lock MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 547 of 1708

K TRANSMISSION 52. Apply ATF to a new O-ring and install it onto the vehicle speed pulse generator. 53. Apply locking compound to the mounting bolt threads, then install the vehicle speed pulse generator. Tightening torque: 7.9-10.7 N-m (80-110 kgtcm, 70-95.4 inmlbf) 54. Apply ATF to the new O-rings and install them into the transmission case. 55. Install the lockup control solenoid. 56. Rotate the manual shaft fully rearward; then return it two notches to the N position. 57. Loosely tighten the parwneutral switch nuts. 58. Remove the screw on the switch body and move the parklneutral switch so that the screw hole on the switch body is aligned with the small hole inside the switch. - Check their alignment by inserting a 2.0mm (0.0079 in) diameter pin into the holes. 59. Tighten the switch attaching nuts. 60. Remove the pin, and tighten the screw into the hole. Tightening torque: 5.0--6.8 Nem (50-70 kgfecrn, 44-60 in-lbf) 61. Ensure that the torque converter is installed correctly by measuring the distance (A) between the end of the torque converter and the end of the converter housing. "A": 22.5mm (0.89 in) 62. Remove the transmission from the engine stand. Gartner Banana

Page 549 of 1708

K TRANSMISSION 1. Transmission 10. ATF thermosensor connector Installation Note . . . . . . . . . . page K-149 11. Solenoid connector 2. Transmission mount bolt 12. Vehicle speed pulse generator connector 3. Starter 13. Parklneutral switch connector 4. Torque converter bolt 14. Vacuum hose lnstallation Note . . . . . . . . . . page K-149 15. Speedometer cable 5. Under cover 16. Propeller shaft 6. Power plant frame (PPF) Installation . . . . . . . . . . . . . . . . . . section L lnstallation Note . . . . . . . . . . page K-149 17. Exhaust pipe 7. Harness 18. Performance rod -1 8. Oil pipe 19. Undercover 9. Lockup solenoid connector 20. Shift rod Gartner Banana

Page 550 of 1708

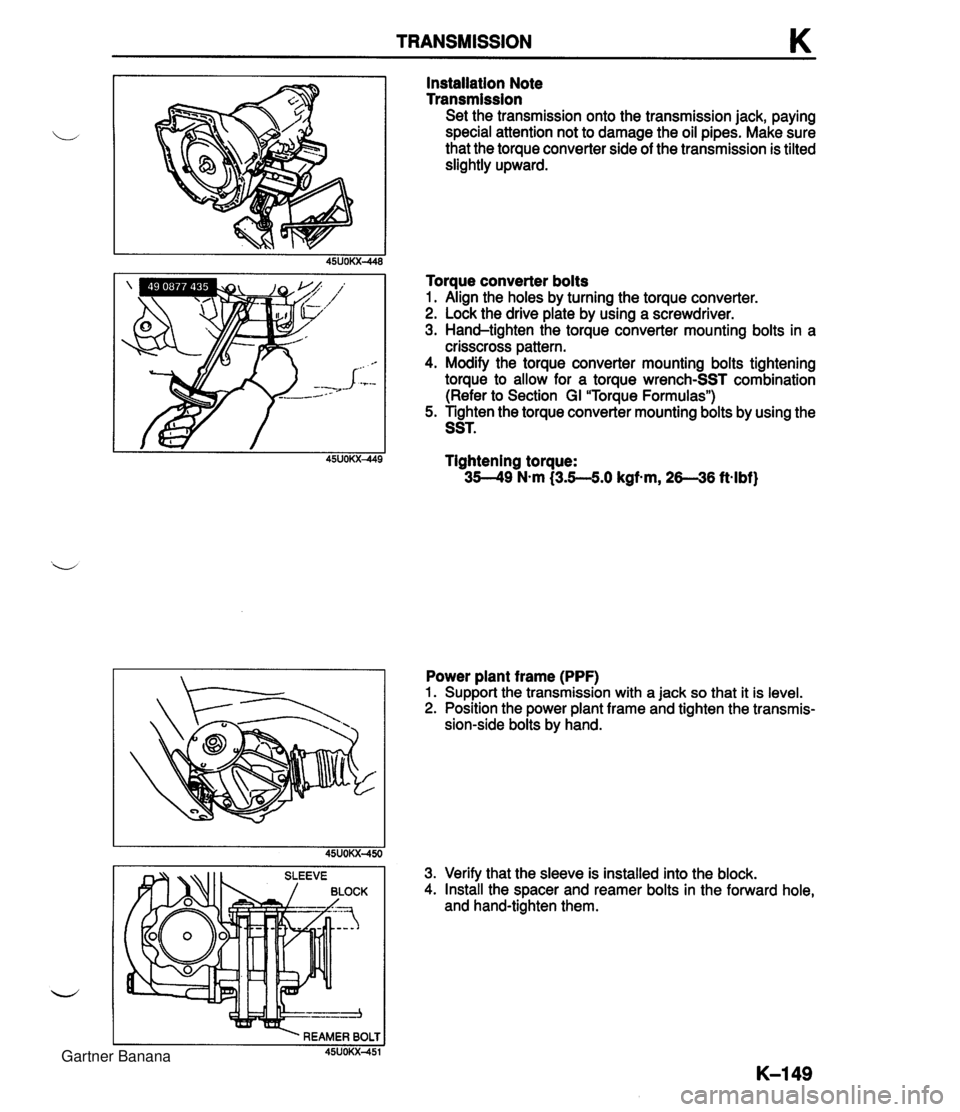

TRANSMISSION K Installation Note Transmission Set the transmission onto the transmission jack, paying special attention not to damage the oil pipes. Make sure that the torque converter side of the transmission is tilted slightly upward. Torque converter bolts 1. Align the holes by turning the torque converter. 2. Lock the drive plate by using a screwdriver. 3. Hand-tighten the torque converter mounting bolts in a crisscross pattern. 4. Modify the torque converter mounting bolts tightening torque to allow for a torque wrench-SST combination (Refer to Section GI "Torque Formulas") 5. Tighten the torque converter mounting bolts by using the SST. Tightening torque: 35-49 N-m (3.5-5.0 kgf-m, 26--36 ft-lbf) Power plant frame (PPF) 1. Support the transmission with a jack so that it is level. 2. Position the power plant frame and tighten the transmis- sion-side bolts by hand. 3. Verify that the sleeve is installed into the block. 4. Install the spacer and reamer bolts in the forward hole, and hand-tighten them. Gartner Banana

Page 555 of 1708

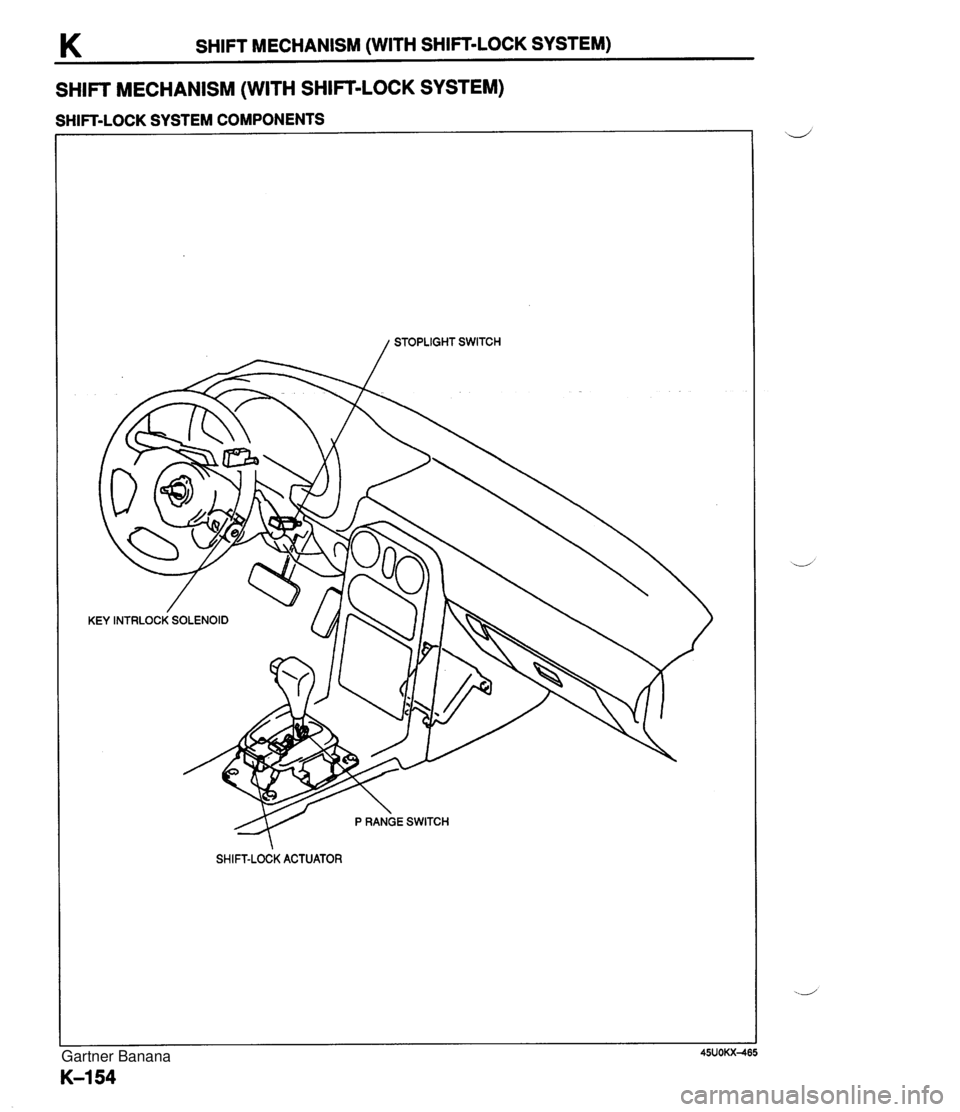

K SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) SHIFT-LOCK SYSTEM COMPONENTS Gartner Banana

Page 556 of 1708

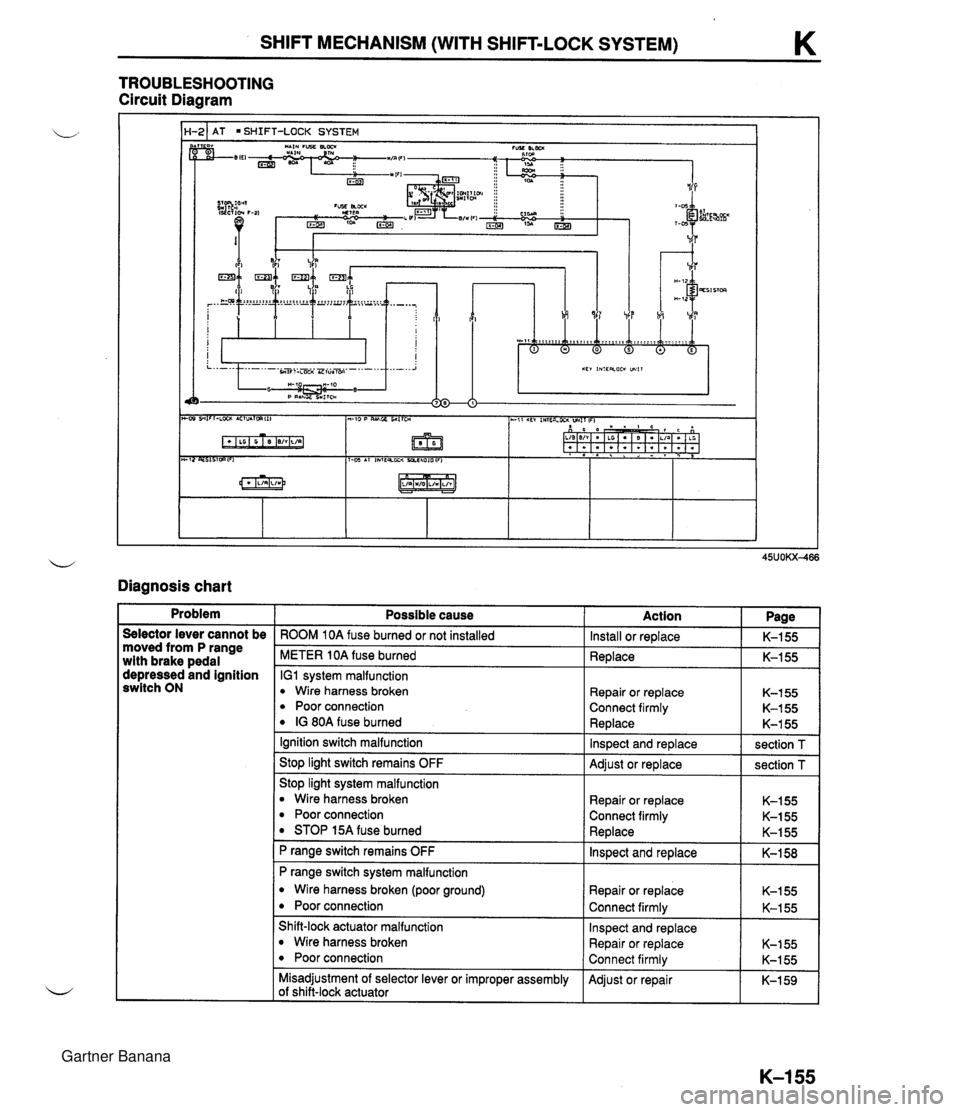

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K TROUBLESHOOTING Circuit Diagram - 1-21 AT SHIFT-LOCK SYSTEM Diagnosis chart Problem -- Selector lever cannot be moved from P range with brake pedal depressed and ignition switch ON Possible cause ROOM 1 OA fuse burned or not installed METER 10A fuse burned IG1 system malfunction Wire harness broken Poor connection IG 80A fuse burned Ignition switch malfunction Stop light switch remains OFF Stop light system malfunction Wire harness broken Poor connection STOP 15A fuse burned P range switch remains OFF P range switch system malfunction Wire harness broken (poor ground) Poor connection Shift-lock actuator malfunction Wire harness broken Poor connection Misadjustrnent of selector lever or improper assembly of shift-lock actuator Action I Page Repair or replace Connect firmly Replace Install or replace Replace K-155 K-155 Repair or replace K-155 Connect firmly K-155 Replace K-155 Inspect and replace Adjust or replace section T section T Repair or replace Connect firmly Inspect and replace Repair or replace Connect firmly Adjust or repair K-155 K-I55 K-155 K-155 K-159 Gartner Banana

Page 557 of 1708

K ' SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) Problem Possible cause Selector lever can be ROOM 1OA fuse burned or not installed moved lrom nnp. [stop light switch remains ON with ignition switch ON, but without brake pedal I Shift-lock actuator malfunction depressed Misadjustment of selector lever or improper assembly of shift-lock actuator Selector lever can be ROOM 10A fuse burned or not installed range Ignition switch malfunction with ignition switch OFF and brake pedal de- Shift-lock actuator malfunction pressed Misadjustrnent of selector lever or improper assembly of shift-iock actuator Shift-lock actuator op- P range switch remains ON eration heard when brake pedal depressed ' Misadjustment of selector lever or improper assembly with ignition switch ON of shift-lock actuator in other than P range Action -- Install or replace Adjust or replace lnspect and replace Adjust or replace Install or replace Inspect and replace inspect and replace Adjust or replace Inspect and replace Adjust or replace section T K-159 Selector lever remains locked when emergency override button oper- ated Emergency override button not pushed fully down Broken emergency override button lgnitlon key can be turned to lock position with selector lever in other than P range Push down fully and hold emergency override but- Misadjustment of indicator pedal ROOM 10A fuse burned or not installed Key interlock solenoid malfunction Wire harness broken Poor connection P range switch remains ON P range switch system malfunction Wire harness broken Poor connection lnspect and replace Repair or replace Connect firmly Adjust Install or replace K-161 - K-151 Inspect and replace Repair or replace Connect firmly I lanition kev cannot be I P ranae switch remains OFF I lns~ect and replace 1 K-158 I K-159 K-166 K-166 Key cylinder (push switch) malfunction Wire harness broken Poor connection Key interlock unit malfunction I ~~~~~$1~~~~ I Key iierlock solenoid malfunction I' I I Inspect and replace I K-158 I range Inspect and replace Repair or replace Connect firmly Inspect and replace Key cylinder (push switch) malfunction I Inspect and replace I section T section T K-155 K-155 section T I I Misadjustment of selector lever 1 Adjust I K-160 ] Gartner Banana

Page 558 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K POSSlBLt TO SHIFT c3 BRAKEPEDAL DEPRESSED 45UOKX42! EMERGENCY OVERRIDE BUTTON '

+ I SHIFT TO P RANGE 1 SHIFT-LOCK lnspection 1. Turn the ignition switch to ON engine OFF. 2. Verify that the selector lever is in P range. 3. Without the brake pedal depressed, verify that the selec- tor lever cannot be shifted from P range. 4. Depress the brake pedal and verify that the selector le- ver can be shifted from P range. 5. If not as specified, check the P range switch continuity andlor shift-lock actuator terminal voltage and continu- ity. (Refer to pages K-159.) EMERGENCY OVERRIDE BUTTON lnspection 1. Verify that the engine is off. 2. Verify that the selector is locked in P range. 3. Remove the indicator panel cover with the screwdriver as shown. 4. Insert the screwdriver into the emergency override hole, push down, and verify that the selector lever can be shifted from P range. 5. If not as specified, inspect and repair as necessary, re- ferring to the Troubleshooting diagnosis chart. (Refer to pages K-155.) KEY INTERLOCK lnspection 1. Turn the ignition switch to ON engine OFF. 2. Shift the selector lever to R range. 3. Verify that the ignition key cannot be turned to the LOCK position. 4. Shift the selector lever to P range. 5. Verify that the ignition key can be turned to the LOCK position. 6. If not as specified, inspect and repair as necessary, re- ferring to Troubleshooting. (Refer to pages K-155.) KEY INTERLOCK SOLENOID lnspection 1. Disconnect the negative battery cable. 2. Remove the column cover. 3. Disconnect the key interlock solenoid connector. 4. Insert the ignition key in the key cylinder. 5. Apply battery voltage between terminals 6 and C, and verify that the solenoid operates. 6. If not as specified, replace key interlock solenoid. 7. Connect the key interlock solenoid connector. 8. Install the column cover. 9. Connect the negative battery cable. Gartner Banana

Page 559 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) Replacement 1. Disconnect the negative battery cable. 2. Remove the column cover. 3. Disconnect the key interlock solenoid connector. 4. Remove the screws and the key interlock solenoid. 5. Install the key interlock solenoid and tighten the screws. Tightening torque: 6.S-13 N-m (70-1 30 kgf-m, 61-11 3 ft-lbf} I I I 6. Verify that the key interlock solenoid operates. (Refer to 45UOKX-576 "Inspection" above.) 7. Connect the key interlock solenoid connector. 8. Install the column cover. 9. Connect the negative battery cable. KEY INTERLOCK UNIT Inspection 1. Remove the column cover. 2. Turn the ignition switch ON, and check terminal volt- ages, referring to the chart below. 3. If not as specified, repair the wiring harness andlor key -, interlock unit. B+: Battery positive voltage - - - Within 2 seconds of twning the P-range switch ON, and either the ACC or IG ON. Except above conditions Correct measurement valve 0 B+ E Condition Terminal I I I I terminal connected to I Ground 1 Constant M 0 Ignition switch ON Ignition switch OFF P-range switch and ACC are ON, or IG is ON Except above condition I B+ 0 S 0 B+ P-range switch ON P-range switch OFF I 0 B+ - ACC switch ON ACC switch OFF B+ 0 Gartner Banana

Page 560 of 1708

SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) K TO GROUND FROM SHIFT-LOCK ACTUATOR Replacement 1. Disconnect the negative battery cable. 2. Disconnect the key interlock unit connector. 3. Remove the key interlock unit. 4. Install the new key interlock unit. 5. Connect the key interlock unit connector. 6. Connect the negative battery cable. P RANGE SWITCH Inspection Continuity 1. Disconnect the negative battery cable. 2. Remove the rear console. 3. Remove the screws and lift up the indicator panel. 4. Disconnect the P range switch connector. 5. Check continuity between the terminals. I Range I Selector lever release button I Continuity I 6. If not as specified, replace the P range switch. (Refer to page K-166.) I 7. Connect the P range switch connector. 8. Adjust the indicator panel. (Refer to page K-161.) Install the screws in the order shown in the figure. 9. Install the rear console. 10. Connect the negative battery cable. 11. Verify correct operation of the shift-lock system. SHIFT-LOCK ACTUATOR Inspection Terminal voltage and continuity 1. Remove the rear console 2. Remove the selector knob and indicator panel screws. Released Depressed Yes No Gartner Banana

Page 561 of 1708

K SHIFT MECHANISM (WITH SHIFT-LOCK SYSTEM) CONNECTOR B CONNECTOR A 3. Lift up slightly on the selector lever, selector sleeve, and indicator panel, and disconnect the hold switch connec- tor. 4. Disconnect the HOLD switch connector. .--' 5. Shift the selector lever to P range. 6. Turn the ignition switch ON, and check terminal voltages and continuity, referring to the chart below. Disconnect the shift-lock actuator connector to check continuity be- tween terminal c (harness side) and ground. 7. If not as specified, repair the wiring harness and/or shift- lock actuator. I ~~UOKX-477 B+: Battery positive voltage I Connector I Terminal connectd to l terminal I Condition I Correct measurement vaive I I 1 I I A a B-C I P range, selector lever release button not depressed I OR I lBl e I B I P ranae, selector lever release button not depressed I OV I A B B B B 8. Grasp the HOLD switch wiring harness and pull it while pushing the selector knob down fully onto the selector le- ver. 9. Connect the HOLD switch connector. 10. Adjust the indicator panel. (Refer to page K-161.) Install the screws in the order shown in the figure. 11. Apply locking compound to the selector knob screw threads after the threads have been cleaned. Tighten the screws. Tightening torque: 2.0-2.9 N-m (20-30 kgf-cm, 18-26 in-lbf) b a b C (harness side) d 12. Install the rear console. 13. Connect the negative battery cable. 14. Verify correct operation of the shift-lock system. B-C B-C B-C Body B-C Constant Ignition switch OFF Ignition switch ON Constant Brake pedal released -t depressed OR B+ El+ on OV -+ B+ -1 Gartner Banana