lock MAZDA MX-5 1994 Workshop Manual

[x] Cancel search | Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 466 of 1708

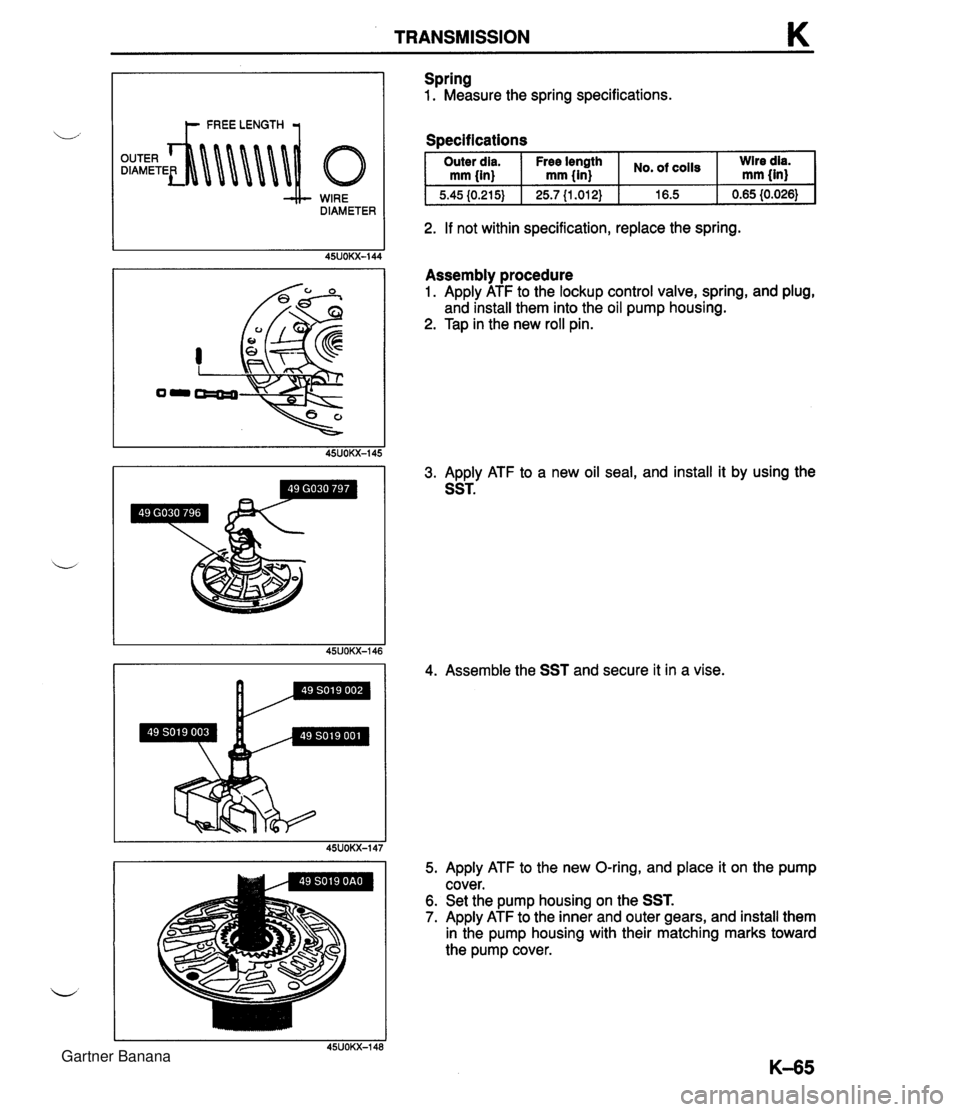

TRANSMISSION K WIRE DIAMETER Spring 1. Measure the spring specifications. Soecifications I Outer dia. I Free Ienpth I cO1ls I :Ired$ mm {in) mm {in) I 2. If not within specification, replace the spring. Assembly procedure 1. Apply ATF to the lockup control valve, spring, and plug, and install them into the oil pump housing. 2. Tap in the new roll pin. 3. Apply ATF to a new oil seal, and install it by using the SST. 4. Assemble the SST and secure it in a vise. 5. Apply ATF to the new O-ring, and place it on the pump cover. 6. Set the pump housing on the SST. 7. Apply ATF to the inner and outer gears, and install them in the pump housing with their matching marks toward the pump cover. Gartner Banana

Page 471 of 1708

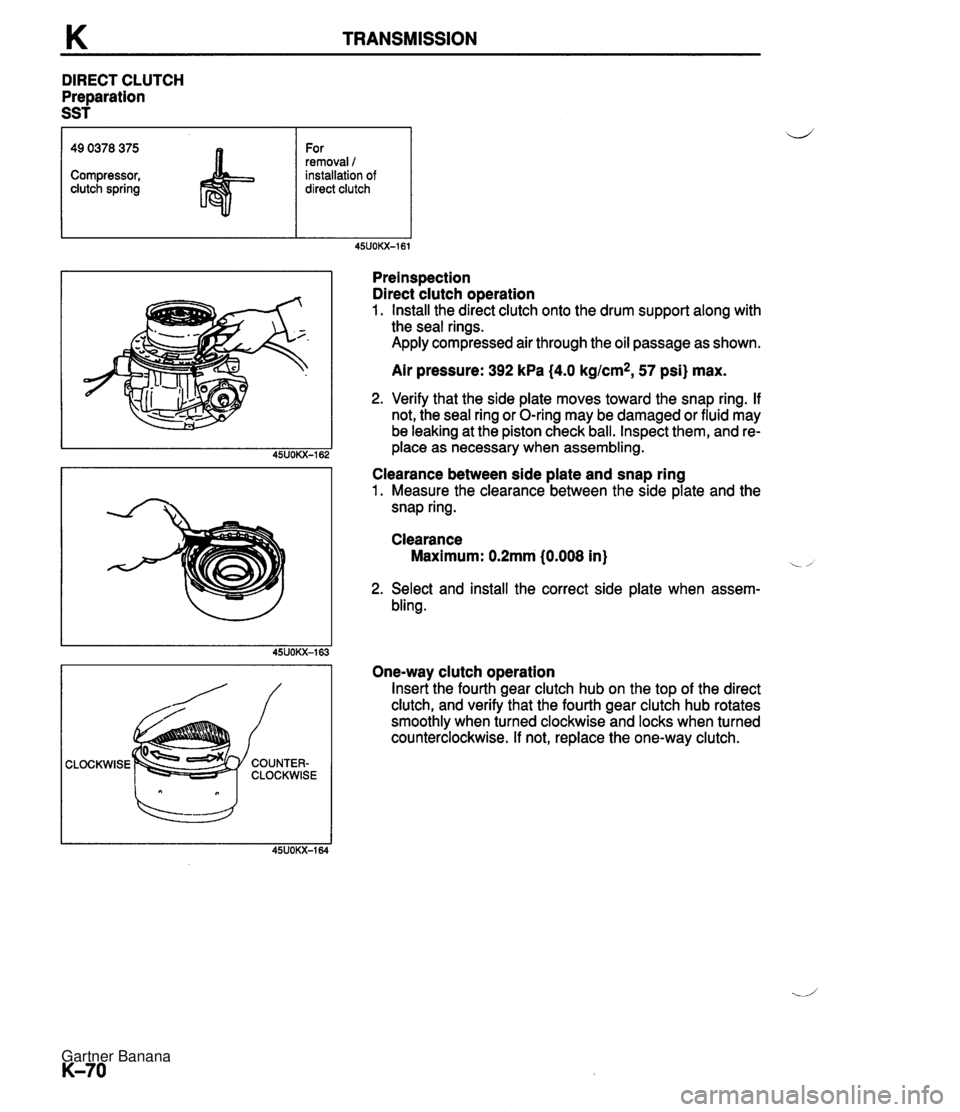

K TRANSMISSION DIRECT CLUTCH Preparation SST CLOCKWISE 49 0378 375 Compressor, clutch spring Preinspection Direct clutch operation 1. Install the direct clutch onto the drum support along with the seal rings. Apply compressed air through the oil passage as shown. For removal 1 installation of direct clutch Air pressure: 392 kPa (4.0 kgtcm*, 57 psi) max. 2. Verify that the side plate moves toward the snap ring. If not, the seal ring or O-ring may be damaged or fluid may be leaking at the piston check ball. Inspect them, and re- place as necessary when assembling. Clearance between side plate and snap ring 1. Measure the clearance between the side plate and the snap ring. Clearance Maximum: 0.2mm (0.008 in) i -, 2. Select and install the correct side plate when assern- bling. One-way clutch operation Insert the fourth gear clutch hub on the top of the direct clutch, and verify that the fourth gear clutch hub rotates smoothly when turned clockwise and locks when turned counterclockwise. If not, replace the one-way clutch. Gartner Banana

Page 476 of 1708

TRANSMISSION K 21. Insert the fourth gear clutch hub on the top of the direct clutch and verify that the fourth gear clutch hub rotates smoothly when turned clockwise and locks when turned counterclockwise. If it does not, then the one-way clutch is installed upside down. Caution Applying compressed air to the assembled clutch pack for longer than 3 seconds at a time will dam- age the seal. 22. Install the direct clutch onto the drum support along with the seal rings. Apply compressed air to the oil passage and check the clutch operation. Air pressure: 392 kPa {4.0 kglcm2, 67 psi) max. Gartner Banana

Page 479 of 1708

K TRANSMISSION 8. Apply ATF to the return spring, and install it into the trans- mission case. 9. Apply even pressure to the perimeter of the body, and install it into the transmission case. 4 10. Install the piston assembly. 11. lnstall and tighten the bolts. Tightening torque: 9.81-14.7 N-m (1 00-150 kgfacm, 86.8--130 in-lbf) On-vehicle Adjustment 1. Remove the exhaust pipe. (Refer to page K-46.) 2. Remove the fourth gear band servo cover and gasket. 3. Loosen the locknut and tighten the piston stem. Tightening torque: 11.8-14.7 Nm (1 20-1 50 kgf-cm, 105--130 in4bf) 4. Loosen the stem the number of turns shown below. Stem: 2 turns 5. Hold the piston stem and tighten the locknut. Tightening torque: 15-49 N-m (1.5-4.0 kgf-m, 11-28 ft-lbf) 6. Install a new gasket and the fourth gear band servo cov- er. Tightening torque: 5.0--6.8 N. m (50-70 kgf-cm, 44--60 in4 bf) 7. Install the exhaust pipe. (Refer to page K-148.) Gartner Banana

Page 486 of 1708

TRANSMISSION K 10. Install and tighten the bolts. Tightening torque: 6.9--8.8 N-m (70-90 kgfmcm, 61-78 in-lbf} On-vehicle Adjustment 1. Remove the exhaust pipe. (Refer to page K-47.) 2. Remove the valve body assembly. (Refer to page K-127.) 3. Loosen the locknut and tighten the piston stem. r u I MANUAL PLATE Tightening torque: 12.3-14.2 N-m (1 2+l45 kgf-cm, 109--125 in-lbf) 4. Loosen the stem the number of turns shown below. Stem: 2 112 turns 5. Hold the piston stem and tighten the locknut. Tightening torque: 1 +39 N.m {l.5--4.O kgf-m, 11-28 ftlbf) 6. Install a new body assembly. (Refer to page K-129.) 7. Install the exhaust pipe. (Refer to page K-148.) Gartner Banana

Page 499 of 1708

K TRANSMISSION 5. Apply ATF to the sun gear, and install it into the front planetary pinion carrier with the groove facing the front (arrow). 6. Apply ATF to the sun gear, and install it into the front planetary pinion carrier. REAR PLANETARY GEAR UNIT (CONNECTING DRUM, REAR PLANETARY PINION CARRIER, ONE-WAY CLUTCH) Preinspection One-way clutch operation Install the rear planetary gear unit and verify that the rear , planetary gear unit rotates smoothly when turned clock- wise and locked when turned counterclockwise. If not, replace the one-way clutch. Gartner Banana

Page 502 of 1708

TRANSMISSION K 8. Apply ATF to the rear planetary pinion carrier, and install it into the connecting drum. 9. Install the snap ring. 10. Apple petroleum jelly to the bearing, and install it onto the rear planetary pinion carrier with the black surface facing upward. Bearing outer diameter: 70.0mm (2.756 in} 11. Insert the rear planetary gear unit into the transmission case, and verify that the one-way clutch turns counter- clockwise. If it does not, then the one-way clutch is installed upside down. Gartner Banana

Page 538 of 1708

TRANSMISSION K 7. Install a new snap ring onto the front of the output shaft. 8. Install the extension housing along with a new gasket. Tightening torque: 20-24 N-m (2.0-2.5 kgfem, 15--18 ft4bf) 9. Verify that the output shaft is locked with the manual le- ver in P range. 10. Set the rear clutch assembly on the top of the front clutch assembly. 11. Install the connecting shell and front planetary gear unit (rear clutch hub, front planetary pinion carrier, rear sun gear) onto the rear clutch assembly. 12. Install the front clutch, rear clutch, rear clutch hub, front planetary pinion carrier, connecting shell, internal gear, sun gear, bearing, and bearing races as a unit into the transmission case. 13. Set a new gasket into the front of the case. Gartner Banana

Page 544 of 1708

TRANSMISSION K 33. Apply ATF to the piston stem. 34. Adjust the 2nd brake band. (1) Loosen the locknut and tighten the piston stem. Tightening torque: 12.3--14.2 N-m (125--145 kgf-cm, lOg--l25 in-lbf) (2) Loosen the stem the number of turns shown below. Stem: 2 112 turns (3) Hold the stem and tighten the locknut. Tightening torque: 15-39 N.m (1.5-4.0 kgf-m, 11-28 ft-lbf) Caution Applying compressed air to the servo piston for longer than 3 seconds at a time will damage the seal. 35. Check the servo piston operation by applying com- pressed air through the oil passages of the 2nd band servo. @: Engage @: Release Air pressure: 392 kPa (4.0 kg/cm2, 57 psi) max. 36. Apply ATF to the piston stem. Adjust the fourth gear brake band. (1) Loosen the locknut and tighten the piston stem. Tightening torque: 12-15 N-m (1.2-1.5 kgf-m, 8.7-11 ft-lbf) 11.8-14.7 N-m (1 20-150 kgf.cm, 105-1 30 in-lbf) (2) Loosen the stem the number of turns shown below. Stem: 2 turns Gartner Banana

Page 545 of 1708

K TRANSMISSION 0 (3) Hold the stem and tighten the locknut. Tightening torque: 15--39 N-m (1.5-4.0 kgf-m, 11-28 ftelbf) Caution Applying compressed air to the servo piston for longer than 3 seconds at a time will damage the seal. I 1 37. Check the servo piston operation by applying com- 45UOM431 pressed air through the oil passage of the fourth gear band servo. Air pressure: 392 kPa (4.0 kg/cm2, 57 psi) max. MANUAL PLATE 38. Set a new gasket on the fourth gear band servo. Install the fourth gear band servo cover. Tightening torque: 5.0-6.8 N-m (50-70 kgfscm, 44--60 indbf) 39. Apply ATF to a new O-ring and install it onto the solenoid valve connector. 40. Install the solenoid valve connector in the transmission case. 41. Set the valve body assembly in piston, and align the manual plate and manual valve. 42. Install the bolts. Tightening torque: 10.8-14.7 N.m (110--150 kgf-cm, 95.5--130 in-lbf) Gartner Banana