lock MAZDA MX-5 1994 Manual Online

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 389 of 1708

TRANSMISSION 1. Clutch hub 2. Synchronizer key 3. Clutch hub sleeve b 4. Synchronizer key springs 5. 4th synchronizer ring 6. Bearing 7. Main drive gear 8. Bearing housing assembly 9. Washer 10. Mainshaft gear assembly Assembly Note .................. below 1 1 . Spacer 12. Countershaft .................. Assembly Note below 13. Counter reverse gear 14. Washer 15. Bearing race 16. Bearing 17. Reverse gear 18. Reverse synchronizer ring 19. Clutch hub assembly (5thlReverse) 20. Locknut (Mainshaft) .................. Assembly Note below 21. 5th synchro-niter ring 22. 5th gear 23. Steel ball 24. Thrust lock washer .............. Assembly Note page J-36 25. C-washer .............. Assembly Note page J-36 26. Retaining ring .............. Assembly Note page J-36 27. Spacer 28. Counter 5th gear 29. Mainshaft rear bearing .............. Assembly Note page J-36 30. C-washer .............. Assembly Note page J-36 31. Retaining ring .............. Assembly Note page J-36 32. Washer .............. Assembly Note page J-36 33. Snap ring 34. Countershaft rear bearing .............. Assembly Note page J-36 35. Locknut (Countershaft) .............. Assembly Note page J-37 45UOJX437 Assembly note Mainshaft and countershaft 1. Place the mainshaft gear assembly and the countershaft on the bearing housing. 2. Use a suitable bar to press in the countershaft. Locknut (Mainshaft) 1. Secure the bearing housing assembly in a vise. 2. Shift the clutch hub sleeves into 1 st and Reverse gears to lock the rotation of the mainshaft. 3. Install a new locknut and tighten it by using the SST. Tightening torque: 128-235 N.m (13-24 kgf.m, 95-173 ftdbf) 4. Use a chisel to stake the locknut. Gartner Banana

Page 390 of 1708

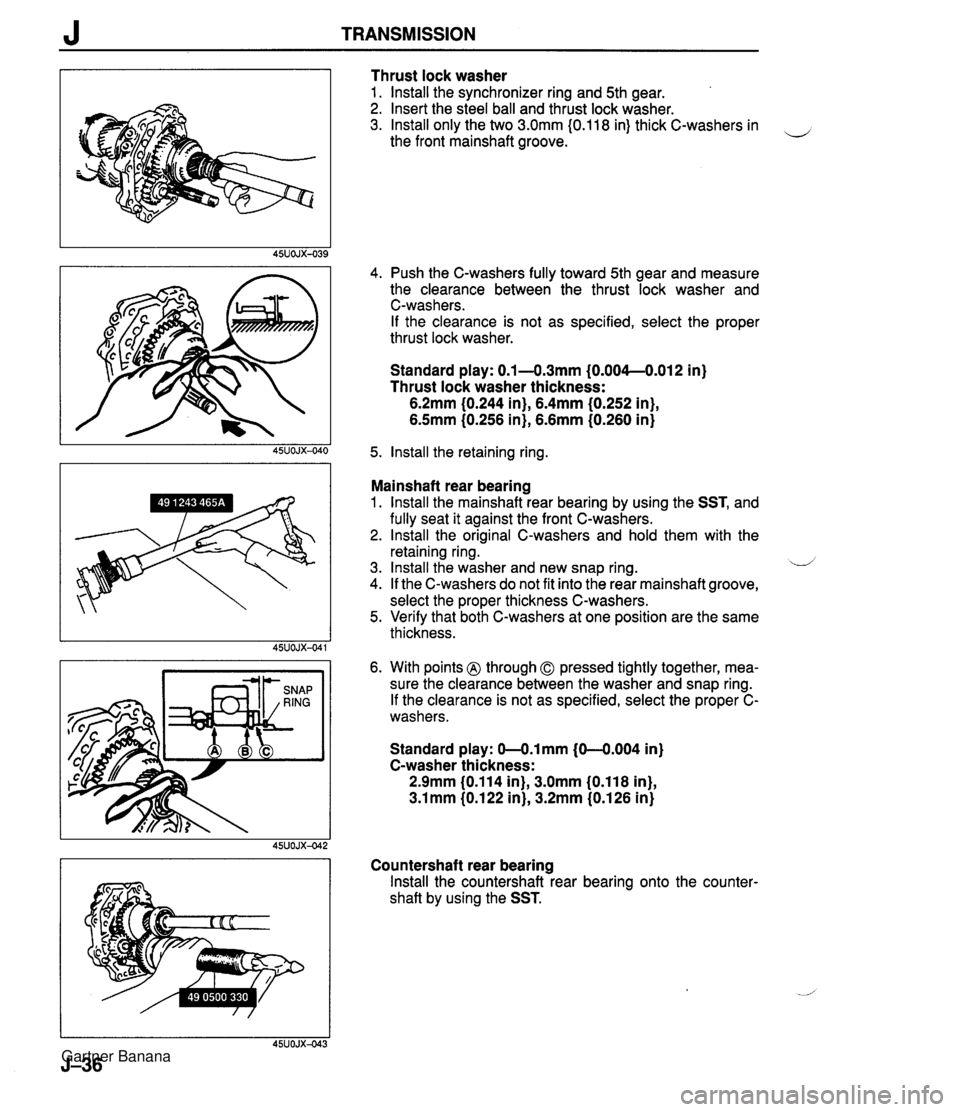

J TRANSMISSION Thrust lock washer 1. lnstall the synchronizer ring and 5th gear. 2. Insert the steel ball and thrust lock washer. 3. lnstall only the two 3.0mm I0.118 in) thick C-washers in the front mainshaft groove. 4. Push the C-washers fully toward 5th gear and measure the clearance between the thrust lock washer and C-washers. If the clearance is not as specified, select the proper thrust lock washer. Standard play: 0.1 -4.3mm {O.OO4--O.Ol2 in) Thrust lock washer thickness: 6.2mm (0.244 in), 6.4mm (0.252 in}, 6.5mm (0.256 in), 6.6mm (0.260 in} 5. lnstall the retaining ring. Mainshaft rear bearing 1. lnstall the rnainshaft rear bearing by using the SST, and fully seat it against the front C-washers. 2. lnstall the original C-washers and hold them with the retaining ring. 3. lnstall the washer and new snap ring. u 4. If the C-washers do not fit into the rear mainshaft groove, select the proper thickness C-washers. 5. Verify that both C-washers at one position are the same thickness. 6. With points @ through 0 pressed tightly together, mea- sure the clearance between the washer and snap ring. If the clearance is not as specified, select the proper C- washers. Standard play: 0-0.lmm (0-4.004 in) C-washer thickness: 2.9mm (0.114 in), 3.0mm (0,118 in), 3.1 mm (0.1 22 in), 3.2mm (0.1 26 in) Countershaft rear bearing lnstall the countershaft rear bearing onto the counter- shaft by using the SST. Gartner Banana

Page 391 of 1708

TRANSMISSION J & BEARING HOUSING Locknut (Countershaft) 1. Shift the clutch hub sleeves into 1 st and Reverse gears to lock the rotation of the mainshaft. 2. Connect the SST to the mainshaft and secure it in a vise. 3. Install a new locknut and tighten it. Tightening torque: 128-1 96 N.m (13-20 kgf-m, 95--144 ft-lbf) 4. Use a chisel to stake the locknut. Gartner Banana

Page 392 of 1708

J TRANSMISSION Shift Fork and Shift Rod Parts Assemble in the order shown in the figure, referring to Assembly Note. 1. Spring and ball 13. Cap plug .............. Assembly Note page J-39 14. Roll pin .............. 2. 5thlReverse shift fork Assembly Note page J-40 .............. Assembly Note page J-39 15. Spring 3. 5thlReverse shift rod Assembly Note .............. page J-40 Assembly Note .............. page J-39 16. Spacer .............. 4. Interlock pin Assembly Note page J-40 .............. Assembly Note page J-39 17. Clip 5. 1 stl2nd shift fork Assembly Note .............. page J-40 Assembly Note .............. page J-40 18. Clip 6. 3rdl4th shift fork Assembly Note .............. page J-40 .............. Assembly Note page J-40 19. Clip .............. 7. Interlock pin Assembly Note page J-40 8. 3rdl4th shift rod 20. Intermediate housing Assembly Note .............. page J-40 Assembly Note .............. page J-41 9. Interlock pin 21. SthlReverse shift rod end Assembly Note .............. page J-40 22. 3rdl4th shift rod end 10. 1 stl2nd shift rod 23. 1 stl2nd shift rod end d 11. Ball and spring 24. Roll pin 12. Washer Assembly Note .............. page J-41 Gartner Banana

Page 393 of 1708

TRANSMISSION J Assembly note Spring and ball 1. Insert the spring and ball (SthIReverse) into the bearing housing. 2. Press down the spring and ball (5thlReverse) by using the SST and a screwdriver, and install the shift rod. Shift fork and rod Install the SthIReverse shift fork and 5thJReverse shift rod into the bearing housing. Interlock pin 1. Position the interlock pin into the bearing housing by using the SST. 2. Verify that the interlock pin is correctly installed. Gartner Banana

Page 394 of 1708

J TRANSMISSION CLUTCH SLEEVE SYNCHRONIZER KEY Shift fork and rod, interlock pin 1. Set the 1 stf2nd shift fork onto the 1 sV2nd clutch hub assembly. 2. Install the 3rdI4th shift fork and 3rdl4th shift rod, and ii install the interlock pin into the bearing housing as shown in the interlock pin assembly note. (Refer to page J-39.) Roll pin Install a new roll pin into each shift fork. The roll pin must be installed with the split facing as shown. Spring, spacer, clip 1. Slide the spring and spacer onto the 5thlReverse shift rod. While pressing the spacer, install a new clip. 2. Install new clips to the 3rdl4th shift rod and 1 sV2nd shift rod. 3. Verify that the centers of the shift fork and clutch hub sleeve are aligned properly< If they are not, select the proper washer to install between 1st gear and the mainshaft front bearing, and between reverse gear and the mainshaft front bearing. Gartner Banana

Page 400 of 1708

J TRANSMISSION -=DIFFERENTIAL MOUNTING SPACER 45UOJX-054 Installation note Transmission 1. Tilt the engine by pushing up on the front of the oil pan with a wooden block and a transmission jack. d 2. Support the transmission with a transmission jack. 3. Raise the transmission into place and install and tighten the installation bolts. Tightening torque: 64-89 N-m (6.5--9.1 kgf-m, 48-65 ft.lbf) Power plant frame (PPF) 1. Install the differential mounting spacer. Tightening torque: 38-51 N.m (3.8-5.3 kgf-m, 28-38 ft-lbf) 2. Support the transmission with a jack so that it is level. 3. Position the PPF and tighten the transmission-side bolts by hand. 4. Verify that the sleeve is installed into the block. 5. Install the spacer and reamer bolts in the forward hole, then hand tighten them. 6. Snugly install the power plant frame bracket. 7. Tighten the transmission-side bolts. Tightening torque: 104-123 N-m (10.S12.6 kgf.m, 76.7-91.1 ft.lbf) 8. Tighten the differential-side bolts. Tightening torque: 104-1 23 N-m (1 0.S12.6 kgf.m, 76.7-91.1 ft-lbf) Gartner Banana

Page 402 of 1708

Before beginning any service procedure. refer to section T of this manual for air bag system service warnings and audio antitheft system alarm conditions . AUTOMATIC TRANSMISSION INDEX ................................ K- 2 OUTLINE ............................. K- 3 SPECIFICATIONS ................... K- 3 ........... CROSS-SECTIONAL VIEW K- 4 POWER FLOW DIAGRAM ............ K- 5 OPERATION OF COMPONENTS ...... K- 5 FLUID PASSAGE LOCATIONS ........ K- 6 TROUBLESHOOTING .................. K- 8 GENERAL NOTES ................... K- 8 .......... QUICK DIAGNOSIS CHART K- 9 ON-BOARD DIAGNOSIS SYSTEM ...... K- 11 DESCRIPTION ...................... K- 11 PREPARATION ...................... K- 11 ....... DIAGNOSTIC TROUBLE CODE K- 11 .......... MECHANICAL SYSTEM TEST K- 22 PREPARATION ...................... K- 22 STALL TEST ........................ K- 22 TIME LAG TEST ..................... K- 25 LINE PRESSURE TEST .............. K- 26 ROAD TEST .......................... K- 29 D-RANGE TEST ..................... K- 29 S-RANGE TEST ..................... K- 31 ..................... L-RANGE TEST K- 32 . P-RANGE TEST ..................... K- 33 AUTOMATIC TRANSMISSION FLUID (ATF) ................................ K- 35 ATF ................................ K- 35 REPLACEMENT ..................... K- 37 ELECTRICAL SYSTEM COMPONENTS . . K- 38 PREPARATION ...................... K- 38 HOLD SWITCH ...................... K- 38 PARWNEUTRAL SWITCH ............ K- 39 .............. ATF THERMOSENSOR K- 41 VEHICLE SPEED PULSE GENERATOR ...................... K- 41 1-2 SHIFT. 2-3 SHIFT. 3-4 SHIFT. ... 3-2 CONTROL SOLENOID VALVE K- 42 LOCKUP CONTROL SOLENOID ....... VALVE ............................ K- 42 POWERTRAIN CONTROL MODULE (TRANSMISSION) .................. K- 43 TRANSMISSION ....................... K- 46 TRANSMISSION UNIT (REMOVAL) .... K- 46 TRANSMISSION UNlT (DISASSEMBLY) ................... K- 50 TORQUE CONVERTER .............. K- 61 OILPUMP .......................... K- 62 FOURTH GEAR CONNECTING SHELL AND FOURTH GEAR PLANETARY GEAR UNIT (FOURTH GEAR SUN GEAR. FOURTH GEAR PLANETARY PINION CARRIER. FOURTH GEAR CLUTCH HUB) ...... K- 67 DIRECT CLUTCH .................... K- 70 FOURTH GEAR BAND SERVO ........ K- 76 DRUM SUPPORT. ACCUMULATOR. AND FOURTH GEAR CASE ......... K- 79 2ND BAND SERVO .................. K- 83 FRONT CLUTCH .................... K- 86 REAR CLUTCH ...................... K- 91 CONNECTING SHELL AND FRONT PLANETARY GEAR UNlT (REAR CLUTCH HUB. FRONT PLANETARY PINION CARRIER. REAR SUN GEAR) ................. K- 96 REAR PLANETARY GEAR UNlT (CONNECTING DRUM. REAR PLANETARY PINION CARRIER. ONE-WAY CLUTCH) K- 98 LOW AND REVERSE BRAKE K-102 ................ ......... EXTENSION HOUSING AND PARKING MECHANISM ............. K-107 OIL SEAL ........................... K-ill CONTROL VALVE BODY ............. K-112 UPPER VALVE BODY ................ K-116 LOWER VALVE BODY ............... K-120 CONTROL VALVE BODY ............. K-125 VACUUM DIAPHRAGM ............... K-130 TRANSMISSION UNIT (ASSEMBLY) ... K-132 TRANSMISSION UNIT (INSTALLATION) ................... K-147 OIL COOLER .......................... K-151 REMOVAL I INSPECTION I INSTALLATION ..................... K-151 DRIVE PLATE ......................... K-152 PREPARATION ...................... K-152 REMOVAL 1 INSPECTION I INSTALLATION ..................... K-152 SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) ......... K-154 SHIFT-LOCK SYSTEM COMPONENTS K-154 TROUBLESHOOTING ................ K-155 SHIFT-LOCK ........................ K-157 EMERGENCY OVERRIDE BUTTON ... K-157 KEY INTERLOCK .................... K-157 KEY INTERLOCK SOLENOID ......... K-157 KEY INTERLOCK UNIT ............... K-158 P RANGE SWITCH .................. K-159 SHIFT-LOCKACTUATOR ............. K-159 SELECTOR LEVER .................. K-161 HYDRAULIC CIRCUIT .................. K-168 P RANGE ........................... K-168 R RANGE ........................... K-169 N RANGE; BELOW 7 kmlh I4.34 mph) . K-170 N RANGE; ABOVE 9 kmlh (5.58 mph} . K-171 D RANGE; 1 ST GEAR ................ K-172 D RANGE; 2ND GEAR ............... K-173 D RANGE; THIRD GEAR ............. K-174 D RANGE; FOURTH GEAR. LOCKUP ON ....................... K-175 S RANGE; 1 ST GEAR ................ K-176 S RANGE; 2ND GEAR ............... K-177 S RANGE; THIRD GEAR ............. K-178 L RANGE; 1 ST GEAR ................ K-179 L RANGE; 2ND GEAR ................ K-180 Gartner Banana

Page 404 of 1708

INDEX, OUTLINE K 1. Hold switch lnspection . . . . . . . . . . . . . . . . page K- 38 Replacement . . . . . . . . . . . . . page K- 39 b 2. ParkINeutral switch lnspection . . . . . . . . . . . . . . . . page K- 39 Adjustment . . . . . . . . . . . . . . . page K- 40 3. Vehicle speed pulse generator lnspection . . . . . . . . . . . . . . . . page K- 41 Replacement . . . . . . . . . . . . . page K- 42 4. ATF thermosensor lnspection . . . . . . . . . . . . . . . . page K- 41 Replacement . . . . . . . . . . . . . page K- 41 5. 1-2 shift, 2-3 shift, 3-4 shift, 3-2 control solenoid valves lnspection . . . . . . . . . . . . . . . . page K- 42 6. Lockup control solenoid valve lnspection . . . . . . . . . . . . . . . . page K- 42 7. Powertrain control module (Transmission) lnspection . . . . . . . . . . . . . . . . page K- 43 Replacement . . . . . . . . . . . . . page K- 45 OUTLINE SPECIFICATIONS 8. Automatic transmission Removal . . . . . . . . . . . . . . . . . page K- 46 Disassembly . . . . . . . . . . . . . page K- 50 Assembly . . . . . . . . . . . . . . . . page K-132 lnstallation . . . . . . . . . . . . . . . page K-147 9. Oil cooler Removal 1 Inspection / lnstallation . . . . . . . . . . . . . . page K-151 10. Drive plate Removal 1 Inspection 1 lnstallation . . . . . . . . . . . . . . page K-152 11. P range switch lnspection . . . . . . . . . . . . . . . . page K-159 12. Shift-lock actuator lnspection . . . . . . . . . . . . . . . . page K-159 13. Selector lever lnspection . . . . . . . . . . . . . . . . page K-161 Adjustment . . . . . . . . . . . . . . . page K-160 Removal / Inspection / lnstallation . . . . . . . . . . . . . . page K-163 Disassembly 1 Inspection / Assembly . . . . . . . . . . . . . . . page K-166 - Model Item - Gear ratio NC4A-EL Torque converter stall torque ratio 1 st 1.900 : 1 2.458 4GR Reverse 0.720 2.182 Number of driveldriven plates Servo diameter (Piston outer diameterketainer inner diam- eter) mm{in} Direct clutch Front clutch Rear clutch Automatic transmission fluid (Am 212 315 515 Low and reverse brake Fourth gear band servo 2nd band servo 4/4 56/36 {2.205/1.417} 72/50 {2.835/1.969} Dexron@II or M-111 7.3 {7.7,6.4} 4.0 {4.2,3.5} Type Capacity L {US qt, Imp qtI Total oil pan Gartner Banana

Page 405 of 1708

DIRECT CLUTCH LOCKUP PISTON I FOURTH GEAR ONE-WAY CLUTCH / FRONT CLUTCH FRONT PLANETARY GEAR UNlT SENSING ROTOR / 1NPu;sHAn / vE,',lcLE AND BMKE PULSE GENERATOR I 1 INTERMEDIATE SHAFT REAR PLANETARY GEAR UNIT FOURTH GEAR PLANETARY I CONTROL VALVE ASSEMBLY TORQUE CONVERTER REAR CLUTCH Gartner Banana