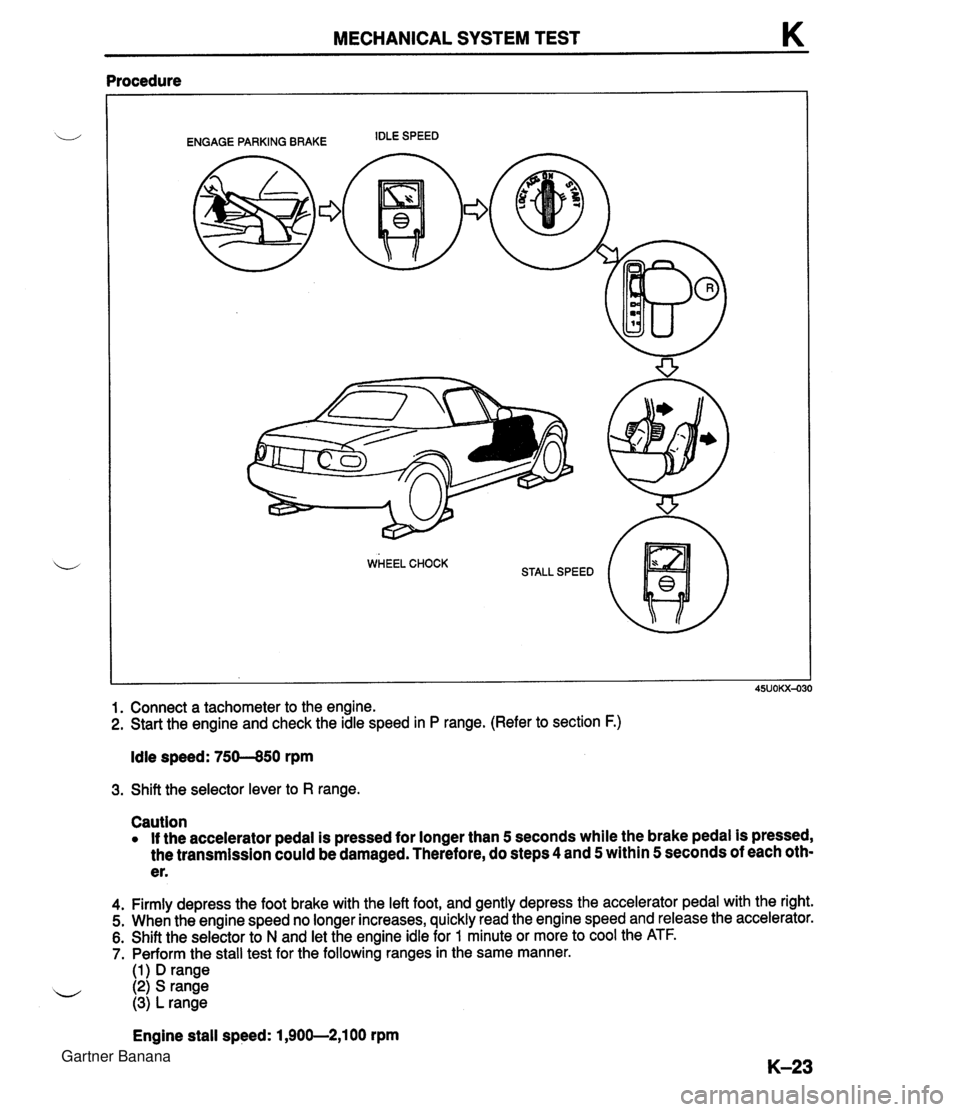

MECHANICAL SYSTEM TEST K Procedure ENGAGE PARKING BRAKE IDLE SPEED 1. Connect a tachometer to the engine. 2. Start the engine and check the idle speed in P range. (Refer to section F.) Idle speed: 750-450 rpm 3. Shift the selector lever to R range. Caution If the accelerator pedal is pressed for longer than 5 seconds while the brake pedal is pressed, the transmission could be damaged. Therefore, do steps 4 and 5 within 5 seconds of each oth- er. 4. Firmly depress the foot brake with the left foot, and gently depress the accelerator pedal with the right. 5. When the engine speed no longer increases, quickly read the engine speed and release the accelerator. 6. Shift the selector to N and let the engine idle for 1 minute or more to cool the ATF. 7. Perform the stall test for the following ranges in the same manner. (1 ) D range u (2) S range (3) L range Engine stall speed: 1,90&2,lOO rpm Gartner Banana

Page 425 of 1708

K MECHANICAL SYSTEM TEST Evaluation of Stall Test 4bove specification Nithin specification In all ranges In D (Normal), and L ranges In D (Normal) range only In R range only 3elow specification Possible cause I Worn oil Dumo Oil leakage from oil pump, control Insufficient line pressure Direct clutch and overdrive one-way clutch sli~~ina Rear clutch slipping One-way clutch slipping Low and reverse brake slipping Front clutch slipping Perform road test to determine if this is caused by low and reverse brake or front clutch as follows: a) Effective engine braking in L range . . . . . . . . . . Front clutch b) No enaine brakina in L range . . . . . Low and reverse brake All ~hiftcont~elements within transmission are functioning normally Engine out of tune One-wav clutch sli~~ina within toraue converter Gartner Banana

Page 427 of 1708

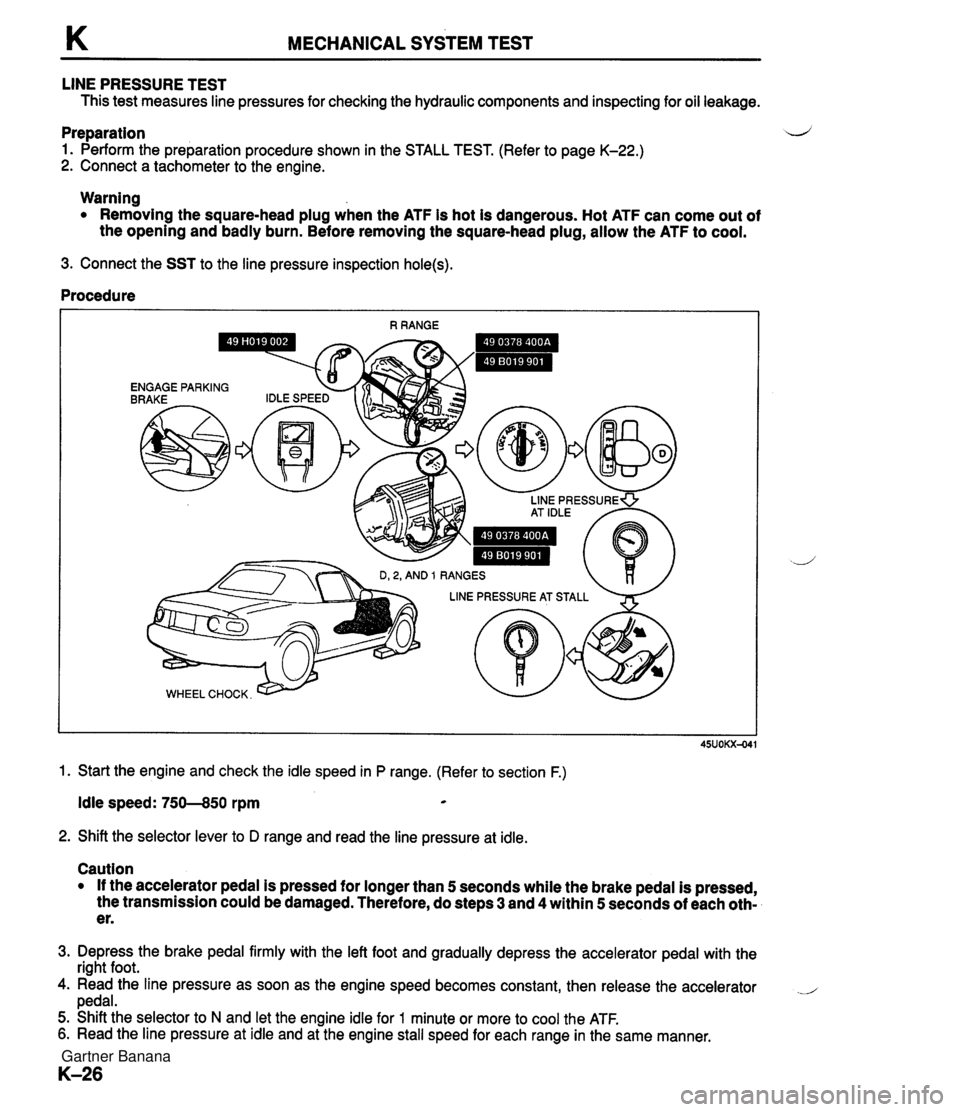

K MECHANICAL SYSTEM TEST LINE PRESSURE TEST This test measures line pressures for checking the hydraulic components and inspecting for oil leakage. Preparation d 1. Perform the preparation procedure shown in the STALL TEST. (Refer to page K-22.) 2. Connect a tachometer to the engine. Warning Removing the square-head plug when the ATF is hot is dangerous. Hot ATF can come out of the opening and badly burn. Before removing the square-head plug, allow the ATF to cool. 3. Connect the SST to the line pressure inspection hole(s). Procedure 1. Start the engine and check the idle speed in P range. (Refer to section F.) Idle speed: 750--850 rpm * 2. Shift the selector lever to D range and read the line pressure at idle. Caution If the accelerator pedal is pressed for longer than 5 seconds while the brake pedal is pressed, the transmission could be damaged. Therefore, do steps 3 and 4 within 5 seconds of each oth- er. 3. Depress the brake pedal firmly with the left foot and gradually depress the accelerator pedal with the right foot. 4. Read the line pressure as soon as the engine speed becomes constant, then release the accelerator .- pedal. 5. Shift the selector to N and let the engine idle for 1 minute or more to cool the ATF. 6. Read the line pressure at idle and at the engine stall speed for each range in the same manner. Gartner Banana

Page 428 of 1708

MECHANICAL SYSTEM TEST K Specified line pressure: 7. Cool the transmission and reconnect the SST to the line pressure inspection hole. 8. Connect a vacuum pump to the vacuum diaphragm and place the pump inside the vehicle. 9. Shift the selector lever to R range. 10. Read the line pressure at idle as described below. Range D range S range L range R range Specified line pressure: Pressure kPa {kgflcm2, psi] Idle 285--362 i2.9-3.7,42-52) 785--921 (8.G9.4, 11 4--133) 295-392 {3.0-4.0,43--56) 775--970 (7.9--9.9, 1 1 S140) Vacuum Atmospheric pressure 1 400 mmHg (15.7 inHg} I 393490 (4.0-5.0,57-71) I Stall 79S912 18.1-9.3, 11 &I321 795--91 2 {8.1-9.3, 11 6--132) 883-1,078 l9.0-11 .O, 128-1 56) 1,972-2,167 (20.1-22.1,286--314) Line pressure kPa {kgf/cm2, psi) 883-1,078 {9.&11 .O, 128--156) 200 mmHg (7.87 inHg) - Evaluation of Line Pressure Test 687-784 17.0-4.0, 10-113) Below specification I Excessive line pressure Condition I Possible Cause In all ranges Worn oil pump Fluid leakage from the oil pump, control valve body, and/or transmission case Stuck pressure regulator valve Fluid leakage from the direct clutch and/or fourth gear band servo release side hydraulic circuit In D (Normal), S (Normal), and L Fluid leakage from the rear clutch hydraulic circuit ranaes I Stuck pressure modifier valve In S (Normal & Hold) and L ranges I Fluid leakage from the throttle backup valve hydraulic circuit In L and R ranges I Fluid leakage from the low and reverse hydraulic circuit In S range (Hold) In R range only Stuck throttle backup valve Stuck backup control valve Backup control function (electronic) not operating properly Stuck pressure modifier valve Stuck backup control valve Fluid leakage from the front clutch and/or 2nd band servo release side hydraulic circuit Below specification Excessive pressure In all ranges Same as Line Pressure Test Leaking or disconnected vacuum hose Leaking vacuum diaphragm Diaphragm rod too long Stuck vacuum throttle valve Stuck Dressure renulator valve I In S ranae (Hold) I Stuck pressure modifier valve Gartner Banana